Engine rebuild gone wrong!

#21

Staging Lane

That is good news. If you are looking for another machine shop in Las Vegas, let me know. I just had my LS3 machined, balanced and assembled at a shop near the speedway. They are pretty busy so the wait is longer but they do stand by their work as I can attest to.

#22

Thanks guys!

Yes i called them over there, like the others said contracts come first and most likely be 2 to 3 months.

I really had no reason to doubt this shop I went too and they said 2 weeks. So far probably everything looks to be good.

Now I will start the build and see where it goes!

Yes i called them over there, like the others said contracts come first and most likely be 2 to 3 months.

I really had no reason to doubt this shop I went too and they said 2 weeks. So far probably everything looks to be good.

Now I will start the build and see where it goes!

#23

Staging Lane

Sounds good... Be sure to check the clearances with the cam bearings and cam journals as there seem to be some variances between different cams and bearings which may lead to low hot oil pressure.

I would suggest real GM lifter trays, new cam retaining plate, "dog bone" timing chain damper (not the spring style tensioner) and watch out for knock off LS7 lifters.

I would suggest real GM lifter trays, new cam retaining plate, "dog bone" timing chain damper (not the spring style tensioner) and watch out for knock off LS7 lifters.

#24

Ok I just remember another important question before i move forward. In the beginning after i dropped off the parts, I called them and asked them to balance everything and i would bring in the crank and stuff. The machine shop told me i didn't need balancing done on a daily driver, that I'm not doing any performance changes. I was like ok i didn't know that, so saved me money.

So do i need to have this done?

New GM stock crankshaft, New GM stock non-dod cam shaft, Original stock rods, New Enginetech oversized .50 pistons and rings.

If so then i will have to take it to another shop.

So do i need to have this done?

New GM stock crankshaft, New GM stock non-dod cam shaft, Original stock rods, New Enginetech oversized .50 pistons and rings.

If so then i will have to take it to another shop.

#25

TECH Fanatic

iTrader: (6)

Ok I just remember another important question before i move forward. In the beginning after i dropped off the parts, I called them and asked them to balance everything and i would bring in the crank and stuff. The machine shop told me i didn't need balancing done on a daily driver, that I'm not doing any performance changes. I was like ok i didn't know that, so saved me money.

So do i need to have this done?

New GM stock crankshaft, New GM stock non-dod cam shaft, Original stock rods, New Enginetech oversized .50 pistons and rings.

If so then i will have to take it to another shop.

So do i need to have this done?

New GM stock crankshaft, New GM stock non-dod cam shaft, Original stock rods, New Enginetech oversized .50 pistons and rings.

If so then i will have to take it to another shop.

#26

If you have a COMPLETE factory rotating assy out of a COMPLETE engine - meaning, the crank, pistons and rods COMPLETE that were in a COMPLETE engine - then if all you're looking for is a grocery cart, you can "get away with" not balancing, if your standards are low enough and you always strive to underachieve them.

If ANY of those parts have been changed, then balancing is almost a requirement. Not something you want to leave to chance.

If ANY of those parts have been changed, then balancing is almost a requirement. Not something you want to leave to chance.

The following users liked this post:

G Atsma (03-28-2024)

#27

TECH Senior Member

"Strive to underachieve.... " That cracked me up! Then I realized how true it is for some people.... lol!

The following users liked this post:

Che70velle (03-29-2024)

#28

Staging Lane

HBR in Las Vegas balanced mine which had all stock crank, rods and pistons. They said it was out of balance although I never noticed anything. They did provide a printout however I don't really know what it shows and can't find it right now. The total was around $200 for the balance work. They may be able to get that done quicker than your previous time estimate. You may also check with what they may charge to assemble the motor as I found their prices were pretty reasonable.

#29

So i thought so to myself! So i will call around and find a shop that can balance this. No i want to build this engine, just trying to start over and do it correctly.

This was a life long bucket list item! It never even came to mind to bypass the machine shop until i called around and was told months away. Then brainwashing ideas flooded me and like you tube guys resurfacing at home. Then i was like i could same thousand dollars!

So now back to the real world, Im doing it correctly.

Get it balanced and maybe i should have them check the block too.

This was a life long bucket list item! It never even came to mind to bypass the machine shop until i called around and was told months away. Then brainwashing ideas flooded me and like you tube guys resurfacing at home. Then i was like i could same thousand dollars!

So now back to the real world, Im doing it correctly.

Get it balanced and maybe i should have them check the block too.

#30

ModSquad

iTrader: (6)

Engine machine shops/builders are a lot like automotive paint shops. Never pick the cheapest OR fastest shop. Would you expect Maaco to give you a show winning, high end paint job? Neither should you expect the local greasy, dirty machine shop to give you a quick, yet dead-on accurate full block machine, full head build, for cheap.

Unfortunately in todays world, anything worth a crap is expensive and all the good shops are backed up for a while…because they are good. If a shop tells you that you don’t need an assembly balanced without even weighing anything, I’d walk out on them. Think about it this way…they get PAID to balance that assembly. Why would they not even consider it?

Unfortunately in todays world, anything worth a crap is expensive and all the good shops are backed up for a while…because they are good. If a shop tells you that you don’t need an assembly balanced without even weighing anything, I’d walk out on them. Think about it this way…they get PAID to balance that assembly. Why would they not even consider it?

#32

Ok sorry it’s been awhile, work and other life challenges!

So found a machine shop and had the rotating assembly balanced. Yesss!

Got crankshaft installed now and working on the piston ring gaps.

The enginetech rings and pistons only showed clocking instructions. Found this on there website

ET piston rings come pre-gapped, however, it is always best practice to check your end gap before installation. We recommend a minimum of .0035” per inch of cylinder diameter. For example, a 4.000” bore would require a minimum end gap of .014” (.0035 x 4 = .014).

So my bore is 3.80 x .0035 = .013 according to this.

But the top ring is pre gapped @ .018 and 2nd ring is almost no gap. I know it said min but…

So, ok to leave the top ring at .018 and file 2nd ring to .018? I thought it should be more on 2nd ring?

I was thinking top ring .018 and 2nd ring .020.

Thanks again for all the help. Getting excited and motivated again.

So found a machine shop and had the rotating assembly balanced. Yesss!

Got crankshaft installed now and working on the piston ring gaps.

The enginetech rings and pistons only showed clocking instructions. Found this on there website

ET piston rings come pre-gapped, however, it is always best practice to check your end gap before installation. We recommend a minimum of .0035” per inch of cylinder diameter. For example, a 4.000” bore would require a minimum end gap of .014” (.0035 x 4 = .014).

So my bore is 3.80 x .0035 = .013 according to this.

But the top ring is pre gapped @ .018 and 2nd ring is almost no gap. I know it said min but…

So, ok to leave the top ring at .018 and file 2nd ring to .018? I thought it should be more on 2nd ring?

I was thinking top ring .018 and 2nd ring .020.

Thanks again for all the help. Getting excited and motivated again.

The following users liked this post:

Billh1961 (05-23-2024)

#34

ModSquad

iTrader: (6)

Ok sorry it’s been awhile, work and other life challenges!

So found a machine shop and had the rotating assembly balanced. Yesss!

Got crankshaft installed now and working on the piston ring gaps.

The enginetech rings and pistons only showed clocking instructions. Found this on there website

ET piston rings come pre-gapped, however, it is always best practice to check your end gap before installation. We recommend a minimum of .0035” per inch of cylinder diameter. For example, a 4.000” bore would require a minimum end gap of .014” (.0035 x 4 = .014).

So my bore is 3.80 x .0035 = .013 according to this.

But the top ring is pre gapped @ .018 and 2nd ring is almost no gap. I know it said min but…

So, ok to leave the top ring at .018 and file 2nd ring to .018? I thought it should be more on 2nd ring?

I was thinking top ring .018 and 2nd ring .020.

Thanks again for all the help. Getting excited and motivated again.

So found a machine shop and had the rotating assembly balanced. Yesss!

Got crankshaft installed now and working on the piston ring gaps.

The enginetech rings and pistons only showed clocking instructions. Found this on there website

ET piston rings come pre-gapped, however, it is always best practice to check your end gap before installation. We recommend a minimum of .0035” per inch of cylinder diameter. For example, a 4.000” bore would require a minimum end gap of .014” (.0035 x 4 = .014).

So my bore is 3.80 x .0035 = .013 according to this.

But the top ring is pre gapped @ .018 and 2nd ring is almost no gap. I know it said min but…

So, ok to leave the top ring at .018 and file 2nd ring to .018? I thought it should be more on 2nd ring?

I was thinking top ring .018 and 2nd ring .020.

Thanks again for all the help. Getting excited and motivated again.

The following users liked this post:

Billh1961 (05-23-2024)

#36

Ok stumped again. I’m using this how to rebuild gm ls series engines chris werner as reference.

I’m trying to check the cam degree timing with a summit racing cam degree wheel. They both say to get the specs from the cam card.

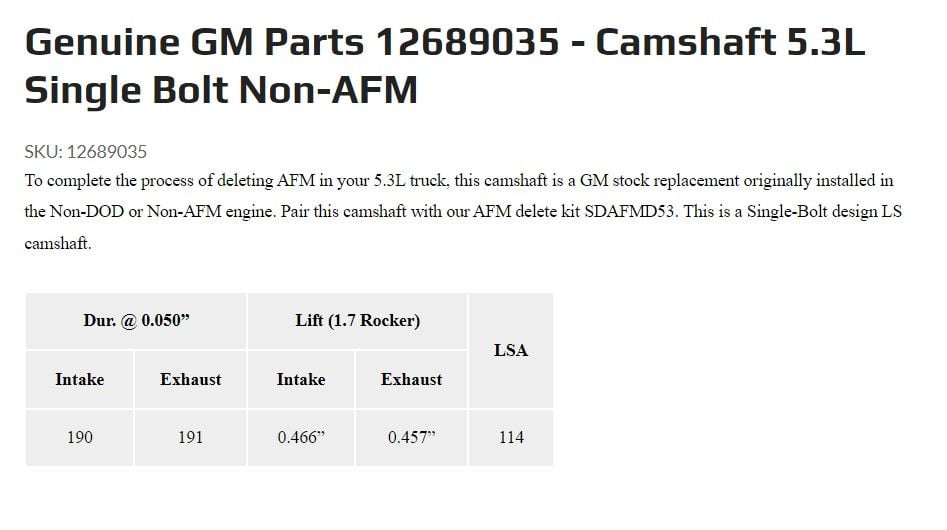

There is no cam card that came with this Gm Stock cam # 12689035.

What is the

Intake open BTDC .050?

Intake close ABDC .050?

I’m getting -17.5 open and 36.0 close

Is it not required since I'm using a stock gm cam?

I’m deleting the afm and using stock cam.

I’m trying to check the cam degree timing with a summit racing cam degree wheel. They both say to get the specs from the cam card.

There is no cam card that came with this Gm Stock cam # 12689035.

What is the

Intake open BTDC .050?

Intake close ABDC .050?

I’m getting -17.5 open and 36.0 close

Is it not required since I'm using a stock gm cam?

I’m deleting the afm and using stock cam.

#38

TECH Senior Member

Not that it really matters, but the durations are switched. Intake is 191 and exhaust is 190. Lifts and LSA are as stated.

#39

12 Second Club

iTrader: (13)

I honestly wouldn't bother with degreeing a used, stock cam. What's the point? It was in a running engine at one point, so it's ground correctly. Unless you're using a new offshore cheapie timing set, the likelihood of you needing to make some sort of adjustment to the timing is about zero. The reason for degreeing a cam is to confirm that the cam was ground correctly at the factory, and I'm pretty sure GM isn't in the habit of allowing mis-ground cams to be installed in their engines. Just install it dot to dot and you'll be good.

The following 3 users liked this post by LS1Formulation:

#40

Installed dot to dot.

Another newbie builder question came up.

I installed my stock rods with Mahle CB-1776A bearings that the machine shop supplied.

A friend asked me if i made sure i put the upper and lower bearings in the right place?

I didn't know there was a different bearing they all looked the same.

Do i need to take oil pan back off and check? I dont remember seeing anything like upper or lower or U or L on the bearings. Ugg

Another newbie builder question came up.

I installed my stock rods with Mahle CB-1776A bearings that the machine shop supplied.

A friend asked me if i made sure i put the upper and lower bearings in the right place?

I didn't know there was a different bearing they all looked the same.

Do i need to take oil pan back off and check? I dont remember seeing anything like upper or lower or U or L on the bearings. Ugg