Lt1 Build Path

#1

Staging Lane

Thread Starter

Join Date: Aug 2013

Location: Rochester,Mi

Posts: 68

Likes: 0

Received 0 Likes

on

0 Posts

So for the first time I dropped the motor and trans with 2 of my buddys help. The lt1 is torn down completely and at first I had an idea of my build plan but theres so much controversy im seeking advice. This will be a longer project just because I dont want to cheap out and costs will extend things a bit. But my goal here is to have a summer car that will be mostly street driven, I want to produce between 400 and 500 at the crank. Now I was thinking going to a 383 sense im rebuilding from top to bottom but I heard staying at 350 you can still produce numbers like that. As far as heads and cams go im stumped, to many different facts and opinions. im even consider just going ls1.

#2

LS1Tech Sponsor

Join Date: Jan 2008

Location: Ohio, Georgia, Nevada, Texas

Posts: 2,005

Received 1,190 Likes

on

648 Posts

The options for your build are pretty wide open, but if you wanted to stick with the LT1 for a street car you can use the TrickFlow LT1 Top End Kit for 438 hp and 401 ft/lbs on a stock 350 LT1 bottom end.

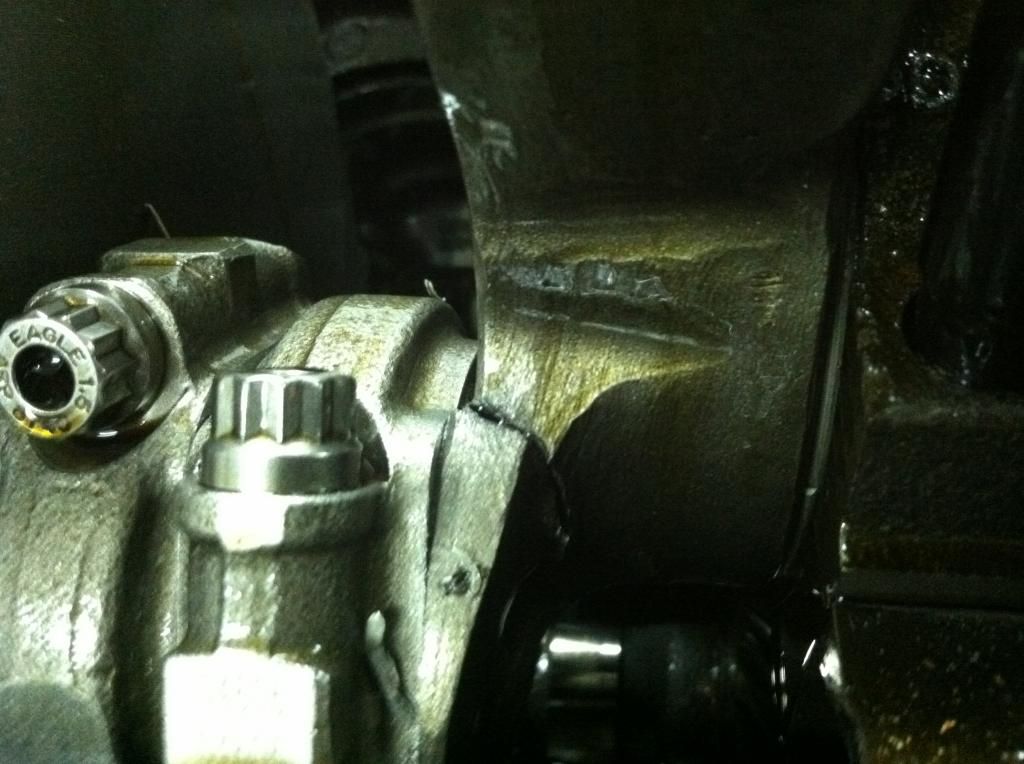

For even more torque and power, add the Eagle 383 Rotating Assembly and I would expect these numbers to increase to around 450-475 Hp and 430-450 ft/lbs.

For even more torque and power, add the Eagle 383 Rotating Assembly and I would expect these numbers to increase to around 450-475 Hp and 430-450 ft/lbs.

#3

11 Second Club

iTrader: (1)

and that there is why do don't call the 800 number for catalog companies.

Increasing displacement and using the same heads and cam will NOT make appreciably more HP. More displacement can allow you to use larger heads and cam which may help make more HP but just changing displacement wont have any significant effect on the HP number.

The examples are all over this forum guys using the same CNC heads on 350s and 383s and even with more cam and compression you barely see that kind of difference.

Increasing displacement and using the same heads and cam will NOT make appreciably more HP. More displacement can allow you to use larger heads and cam which may help make more HP but just changing displacement wont have any significant effect on the HP number.

The examples are all over this forum guys using the same CNC heads on 350s and 383s and even with more cam and compression you barely see that kind of difference.

#4

Kumaro...

you first need to take your block & crank to a machine shop so they can determine if it needs a .030 overbore to clean up the cyl walls vs just a hone and if the crank just needs a polish or grind so you know what bearing size to get. .030 you either have a 355 or with a stroker rotateing assembly (crank/rods) you have a 383. C.I. increase will yield more TQ vs an identically built 350-355

The Summit reply is "one" option.....but most would agree a head/cam package from Lloyd Elliott or Advanced Induction will yield better power over the off the shelf one offered through Summit. With that said there is nothing wrong with the TF package they offer and I have spent a college education on parts from Summit, good outfit for parts. Just that there are other options with very proven performance results for AI or LE. I didn't see what cam specs the TF package came with or what head gasket thickness is included but I would encourage you clarify that so you can compare effectively with other packages.

if staying 350 or 355 the stock crank is quite strong. I would use it over any other aftermarket "cast" crank. IMHO go forged if going aftermarket. using the stock crank, having the stock rods re-sized with ARP fasteners and new pistons with all new bearings is often done. then a head/cam package of choice.

Think through your build first as combustion chamber size, how far the pistons are in the hole (meaning that changes when the block gets decked if that is what you do), piston choice, head gasket thickness all need to be considered so you wind up with the right "quench".

I had a VERY mild custom grind cam (214/220 on a 112 LSA) with stock AL ported heads (2.02/1.60) and a tune with a bone stock bottom end and made 350 RWHP/351 RWTQ (add roughly 15% for FW #'s) on a calif. smog legal car so your FW #'s are achievable with the right combo of parts AND good tune.....but if the 500 FWHP is what you are after....your machine work and parts choice and tune will have to be spot on to hit that #. doable but again take your time to get the right stuff.

you first need to take your block & crank to a machine shop so they can determine if it needs a .030 overbore to clean up the cyl walls vs just a hone and if the crank just needs a polish or grind so you know what bearing size to get. .030 you either have a 355 or with a stroker rotateing assembly (crank/rods) you have a 383. C.I. increase will yield more TQ vs an identically built 350-355

The Summit reply is "one" option.....but most would agree a head/cam package from Lloyd Elliott or Advanced Induction will yield better power over the off the shelf one offered through Summit. With that said there is nothing wrong with the TF package they offer and I have spent a college education on parts from Summit, good outfit for parts. Just that there are other options with very proven performance results for AI or LE. I didn't see what cam specs the TF package came with or what head gasket thickness is included but I would encourage you clarify that so you can compare effectively with other packages.

if staying 350 or 355 the stock crank is quite strong. I would use it over any other aftermarket "cast" crank. IMHO go forged if going aftermarket. using the stock crank, having the stock rods re-sized with ARP fasteners and new pistons with all new bearings is often done. then a head/cam package of choice.

Think through your build first as combustion chamber size, how far the pistons are in the hole (meaning that changes when the block gets decked if that is what you do), piston choice, head gasket thickness all need to be considered so you wind up with the right "quench".

I had a VERY mild custom grind cam (214/220 on a 112 LSA) with stock AL ported heads (2.02/1.60) and a tune with a bone stock bottom end and made 350 RWHP/351 RWTQ (add roughly 15% for FW #'s) on a calif. smog legal car so your FW #'s are achievable with the right combo of parts AND good tune.....but if the 500 FWHP is what you are after....your machine work and parts choice and tune will have to be spot on to hit that #. doable but again take your time to get the right stuff.

#7

TECH Addict

iTrader: (1)

The options for your build are pretty wide open, but if you wanted to stick with the LT1 for a street car you can use the TrickFlow LT1 Top End Kit for 438 hp and 401 ft/lbs on a stock 350 LT1 bottom end.

For even more torque and power, add the Eagle 383 Rotating Assembly and I would expect these numbers to increase to around 450-475 Hp and 430-450 ft/lbs.

For even more torque and power, add the Eagle 383 Rotating Assembly and I would expect these numbers to increase to around 450-475 Hp and 430-450 ft/lbs.

Trending Topics

#9

Village Troll

iTrader: (2)

My 350 did a best of 12.0 @ 115 with LPE heads/intake/211 cam/58mm TB/LT's

My 396 did a best of 11.22 @ 122 with the same heads/intake/TB/headers and a mild SR cam. Still hoping to get a pass in the same kind of weather I ran the 12.0 in...

#10

TECH Regular

There is a well known recipe for success if 400-500 flywheel is your goal. It's not difficult at all. Been done many, many times over the years.

Start with a good budget rebuild of the stock shortblock, if it needs such. No need to go stroker if you're chasing anything under 450rwhp, which is about 530 flywheel. As far as components, use the OEM stock crank (it's a VERY durable piece and better than all the cast aftermarket offererings), a decent set of forged rods and pistons with some good ARP rod bolts and high-quality bearings. There are dozens of people on here who have done 355 builds like this, ask and look around. Having a competent machine shop that is familiar with LT1 builds in particular (NOT just generic SBC builds) is very important too. While generically similar to traditional SBCs, LTx motors are a different enough animal to require someone be familiar with their features and nuances.

For the top end I'd go either Advanced Induction 200cc heads (my personal preference) or Lloyd's "LE3" offering. The stock intake manifold will be fine with nothing more than the inlets enlarged for a 58mm throttle body, if you end up getting one (it's not absolutely neccesary at those hp numbers). Get your quench and chamber demensions figured out to yield a compression number in the mid-11s or so NA.

Cam choice is up to you....you'll probably want to consult with whoever you go with to port your heads on that matter.

If researched and sorted correctly, such a combo will make right at or very close to 500 flywheel (around 420-430ish rwhp) and have good street manners.

As for what Summit suggested. It's not anywhere near optimal for this application, and it will cost more than doing what is suggested above. Quite simply, you'll spend 30-50% more money in the end to make 50 less rwhp....or worse.

Summit is a large parts warehouse outfit. In my experience, they have good customer service. Great place to go for things like gaskets, hardware, bolts, exhaust systems, gears/diffs, wheels, and other things that are not highly application-specific. LT1 builds are very application specific, believe me. There is the right way to do a build like this that will yield great results, and there is the other way which won't. Take your advice from those on here who have been down this road multiple times and you'll be good to go.

Start with a good budget rebuild of the stock shortblock, if it needs such. No need to go stroker if you're chasing anything under 450rwhp, which is about 530 flywheel. As far as components, use the OEM stock crank (it's a VERY durable piece and better than all the cast aftermarket offererings), a decent set of forged rods and pistons with some good ARP rod bolts and high-quality bearings. There are dozens of people on here who have done 355 builds like this, ask and look around. Having a competent machine shop that is familiar with LT1 builds in particular (NOT just generic SBC builds) is very important too. While generically similar to traditional SBCs, LTx motors are a different enough animal to require someone be familiar with their features and nuances.

For the top end I'd go either Advanced Induction 200cc heads (my personal preference) or Lloyd's "LE3" offering. The stock intake manifold will be fine with nothing more than the inlets enlarged for a 58mm throttle body, if you end up getting one (it's not absolutely neccesary at those hp numbers). Get your quench and chamber demensions figured out to yield a compression number in the mid-11s or so NA.

Cam choice is up to you....you'll probably want to consult with whoever you go with to port your heads on that matter.

If researched and sorted correctly, such a combo will make right at or very close to 500 flywheel (around 420-430ish rwhp) and have good street manners.

As for what Summit suggested. It's not anywhere near optimal for this application, and it will cost more than doing what is suggested above. Quite simply, you'll spend 30-50% more money in the end to make 50 less rwhp....or worse.

Summit is a large parts warehouse outfit. In my experience, they have good customer service. Great place to go for things like gaskets, hardware, bolts, exhaust systems, gears/diffs, wheels, and other things that are not highly application-specific. LT1 builds are very application specific, believe me. There is the right way to do a build like this that will yield great results, and there is the other way which won't. Take your advice from those on here who have been down this road multiple times and you'll be good to go.

#11

Staging Lane

Thread Starter

Join Date: Aug 2013

Location: Rochester,Mi

Posts: 68

Likes: 0

Received 0 Likes

on

0 Posts

Im thinking im going to be staying with my stock crank as of right now but I still have to head up to the machine shop sometime this week and see what they think about the conditions of everything. Ive heard a bunch of great things about both AI and Loyld Elliot but I feel like Loyld might be more in my price range. Ive heard the LE2 package is most commonly bought. Thats one i was looking at also, is the LE3 worth the extra money? What do you guys think of AI there a bit more pricey but does that mean there better than what Loyd id offering?

#12

Staging Lane

Thread Starter

Join Date: Aug 2013

Location: Rochester,Mi

Posts: 68

Likes: 0

Received 0 Likes

on

0 Posts

There is a well known recipe for success if 400-500 flywheel is your goal. It's not difficult at all. Been done many, many times over the years.

Start with a good budget rebuild of the stock shortblock, if it needs such. No need to go stroker if you're chasing anything under 450rwhp, which is about 530 flywheel. As far as components, use the OEM stock crank (it's a VERY durable piece and better than all the cast aftermarket offererings), a decent set of forged rods and pistons with some good ARP rod bolts and high-quality bearings. There are dozens of people on here who have done 355 builds like this, ask and look around. Having a competent machine shop that is familiar with LT1 builds in particular (NOT just generic SBC builds) is very important too. While generically similar to traditional SBCs, LTx motors are a different enough animal to require someone be familiar with their features and nuances.

Start with a good budget rebuild of the stock shortblock, if it needs such. No need to go stroker if you're chasing anything under 450rwhp, which is about 530 flywheel. As far as components, use the OEM stock crank (it's a VERY durable piece and better than all the cast aftermarket offererings), a decent set of forged rods and pistons with some good ARP rod bolts and high-quality bearings. There are dozens of people on here who have done 355 builds like this, ask and look around. Having a competent machine shop that is familiar with LT1 builds in particular (NOT just generic SBC builds) is very important too. While generically similar to traditional SBCs, LTx motors are a different enough animal to require someone be familiar with their features and nuances.

#13

11 Second Club

iTrader: (2)

Join Date: Apr 2007

Location: chats,ga

Posts: 1,722

Likes: 0

Received 0 Likes

on

0 Posts

If sticking with the stock crank. Then run a good forged 6in rod along with a good forged piston. Dont be afraid of compression either. Id shoot for atleast 11.5. As far as le or ai there both great companys. Either 1 will steer u in the right direction. Another thing is to makes sure ur susp., tires, and exhaust are all gona work with the extra power. 500hp aint worth crap if u cant hook. Good luck

#14

11 Second Club

iTrader: (2)

Join Date: Apr 2007

Location: chats,ga

Posts: 1,722

Likes: 0

Received 0 Likes

on

0 Posts

Mahle pistons and a forged eagle or scat rods would work great. Id run 6in rods with 7/16 rod bolts. Summit is a good place to order stuff. As long as you have your parts numbers. I wouldn't take there advice on stuff.

#15

Staging Lane

Thread Starter

Join Date: Aug 2013

Location: Rochester,Mi

Posts: 68

Likes: 0

Received 0 Likes

on

0 Posts

If I went with the LE3, what custom cam grind would work best with it. I'm already planned to get headers and 3.73 gears. I'm swapping over to a t-56 because I don't want to rebuild another 4l60e. Also how about push rods and lifters?

#16

11 Second Club

iTrader: (1)

3.73s are a bad choice with a 94 or later T-56 the double OD pretty much demands 4.10s. Swapping to a T-56 because you refuse to use a good 4L60E builder is stupid because you will break the axle a lot quicker with the T-56 than with a 4L60E.

The 4L60E competently assembled can handle this no problem and does NOT need a bunch of fancy parts, more than anything just a competent builder who pays attention to clearances.

You are still very far off the mark here, slow down.

Maybe I missed it but why was the engine pulled?

The 4L60E competently assembled can handle this no problem and does NOT need a bunch of fancy parts, more than anything just a competent builder who pays attention to clearances.

You are still very far off the mark here, slow down.

Maybe I missed it but why was the engine pulled?

#17

Staging Lane

Thread Starter

Join Date: Aug 2013

Location: Rochester,Mi

Posts: 68

Likes: 0

Received 0 Likes

on

0 Posts

3.73s are a bad choice with a 94 or later T-56 the double OD pretty much demands 4.10s. Swapping to a T-56 because you refuse to use a good 4L60E builder is stupid because you will break the axle a lot quicker with the T-56 than with a 4L60E.

The 4L60E competently assembled can handle this no problem and does NOT need a bunch of fancy parts, more than anything just a competent builder who pays attention to clearances.

You are still very far off the mark here, slow down.

Maybe I missed it but why was the engine pulled?

The 4L60E competently assembled can handle this no problem and does NOT need a bunch of fancy parts, more than anything just a competent builder who pays attention to clearances.

You are still very far off the mark here, slow down.

Maybe I missed it but why was the engine pulled?

#18

12 Second Club

iTrader: (3)

I'd do rods resized for arp bolts, ball hone, new rings, rod and main bearings, reuse the main bolts assuming you are a 95 and not tty, 0.026 head gaskets and heads milled 0.010 to get to 11.5:1, then do either AI200s, LE3, or TEAs big stock heads, or whatever used heavily ported heads you can find, and a 23x/24x cam, 30-36lb injectors, and a tune and you'll be 420-450 to the tires. (This is exactly the build I'm doing right now)

#19

Staging Lane

Thread Starter

Join Date: Aug 2013

Location: Rochester,Mi

Posts: 68

Likes: 0

Received 0 Likes

on

0 Posts

I'd do rods resized for arp bolts, ball hone, new rings, rod and main bearings, reuse the main bolts assuming you are a 95 and not tty, 0.026 head gaskets and heads milled 0.010 to get to 11.5:1, then do either AI200s, LE3, or TEAs big stock heads, or whatever used heavily ported heads you can find, and a 23x/24x cam, 30-36lb injectors, and a tune and you'll be 420-450 to the tires. (This is exactly the build I'm doing right now)

More. Sorry but what do you mean resized for arp bolts?

#20

11 Second Club

iTrader: (2)

Join Date: Apr 2007

Location: chats,ga

Posts: 1,722

Likes: 0

Received 0 Likes

on

0 Posts

No the le3 do not come with lifters or pushrods. You can pick up some ls7 lifters for around $120. For push rods you will have to check for the right length. After the motor is put together. The small things is what adds up when building a motor. 1.6rr, timing chain set, tune, gaskets, fluids, injectors, tune, and supporting mods.