Issue After Cam Install

#21

10 Second Club

typically after zero lash a guy will give a hydraulic lifter from 1\2 to a full turn on the nut. but since it was ran for a while with a loose rocker the lifter would be pumped all the way up. that's why it would misfire after re adjusting the rocker. it would have been holding the valve open a little bit. this is a very common occurrence, and a non issue. all one has to do is run it for a few minutes and the lifter will bleed back down to where it needs to be.

Pump up? Lifter pump up occurs at high rpm while the lifter doesnt have the time to bleed down. And it holds the vlv open the amount it was compressed on adj - like 0.20" to 0.060"max. Once at low rpm again the lifter can bleed down. Aint no pump up while he adjusted at idle. The lifter bleeds down immediately as rpm is reduced. Too bad u continue to post when u dont know WTF your talking about.

If u took 30 to 60 minutes to google a hyd lifter and how it works u could learn enough to help yourself rather than bum dope others.

If u took 30 to 60 minutes to google a hyd lifter and how it works u could learn enough to help yourself rather than bum dope others.

A hyd lifter has a reservoir behind a check vlv that fills up as the p-rod cup is depressed. This oil press bleeds out around the sides of the lifter internal piston. The clearance between the piston and the lifter body side wall determines the bleed down rate and are high tolerance parts.

Once a hyd lifter is bottomed out after over adj (>0.060") it now holds the vlv open and Wall should recognize that imediately.

Reading nonsense posted here on hyd lifters is getting way old.

Pump up? Lifter pump up occurs at high rpm while the lifter doesnt have the time to bleed down. And it holds the vlv open the amount it was compressed on adj - like 0.20" to 0.060"max. Once at low rpm again the lifter can bleed down. Aint no pump up while he adjusted at idle. The lifter bleeds down immediately as rpm is reduced. Too bad u continue to post when u dont know WTF your talking about.

If u took 30 to 60 minutes to google a hyd lifter and how it works u could learn enough to help yourself rather than bum dope others.

If u took 30 to 60 minutes to google a hyd lifter and how it works u could learn enough to help yourself rather than bum dope others.A hyd lifter has a reservoir behind a check vlv that fills up as the p-rod cup is depressed. This oil press bleeds out around the sides of the lifter internal piston. The clearance between the piston and the lifter body side wall determines the bleed down rate and are high tolerance parts.

Once a hyd lifter is bottomed out after over adj (>0.060") it now holds the vlv open and Wall should recognize that imediately.

Reading nonsense posted here on hyd lifters is getting way old.

either you need a lesson in reading and comprehension or you just plain don't know what you're talking about.

#22

Ok let me itemize it for u.

"but since it was ran for a while with a loose rocker the lifter would be pumped all the way up."

Again its high RPM that can pump up a hyd lifter (some, not all), loose rocker has no effect to make the lifter pump up.

"that's why it would misfire after re adjusting the rocker. it would have been holding the valve open a little bit."

Flat out brainless comment as, once again, lose rockers dont cause the lifter to pump up.

"this is a very common occurrence, and a non issue."

Common in your brain only.

"all one has to do is run it for a few minutes and the lifter will bleed back down to where it needs to be."

All he has to do it take his foot off the throttle. Again u need to google hyd lifters and read up for at least an hour until u understand how a hyd lifter bleeds down - or pumps up too.

Yes i do know what im talking about or please prove me wrong. Id enjoy that BS even more than read how u fabricate here to the poor enthusiast with the real problem.

cardo

"but since it was ran for a while with a loose rocker the lifter would be pumped all the way up."

Again its high RPM that can pump up a hyd lifter (some, not all), loose rocker has no effect to make the lifter pump up.

"that's why it would misfire after re adjusting the rocker. it would have been holding the valve open a little bit."

Flat out brainless comment as, once again, lose rockers dont cause the lifter to pump up.

"this is a very common occurrence, and a non issue."

Common in your brain only.

"all one has to do is run it for a few minutes and the lifter will bleed back down to where it needs to be."

All he has to do it take his foot off the throttle. Again u need to google hyd lifters and read up for at least an hour until u understand how a hyd lifter bleeds down - or pumps up too.

Yes i do know what im talking about or please prove me wrong. Id enjoy that BS even more than read how u fabricate here to the poor enthusiast with the real problem.

cardo

#23

On The Tree

Thread Starter

iTrader: (1)

Join Date: Oct 2012

Location: Greenwood, IN

Posts: 173

Likes: 0

Received 0 Likes

on

0 Posts

Just to keep the thread updated. I got a new pushrod in, set everything up, changed all the spark plugs and started the car up. Car ran very well, I let it sit for a few minutes idling. Seemed nice and smooth. Also, no SES light now.

My only slight concern is the rocker nut on the rear rocker. It was the one that got a new pushrod. I noticed that when I set everything up, the nut is higher than the rest. There is no play in the pushrod it's at zero lash. Everything seems to be running good with little noise so should I be worried?

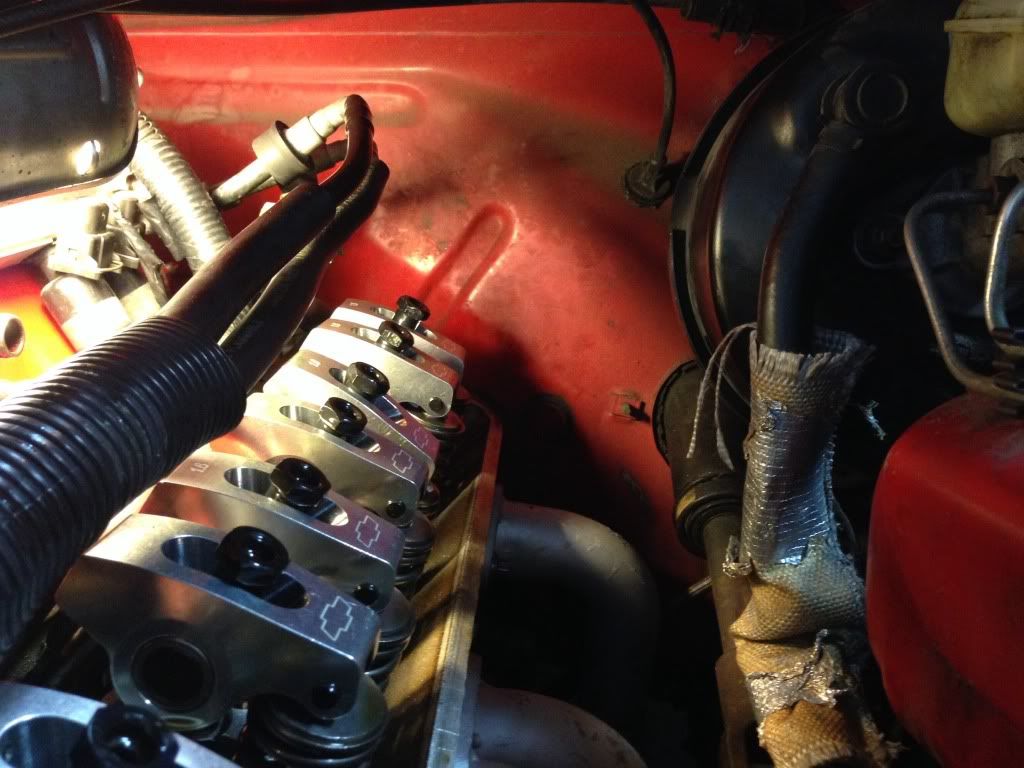

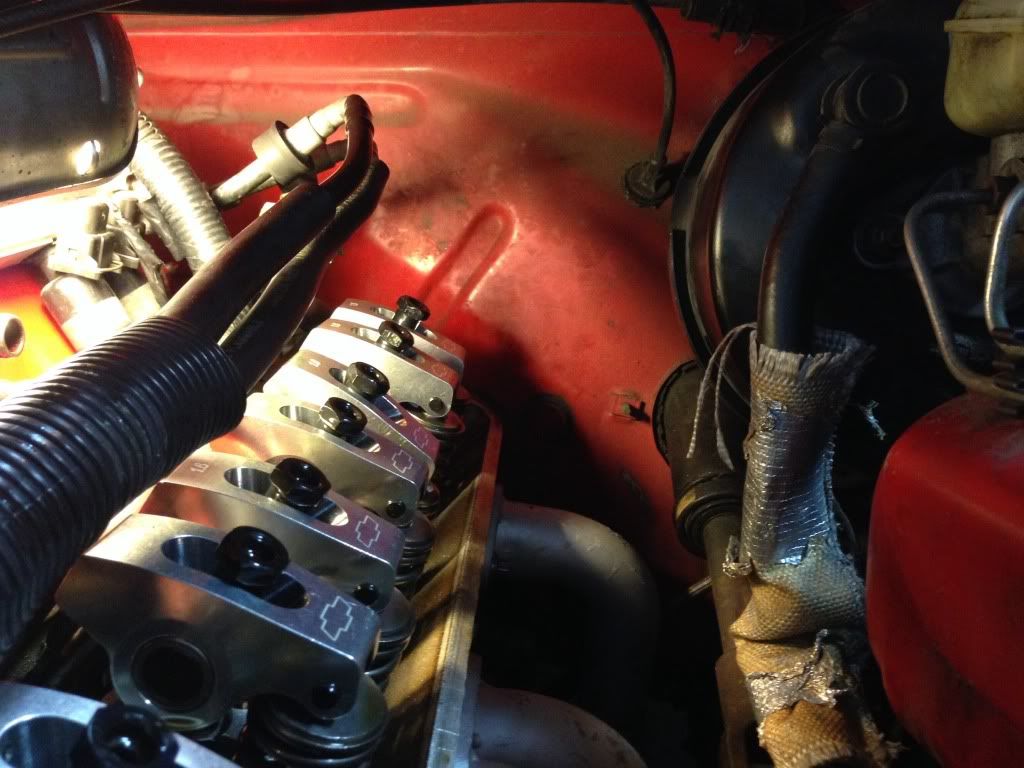

Pics for reference:

My only slight concern is the rocker nut on the rear rocker. It was the one that got a new pushrod. I noticed that when I set everything up, the nut is higher than the rest. There is no play in the pushrod it's at zero lash. Everything seems to be running good with little noise so should I be worried?

Pics for reference:

#24

Good catch Wall. Something is gooficated with that rocker nut. I would take the extra time to try and swap that rocker & nut with another one.

Since that was the previous bad rocker/p-rod u need to get the mirrors out and check for interference. Maybe that lifter is somehow stuck. Could be stuck/hung on the spring retainer. Can u turn it over to watch that rocker move up and down??

Those pix are a great help,

cardo

Since that was the previous bad rocker/p-rod u need to get the mirrors out and check for interference. Maybe that lifter is somehow stuck. Could be stuck/hung on the spring retainer. Can u turn it over to watch that rocker move up and down??

Those pix are a great help,

cardo

#26

Village Troll

iTrader: (2)

That

And that. Moving the pushrod up/down is far more consistent.

After rockers are adjusted it should sound like a sewing machine with no one rocker noise standing out.

I still think things are too tight with the spin the pushrod method.

After rockers are adjusted it should sound like a sewing machine with no one rocker noise standing out.

#27

On The Tree

Thread Starter

iTrader: (1)

Join Date: Oct 2012

Location: Greenwood, IN

Posts: 173

Likes: 0

Received 0 Likes

on

0 Posts

Good catch Wall. Something is gooficated with that rocker nut. I would take the extra time to try and swap that rocker & nut with another one.

Since that was the previous bad rocker/p-rod u need to get the mirrors out and check for interference. Maybe that lifter is somehow stuck. Could be stuck/hung on the spring retainer. Can u turn it over to watch that rocker move up and down??

Those pix are a great help,

cardo

Since that was the previous bad rocker/p-rod u need to get the mirrors out and check for interference. Maybe that lifter is somehow stuck. Could be stuck/hung on the spring retainer. Can u turn it over to watch that rocker move up and down??

Those pix are a great help,

cardo

#28

On The Tree

Thread Starter

iTrader: (1)

Join Date: Oct 2012

Location: Greenwood, IN

Posts: 173

Likes: 0

Received 0 Likes

on

0 Posts

Well you guys are awesome! Sure enough, the trunion was upside down. I also didn't use the spinning the pushrod method this time. Lastly, I had originally done 3/4 extra turn after zero lash, I went ahead and backed off 1/4 turn on each rocker so now each rocker is at 1/2 turn.