electric wp? realistic numbers

#61

Originally Posted by Justin00SS

The electric waterpumps I was looking at were ~$400 and more.

http://www.lmperformance.com/4863/1.html

http://www.lmperformance.com/4863/1.html

talking about lt1 not ls1

#63

Wow, there are some real boneheads in this thread that have no clue about the laws of physics.

It is called electromechanical energy conversion. The alternator is converting mechanical energy to electrical energy. The alternator may have a max of 140 amps, but the amount of current actually produced depends on the load. The alternator actually just provides a voltage, and the current = the voltage/impedance. The more the load, the more the current. Power = voltage * current so 20 amps * 12 volts = 240 watts. 240 watts /746 = .3hp to turn the alternator (excluding losses.)

Now, an electric motor is supplied with a constant voltage. The motor will pull as much current as needed to keep turning at a constant speed. As the load increases, the current will increase until the max value (limited) if the current is not sufficient, the motor will slow down and pump less water.

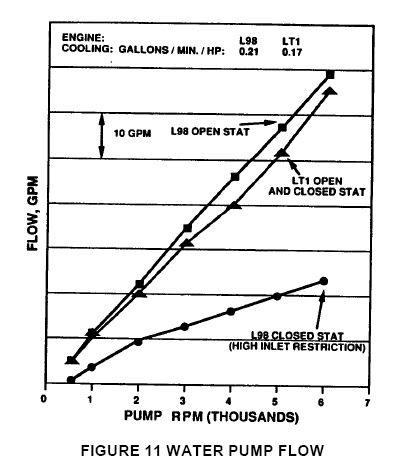

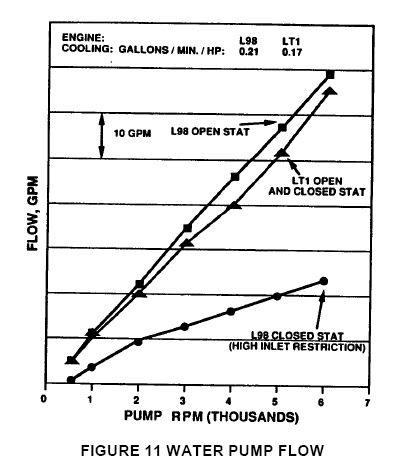

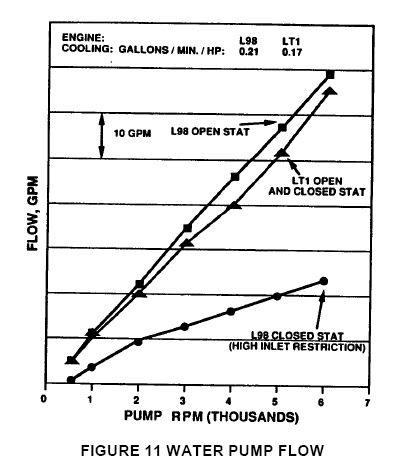

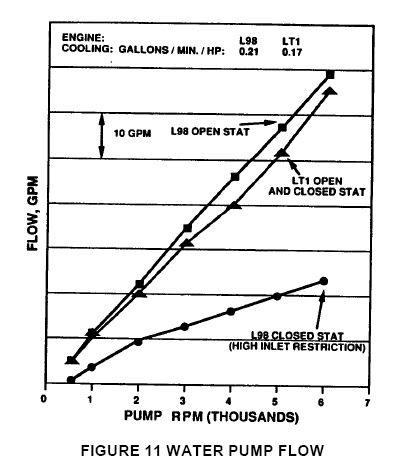

Here is a graph of the volume of the stock pump. Do you think a small electrical motor can flow this much under load?

It is called electromechanical energy conversion. The alternator is converting mechanical energy to electrical energy. The alternator may have a max of 140 amps, but the amount of current actually produced depends on the load. The alternator actually just provides a voltage, and the current = the voltage/impedance. The more the load, the more the current. Power = voltage * current so 20 amps * 12 volts = 240 watts. 240 watts /746 = .3hp to turn the alternator (excluding losses.)

Now, an electric motor is supplied with a constant voltage. The motor will pull as much current as needed to keep turning at a constant speed. As the load increases, the current will increase until the max value (limited) if the current is not sufficient, the motor will slow down and pump less water.

Here is a graph of the volume of the stock pump. Do you think a small electrical motor can flow this much under load?

Last edited by timz06; 03-02-2007 at 02:02 PM.

#64

Summing up some other posts;

The amount of load doesn't slow down the alternator. It either supplied enough juice or it doesn't.

__________________

Wrong!

Where did you come up with that hypothesis. Electricity has nothing to do with pully's and cranks....Well not al leats in the internal cubustion engine Alternator takes over after the car is started, ignition, stereo, power windows, power locks, all the crap on your dash, injectors, A/C.... no pully's no crank. The crank is driven by explosions in your piston chamber

__________________

Wrong!

There is nothing in the alternator to slow it down. You can spin it by hand. lol

Wrong!

The increase in current draw on an electrical system from an EWP does not cause the alternator pulley to have more drag on the engine, period. Like Justin00SS stated "it either has enough juice or it doesn't."

Wrong!

There are no gears in the alternator to speed it up or slow it down. Not in car alternators anyway. Maybe with larger industrial alternators.

A cars alternator produces a set about of electricity (amps) at a certain rpm. Spinning it faster then that will not make it produce anymore. Just like spinning a motor faster and faster does not mean it will make more hp.

The only drag from and alternator is if you went with a heavy heavy duty one for putting out alot more amps then then stock. Like a 300amp alt or something.

That would mean there is more are more metal coils for the alt to spin through the magnets to create hp and more metal means its heavier and harder to turn.

But the alternator doesn't get harder to turn because of the power being drained from it. It either has the juice or it doesn't.

Wrong!

To produce more amps you need more metal. More metal equals heavier and harder to turn durr.

But 140amp alternator is still a 140am alt and doesn't get harder to turn as the load is increased.

Besides. Its not going to strain the alt anyway. Its gonna put a load on the bat first.

What's the first thing that starts getting drained when the alt goes out? The battery. If the alt is giving the charge then it gets it from the battery.

Wrong!

The amount of load doesn't slow down the alternator. It either supplied enough juice or it doesn't.

__________________

Wrong!

Where did you come up with that hypothesis. Electricity has nothing to do with pully's and cranks....Well not al leats in the internal cubustion engine Alternator takes over after the car is started, ignition, stereo, power windows, power locks, all the crap on your dash, injectors, A/C.... no pully's no crank. The crank is driven by explosions in your piston chamber

__________________

Wrong!

There is nothing in the alternator to slow it down. You can spin it by hand. lol

Wrong!

The increase in current draw on an electrical system from an EWP does not cause the alternator pulley to have more drag on the engine, period. Like Justin00SS stated "it either has enough juice or it doesn't."

Wrong!

There are no gears in the alternator to speed it up or slow it down. Not in car alternators anyway. Maybe with larger industrial alternators.

A cars alternator produces a set about of electricity (amps) at a certain rpm. Spinning it faster then that will not make it produce anymore. Just like spinning a motor faster and faster does not mean it will make more hp.

The only drag from and alternator is if you went with a heavy heavy duty one for putting out alot more amps then then stock. Like a 300amp alt or something.

That would mean there is more are more metal coils for the alt to spin through the magnets to create hp and more metal means its heavier and harder to turn.

But the alternator doesn't get harder to turn because of the power being drained from it. It either has the juice or it doesn't.

Wrong!

To produce more amps you need more metal. More metal equals heavier and harder to turn durr.

But 140amp alternator is still a 140am alt and doesn't get harder to turn as the load is increased.

Besides. Its not going to strain the alt anyway. Its gonna put a load on the bat first.

What's the first thing that starts getting drained when the alt goes out? The battery. If the alt is giving the charge then it gets it from the battery.

Wrong!

#65

Originally Posted by timz06

Here is a graph of the volume of the stock pump. Do you think a small electrical motor can flow this much under load?

correct me if i am wrong. but doesn't the EWP flow more at idle but less then the mech at higher rpms(i.e. 4500)? the ewp is a constant, while the mech depends on the speed of the motor.

btw, i agree, alot of wrong info in here as far as electrical knowledge goes.

#66

It will always turn the same speed, if the load is small enough. The speed of a DC motor is proportional to the voltage. If the load is too high, it will slow down, assuming there is a current limiting circuit. If no circuit, the motor would burn up. On the other hand, AC motor speed is controlled by the frequency, not the voltage. So to control a varialble speed ac motor, you need a frequency converter.

#67

thanks timz06, i wish i had you on my side at the begining of this thread when i had to hold up the correct information by myself. i didnt know the technical terms for everything, but i knew how it worked. im glad some people have some sense

#68

Originally Posted by LT1Falcon

thanks timz06, i wish i had you on my side at the begining of this thread when i had to hold up the correct information by myself. i didnt know the technical terms for everything, but i knew how it worked. im glad some people have some sense

Thanks, I knew that electrical engineering degree would be useful someday. One downside of the internet is that people write posts when they have absoultley no idea what they are talking about. This leads to the spread of misinformation.

Thanks, I knew that electrical engineering degree would be useful someday. One downside of the internet is that people write posts when they have absoultley no idea what they are talking about. This leads to the spread of misinformation.

#69

Originally Posted by timz06

Thanks, I knew that electrical engineering degree would be useful someday. One downside of the internet is that people write posts when they have absoultley no idea what they are talking about. This leads to the spread of misinformation.

Thanks, I knew that electrical engineering degree would be useful someday. One downside of the internet is that people write posts when they have absoultley no idea what they are talking about. This leads to the spread of misinformation.

#71

Originally Posted by BlazerINtheWork

correct me if i am wrong. but doesn't the EWP flow more at idle but less then the mech at higher rpms(i.e. 4500)? the ewp is a constant, while the mech depends on the speed of the motor.

btw, i agree, alot of wrong info in here as far as electrical knowledge goes.

btw, i agree, alot of wrong info in here as far as electrical knowledge goes.

You are basically right BUT you need to consider the graph he posted is what a mechanical flows as restricted in the stock system. The electric ratings are freeflow, you choke them down with a cooling system and the flow will drop, I suspect signifigantly, and the break even rpm will be much lower than 4500rpms.

#72

Originally Posted by 96capricemgr

The electric ratings are freeflow, you choke them down with a cooling system and the flow will drop, I suspect signifigantly, and the break even rpm will be much lower than 4500rpms.

#73

I admit I was wrong. I really did not put much thought into the magnetic field increasing when more load is applied and causing that much drag. Though the load applied, in my opinion, is not significant enough to worry about a hp loss. I am willing to bet you gain more from the EWP itself than what you would lose in alternator drag. LT1 FALCON, you have proven your point. Others have joined in to prove that we are stupid and know nothing. One thing I do know is that I would never put a CHEVY MOTOR in a F****** FORD. After all this, I just had to say it.

#74

Originally Posted by rkinney

I admit I was wrong. I really did not put much thought into the magnetic field increasing when more load is applied and causing that much drag. Though the load applied, in my opinion, is not significant enough to worry about a hp loss. I am willing to bet you gain more from the EWP itself than what you would lose in alternator drag. LT1 FALCON, you have proven your point. Others have joined in to prove that we are stupid and know nothing. One thing I do know is that I would never put a CHEVY MOTOR in a F****** FORD. After all this, I just had to say it.

lol probably cus you lack the ability

#75

Originally Posted by arklie

ah...but the LT1 EW pumps are only about $200ish. I got one used for alot less.

I bought mine brand new from a local shop, installed in a LT1 housing for $150 even i think. I figured that was pretty good so I didnt have to hassle with putting it in my waterpump housing once I got it off.

#76

So what your saying is that you can put enough of a load on the alternator to keep the engine from turning?

I mean you lose hp with more load in the alternator so that would make the alternator harder to turn.

I don't buy that. The alternator produces voltage as the engine turns. The faster it turns (engine rpms) the more voltage/amps it puts out and has available for you accessories to use.

I still don't think it puts anymore load on the engine than required energy to overcome the built-in friction of just spinning it.

I mean you lose hp with more load in the alternator so that would make the alternator harder to turn.

I don't buy that. The alternator produces voltage as the engine turns. The faster it turns (engine rpms) the more voltage/amps it puts out and has available for you accessories to use.

I still don't think it puts anymore load on the engine than required energy to overcome the built-in friction of just spinning it.

#77

Originally Posted by Justin00SS

So what your saying is that you can put enough of a load on the alternator to keep the engine from turning?

I mean you lose hp with more load in the alternator so that would make the alternator harder to turn.

I don't buy that. The alternator produces voltage as the engine turns. The faster it turns (engine rpms) the more voltage/amps it puts out and has available for you accessories to use.

I still don't think it puts anymore load on the engine than required energy to overcome the built-in friction of just spinning it.

I mean you lose hp with more load in the alternator so that would make the alternator harder to turn.

I don't buy that. The alternator produces voltage as the engine turns. The faster it turns (engine rpms) the more voltage/amps it puts out and has available for you accessories to use.

I still don't think it puts anymore load on the engine than required energy to overcome the built-in friction of just spinning it.

lol dude when are you gonna give it up. have you read the whole thread? the point has been argued and explained so well that youd have to be stubborn and bone headed not to understand.

#78

Originally Posted by Justin00SS

So what your saying is that you can put enough of a load on the alternator to keep the engine from turning?

I mean you lose hp with more load in the alternator so that would make the alternator harder to turn.

I don't buy that. The alternator produces voltage as the engine turns. The faster it turns (engine rpms) the more voltage/amps it puts out and has available for you accessories to use.

I still don't think it puts anymore load on the engine than required energy to overcome the built-in friction of just spinning it.

I mean you lose hp with more load in the alternator so that would make the alternator harder to turn.

I don't buy that. The alternator produces voltage as the engine turns. The faster it turns (engine rpms) the more voltage/amps it puts out and has available for you accessories to use.

I still don't think it puts anymore load on the engine than required energy to overcome the built-in friction of just spinning it.

Check out this website where a guy uses an automotive alternator in the construction of an excercise bike. He uses light bulbs as the load (ie increasing the number of bulbs being powered increases the workload on person pedaling.

http://www.allaboutcircuits.com/vol_6/chpt_4/8.html

You're correct that the load on an alternator won't stop the engine at speed however, a loaded alternator costs enough horsepower that some performance cars have wot alternator cut out (ie a relay opens the field during wideopen throttle)

Now back on topic, I believe its good for less than 10rwhp however, it's free horsepower since using an EWP on an LT1 allows the use of double roller timing chains that are about 200 dollars cheaper than the LTX Heavy duty timing set.

Last edited by aboatguy; 03-04-2007 at 07:40 AM.

#79

Everyone gets a hardon over getting to use a gen 1 timing chain as an "upgrade".

Find me some examples of stock chains breaking?

Frankly I have seen examples of LT4 ED sets breaking but can not think of anyone posting about a single stock chain breaking. The stock chain on my car has 40K on it and seems just fine, even with the load from the waterpump still on it.

This is pretty typical though you kids grasp onto some "reason" to defend something you decided was a good idea and could not be bothered to use any rationality or logic or even real world results.

Even if you believe the stock chain weak just going too an electric pump will reduce the load placed on it.

Find me some examples of stock chains breaking?

Frankly I have seen examples of LT4 ED sets breaking but can not think of anyone posting about a single stock chain breaking. The stock chain on my car has 40K on it and seems just fine, even with the load from the waterpump still on it.

This is pretty typical though you kids grasp onto some "reason" to defend something you decided was a good idea and could not be bothered to use any rationality or logic or even real world results.

Even if you believe the stock chain weak just going too an electric pump will reduce the load placed on it.

#80

I personally went to an electric water pump because:

1) The bearings on my LT1 with 80k miles on it were bronze in color. I had a religiously maintained engine everything else and all other bearings were perfect. This was caused by IMO... the cam driven waterpump. I have saw a few others disassmbled and ditto for them.

2) I have personally saw fragged water pump drives and the coupler.

3) Free up some HP. Electric pumps don't burn anywhere near what they save in hp otherwise how are so many people picking up 1 to 2 tenths with just the waterpump swap and always some MPH gain.

4) Obviously with the water pump properly installed you are less likely to ever have to worry about drowning the opti.

5) The cheaper chain was a very nice bonus IMO.

The con side of it IMO:

1)That I am going to carry a spare because with very little experience with this brand of water pumps the one I have currently is a CSR. I have no Idea the longevity. There is a poll here somewhere on the longevity debate.

2)And as always if you don't have an adquate cooling system and tune by installing the EWP your only making trouble for yourself.

1) The bearings on my LT1 with 80k miles on it were bronze in color. I had a religiously maintained engine everything else and all other bearings were perfect. This was caused by IMO... the cam driven waterpump. I have saw a few others disassmbled and ditto for them.

2) I have personally saw fragged water pump drives and the coupler.

3) Free up some HP. Electric pumps don't burn anywhere near what they save in hp otherwise how are so many people picking up 1 to 2 tenths with just the waterpump swap and always some MPH gain.

4) Obviously with the water pump properly installed you are less likely to ever have to worry about drowning the opti.

5) The cheaper chain was a very nice bonus IMO.

The con side of it IMO:

1)That I am going to carry a spare because with very little experience with this brand of water pumps the one I have currently is a CSR. I have no Idea the longevity. There is a poll here somewhere on the longevity debate.

2)And as always if you don't have an adquate cooling system and tune by installing the EWP your only making trouble for yourself.

Last edited by The stunningman; 03-04-2007 at 10:07 AM.