Does YOUR Clutch Setup need a Shim?

#1

I get a ton of PMs from guys asking if their clutch setups need to be shimmed and when I suggest measuring to be sure, their first response is usually "how?" To be as helpful as I can to everyone, I'm going to try and describe the measurement process. It's tough to do without pictures, but try and follow me here:

During your next clutch install, determine if your slave cylinder needs to be shimmed or not. To do so, you need to take two measurements:

If there is no difference between the two measurements, or if "B" is greater than "A", there could be a problem with clutch engagement which could result in premature clutch slip and eventually a total failure.

I'm proud to announce that Tick Performance is now making the use of shims even more precise by offering THREE difference thicknesses:

We're always in pursuit of new ways to get you guys shifting as quickly & efficiently as possible. Determining if your setup needs a shim or not is quick, easy and cheap way to ensure proper function and long life out of your next clutch.

Good luck guys!

During your next clutch install, determine if your slave cylinder needs to be shimmed or not. To do so, you need to take two measurements:

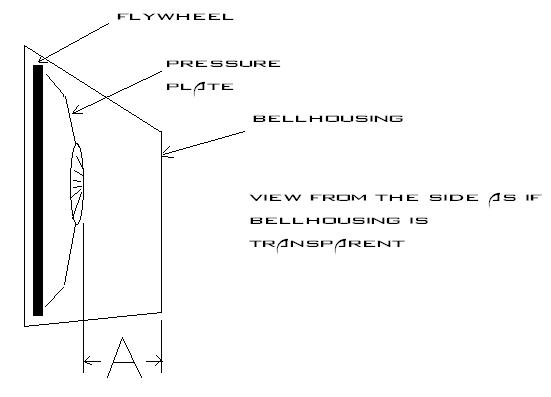

- Measurement "A" is the distance between the surface of the bellhousing that meets the transmission to the tip of the pressure plate fingers. To get an accurate measurement, the clutch must be torqued properly.

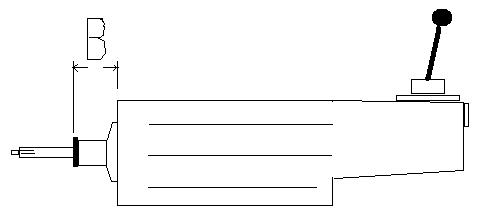

- Measurement "B" is the distance between the throwout bearing surface to the transmission surface that meets the bellhousing. To get an accurate measurement, the slave spring must be removed and the bearing must be fully seated at the bottom of it's travel; resting on the slave's base.

If there is no difference between the two measurements, or if "B" is greater than "A", there could be a problem with clutch engagement which could result in premature clutch slip and eventually a total failure.

I'm proud to announce that Tick Performance is now making the use of shims even more precise by offering THREE difference thicknesses:

- Tick Performance Slave Cylinder Shim (.055")

- Tick Performance Slave Cylinder Shim (.113")

- Tick Performance Slave Cylinder Shim (.180")

We're always in pursuit of new ways to get you guys shifting as quickly & efficiently as possible. Determining if your setup needs a shim or not is quick, easy and cheap way to ensure proper function and long life out of your next clutch.

Good luck guys!

Last edited by Joey@Tick; 09-13-2011 at 12:26 PM.

Trending Topics

#9

LS1Tech Sponsor

iTrader: (12)

Good post.It is probly the #1 reason clutches prematurely wear out.

In my experiance it is needed to check on every single clutch setup.Atleast 60% of the SPEC's we do never need the shim and the burnt one's we've pulled had the shim when it wasn't needed.I like 1/8 -1/4" air gap to make room for clutch break in.

In my experiance it is needed to check on every single clutch setup.Atleast 60% of the SPEC's we do never need the shim and the burnt one's we've pulled had the shim when it wasn't needed.I like 1/8 -1/4" air gap to make room for clutch break in.

#10

TECH Addict

iTrader: (12)

my spec clutch just went because the installer did not shim it. i am willing to bet all the spec failures on this board are due to the same problem. good info guys! just want you to know i'm picking up my car tomorrow and will be the first time i drive my car with teh new Tick Master Cylinder

The following users liked this post:

oldngray (06-19-2020)

#12

LS1TECH Sponsor

iTrader: (5)

One other bit of info that should be added is something that Joey already made note of in the original post. The tob must be seated against the base of the slave when taking your measurement. Sometimes in order to do this, the bleader will need to be loosened. If the TOB won't seat even with the bleeder cracked, there could be a problem with the slave itself which could also cause clutch engagement issues and premature clutch failure. Basically you're just looking for a little gap, and Slowhawk is correct. As the clutch breaks in the gap will become a bit less and less. Too much gap however, and there will be dissengagement and shifting issues due to a dragging clutch.

#18

I think you misunderstood my post. "A" is the measurement of the clutch, "B" is the measurement of the slave. With those numbers you find out what size shim, if any, is needed.

Definately make this a sticky.

Just what I thought!

#19

Launching!

iTrader: (18)

Join Date: Mar 2003

Location: Jacksonville, Florida

Posts: 232

Likes: 0

Received 0 Likes

on

0 Posts

Awesome info guys - Thanks!

Here is some info from RAM's site on shimming. I have a dual disc I am about to install but I need to measure for the correct shim.

Where can we get a set of shims? I don't want to have the driveline all torn down and then have to order up some shims.. lol

http://www.ramclutches.com/Tech/Tech...%20Bearing.jpg

Here is some info from RAM's site on shimming. I have a dual disc I am about to install but I need to measure for the correct shim.

Where can we get a set of shims? I don't want to have the driveline all torn down and then have to order up some shims.. lol

http://www.ramclutches.com/Tech/Tech...%20Bearing.jpg

so i can always find it when i need it

so i can always find it when i need it