900rwhp roll/mile/occational strip trans

#62

TECH Fanatic

iTrader: (16)

Havent picked a pump yet. I was just going to call tick or rpm and see what they suggest. If not, im sure a google search would lead to one.

I also use the n2mb WOT box and it seriously takes the hit off the trans/gears when shifting. It cuts spark when you engage the clutch and reactivates once you let up. No lift shifting is actually easier and smoother than shifting normal at WOT now.

I also use the n2mb WOT box and it seriously takes the hit off the trans/gears when shifting. It cuts spark when you engage the clutch and reactivates once you let up. No lift shifting is actually easier and smoother than shifting normal at WOT now.

#63

Havent picked a pump yet. I was just going to call tick or rpm and see what they suggest. If not, im sure a google search would lead to one.

I also use the n2mb WOT box and it seriously takes the hit off the trans/gears when shifting. It cuts spark when you engage the clutch and reactivates once you let up. No lift shifting is actually easier and smoother than shifting normal at WOT now.

I also use the n2mb WOT box and it seriously takes the hit off the trans/gears when shifting. It cuts spark when you engage the clutch and reactivates once you let up. No lift shifting is actually easier and smoother than shifting normal at WOT now.

#64

10 Second Club

iTrader: (5)

Join Date: Nov 2007

Location: Cincinnati

Posts: 1,052

Likes: 0

Received 0 Likes

on

0 Posts

Havent picked a pump yet. I was just going to call tick or rpm and see what they suggest. If not, im sure a google search would lead to one.

I also use the n2mb WOT box and it seriously takes the hit off the trans/gears when shifting. It cuts spark when you engage the clutch and reactivates once you let up. No lift shifting is actually easier and smoother than shifting normal at WOT now.

I also use the n2mb WOT box and it seriously takes the hit off the trans/gears when shifting. It cuts spark when you engage the clutch and reactivates once you let up. No lift shifting is actually easier and smoother than shifting normal at WOT now.

http://www.jegs.com/i/Tilton/454/40-525/10002/-1

this is the pump i use on mine

#65

TECH Fanatic

iTrader: (16)

i have a pic i can post later.

i run the lnc-003 and it does wonders working as a tq cut to help wot shifts and keep the trans in one piece.

http://www.jegs.com/i/Tilton/454/40-525/10002/-1

this is the pump i use on mine

i run the lnc-003 and it does wonders working as a tq cut to help wot shifts and keep the trans in one piece.

http://www.jegs.com/i/Tilton/454/40-525/10002/-1

this is the pump i use on mine

Anymore details on the pump? That jegs description is pretty general lol. What size fittings does it use?

#66

TECH Resident

iTrader: (127)

I am just giving you guys my personal opinion. I build these transmissions for a living, I am not just guessing at what is happening to them. Every turbo cars trans that I have torn down has had discoloring in the gears. Mainly in 3rd/4th. I have had them cryo treated and micro polished with the same outcome. When it comes to serious power customers want consistency and trouble free transmissions. That's why most cars in the higher hp range and doing a 4L80e conversion. I am currently working on a setup to feed the gears and needle bearing cages to help them from starvation. Once I get this going I will be testing it on a couple of customers cars that have already agreed to being the test mules. I REALLY want to know if this will actually help 1k plus hp cars. That is the goal.. for cars over 1k. What company do you guys know that warranty's their 1K hp rated t56/tr6060? NO ONE.

#67

You should also know that its never only one roll race. I"ve been there and have done it. 5 to 6 roll races a night and never giving the trans to cool down is where I am getting at. Around here you can make a pass at the track and have to wait another hour and a half in line again before you can make another pass. Lets the trans cool down.

I am just giving you guys my personal opinion. I build these transmissions for a living, I am not just guessing at what is happening to them. Every turbo cars trans that I have torn down has had discoloring in the gears. Mainly in 3rd/4th. I have had them cryo treated and micro polished with the same outcome. When it comes to serious power customers want consistency and trouble free transmissions. That's why most cars in the higher hp range and doing a 4L80e conversion. I am currently working on a setup to feed the gears and needle bearing cages to help them from starvation. Once I get this going I will be testing it on a couple of customers cars that have already agreed to being the test mules. I REALLY want to know if this will actually help 1k plus hp cars. That is the goal.. for cars over 1k. What company do you guys know that warranty's their 1K hp rated t56/tr6060? NO ONE.

I am just giving you guys my personal opinion. I build these transmissions for a living, I am not just guessing at what is happening to them. Every turbo cars trans that I have torn down has had discoloring in the gears. Mainly in 3rd/4th. I have had them cryo treated and micro polished with the same outcome. When it comes to serious power customers want consistency and trouble free transmissions. That's why most cars in the higher hp range and doing a 4L80e conversion. I am currently working on a setup to feed the gears and needle bearing cages to help them from starvation. Once I get this going I will be testing it on a couple of customers cars that have already agreed to being the test mules. I REALLY want to know if this will actually help 1k plus hp cars. That is the goal.. for cars over 1k. What company do you guys know that warranty's their 1K hp rated t56/tr6060? NO ONE.

For the sub 1KHP car a pump is going to work. Consistent failures mean consistent solutions. You should share your ideas by taking photos and posting them for others to see

#68

10 Second Club

iTrader: (5)

Join Date: Nov 2007

Location: Cincinnati

Posts: 1,052

Likes: 0

Received 0 Likes

on

0 Posts

http://tiltonracing.com/product/cooler-pumps/

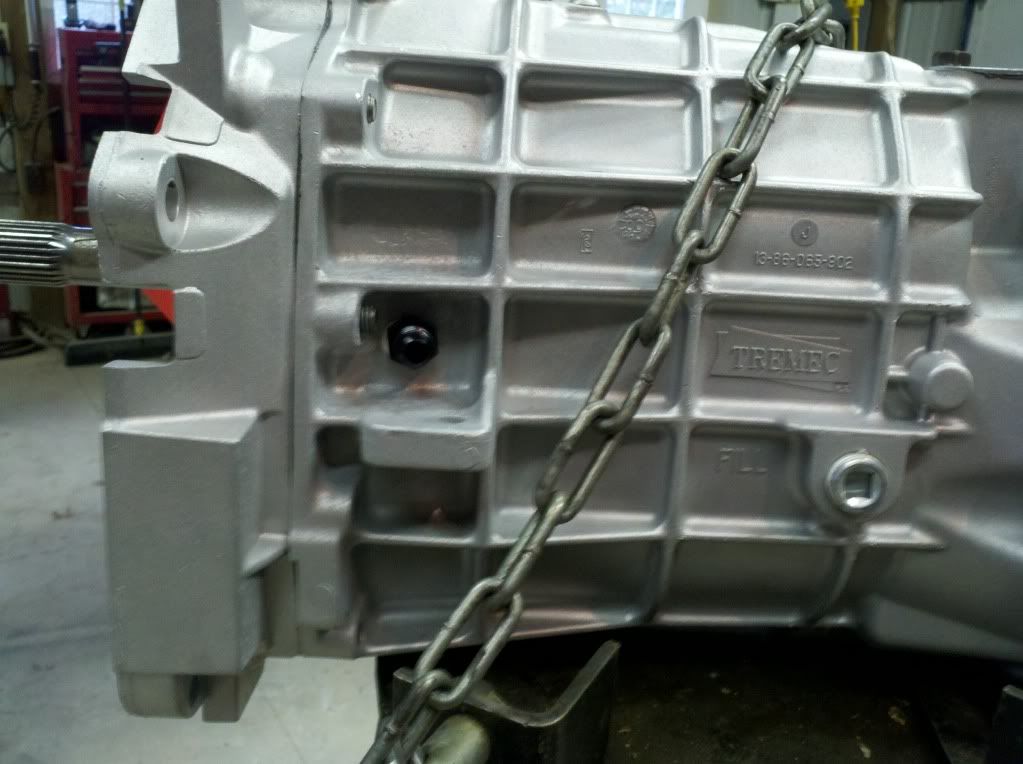

here is the only pic i can find from about 3 years ago cars torn apart now but pump is still set up similar

i have pump on a toggle switch i turn on before i make a pass or hard n2o pull on the street. some put them on a wide open throttle switch but then you cant hear the pump turn on do to noise so i dont care for that option but it does keep you from forgetting to turn it on.

#70

TECH Addict

iTrader: (9)

You should also know that its never only one roll race. I"ve been there and have done it. 5 to 6 roll races a night and never giving the trans to cool down is where I am getting at. Around here you can make a pass at the track and have to wait another hour and a half in line again before you can make another pass. Lets the trans cool down.

I am just giving you guys my personal opinion. I build these transmissions for a living, I am not just guessing at what is happening to them. Every turbo cars trans that I have torn down has had discoloring in the gears. Mainly in 3rd/4th. I have had them cryo treated and micro polished with the same outcome. When it comes to serious power customers want consistency and trouble free transmissions.

I am just giving you guys my personal opinion. I build these transmissions for a living, I am not just guessing at what is happening to them. Every turbo cars trans that I have torn down has had discoloring in the gears. Mainly in 3rd/4th. I have had them cryo treated and micro polished with the same outcome. When it comes to serious power customers want consistency and trouble free transmissions.

#71

TECH Resident

iTrader: (127)

Pumps here aren't about cooling the transmission like the stock ones, they're about keeping fluid on the 3-4 interface gears that get uncovered under hard acceleration and/or cornering. As you pointed out, these are the gears that heat up and blue, but only from lack of lubrication, not from hot lubrication...

#74

I'm trying to decide if I want to run a pump or not. I have about 2 days to decide.

I have an LS7 case so I already have the input hole but not sure where it is directed. I'm curious if I should add another hole more forward. Then the question is how to add some kind of nozzel.

I have actually done a study on this for my senior project in college. We needed to lube a set of spur gears. I'll see what I can dig up.

I have an LS7 case so I already have the input hole but not sure where it is directed. I'm curious if I should add another hole more forward. Then the question is how to add some kind of nozzel.

I have actually done a study on this for my senior project in college. We needed to lube a set of spur gears. I'll see what I can dig up.

#75

If anyone is interested about making a nozzle. Our goal for this was to produce a steady stream of ATF, not a spray, and have zero foaming. We also used the geometry of the 'nozzles' to limit flow. So if you guys want multiple nozzles you can size them so that they flow evenly without a complicated hydraulic circuit.

I have a pic of what I came up with followed by some screen shots of our presentation where we present some data. Maybe this will help someone?

you can see we never reached our .875gpm goal but we had other issues...our main gear pump wasn't putting out the flow we needed so pressure dropped.

this was done at 125psi BTW. I'm not sure what the pumps you guys use are putting out.

I have a pic of what I came up with followed by some screen shots of our presentation where we present some data. Maybe this will help someone?

you can see we never reached our .875gpm goal but we had other issues...our main gear pump wasn't putting out the flow we needed so pressure dropped.

this was done at 125psi BTW. I'm not sure what the pumps you guys use are putting out.

Last edited by cajundragger; 03-04-2014 at 02:54 PM.

#77

Man those nozzles look sweet but I was hoping for a less complicated solution.. more like a hole in the side of the trans with a pump  I think a lot of the guys running a pump kept it pretty simple but hey this thread was created to find solutions so keep them coming.

I think a lot of the guys running a pump kept it pretty simple but hey this thread was created to find solutions so keep them coming.

#79

I'm trying to decide if I want to run a pump or not. I have about 2 days to decide.

I have an LS7 case so I already have the input hole but not sure where it is directed. I'm curious if I should add another hole more forward. Then the question is how to add some kind of nozzel.

I have actually done a study on this for my senior project in college. We needed to lube a set of spur gears. I'll see what I can dig up.

I have an LS7 case so I already have the input hole but not sure where it is directed. I'm curious if I should add another hole more forward. Then the question is how to add some kind of nozzel.

I have actually done a study on this for my senior project in college. We needed to lube a set of spur gears. I'll see what I can dig up.

#80

my application is not roll or drag...I'm building a road/grip car.

My power will be around 800fwhp but I doubt the trans will see it much given traction limitations.

I'm concerned with does the flow need to be directed and regulated or does fluid just need to be dumped into the case.

If the later is true then I'll just drill and tap a 3/8 npt hole now..assemble my trans with a plug in the hole and later on screw in a fitting and be done with it. I could probably press a machined 'reducer' or 'nozzle' inside the NPT side of a NPT to AN fitting to use.

On that senior project we welded AN to AN unions in the wall of the case so we had a nice AN junction on either side. It worked great.

Just need more details on Blue99's setup(nozzle or termination). I also need to figure out where the stock corvette dumps the fluid. I know where on the case but I need to see what that correlates to in terms of internal components.

Sorry for the thread jack..but we are chasing the same thing.

My power will be around 800fwhp but I doubt the trans will see it much given traction limitations.

I'm concerned with does the flow need to be directed and regulated or does fluid just need to be dumped into the case.

If the later is true then I'll just drill and tap a 3/8 npt hole now..assemble my trans with a plug in the hole and later on screw in a fitting and be done with it. I could probably press a machined 'reducer' or 'nozzle' inside the NPT side of a NPT to AN fitting to use.

On that senior project we welded AN to AN unions in the wall of the case so we had a nice AN junction on either side. It worked great.

Just need more details on Blue99's setup(nozzle or termination). I also need to figure out where the stock corvette dumps the fluid. I know where on the case but I need to see what that correlates to in terms of internal components.

Sorry for the thread jack..but we are chasing the same thing.