Hmmm is it time for advancement?

#21

There are a lot of good statements in this post… The first post I read that nailed what I am looking for is FastBlackTA.

“I think the real issue is we have nowhere near the control of power delivery that the turbo cars have. Most nitrous systems (unless you are using a progressive unit) are either ON or OFF. There is no in between. Therefore, if you are running 3 stages each set for 200, you would see a dyno graph that looks like a stair-step. It's crude, and instead of gradually bringing in power we are bringing it in 200 hp at a time.”

This is a great statement for this reason. Keep in mind we are talking about LS based race applications. We are not talking about pro mod’s and old school big block or small block motors where keeping the heads down are not an issue. I do feel this would also benefit those applications as well but I am merely focused on the LSX based issue at the time. The problem that all the big nitrous cars are dealing with is CONTROLL. They are not using the resources available to have more tune ability and control over the delivery of the system. I am referring to Bottle pressure, fuel pressure and nitrous delivery.

The key to keeping the heads down is going to be the control of delivery and cylinder pressure. Like FastBlackTA said above the turbo guys have the ability of tuning control and delivery. With this control the turbo guys can gradually ramp the boost in at steady rate while maintaining a flat air fuel curve through tuning.

The second issue is that with a boosted application you are forcing airflow into the engine. For this reason you are not as limited as you are with a nitrous motor that is restricted by air delivery. With a nitrous engine you may hit a point of saturation into which the motor just simply can not digest anymore nitrous due to not enough airflow/delivery. I do not feel that we are at that wall as of yet… I feel there is more to tune out of the setup that we are not taking proper advantage of.

Understanding these key factors, we have to ask how do we get more control out of the system. How do we maintain a steady rate of delivery of nitrous, fuel and air?

I feel the answers are easy and right in front of our face.

Let’s say we have the right engine and accessory combination to maintain the air in and out of the engine. We all know that this is key to making power. Now lets go ahead and skip the obvious and focus on Nitrous.

I personally feel the right set up for achieving steady delivery ant tenability with even cylinder pressure is a given. Directport.

I really don’t think it matters if it is wet or dry as long as you have the true tune ability a direct port is designed to accomplish. You need to have the ability to individually tune the fuel delivery to each cylinder to maintain the correct cylinder temp.

Fuel system is a given. We have to be able to reduce the changes of large lean spikes. Either you need a real fuel system on the car that can provide rock solid delivery when the fuel solenoids open or put a dedicated fuel system to supply the fuel solenoids with the understanding you have enough fuel system to supply the motor.

Next import thing that you need control over is nitrous delivery. In the past there were not a lot of options here. On large shots either tie multiple bottles together to reduce pressure drop or run a homemade push system. Using the bottles Y together method you would still have the issue of the pressure dropping though out the run causing the car to go richer on the top end. Using the home made Push systems you had a more steady flow of pressure but every time the push system solenoid opens or closes there will be a split second fluctuating flow.

So how do we fix the above. Simple. Lay aside everything you have ever known and open your mind to change. The answer lies in the Nano system. Using the Nano system we can have a steady rate of nitrous flow that will not fluctuate. Why is this possible? Well the reason why is really simple. The Nano is designed to operate at a flowing pressure of 900 to max 1050 psi. We want to stay around this rate to maintain the nitrous in its liquid form. So with the nano compressed air is flowed from the regulated 4500 psi Nano bottle into the Nitrous bottle. The Nitrous is compacted down into a 100 percent liquid form. Easiest way of describing it is no air bubbles. As the Nitrous solenoid opens and liquid nitrous leaves the nitrous bottles compressed air from the nano bottle is flowing at the needed rate of pressure to maintain a steady rate of Nitrous flow until the nitrous solenoid closes. We have now taken away the pressure fluctuating issues.

With steady fuel flow and steady nitrous flow we can maintain a flat and accurate air fuel through out the HP curve. WE WILL BE COMING BACK TO THIS…

Now let’s talk about the delivery of power. For ages the options for progressive controllers were not that great. (While they have improved I still do not have what I think is the best answer. However there are better options that will work for now). Since progressive controllers sucked the best answers for tenability was stages. The more stages the smaller the size **** you could bring in keeping the spike in cylinder pressure low allowing you to spray more hp. The problem is we are looking for little to NO cylinder pressure spike.

The key to little to NO cylinder pressure spike is with one system gradually adding power at a steady rate of flow. The answer is in a progressive controller. There are much better options for controllers in today’s technology. Using the right controller you will be able to handle the amp load of the solenoid and be able to use a solenoid that can respond and work well with the controller.

Keeping in mind we need no Spikes in any flow take to consideration that if the nitrous is hitting before the fuel we have to tune that out. To so you have two options put distance between the nitrous solenoid and distribution block, shortening the fuel delivery distance or some controllers will let you tune in a delay between the fuel and nitrous solenoids upon activation.

The problem I do have with a progressive controller is that the fuel and nitrous delivery is interrupted at a steady rate. This will sometimes fluctuate the air fuel while progressing the solenoids. However this should still be better than the cylinder spike created by bringing in stages. I have been discussing and brain storming somethings with a few people trying to figure out how we can deliver a steady rate of flow with out shutting off and on the solenoids. This is something I am currently putting a lot of thought process into.

Ok moving on..

So as you read above we have covered just about all the key ingredients to tenability and maintaining a steady rate of flow. However that is only part of the tune up. Timing is a large factor in the combustion process witch will play with cylinder pressure as well. We have to have the ability to gradually take away timing as we start ramping up on the HP level. I know there are aftermarket systems that due this but I have to admit I do not know enough about the stock PCM. We have to have a method that is very reliable. None of this iat mod crap or plug in play devices. We need real factual tenability. Is there anyway using the stock PCM that we can gradually pull timing at the rate we are adding power? I don’t think so. If the answer is no we need to find a solution.

OK I know this is a novel and I wanted to drag it out longer and break it up in smaller sections but I only have a small amount of time these days.

Let me here what you guys are thinking,

Time to go visit my niece and nephew. You guys have a safe and Happy Halloween.

Dave

“I think the real issue is we have nowhere near the control of power delivery that the turbo cars have. Most nitrous systems (unless you are using a progressive unit) are either ON or OFF. There is no in between. Therefore, if you are running 3 stages each set for 200, you would see a dyno graph that looks like a stair-step. It's crude, and instead of gradually bringing in power we are bringing it in 200 hp at a time.”

This is a great statement for this reason. Keep in mind we are talking about LS based race applications. We are not talking about pro mod’s and old school big block or small block motors where keeping the heads down are not an issue. I do feel this would also benefit those applications as well but I am merely focused on the LSX based issue at the time. The problem that all the big nitrous cars are dealing with is CONTROLL. They are not using the resources available to have more tune ability and control over the delivery of the system. I am referring to Bottle pressure, fuel pressure and nitrous delivery.

The key to keeping the heads down is going to be the control of delivery and cylinder pressure. Like FastBlackTA said above the turbo guys have the ability of tuning control and delivery. With this control the turbo guys can gradually ramp the boost in at steady rate while maintaining a flat air fuel curve through tuning.

The second issue is that with a boosted application you are forcing airflow into the engine. For this reason you are not as limited as you are with a nitrous motor that is restricted by air delivery. With a nitrous engine you may hit a point of saturation into which the motor just simply can not digest anymore nitrous due to not enough airflow/delivery. I do not feel that we are at that wall as of yet… I feel there is more to tune out of the setup that we are not taking proper advantage of.

Understanding these key factors, we have to ask how do we get more control out of the system. How do we maintain a steady rate of delivery of nitrous, fuel and air?

I feel the answers are easy and right in front of our face.

Let’s say we have the right engine and accessory combination to maintain the air in and out of the engine. We all know that this is key to making power. Now lets go ahead and skip the obvious and focus on Nitrous.

I personally feel the right set up for achieving steady delivery ant tenability with even cylinder pressure is a given. Directport.

I really don’t think it matters if it is wet or dry as long as you have the true tune ability a direct port is designed to accomplish. You need to have the ability to individually tune the fuel delivery to each cylinder to maintain the correct cylinder temp.

Fuel system is a given. We have to be able to reduce the changes of large lean spikes. Either you need a real fuel system on the car that can provide rock solid delivery when the fuel solenoids open or put a dedicated fuel system to supply the fuel solenoids with the understanding you have enough fuel system to supply the motor.

Next import thing that you need control over is nitrous delivery. In the past there were not a lot of options here. On large shots either tie multiple bottles together to reduce pressure drop or run a homemade push system. Using the bottles Y together method you would still have the issue of the pressure dropping though out the run causing the car to go richer on the top end. Using the home made Push systems you had a more steady flow of pressure but every time the push system solenoid opens or closes there will be a split second fluctuating flow.

So how do we fix the above. Simple. Lay aside everything you have ever known and open your mind to change. The answer lies in the Nano system. Using the Nano system we can have a steady rate of nitrous flow that will not fluctuate. Why is this possible? Well the reason why is really simple. The Nano is designed to operate at a flowing pressure of 900 to max 1050 psi. We want to stay around this rate to maintain the nitrous in its liquid form. So with the nano compressed air is flowed from the regulated 4500 psi Nano bottle into the Nitrous bottle. The Nitrous is compacted down into a 100 percent liquid form. Easiest way of describing it is no air bubbles. As the Nitrous solenoid opens and liquid nitrous leaves the nitrous bottles compressed air from the nano bottle is flowing at the needed rate of pressure to maintain a steady rate of Nitrous flow until the nitrous solenoid closes. We have now taken away the pressure fluctuating issues.

With steady fuel flow and steady nitrous flow we can maintain a flat and accurate air fuel through out the HP curve. WE WILL BE COMING BACK TO THIS…

Now let’s talk about the delivery of power. For ages the options for progressive controllers were not that great. (While they have improved I still do not have what I think is the best answer. However there are better options that will work for now). Since progressive controllers sucked the best answers for tenability was stages. The more stages the smaller the size **** you could bring in keeping the spike in cylinder pressure low allowing you to spray more hp. The problem is we are looking for little to NO cylinder pressure spike.

The key to little to NO cylinder pressure spike is with one system gradually adding power at a steady rate of flow. The answer is in a progressive controller. There are much better options for controllers in today’s technology. Using the right controller you will be able to handle the amp load of the solenoid and be able to use a solenoid that can respond and work well with the controller.

Keeping in mind we need no Spikes in any flow take to consideration that if the nitrous is hitting before the fuel we have to tune that out. To so you have two options put distance between the nitrous solenoid and distribution block, shortening the fuel delivery distance or some controllers will let you tune in a delay between the fuel and nitrous solenoids upon activation.

The problem I do have with a progressive controller is that the fuel and nitrous delivery is interrupted at a steady rate. This will sometimes fluctuate the air fuel while progressing the solenoids. However this should still be better than the cylinder spike created by bringing in stages. I have been discussing and brain storming somethings with a few people trying to figure out how we can deliver a steady rate of flow with out shutting off and on the solenoids. This is something I am currently putting a lot of thought process into.

Ok moving on..

So as you read above we have covered just about all the key ingredients to tenability and maintaining a steady rate of flow. However that is only part of the tune up. Timing is a large factor in the combustion process witch will play with cylinder pressure as well. We have to have the ability to gradually take away timing as we start ramping up on the HP level. I know there are aftermarket systems that due this but I have to admit I do not know enough about the stock PCM. We have to have a method that is very reliable. None of this iat mod crap or plug in play devices. We need real factual tenability. Is there anyway using the stock PCM that we can gradually pull timing at the rate we are adding power? I don’t think so. If the answer is no we need to find a solution.

OK I know this is a novel and I wanted to drag it out longer and break it up in smaller sections but I only have a small amount of time these days.

Let me here what you guys are thinking,

Time to go visit my niece and nephew. You guys have a safe and Happy Halloween.

Dave

Last edited by Nitro Dave's Nitrous Outlet; 10-31-2008 at 06:13 PM.

#22

OWN3D BY MY PROF!

iTrader: (176)

I think the NANO and progressive would help, but I still don't know if you're going to be able to hit a LS engine with a 1200 shot. That's pretty much what it is going to take to keep up with the turbo cars running low 7s.

I'd love to have the money to try it out. There is that very steep learning curve though and I could see easily nuking a few engines in the process.

I'd love to have the money to try it out. There is that very steep learning curve though and I could see easily nuking a few engines in the process.

#23

No I am not saying we can out run the faster turbo cars. I dont know if that is possible. I am saying we can compete. I am saying high 7s maybe even low 7s is possible. You do not always have to have the fastest car in the field to compete. These turbo guys are breaking left and right as well as battling tune ups. Some of us do not have the money to build a competitive turbo car. I think with the right nitrous set up we can build a nitrous car for a fraction of the price and knock on the doors of the fater turbo cars and put the not so fast and reliable turbo cars back onthe trailer.

Dave

Dave

#24

8 Second Club

iTrader: (7)

Join Date: Dec 2002

Location: Maryland

Posts: 1,086

Likes: 0

Received 0 Likes

on

0 Posts

I have this worked out on paper, but not in practice. It's going to be a part of my winter mods. I am going to try and run a 600 shot one three stages pulling timing at every stage, and possibly as a function of time. It all sounds great, but I haven't started building it yet. I was a ME, not an EE lol.

#26

I have this worked out on paper, but not in practice. It's going to be a part of my winter mods. I am going to try and run a 600 shot one three stages pulling timing at every stage, and possibly as a function of time. It all sounds great, but I haven't started building it yet. I was a ME, not an EE lol.

If using a stock pcm how are you pulling out the timing in a manner to match the hp increase?

Dave

#27

Ok but you are still going to have a sudden rise in cylinder pressure everytime you bring a stage in. It will not be as bad as using tow larger stages though.

If using a stock pcm how are you pulling out the timing in a manner to match the hp increase?

Dave

If using a stock pcm how are you pulling out the timing in a manner to match the hp increase?

Dave

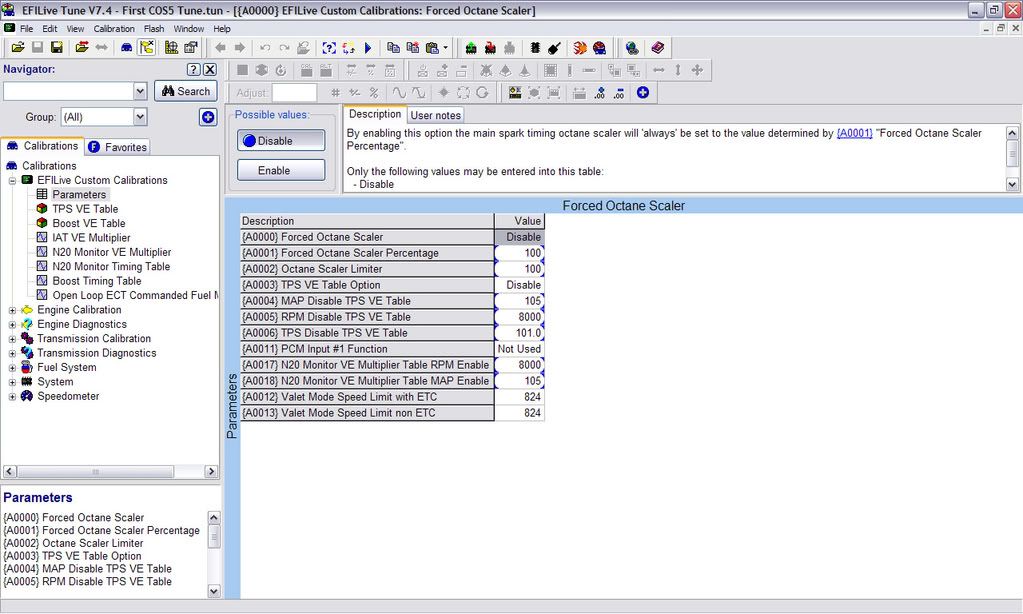

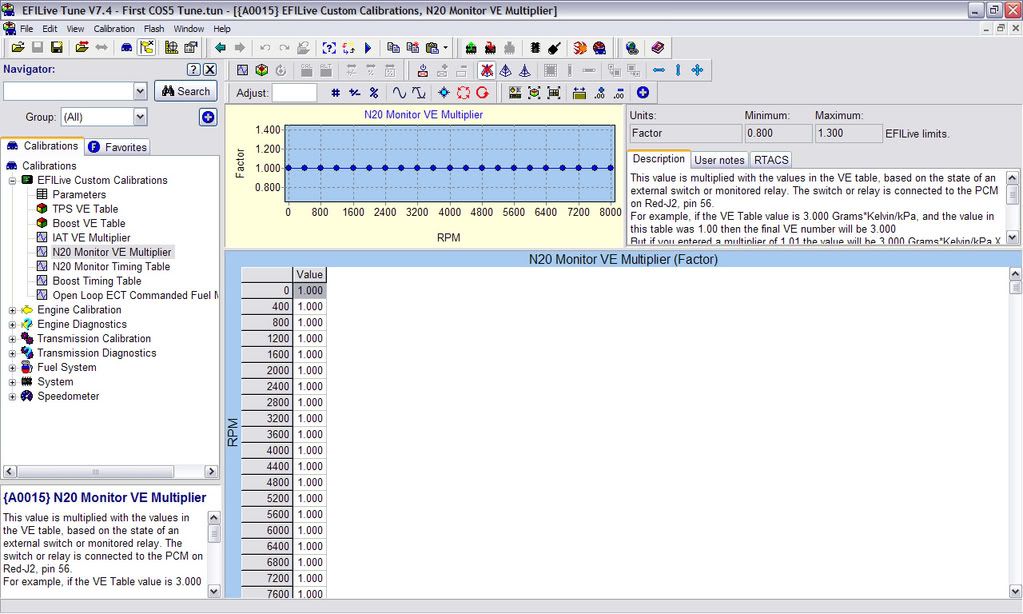

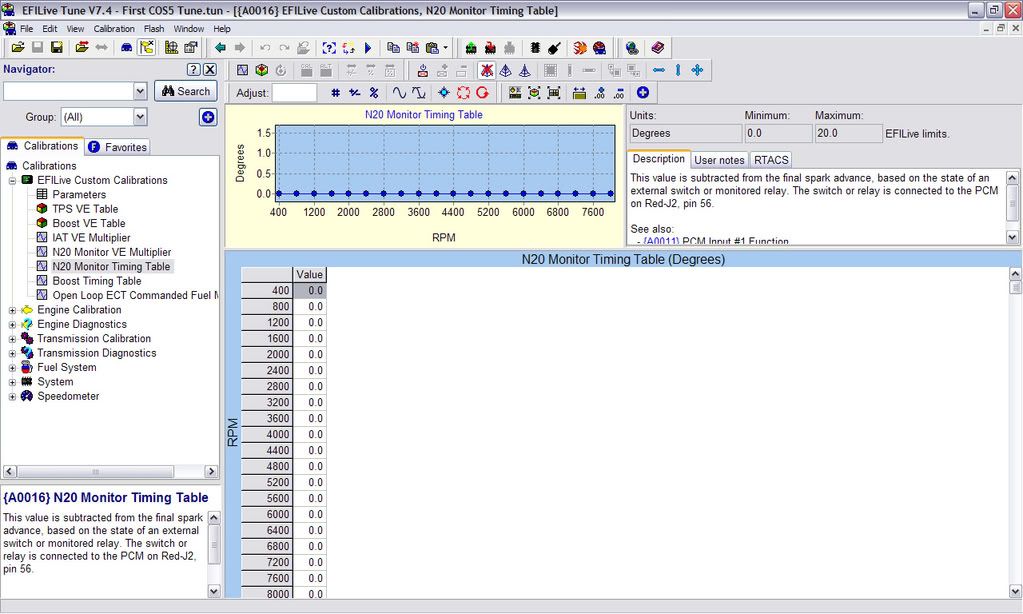

Dave EFILIVE cos5 can pull timing via RPM and add fuel via a seperate VE table multiplier, great for a dry shot... u can also use this function w/ a wet kit..

its already infront of us as we speak... at least the one's who use EFILIVE...LOL

all on a stock PCM, 2001-2005 pcm's to be exact

#28

8 Second Club

iTrader: (7)

Join Date: Dec 2002

Location: Maryland

Posts: 1,086

Likes: 0

Received 0 Likes

on

0 Posts

Dave EFILIVE cos5 can pull timing via RPM and add fuel via a seperate VE table multiplier, great for a dry shot... u can also use this function w/ a wet kit..

its already infront of us as we speak... at least the one's who use EFILIVE...LOL

all on a stock PCM, 2001-2005 pcm's to be exact

its already infront of us as we speak... at least the one's who use EFILIVE...LOL

all on a stock PCM, 2001-2005 pcm's to be exact

Yes! But I'm stuck with HPTuners LOL.

#29

hey we all make our desicions with what we use... I just happned to get my efilive from lingenfelter (lpe) at the time...

cos5 has been out for atleast a year or so.....

now i just wish we could have individual cylinder fueling control w/ the stock pcm...

cos5 has been out for atleast a year or so.....

now i just wish we could have individual cylinder fueling control w/ the stock pcm...

#32

TECH Junkie

iTrader: (10)

Join Date: Nov 2002

Location: Deerfield Beach, FL

Posts: 3,672

Likes: 0

Received 0 Likes

on

0 Posts

Dave EFILIVE cos5 can pull timing via RPM and add fuel via a seperate VE table multiplier, great for a dry shot... u can also use this function w/ a wet kit..

its already infront of us as we speak... at least the one's who use EFILIVE...LOL

all on a stock PCM, 2001-2005 pcm's to be exact

its already infront of us as we speak... at least the one's who use EFILIVE...LOL

all on a stock PCM, 2001-2005 pcm's to be exact

#33

OWN3D BY MY PROF!

iTrader: (176)

Dave EFILIVE cos5 can pull timing via RPM and add fuel via a seperate VE table multiplier, great for a dry shot... u can also use this function w/ a wet kit..

its already infront of us as we speak... at least the one's who use EFILIVE...LOL

all on a stock PCM, 2001-2005 pcm's to be exact

its already infront of us as we speak... at least the one's who use EFILIVE...LOL

all on a stock PCM, 2001-2005 pcm's to be exact

#34

#35

TECH Junkie

iTrader: (10)

Join Date: Nov 2002

Location: Deerfield Beach, FL

Posts: 3,672

Likes: 0

Received 0 Likes

on

0 Posts

It works with the '99 - '02 pcms, but if it's not an '01 or '02 you have to put in an '01 or '02 operating systems, the '98 pcm is different and can not be upgraded to an '01 or '02 operating system, so the custom operating system can not be used. Mine is a '99 and I put an '02 operating system in and cos5.

#36

12 Second Club

iTrader: (17)

Join Date: Dec 2004

Location: Cooper City, FL

Posts: 1,449

Likes: 0

Received 0 Likes

on

0 Posts

It works with the '99 - '02 pcms, but if it's not an '01 or '02 you have to put in an '01 or '02 operating systems, the '98 pcm is different and can not be upgraded to an '01 or '02 operating system, so the custom operating system can not be used. Mine is a '99 and I put an '02 operating system in and cos5.

but you still can only do it via 1st gear? and no other gears?

Chad

#37

TECH Junkie

iTrader: (10)

Join Date: Nov 2002

Location: Deerfield Beach, FL

Posts: 3,672

Likes: 0

Received 0 Likes

on

0 Posts

Here's some screen shots of some of the custom tables:

#38

7 Second Club

iTrader: (42)

Join Date: Jun 2004

Location: paducah, ky

Posts: 4,558

Likes: 0

Received 0 Likes

on

0 Posts

there should be no progression of a nitrous system as far as im concerned... you should detune the car either by the ramping of timing or multiple kits by a clutch or all 3....

the reason glidden is going so fast is because he is VERY light and has a perfect clutch tune up.... he's using his vast amount of prostock knowledge to go fast.... prostock cars arent loaded with HP by any means but they use every bit of it...

what we need to figure out how to do is keep the intake runners from backing up and loading up #7.... if some one could figure out how to pressurize the cylinder with nitrous you'd have the fastest setup....

i've thought about putting reed valves in the intake runners only letting air in and keeping pressure in the cylinder = forcing nitrous in... pressurizing the cylinder with a nitrous bottle...

many people dont understand that the reason nitrous works isnt becuase nitrous is some magical fuel.... it only lets you burn more race gas.... i like running my nitrous stuff on the fat side... when the car loads it takes fuel to make power...

also what many people are doing that are going very fast is they have taken the compression away from these nitrous motors allowing them to flow more nitrous and use more fuel thus making more power....

the reason glidden is going so fast is because he is VERY light and has a perfect clutch tune up.... he's using his vast amount of prostock knowledge to go fast.... prostock cars arent loaded with HP by any means but they use every bit of it...

what we need to figure out how to do is keep the intake runners from backing up and loading up #7.... if some one could figure out how to pressurize the cylinder with nitrous you'd have the fastest setup....

i've thought about putting reed valves in the intake runners only letting air in and keeping pressure in the cylinder = forcing nitrous in... pressurizing the cylinder with a nitrous bottle...

many people dont understand that the reason nitrous works isnt becuase nitrous is some magical fuel.... it only lets you burn more race gas.... i like running my nitrous stuff on the fat side... when the car loads it takes fuel to make power...

also what many people are doing that are going very fast is they have taken the compression away from these nitrous motors allowing them to flow more nitrous and use more fuel thus making more power....

Last edited by ty_ty13; 11-03-2008 at 01:32 PM.

#39

Race your car!

iTrader: (50)

I have seen a setup with the nitrous nozzle right in the head, not in the intake.

As for the intake distribution, if you use anything other then the modled plastic intakes, like a single plane, sheet metal or the like the issues with #7 go away.

A DP with the stock plastic style works as well, because now you can tune each cylinder individually.

I think it's gonna take 3, maybe 4 kits to go as fast as possible, turn them on in stages to get the power to the ground and bring them all in as fast as the track will allow. That, and you're gonna need 2 bottles in the car to supprt the 4 kits.

As for the intake distribution, if you use anything other then the modled plastic intakes, like a single plane, sheet metal or the like the issues with #7 go away.

A DP with the stock plastic style works as well, because now you can tune each cylinder individually.

I think it's gonna take 3, maybe 4 kits to go as fast as possible, turn them on in stages to get the power to the ground and bring them all in as fast as the track will allow. That, and you're gonna need 2 bottles in the car to supprt the 4 kits.

#40

7 Second Club

iTrader: (42)

Join Date: Jun 2004

Location: paducah, ky

Posts: 4,558

Likes: 0

Received 0 Likes

on

0 Posts

runners still fill up even on sheet metal manifolds in a direct port system if you spray enough... if some one could figure out how to use a reed valve i think it would make for one hellacious setup... allowing air in but not back out