found the limit of my 408 :(

#21

8 Second Club

Thread Starter

iTrader: (1)

Join Date: Nov 2001

Location: the not so stock tribe

Posts: 3,697

Likes: 0

Received 0 Likes

on

0 Posts

thanks for the advise guys.

i started taking the motor apart, and i can't find anything wrong so far .

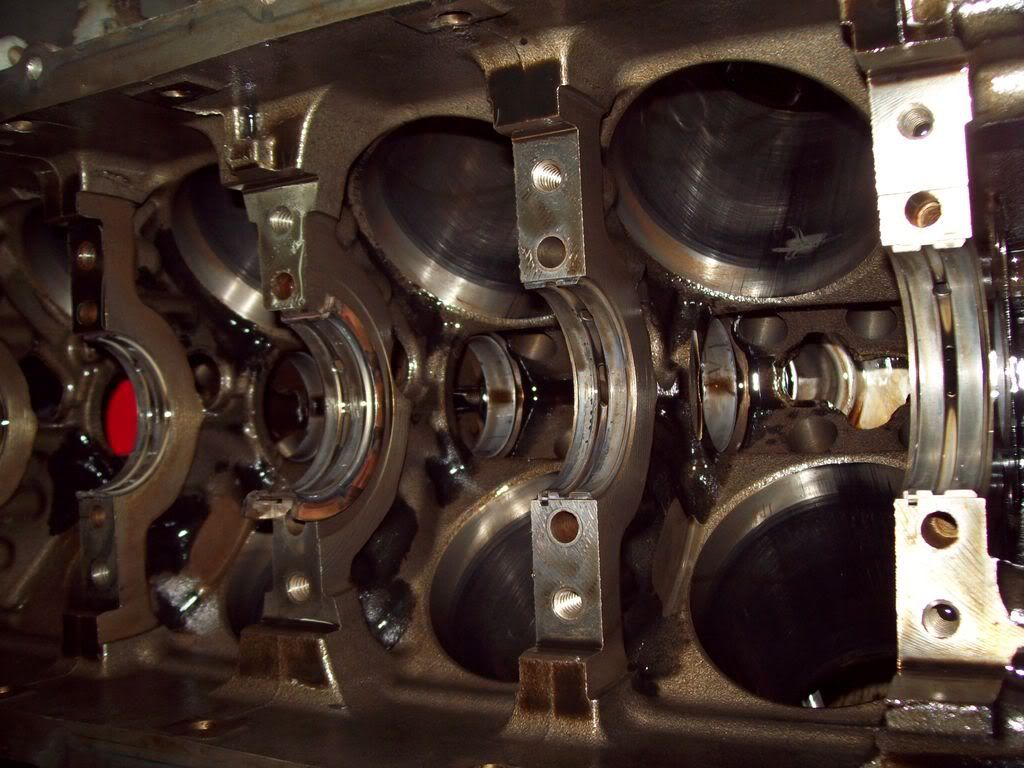

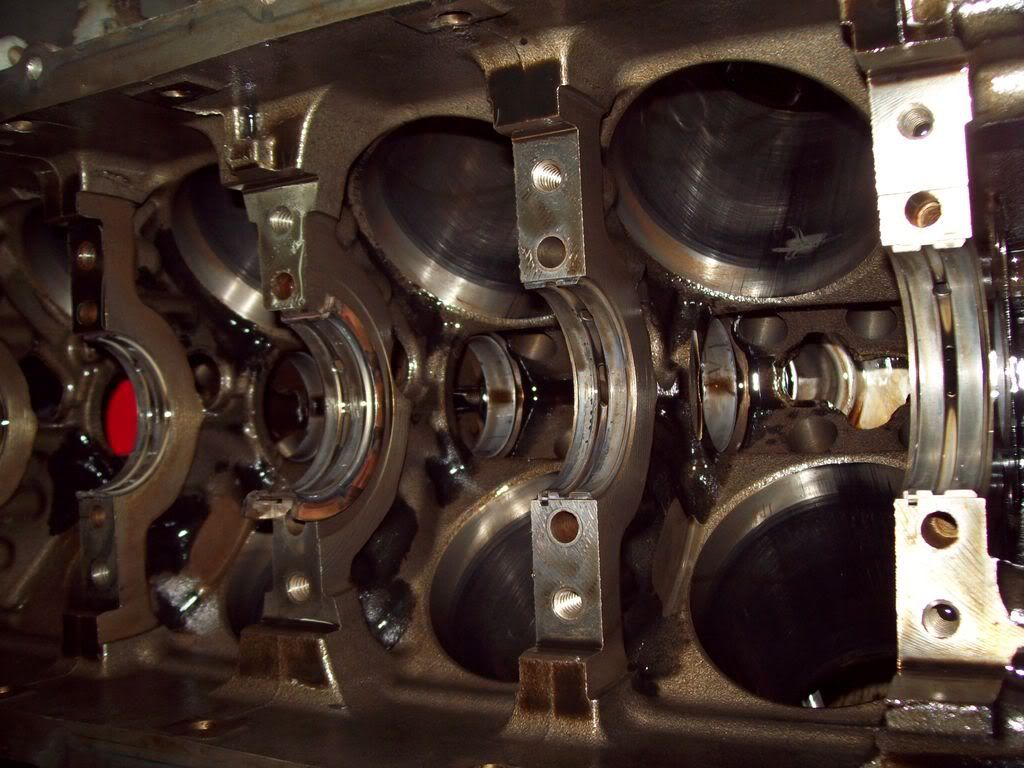

the rods, wrist pins , and rod bearings look great , which is not what i was expecting to see. i was under the impression that the rod bearings will take a beating whith detonation, but these look real good.

all the cylinder walls look ok , minor scratches but nothing a quick hone won't fix. pistons look kinda ok , all in relatively good shape except on which had some scouring on the side ( surprisingly , the wall was real clean - don't let the pic fool you , you can barely get a finger nail caught on that , it looks much worse in pictures than it does in real). i still have to take the rings off and inspect the ringlands more closely . and i still have to remove the crank and inspect the main bearings. should be doing that today.

, all in relatively good shape except on which had some scouring on the side ( surprisingly , the wall was real clean - don't let the pic fool you , you can barely get a finger nail caught on that , it looks much worse in pictures than it does in real). i still have to take the rings off and inspect the ringlands more closely . and i still have to remove the crank and inspect the main bearings. should be doing that today.

and i think i found a new set of low comression pistons over here that i might be getting soon .

i started taking the motor apart, and i can't find anything wrong so far .

the rods, wrist pins , and rod bearings look great , which is not what i was expecting to see. i was under the impression that the rod bearings will take a beating whith detonation, but these look real good.

all the cylinder walls look ok , minor scratches but nothing a quick hone won't fix. pistons look kinda ok

, all in relatively good shape except on which had some scouring on the side ( surprisingly , the wall was real clean - don't let the pic fool you , you can barely get a finger nail caught on that , it looks much worse in pictures than it does in real). i still have to take the rings off and inspect the ringlands more closely . and i still have to remove the crank and inspect the main bearings. should be doing that today.

, all in relatively good shape except on which had some scouring on the side ( surprisingly , the wall was real clean - don't let the pic fool you , you can barely get a finger nail caught on that , it looks much worse in pictures than it does in real). i still have to take the rings off and inspect the ringlands more closely . and i still have to remove the crank and inspect the main bearings. should be doing that today.

and i think i found a new set of low comression pistons over here that i might be getting soon .

#22

8 Second Club

Thread Starter

iTrader: (1)

Join Date: Nov 2001

Location: the not so stock tribe

Posts: 3,697

Likes: 0

Received 0 Likes

on

0 Posts

wll i took the crank out , but nothing special there. the main bearings were slightly worn , but nothing out of he ordinary for 40k miles of abuse.

i'm not sure about the thrust bearing though, doeas this look normal?

another think i found out is that the cam dowl was broken in the cam , but the bolts were ok!!? does that make any sense?

i also found that the first cam bearing has a small crack in it , but not on the loading side. oh and the cam bearings need to be replaced

i took a closer look at the lifters, but they all were ok .

i then took each piston for a closer look. found two of them with collapsed ringlans i guess , since the top ring was pinched on one side of the piston ( but could be pryed out). the piston with the scouring on the side was not as smooth as i though it was , so it needs to be replaced. all the pins looked good. the good news is that i found a set of weisco 8.5:1 slugs and pins localy , all i need to do now is to order a set of rings. any recomendations?

, so it needs to be replaced. all the pins looked good. the good news is that i found a set of weisco 8.5:1 slugs and pins localy , all i need to do now is to order a set of rings. any recomendations?

so now i'm kinda confused as to what was knoking in my engine? could it be the main bearings ? (it had great oil pressure ) or could it be because of the pinched rings? or could it be something else that i overlooked?

i'm not sure about the thrust bearing though, doeas this look normal?

another think i found out is that the cam dowl was broken in the cam , but the bolts were ok!!? does that make any sense?

i also found that the first cam bearing has a small crack in it , but not on the loading side. oh and the cam bearings need to be replaced

i took a closer look at the lifters, but they all were ok .

i then took each piston for a closer look. found two of them with collapsed ringlans i guess , since the top ring was pinched on one side of the piston ( but could be pryed out). the piston with the scouring on the side was not as smooth as i though it was

, so it needs to be replaced. all the pins looked good. the good news is that i found a set of weisco 8.5:1 slugs and pins localy , all i need to do now is to order a set of rings. any recomendations?

, so it needs to be replaced. all the pins looked good. the good news is that i found a set of weisco 8.5:1 slugs and pins localy , all i need to do now is to order a set of rings. any recomendations?so now i'm kinda confused as to what was knoking in my engine? could it be the main bearings ? (it had great oil pressure ) or could it be because of the pinched rings? or could it be something else that i overlooked?

#27

10 Second Club

iTrader: (12)

Join Date: Dec 2004

Location: Birmingham, Alabama

Posts: 2,034

Likes: 0

Received 0 Likes

on

0 Posts

Since we are on this subject.. What kind of timing and plugs for 300 shot on 408 with just under 12:1 compression? I was thinking TR8's gapped around .035 and something like 12*-15* of timing with C16 fuel.. I need some opinions from all you pros!

#29

8 Second Club

iTrader: (7)

Join Date: Dec 2002

Location: Maryland

Posts: 1,086

Likes: 0

Received 0 Likes

on

0 Posts

Collapsed ringlands WILL make a knocking noise. The piston rings are what is mostly in contact with the cylinder wall (not the piston itself). Since there is clearence between the wall and the piston skirt, your motor will make a knocking noise since the tension has been removed between the ring and the cylinder wall (the ring is smashed in the piston and can't expand outward).

Last edited by FastBlackTA; 07-22-2008 at 01:35 PM.

#30

10 Second Club

iTrader: (12)

Join Date: Dec 2004

Location: Birmingham, Alabama

Posts: 2,034

Likes: 0

Received 0 Likes

on

0 Posts

Not sure on the exact jetting yet, but fuel pressure will be around 7lbs depending on what it likes the most.. I ran some TR8's last year and it seemed like the car had to warm up forever until it would run good.. I went back to 6's because I was only running a 100 shot and the E.T. didn't change at all. I know with a 300 hit its gonna need something hotter though thats why I asked. I can only imagine how it will act with TR11's..

I can check the jetting chart from SpeedTech when I get to the shop..

I can check the jetting chart from SpeedTech when I get to the shop..

#31

8 Second Club

Thread Starter

iTrader: (1)

Join Date: Nov 2001

Location: the not so stock tribe

Posts: 3,697

Likes: 0

Received 0 Likes

on

0 Posts

stuff showed up today

i got the new balancer in today ( the old one was a "loaner" from a friend over here )

)

the rings are in too,

i'll hopefulley clean the pistons i got tonight and then i'll be taking the old slugs off the rods ( and rechecking the rods) and putting in the new ones on.

should also be taking the heads and block to the machine shop. the heads need to be checked, and the block needs have new cam bearings put in.

i got the new balancer in today ( the old one was a "loaner" from a friend over here

)

)the rings are in too,

i'll hopefulley clean the pistons i got tonight and then i'll be taking the old slugs off the rods ( and rechecking the rods) and putting in the new ones on.

should also be taking the heads and block to the machine shop. the heads need to be checked, and the block needs have new cam bearings put in.

#32

TECH Apprentice

iTrader: (2)

Join Date: Jul 2005

Location: Texas

Posts: 305

Likes: 0

Received 0 Likes

on

0 Posts

Collapsed ringlands WILL make a knocking noise. The piston rings are what is mostly in contact with the cylinder wall (not the piston itself). Since there is clearence between the wall and the piston skirt, your motor will make a knocking noise since the tension has been removed between the ring and the cylinder wall (the ring is smashed in the piston and can't expand outward).

X2 on the knocking. My Cummins diesel did knock and when the motor was torn down I found two pistons scored like that from all the fuel running through it.

#33

8 Second Club

Thread Starter

iTrader: (1)

Join Date: Nov 2001

Location: the not so stock tribe

Posts: 3,697

Likes: 0

Received 0 Likes

on

0 Posts

took the heads and block to the machine shop, the heads are fine, just need to be slightly milled to clean them up . the block will be done tomorow morning - new cam bearings only- then i'll have to hone it and clean it thoroughly and begin the assembly process.

i'm hoping to have the engine all buttoned up by friday evening .

i'm hoping to have the engine all buttoned up by friday evening .

#35

9 Second Club

iTrader: (4)

Join Date: Dec 2004

Location: Cali

Posts: 2,607

Likes: 0

Received 0 Likes

on

0 Posts

18* HOLY **** !!! my motor is only 10.5:1 and just because yours is 8.5 doesnt mean you should be running 10 more * of timing. If my motor was 12.5:1 I might take out another degree or two.

If it were my car I would be on strait C16 no mixing, NGK 11 plugs, and around 8-10* of timing. Hope you have better luck when its back up and running.

If it were my car I would be on strait C16 no mixing, NGK 11 plugs, and around 8-10* of timing. Hope you have better luck when its back up and running.

150 hp = 24 degrees advance

175 hp = 22.5 degrees

225 hp = 20 degrees

300 hp = 15 degrees

So if you were running a 400 shot and say your base was 34 your timing should have been down around 12 degrees....

ATV, I'm with you on the lean/rich deal man.... there are pro mod teams that run upwards of 13:1 AF ratios with 500-600 shots or more with 4 units.... never hurt anything. Granted on alchohol which is more forgiving but still... I'm planning on shooting for around 12:1..... Maybe 11.5:1 on the 300 hit...

#36

8 Second Club

Thread Starter

iTrader: (1)

Join Date: Nov 2001

Location: the not so stock tribe

Posts: 3,697

Likes: 0

Received 0 Likes

on

0 Posts

thanks for the input guys, but a quick question : how would having a 8.5:1 compression motor factor into those timing numbers ( assuming those numbers are based on a 10:1 or higher compression engine)??

#40

8 Second Club

Thread Starter

iTrader: (1)

Join Date: Nov 2001

Location: the not so stock tribe

Posts: 3,697

Likes: 0

Received 0 Likes

on

0 Posts

so i assemble the shortblock , and in the process i noticed that the crank doesn't spin freely ( as i'm used to have them), thinking its just a rough spot and it would go away i carry on.

so when i'm done the crank is very very hard to turn , i'm still thinking at that time its a rough spot ( didn't have any sleep the last few days, so as you can tell my judgement is impaired )

)

so on the way back from the garage , i was discussing this with a friend, and he told me that running the engine like that would result in an overheatd or welded bearing ( no why didn't i think of that )

)

which brings me to my question : are all the main bearings for lsx engines the same dimetion throughout the years ( mainly 2000 to 2004 ) ?? cause i'm starting to think that i got main bearings that are a bit tighter than whet was in there originally . keep in mind no machining was done to the crank.

so when i'm done the crank is very very hard to turn , i'm still thinking at that time its a rough spot ( didn't have any sleep the last few days, so as you can tell my judgement is impaired

)

)so on the way back from the garage , i was discussing this with a friend, and he told me that running the engine like that would result in an overheatd or welded bearing ( no why didn't i think of that

)

)which brings me to my question : are all the main bearings for lsx engines the same dimetion throughout the years ( mainly 2000 to 2004 ) ?? cause i'm starting to think that i got main bearings that are a bit tighter than whet was in there originally . keep in mind no machining was done to the crank.