Fiberglass and plastic

#1

Launching!

Thread Starter

iTrader: (2)

Join Date: Mar 2013

Location: Florida

Posts: 252

Likes: 0

Received 0 Likes

on

0 Posts

Ok, So I have made a few things solely out of fiberglass.

Used a wood template with cloth, resined it threw fiber on it and so on.

however I havent added glass to plastic. I want to customize my center console by cutting out the ash tray and cup holder. Gluing cloth on the underside and fiberglassing the top. Then sand bondo repaint.

I have read that glass wont stick to the plastic, that it will but will come off, that it will but crack, and that it will if I scuff. So clearly there is some misinformation or a right and wrong way.

Again I plan to have two holes in the center console and then want to law fiber ontop and smooth and bondo it seemlessly into the rest of the dash.

Used a wood template with cloth, resined it threw fiber on it and so on.

however I havent added glass to plastic. I want to customize my center console by cutting out the ash tray and cup holder. Gluing cloth on the underside and fiberglassing the top. Then sand bondo repaint.

I have read that glass wont stick to the plastic, that it will but will come off, that it will but crack, and that it will if I scuff. So clearly there is some misinformation or a right and wrong way.

Again I plan to have two holes in the center console and then want to law fiber ontop and smooth and bondo it seemlessly into the rest of the dash.

#2

TECH Resident

iTrader: (13)

Join Date: Mar 2008

Location: On the coast of somewhere

Posts: 779

Likes: 0

Received 1 Like

on

1 Post

I have to glass plastic all of the time in what I do. Wipe area with degreaser to get rid of Armour All and the like. I use a 36 grit grinding disc to rough the area. Glass as usual. No, it's not an end all, be all fix to everything but, it'll work well with what you're doing. Let us know how it worked out.

#3

Launching!

Thread Starter

iTrader: (2)

Join Date: Mar 2013

Location: Florida

Posts: 252

Likes: 0

Received 0 Likes

on

0 Posts

I have to glass plastic all of the time in what I do. Wipe area with degreaser to get rid of Armour All and the like. I use a 36 grit grinding disc to rough the area. Glass as usual. No, it's not an end all, be all fix to everything but, it'll work well with what you're doing. Let us know how it worked out.

#4

TECH Fanatic

iTrader: (3)

I would stay away from fiberglass on plastic. ABS is probably the most forgivable plastics in regards to using different adhesive and filler, but it can still fail. Especially in the heat interiors go through. Fiberglass doesn't have same expand/contract rates as plastics, so in an area that will be touched alot you may run onto problems of eventual delamination. On my custom console project I bought 12x12 sheets of ABS plastic and heat formed( with a cheap heat gun ) sections and attached with plastic weld epoxy. Then to finish, fill and blend I used a flexible plastic filler from dynatron, I used it as a filler like you would bondo, and then used a 3m plastic filler for finish surface work like you would a glaze on body work. End result is something nearly as strong as a single molded piece that wont fail over time. I used to use bondo and fiberglass for almost all my custom stuff, until someone educated me a little. Now I couldnt imagine using fiberglass or bondo for any other than what it was intended for. Something like the console lid your making with the chicken wire, thats a perfect fiberglass project as it all glass.

I used green painters tape to make patterns to cut out of the ABS sheets.

In process not complete or fully sanded

I used green painters tape to make patterns to cut out of the ABS sheets.

In process not complete or fully sanded

#6

Staging Lane

iTrader: (1)

Join Date: Jun 2013

Location: San Diego, CA

Posts: 50

Likes: 0

Received 0 Likes

on

0 Posts

totally agree with the plastic and fiberglass - depending on where you live you could easily see 140 degrees in your car. That's more than enough to get some flexing. unless you were wrapping in cloth, best to stick with the abs

#7

TECH Resident

iTrader: (13)

Join Date: Mar 2008

Location: On the coast of somewhere

Posts: 779

Likes: 0

Received 1 Like

on

1 Post

Done the glass and plastic for years in a hot *** aircraft that does get as hot as a car. Structurally, no I would not go that route. Cosmetics wise I think it will be fine. Just saying I've had no issues with flexing or separating or what ever.

Trending Topics

#8

TECH Fanatic

iTrader: (3)

Thats I went the route of abs and properly matched adhesives and filler. A center console is touched ALOT. 1 wrong move like bracing your hand on the console leaning in the car could "potentially" cause a problem. Its not gonna break, but it would suck to see the line where the plastic meets the filler that was previously sanded smooth because it delaminated a bit.

#9

Launching!

Thread Starter

iTrader: (2)

Join Date: Mar 2013

Location: Florida

Posts: 252

Likes: 0

Received 0 Likes

on

0 Posts

Yup im trying to compile a list and order everything as my console is just sitting starring at me wanting to be finished.

Sucks though as Im gonna have to "weld" it up with sodering iron. I mean Im pretty handy and what not but thats a whole lot of fun id be just fine passing on lol.

LT4Vert im having a hard time finding the right things, and what I mean is there are all sorts of plastic filler and weld epoxy along with different types of abs plastic sheets.

Sucks though as Im gonna have to "weld" it up with sodering iron. I mean Im pretty handy and what not but thats a whole lot of fun id be just fine passing on lol.

LT4Vert im having a hard time finding the right things, and what I mean is there are all sorts of plastic filler and weld epoxy along with different types of abs plastic sheets.

Last edited by silent_soul; 07-19-2013 at 05:22 PM.

#10

TECH Fanatic

iTrader: (3)

If your referring to plastic welding with a soldering iron, I wouldnt do that, not unless there is some technique I dont know about. A plastic welder blows hot air and you feed plastic sticks thru a hole and it welds that way. If you just try to simply melt 2 pieces of plastic at the seams and try to join that way, it wont work. Correct me if I am misunderstanding what you meant. There is another way, if your gonna stick to ABS to ABS, you could solvent weld it. Apply acetone to each part at the place you want to join together and then press together, let the acetone evaporate and the ABS to re-solidify, then sand the area and fill for a good finish. If you wanna take that route, google solvent welding ABS. Youll pull up enough info.

I got my ABS sheets MSC industrial supply. I had 12"x12" natural sheets in 1/8" thickness. Its listed under raw materials. The Dynatron and the 3m fillers I googled and went with the lowest cost supplier.

I got my ABS sheets MSC industrial supply. I had 12"x12" natural sheets in 1/8" thickness. Its listed under raw materials. The Dynatron and the 3m fillers I googled and went with the lowest cost supplier.

#11

Launching!

Thread Starter

iTrader: (2)

Join Date: Mar 2013

Location: Florida

Posts: 252

Likes: 0

Received 0 Likes

on

0 Posts

If your referring to plastic welding with a soldering iron, I wouldnt do that, not unless there is some technique I dont know about. A plastic welder blows hot air and you feed plastic sticks thru a hole and it welds that way. If you just try to simply melt 2 pieces of plastic at the seams and try to join that way, it wont work. Correct me if I am misunderstanding what you meant. There is another way, if your gonna stick to ABS to ABS, you could solvent weld it. Apply acetone to each part at the place you want to join together and then press together, let the acetone evaporate and the ABS to re-solidify, then sand the area and fill for a good finish. If you wanna take that route, google solvent welding ABS. Youll pull up enough info.

I got my ABS sheets MSC industrial supply. I had 12"x12" natural sheets in 1/8" thickness. Its listed under raw materials. The Dynatron and the 3m fillers I googled and went with the lowest cost supplier.

I got my ABS sheets MSC industrial supply. I had 12"x12" natural sheets in 1/8" thickness. Its listed under raw materials. The Dynatron and the 3m fillers I googled and went with the lowest cost supplier.

I want to repaint over the whole deal and will the type of fillers affect the type of paint I can use? I will definently look into the solvent welding sounds easiest.

#13

Launching!

Thread Starter

iTrader: (2)

Join Date: Mar 2013

Location: Florida

Posts: 252

Likes: 0

Received 0 Likes

on

0 Posts

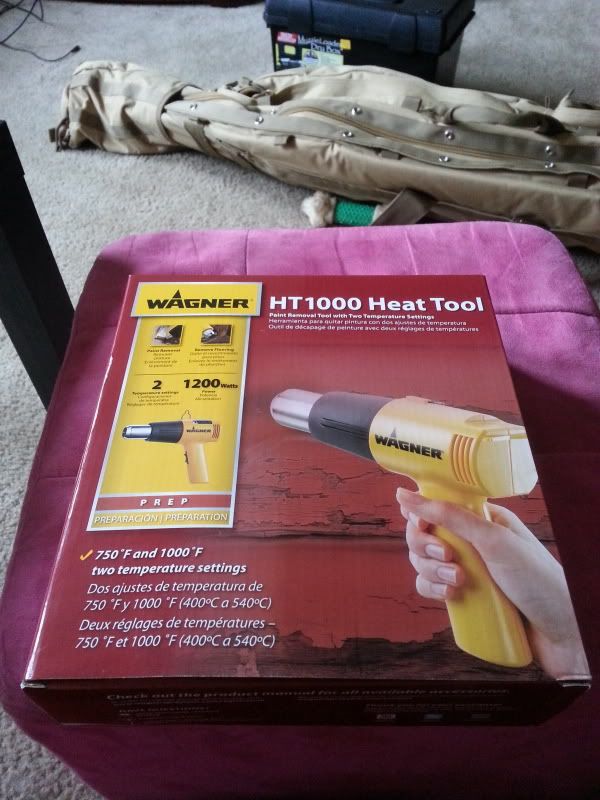

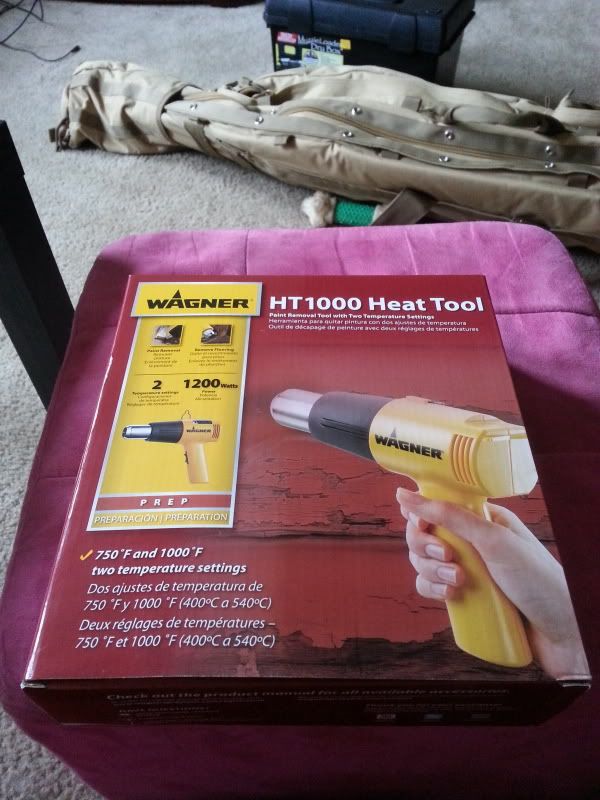

Well I ordered some sheets off amazon:

picked up some other supplies from home depot.

Heat gun for shaping:

[IMG] [/IMG]

[/IMG]

Plastic Filler, Would this work? I mean I would think it would but ive never done this before:

[IMG] [/IMG]

[/IMG]

Picked up the wrong cement, it was in the abs cement box should have red the can, will have to exchange:

[IMG] [/IMG]

[/IMG]

Some acetone for prepping the area for cement:

[IMG] [/IMG]

[/IMG]

abs shows up tuesday hopefully will redneck fix my dremel before then. Get this project going again. Gonna pick up some SEM paint stuff this coming paycheck.

I was considering ordering this abs cement, any suggestions other than that?

http://www.homedepot.com/p/Oatey-8-o...6#.Uex-v1O1vWQ

picked up some other supplies from home depot.

Heat gun for shaping:

[IMG]

[/IMG]

[/IMG]Plastic Filler, Would this work? I mean I would think it would but ive never done this before:

[IMG]

[/IMG]

[/IMG]Picked up the wrong cement, it was in the abs cement box should have red the can, will have to exchange:

[IMG]

[/IMG]

[/IMG]Some acetone for prepping the area for cement:

[IMG]

[/IMG]

[/IMG]abs shows up tuesday hopefully will redneck fix my dremel before then. Get this project going again. Gonna pick up some SEM paint stuff this coming paycheck.

I was considering ordering this abs cement, any suggestions other than that?

http://www.homedepot.com/p/Oatey-8-o...6#.Uex-v1O1vWQ

Last edited by silent_soul; 07-21-2013 at 07:42 PM.