Custom Hood Mods

#122

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

A friend suggested I make a wooden buck to lay under the hood and then carefully hammer the back edge down so it's a nice, curved shape. I think I can make a simple buck that can support the end cuts and then just carefully work the metal down with a body shop style hammer. The ones with a nice smooth curve in them. I don't know. I'll think of something.

#123

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

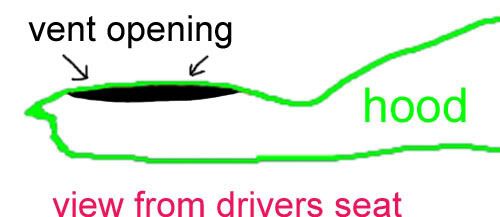

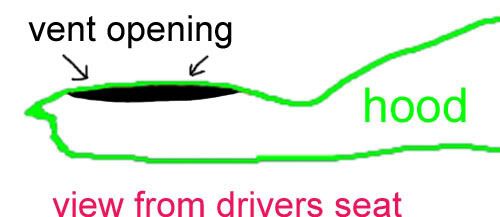

The opening doesn't need to be very big since it's mainly just to look nice. It's still functional, but it doesn't have to move massive amounts of air or anything. I'm thinking it should be a slim opening kind of like this:

#127

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

I think their too big myself. That's why I said their interesting as opposed to they would look good on the car.

I'm slowly putting together a picture of all 3 elements I mentioned earlier.

I just need to add the air extractor Vents on the hood.

Instead of a straight cut, I'm toying with some slightly curved cuts. I could then bend the backside down slightly to create a crescent shape Vent.

I'm slowly putting together a picture of all 3 elements I mentioned earlier.

I just need to add the air extractor Vents on the hood.

Instead of a straight cut, I'm toying with some slightly curved cuts. I could then bend the backside down slightly to create a crescent shape Vent.

#131

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

Well, I made the first cut in the hood up by the headlight. The metal doesn't want to pop down as it has too much tension on it. I tried a few different things to get it to stay down, but no go. I wish the hood sides were curved a bit more so the air slots would be a tad bigger. Just by holding the metal down with a spacer and looking at it, it seems very subtle. Especially on a black hood.

I may have to cut 3 sides and fold the metal down some or I can try a curved cut and then fold down the rear edge. Now those 2 techniques would work well on a flat sheet of metal, but I'm not sure on this slightly curved hood.

It also doesn't look quite professional enough, either.

Maybe I could cut off the triangle side sections of the hood and ship it off to have metal masters add some nice vents and then weld it back in. Might be easier to have them buy a hood local, cut away the reinforcement, make their nice vents and then weld the reinforcment back on.

I don't know. It's just not going well.

I may have to cut 3 sides and fold the metal down some or I can try a curved cut and then fold down the rear edge. Now those 2 techniques would work well on a flat sheet of metal, but I'm not sure on this slightly curved hood.

It also doesn't look quite professional enough, either.

Maybe I could cut off the triangle side sections of the hood and ship it off to have metal masters add some nice vents and then weld it back in. Might be easier to have them buy a hood local, cut away the reinforcement, make their nice vents and then weld the reinforcment back on.

I don't know. It's just not going well.

#132

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

Aesthetically speaking, I'm not really digging the home made extractors. They look too "home made".

Looking back at my Raptor hood, I wonder if these side vents can be molded into it? The V shape looks about right, so does the curvature.

Looking back at my Raptor hood, I wonder if these side vents can be molded into it? The V shape looks about right, so does the curvature.

#133

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

Here's a rare pic of the Raptor on my car. I masked off some stripes and used rattle cans to paint it so it would look a little more proper.

After a while like that I decided I don't care for stripes. Maybe if they were a charcoal or silver color or something that doesn't stand out so much. It's a damn fine hood. Fits very well, also.

After a while like that I decided I don't care for stripes. Maybe if they were a charcoal or silver color or something that doesn't stand out so much. It's a damn fine hood. Fits very well, also.

Last edited by JasonWW; 04-10-2008 at 02:10 AM.

#135

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

I don't think anyone mentioned a Firehawk, did they?

The WS6 hoods are similar to fiberglass, but it's actually an epoxy liquid mixed into the cloth. It's usually close enough that people know what you mean, though. It takes paint much better than an actual fiberglass hood.

The Firehawks are made from fiberglass, I believe. They have a history of the paint bubbling on them as well.

The flat LS1 hoods are steel.

My Raptor is made by Suncoast Automotive Performance. I think it's fiberglass, but I haven't actually cut into it any to see for sure. It's either fiberglass or the epoxy style like the WS6 hoods. Their pricey at $900, so I hope it's not a basic fiberglass material. I don't know. Most fiberglass hoods sell for closer to $500-$600. Hopefully the quality and paint adhesion are better than most. I haven't heard any stories about paint issues with this hood.

The WS6 hoods are similar to fiberglass, but it's actually an epoxy liquid mixed into the cloth. It's usually close enough that people know what you mean, though. It takes paint much better than an actual fiberglass hood.

The Firehawks are made from fiberglass, I believe. They have a history of the paint bubbling on them as well.

The flat LS1 hoods are steel.

My Raptor is made by Suncoast Automotive Performance. I think it's fiberglass, but I haven't actually cut into it any to see for sure. It's either fiberglass or the epoxy style like the WS6 hoods. Their pricey at $900, so I hope it's not a basic fiberglass material. I don't know. Most fiberglass hoods sell for closer to $500-$600. Hopefully the quality and paint adhesion are better than most. I haven't heard any stories about paint issues with this hood.

#139

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

Remember this idea?

I'm checking into relocating the radiator so there will be more room in front of the engine. This will let me cut out the core support the stock filter box sits on. I could then place the filters right behind the air intakes on the hood.

I'm working on a new induction system as well. Here is a Photoshop I did that is very close, but I will run silicone elbows (probably blue) and the new radiator shroud will extend forward about 4 inches.

#140

Thread Starter

TECH Senior Member

iTrader: (2)

Joined: Sep 2004

Posts: 6,814

Likes: 3

From: Hou. TX.

Does anyone know of a good hood latch besides hood pins? I'm going to have to make something up.

Also, the battery will be relocated to the rear and fuse boxes will be relocated to where the airpump would be. This is going to leave 2 big gaps on either side of the engine bay. What could I use them for?

I thought about extending the intake piping into both areas and use some larger filters.

Or since I'm considering having heat extractors right above those areas, why not mount something hot there? Maybe a fan controlled oil cooler on one side and a similar cooler for the power steering fluid?

Any other ideas?

Also, the battery will be relocated to the rear and fuse boxes will be relocated to where the airpump would be. This is going to leave 2 big gaps on either side of the engine bay. What could I use them for?

I thought about extending the intake piping into both areas and use some larger filters.

Or since I'm considering having heat extractors right above those areas, why not mount something hot there? Maybe a fan controlled oil cooler on one side and a similar cooler for the power steering fluid?

Any other ideas?