need some advanced help

#1

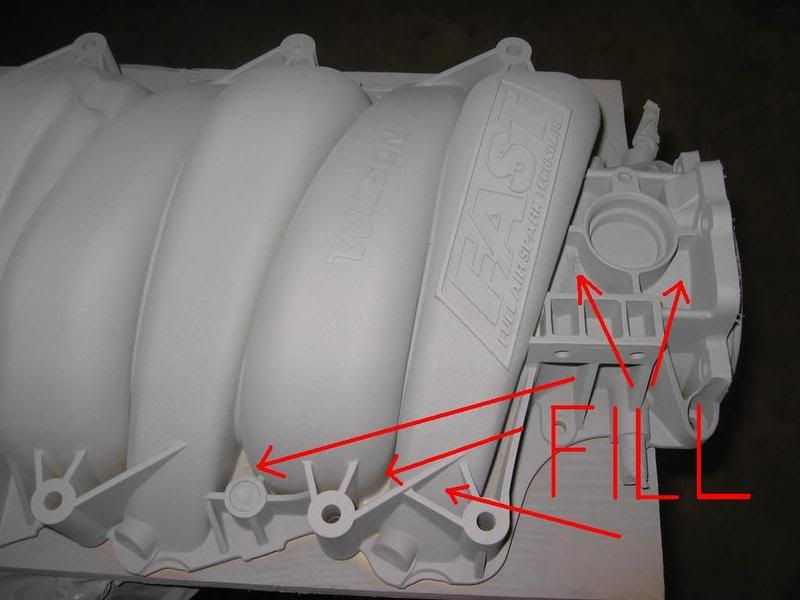

i have never seen this done, nor have i ever heard of it being done but im sure someone has thought of it and im wanting to know if it can be done and how i can do it. i want to fill in all of the voids in my fast intake (meaning all of the casting holes where you can't get your fingers down into to sand). i've tried to explain what i want to do with some pics below. hopefully someone can help me.

fill in all of the holes like these:

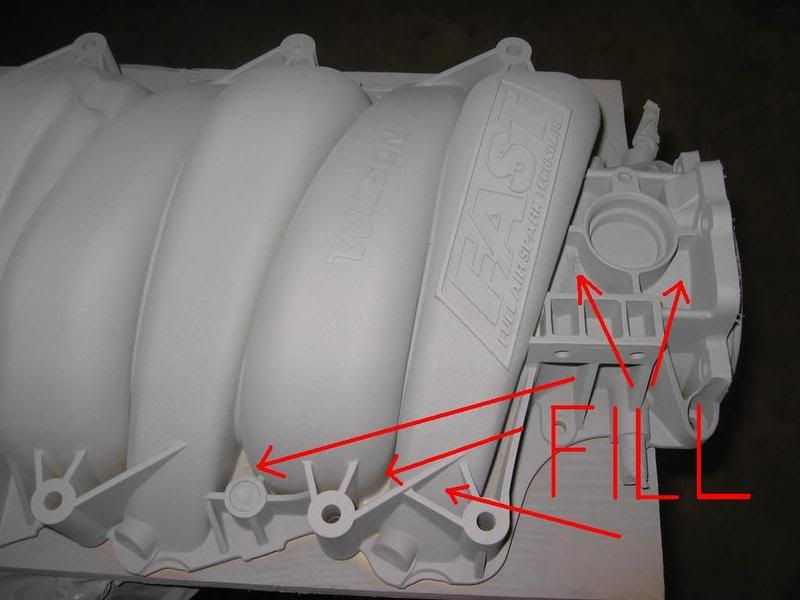

to look like this:

sorry if it looks like crap, but it was a quickie from paint. hopefully you'll get the gist. what im wanting to know is, what type material can be used to fill in these voids, and be durable enough to withstand the heat, engine shaking, and sanding (during paint)? after the voids are filled, im wanting to sand the "said filler" to make the intake look nice and smooth, without all of the reinforcement bars showing.

any and all advice will be greatly appreciated and considered.

fill in all of the holes like these:

to look like this:

sorry if it looks like crap, but it was a quickie from paint. hopefully you'll get the gist. what im wanting to know is, what type material can be used to fill in these voids, and be durable enough to withstand the heat, engine shaking, and sanding (during paint)? after the voids are filled, im wanting to sand the "said filler" to make the intake look nice and smooth, without all of the reinforcement bars showing.

any and all advice will be greatly appreciated and considered.

#2

Chances are whatever you pour in there will seperate with heat difference between materials. But if i really wanted to do it i would scuff with like 40grt in the voids as best i could and then fill in with 3m epoxy. I would recomend the 8115 panel bonding adhesive. I've used it numerous times fixing bike feiring. It sands really easy and gets as hard as plastic.

#3

that is something along the lines of what im looking for. how easily would that stuff crack? because it would suck to spend all of that time making my intake look all nice a pretty and then 2 months down the road, the epoxy crack and start trying to walk out.

#4

It will not crack, especially for what you are going to use it for. I have v grooved bike feiring and filled it in and no cracking. i have fixed parts right next to the headers and the stuff does not crack with heat. It is verry strong stuff.

#6

There's always JB Weld. That stuff's damn near indestructable! I've combat proven JB Weld, so it's A+ in my book. Plus it's soft enough when first mixxed that it'll settle down in those spaces completely and not leave any voids of air that may expand with heat and cause problems. Just another option. Swat

#7

3M 8115 will work great. It is expensive ($50 for about a toothpaste tube's worth) and extreme overkill, but will give you no problems. Another product I like a lot is Evercoat's "Fiber-Tech" It is a kevlar-reinforced filler and will harden in those crevices like cement. You can then sand it smooth and primer over top of it.