Rookie 4l60e rebuild

#101

TECH Fanatic

Your Rear Stator Bushing is set too deep, Set it just below the "Chamfer".

If they ran the Front bushing into the step....Redo it.

Just Loctite the Front Seal in, No retainer needed.

Forward Clearance is fine.

DO NOT run that Bullshit flimsy Alto .128" 3-4 Backing Plate! I already gave my recommendation on this..... Your Friction Count doesn't mean jack if the clutch pack is bowing & flexing.

There should be a gap between the Reverse Input Drum & the Pump Thrust Washer. Is the Selective & Torrington bearing installed on the Input Drum? When Assembled the RID rides on the Sunshell, Not the Torrington on the Input Drum.

If they ran the Front bushing into the step....Redo it.

Just Loctite the Front Seal in, No retainer needed.

Forward Clearance is fine.

DO NOT run that Bullshit flimsy Alto .128" 3-4 Backing Plate! I already gave my recommendation on this..... Your Friction Count doesn't mean jack if the clutch pack is bowing & flexing.

There should be a gap between the Reverse Input Drum & the Pump Thrust Washer. Is the Selective & Torrington bearing installed on the Input Drum? When Assembled the RID rides on the Sunshell, Not the Torrington on the Input Drum.

Last edited by clinebarger; 04-08-2016 at 10:10 PM.

#102

TECH Junkie

Thread Starter

Your Rear Stator Bushing is set too deep, Set it just below the "Chamfer".

If they ran the Front bushing into the step....Redo it.

Just Loctite the Front Seal in, No retainer needed.

Forward Clearance is fine.

DO NOT run that Bullshit flimsy Alto .128" 3-4 Backing Plate! I already gave my recommendation on this..... Your Friction Count doesn't mean jack if the clutch pack is bowing & flexing.

There should be a gap between the Reverse Input Drum & the Pump Thrust Washer. Is the Selective & Torrington bearing in stalled on the Input Drum? When Assembled the RID rides on the Sunshell, Not the Torrington on the Input Drum.

If they ran the Front bushing into the step....Redo it.

Just Loctite the Front Seal in, No retainer needed.

Forward Clearance is fine.

DO NOT run that Bullshit flimsy Alto .128" 3-4 Backing Plate! I already gave my recommendation on this..... Your Friction Count doesn't mean jack if the clutch pack is bowing & flexing.

There should be a gap between the Reverse Input Drum & the Pump Thrust Washer. Is the Selective & Torrington bearing in stalled on the Input Drum? When Assembled the RID rides on the Sunshell, Not the Torrington on the Input Drum.

For my 3-4 setup I absolutely will change it. I honestly did not know it was that critical but now see how heat and a thin backing plate can lead to bowing and conning.

Was not trying to add a bunch of Frictions to make it better or disregard your advice, just concentrated on clutch clearance and don't know any better. Lol

Yes the bearing and selective washer are installed.

What is the purpose of the pump thrust washer then if there is a gap?

#103

TECH Fanatic

Did you try my recommended stack up? If so, And it was loose.....You may have a Thin Alto Snap Ring, You need a .093" 3-4 Snap Ring which would have been stock in your unit.

With the unit assembled, The Reverse Input Drum rides on the Sunshell & will tighten the endplay between the Drum & Pump Cover, The Trust Washer is to keep the Drum from walking into the Pump Cover.

With the unit assembled, The Reverse Input Drum rides on the Sunshell & will tighten the endplay between the Drum & Pump Cover, The Trust Washer is to keep the Drum from walking into the Pump Cover.

#104

TECH Junkie

Thread Starter

Did you try my recommended stack up? If so, And it was loose.....You may have a Thin Alto Snap Ring, You need a .093" 3-4 Snap Ring which would have been stock in your unit.

With the unit assembled, The Reverse Input Drum rides on the Sunshell & will tighten the endplay between the Drum & Pump Cover, The Trust Washer is to keep the Drum from walking into the Pump Cover.

With the unit assembled, The Reverse Input Drum rides on the Sunshell & will tighten the endplay between the Drum & Pump Cover, The Trust Washer is to keep the Drum from walking into the Pump Cover.

But I was messing around for fun with what I have here. I don't plan on keeping it......

Frictions

(2) .080"

(5) .065"

(Steels)

(1) .078"

(5) .097"

Snap ring .078"

Apply .220"

Backing plate .192

Ended up with about .030" clearance wet

Also when the pump is assembled in the case I have .013" end play. I'm assuming I'm fine there but figured I would post it up

Last edited by 98CayenneT/A; 04-10-2016 at 11:48 AM.

#105

Moderator

Yeah that is an odd combo of thick and thin frictions and steels.

4 years ago a slight majority of the pro builders I spoke to recommended thicker steels and thinner frictions as GM does with their 4L65E. I therefore used and published these combos in post #2:

https://ls1tech.com/forums/automatic...some-info.html

I know that a bunch of members successfully used both the 7 and 8 friction combos.

Now the majority of pro builders, including Clinebarger, recommend thicker frictions and thinner steels.

Your .013 end play is fine; I would say perfect. If you were to measure it after driving it a bit you would see that it increased a bit to the official .015-.035 range.

4 years ago a slight majority of the pro builders I spoke to recommended thicker steels and thinner frictions as GM does with their 4L65E. I therefore used and published these combos in post #2:

https://ls1tech.com/forums/automatic...some-info.html

I know that a bunch of members successfully used both the 7 and 8 friction combos.

Now the majority of pro builders, including Clinebarger, recommend thicker frictions and thinner steels.

Your .013 end play is fine; I would say perfect. If you were to measure it after driving it a bit you would see that it increased a bit to the official .015-.035 range.

#106

TECH Junkie

Thread Starter

Yeah that is an odd combo of thick and thin frictions and steels.

4 years ago a slight majority of the pro builders I spoke to recommended thicker steels and thinner frictions as GM does with their 4L65E. I therefore used and published these combos in post #2:

https://ls1tech.com/forums/automatic...some-info.html

I know that a bunch of members successfully used both the 7 and 8 friction combos.

Now the majority of pro builders, including Clinebarger, recommend thicker frictions and thinner steels.

Your .013 end play is fine; I would say perfect. If you were to measure it after driving it a bit you would see that it increased a bit to the official .015-.035 range.

4 years ago a slight majority of the pro builders I spoke to recommended thicker steels and thinner frictions as GM does with their 4L65E. I therefore used and published these combos in post #2:

https://ls1tech.com/forums/automatic...some-info.html

I know that a bunch of members successfully used both the 7 and 8 friction combos.

Now the majority of pro builders, including Clinebarger, recommend thicker frictions and thinner steels.

Your .013 end play is fine; I would say perfect. If you were to measure it after driving it a bit you would see that it increased a bit to the official .015-.035 range.

I guess if there is no issues with the last 3-4 setup I posted with the thicker backing plate I will leave it.

Otherwise I will run to Whatever It Takes and do exactly what clinebarger recommended. I need to run there anyways to get another input shaft o-ring and bell housing to case bolts.

Hopefully have the transmission back in the car next Saturday if all goes smooth.

#107

Moderator

Ya, I actually have that thread along with the others bookmarked and have referenced then quite often.

I guess if there is no issues with the last 3-4 setup I posted with the thicker backing plate I will leave it.

Otherwise I will run to Whatever It Takes and do exactly what clinebarger recommended. I need to run there anyways to get another input shaft o-ring and bell housing to case bolts.

Hopefully have the transmission back in the car next Saturday if all goes smooth.

I guess if there is no issues with the last 3-4 setup I posted with the thicker backing plate I will leave it.

Otherwise I will run to Whatever It Takes and do exactly what clinebarger recommended. I need to run there anyways to get another input shaft o-ring and bell housing to case bolts.

Hopefully have the transmission back in the car next Saturday if all goes smooth.

Next, IMO, the most important parts in the 3/4 clutch are the thickest apply and backing plates (to reduce coning) and BW Hi-Energy or Raybestos GPZ frictions.

Then, in IMHO(!) the exact thickness combination of 7 or 8 frictions and steels isn't all that important.

In the case of your unusual combo, I would put the thickest frictions and steels in the middle where the heat might be a bit higher.

#108

TECH Junkie

Thread Starter

Just took it apart again to mess around and came up with this.....

Frictions

(8) .065"

Steels

(7) .078"

Snap ring .078"

Apply .220

Backing .192"

Ended up with .025" clearance wet. Is that to tight?

Frictions

(8) .065"

Steels

(7) .078"

Snap ring .078"

Apply .220

Backing .192"

Ended up with .025" clearance wet. Is that to tight?

#109

Moderator

Assuming that is wet clearance, it should be at the very lower limit, but I would prefer an expert to answer that more definitively.

I'll bet a bunch of MN members are thinking about driving to White Bear to bribe you to rebuild their 4L60E.

I'll bet a bunch of MN members are thinking about driving to White Bear to bribe you to rebuild their 4L60E.

#110

TECH Junkie

Thread Starter

Me and a bunch of my buddies hit the track quite often. Half of them being auto's the other half 6 speeds. I would be more than happy to help them if I can get this down as for I have had lots of help myself along the way

Yes the clearance was wet.

Last edited by 98CayenneT/A; 04-10-2016 at 07:00 PM.

#111

TECH Fanatic

#114

Moderator

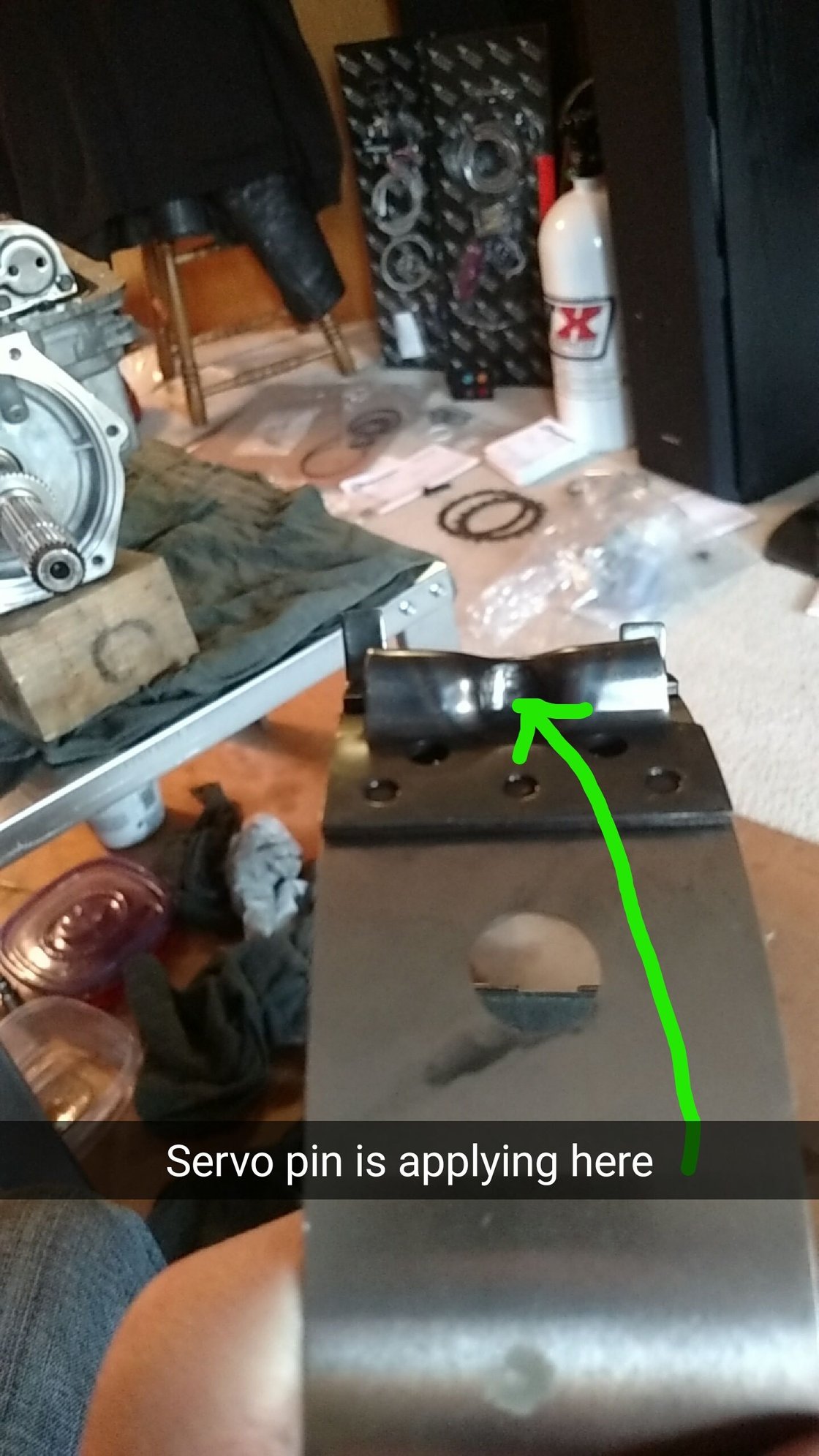

How are you measuring this? (I.e what the heck are you measuring).

The servo endplay should be between .075 and .125, aiming for the low end when installing new parts.

It is measured with the servo cover on.

No way is it .200 with a new band; that wouldn't even come close to working.

I could say that adding a washer won't make any difference, but I suspect you are measuring something completely different.

Do you still have the pump off so that you can see how the servo engages the band?

The servo endplay should be between .075 and .125, aiming for the low end when installing new parts.

It is measured with the servo cover on.

No way is it .200 with a new band; that wouldn't even come close to working.

I could say that adding a washer won't make any difference, but I suspect you are measuring something completely different.

Do you still have the pump off so that you can see how the servo engages the band?

#115

TECH Junkie

Thread Starter

How are you measuring this? (I.e what the heck are you measuring).

The servo endplay should be between .075 and .125, aiming for the low end when installing new parts.

It is measured with the servo cover on.

No way is it .200 with a new band; that wouldn't even come close to working.

I could say that adding a washer won't make any difference, but I suspect you are measuring something completely different.

Do you still have the pump off so that you can see how the servo engages the band?

The servo endplay should be between .075 and .125, aiming for the low end when installing new parts.

It is measured with the servo cover on.

No way is it .200 with a new band; that wouldn't even come close to working.

I could say that adding a washer won't make any difference, but I suspect you are measuring something completely different.

Do you still have the pump off so that you can see how the servo engages the band?

I do not still have the pump out, everything is installed except the 2-4 servo.

I will disassemble if it would help : ( lol

#116

TECH Junkie

Thread Starter

Before I used the depth finder and pushed the servo cover in I guessed it to be around a ¼ in.

I can take two pictures of the servo pushed in and one relaxed if ya want....

I can take two pictures of the servo pushed in and one relaxed if ya want....