Spun a cam bearing. Block trashed?

#21

TECH Senior Member

iTrader: (16)

Exactly. You said exactly what I wanted to say...just a lot nicer lol.

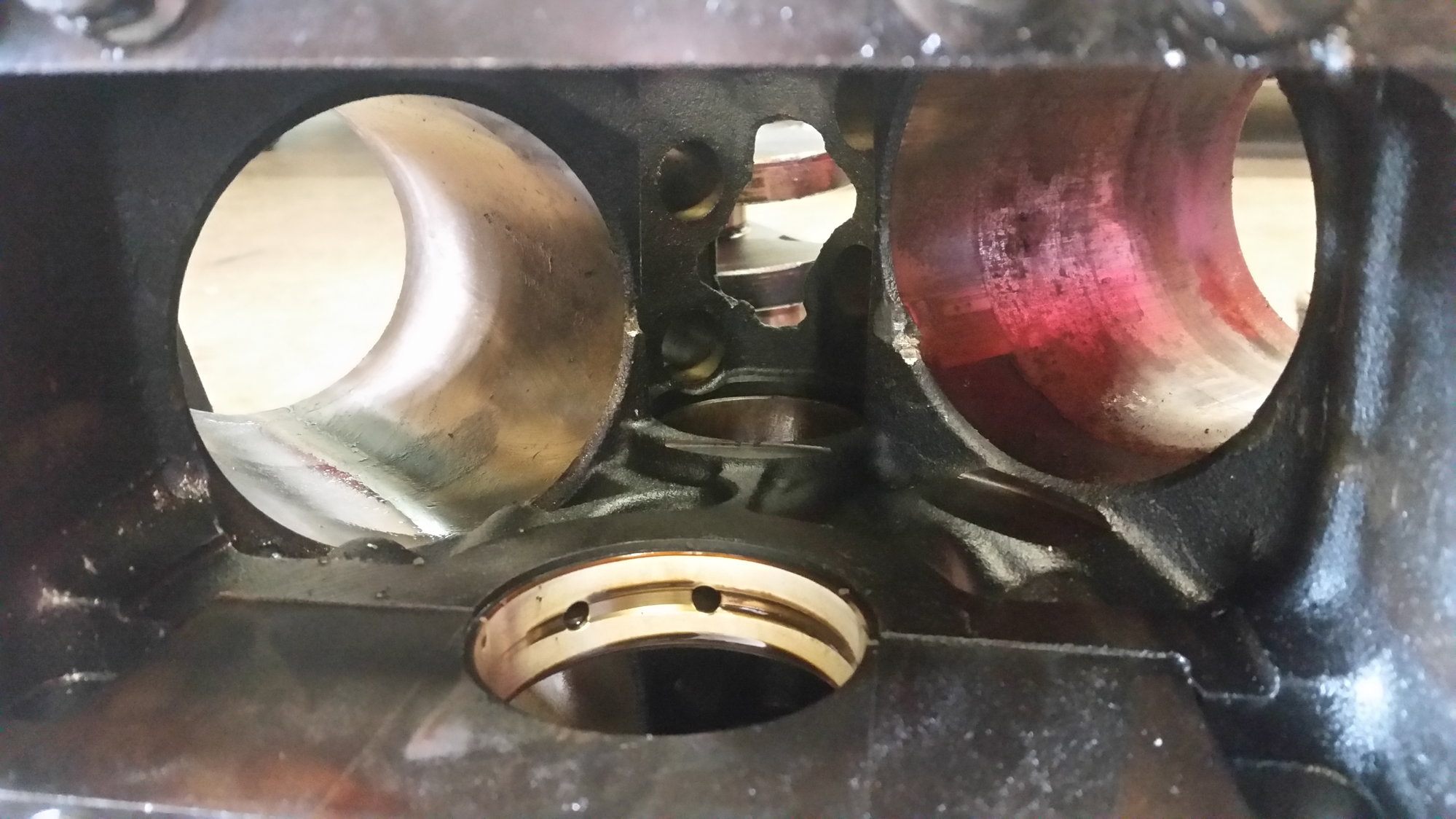

The iron block I'm using had a piston explode and a connecting rod snap in two. It didn't take much more than a power washer, a 5 gallon bucket of hot water and Tide detergent, and a good set of engine brushes to clean it all out.

The iron block I'm using had a piston explode and a connecting rod snap in two. It didn't take much more than a power washer, a 5 gallon bucket of hot water and Tide detergent, and a good set of engine brushes to clean it all out.

#24

TECH Senior Member

iTrader: (16)

The bearings actually look almost perfect. If it wasn't a long crank, I would use it... maybe I should machine the rear flange down...

#26

Banned

iTrader: (1)

I have rebuilt several engines that have been on fire, run low on oil, snapped rods, spun bearings, collapsed pistons, broken ring lands on the piston, Blown head gaskets- overheated, and so on.

As long as the block's integrity has not been compromised past the worth of the block, it can be repaired, properly cleaned and put back into service.

That being said, I have also seen other assembled engines that were in good shape that were rebuilt and fail shortly after due to a lack of proper cleaning.

IMO, a thermal cleaning is the best way to start after a major engine failure issue. It strips the block to a rawest form. That followed up by a proper cleaning of the oil galleries with the proper brushes with hot soapy water after all machine work is finished makes a huge difference. I also like to use some cleaning solvents as well.

Several places sell engine cleaning brush kits , But By far the best kit I have found is from Brush Research Manufacturing a.k.a. BRM.

Part# 1EK

The BRM 1-E KIT- OIL LINE/GALLERY BRUSH KIT contains 29 brushes in various size to clean just about every standard engine out there. Some of the smaller more common sizes even come with spares.

Part# 1EK

The BRM 1-E KIT- OIL LINE/GALLERY BRUSH KIT contains 29 brushes in various size to clean just about every standard engine out there. Some of the smaller more common sizes even come with spares.

Last edited by kingtal0n; 06-03-2016 at 01:41 PM.

#27

TECH Junkie

iTrader: (4)

kingtal0n I call BS on almost 100% of your posts lol, Core motors are used all the time and hold up just fine. You do realize how the blocks are made in the first place and what they are made out of don't you? Then they are machined and come on contact with many different types of material. Many people prefer seasoned blocks over new. Even a brand new block has to be cleaned and machined before it's used unless you trust something that is mass produced is going to be up to spec when you get it, Most are not. Brand new does not mean better in many cases.

#28

Banned

iTrader: (1)

kingtal0n I call BS on almost 100% of your posts lol, Core motors are used all the time and hold up just fine. You do realize how the blocks are made in the first place and what they are made out of don't you? Then they are machined and come on contact with many different types of material. Many people prefer seasoned blocks over new. Even a brand new block has to be cleaned and machined before it's used unless you trust something that is mass produced is going to be up to spec when you get it, Most are not. Brand new does not mean better in many cases.

If you find an engine in the scrap yard, I give it a 50/50 general chance of success regardless of how careful you are. If you collect data and compare salvage yard blocks vs good running blocks rebuilt you will see a higher rate of failure in the blocks with questionable backgrounds. It is simply statistics at work here. Much higher percentage of current running, high mileage engines will survive the rebuild because generally these engines cleaner and more well maintained. It is basically a cleanliness problem, where an engine spends its entire life headed towards disgusting muck and carbon fragments embedding and conglomerating in every conceivable space whether burnt or breathed, carbon from fungus is just like carbon from gasoline, fungus spores contain a myriad of other compounds that also facilitate their own reactions and contain many different kinds of atoms ranging from Nitrogen to metal.

Call BS all you want thats what the internet is for. Plenty of "crazy people" Over the years (Look through my telescope! Look through my microscope!) almost got lynched/stoned to death for their outrageous ideas which turned out to be scary or relevant uniquely

an edit to apply this also:

Imagine we actually tested a series of JY blocks and found that it was more like 70/30, 70% of the time you get a good block. The test could be repeated in another state and those stats could reverse. The availability and location of your personal existence is a factor when deciding whether to go JY for a block or attempt something with what you already have. That is why I specifically chose 50% as a general number because truly there is no good way to express percentage of good JY blocks to a forum which includes the entire world.

Last edited by kingtal0n; 06-03-2016 at 01:32 PM.

#29

TECH Senior Member

iTrader: (16)

kingtal0n I call BS on almost 100% of your posts lol, Core motors are used all the time and hold up just fine. You do realize how the blocks are made in the first place and what they are made out of don't you? Then they are machined and come on contact with many different types of material. Many people prefer seasoned blocks over new. Even a brand new block has to be cleaned and machined before it's used unless you trust something that is mass produced is going to be up to spec when you get it, Most are not. Brand new does not mean better in many cases.

Your spot on though. Look at how they assemble theses engine's new on an assembly line. They literally slap them together with parts from bins. No measureing, no cleaning casting flash, no clean room. Just lube it up and assemble it. Every thing is within a spec and it is slapped together.

#30

Banned

iTrader: (1)

It does if your the one collecting the money and making the profit...

Your spot on though. Look at how they assemble theses engine's new on an assembly line. They literally slap them together with parts from bins. No measureing, no cleaning casting flash, no clean room. Just lube it up and assemble it. Every thing is within a spec and it is slapped together.

Your spot on though. Look at how they assemble theses engine's new on an assembly line. They literally slap them together with parts from bins. No measureing, no cleaning casting flash, no clean room. Just lube it up and assemble it. Every thing is within a spec and it is slapped together.

lol at "slapped together" I am sure even FORD has taken measures to improve the cleanliness of their facility where engines are assembled. I'd be surprised if someone from ford doesn't jump out of the bushes with a video of such a place (looks around)'

And I am not sure about Ferrari, but I assumed they had the intention of giving their real performance engines the cleanest startest bill. It was just a wild guess though. The GT-R I am sure is built clean room style, I've seen that video. Anything you really care about, even your own body, should be kept in a 'cleanest possible' room. Don't let mold take over your houses walls and just live with it, because you won't be living with it for long.

Last edited by kingtal0n; 06-03-2016 at 01:44 PM.

#33

TECH Senior Member

iTrader: (16)

Clearly!!!

Clearly!!! First he talks about regular production engines going 100k miles then he brings Ferrari's into it which are not even capable of going that many miles without a major overhaul. Why would anyone tear down a perfectly good running and well maintained 50K-100K mile motor and rebuild it? That's a waste of a perfectly good donner engine.

Trolls are like rodents. Once they find a little bit of food, they keep coming back and shitting all over the place. Eventually they move on and find somewhere else to ****...

blk00ss, You know what they say; "You Can't Fix Stupid No Matter How Hard You Try"

The following users liked this post:

Dopeydinerdog (03-15-2023)

#34

10 Second Club

iTrader: (8)

He's no engineer. Yes, over thinking things is a trademark but it also requires fundamental understanding of certain principles which he is clearly lacking. Engine can't be cleaned or are forever junk if they get metal shavings in the oil passages? Wtf? That means every engine block that has ever been manufactured is junk based on the processes required to create them in the first place! How does he think oil passages were created in a sand cast block? SMH.

The following users liked this post:

Dopeydinerdog (03-15-2023)

#35

10 Second Club

iTrader: (8)

Oh, and now that this thread is back from the dead, a spun or displaced cam bearing doesn't instantly make the block junk, but it could be too expensive to fix than its worth. On my lq4, the number 3 cam bearing walked out. No obvious signs of spinning and the cam journal took the brunt of the damage. I had the shop measure and then install new bearings with loctite to insure clamp up before moving on to machining. I lucked out and it's perfect. However, if it was a no-go, I would have just sourced a different used block because the cost to machine the bearing journals oversize is more that a good used LQ block! None of this BS about not being able to clean the block...

The following users liked this post:

Dopeydinerdog (03-15-2023)

The following users liked this post:

Dopeydinerdog (03-15-2023)

#39

Banned

iTrader: (1)

How does one become an engineer BTW? I worked hard for the degree with a similar title but I am no engineer. I like math for fun, but never have needed to rely on it for safety.

Last edited by kingtal0n; 06-03-2016 at 01:39 PM.

#40

Banned

iTrader: (1)

He's no engineer. Yes, over thinking things is a trademark but it also requires fundamental understanding of certain principles which he is clearly lacking. Engine can't be cleaned or are forever junk if they get metal shavings in the oil passages? Wtf? That means every engine block that has ever been manufactured is junk based on the processes required to create them in the first place! How does he think oil passages were created in a sand cast block? SMH.

My post emphasis is on using a clean engine to start with if it is available; a good, solid piece of advice that nobody can argue with. Mileage isnt a factor; it is cleanliness. I'd rather rebuild an engine with 248k that still runs than one with 50k and has a questionable background.

Last edited by kingtal0n; 06-03-2016 at 01:40 PM.