What compression am I running?

#1

Stock bottom end LM7

Stock .051 head gasket

799 heads milled .017

I ask because I think the heads should be milled more for my cam (228r). How much more milling could I go on 91 octane?

Car is cam only, no boost.

Stock .051 head gasket

799 heads milled .017

I ask because I think the heads should be milled more for my cam (228r). How much more milling could I go on 91 octane?

Car is cam only, no boost.

#3

Hello there,

http://www.race-cars.net/calculators...alculator.html

If you know the cc of the parts you could guestimate based on above link. I would conversely refer to your blueprints and share more information for some of the ever-so-kind engine builders on here.

P

http://www.race-cars.net/calculators...alculator.html

If you know the cc of the parts you could guestimate based on above link. I would conversely refer to your blueprints and share more information for some of the ever-so-kind engine builders on here.

P

#4

10 Second Club

I'm coming up with 10.6 comp if you mill and do the .040 gasket. From what I found the stock LM7 is a -2 cc piston. Assuming thats right and the is piston flush with the top of the block that should be right. That set up should be fine on 91. I run 93 with 11.5.

#7

TECH Senior Member

iTrader: (16)

The factory 706/862 heads have approx. a 61 cc chamber.

The 799/243 is approx. a 65cc chamber.

You would need to mill approx. .030 to get the compression back If I recal. I believe it is approx .007 of mill for roughly 1 CC.

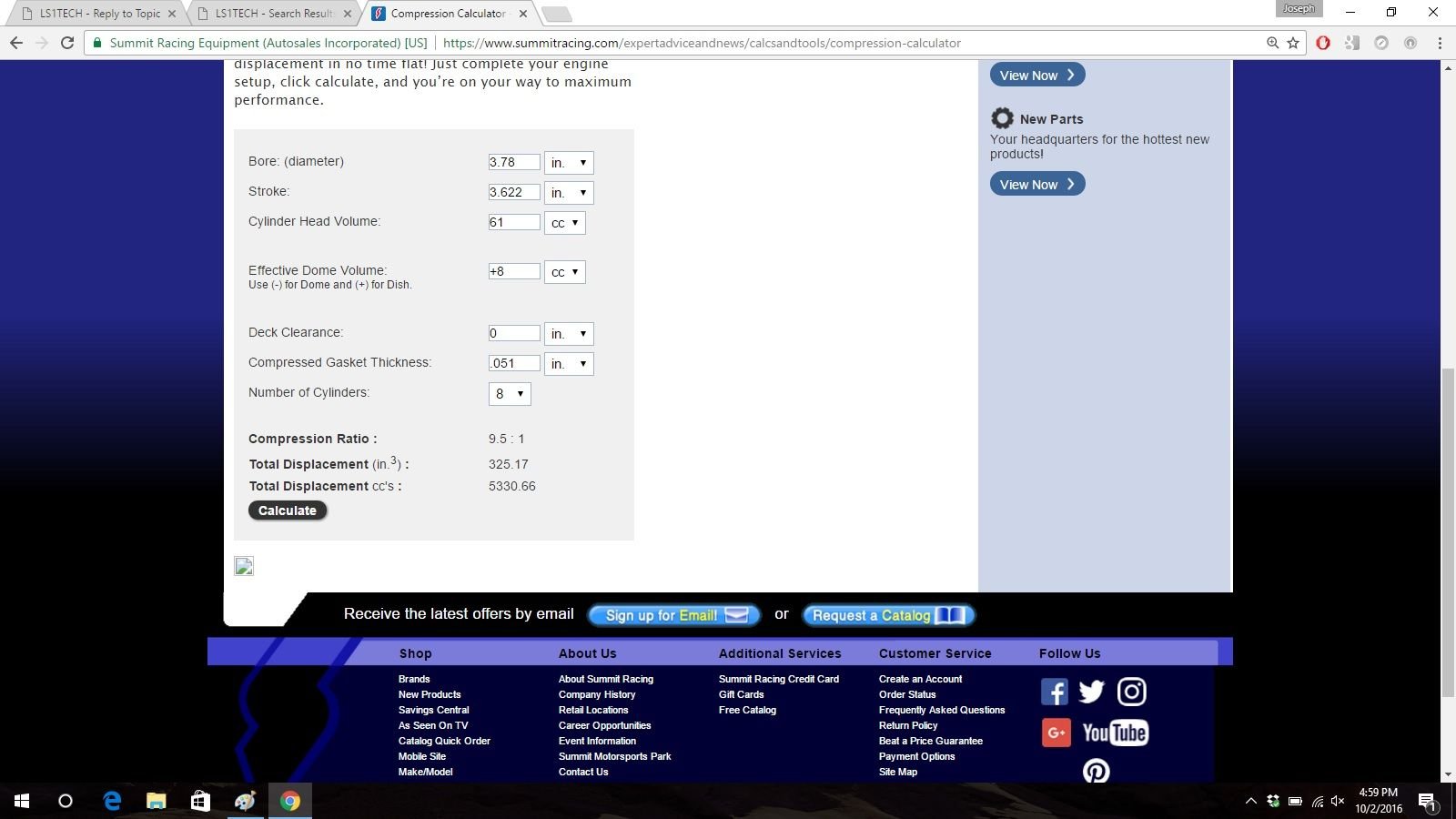

If a factory LM7 is 9.5:1 with a factory 61 CC head with .051 gasket

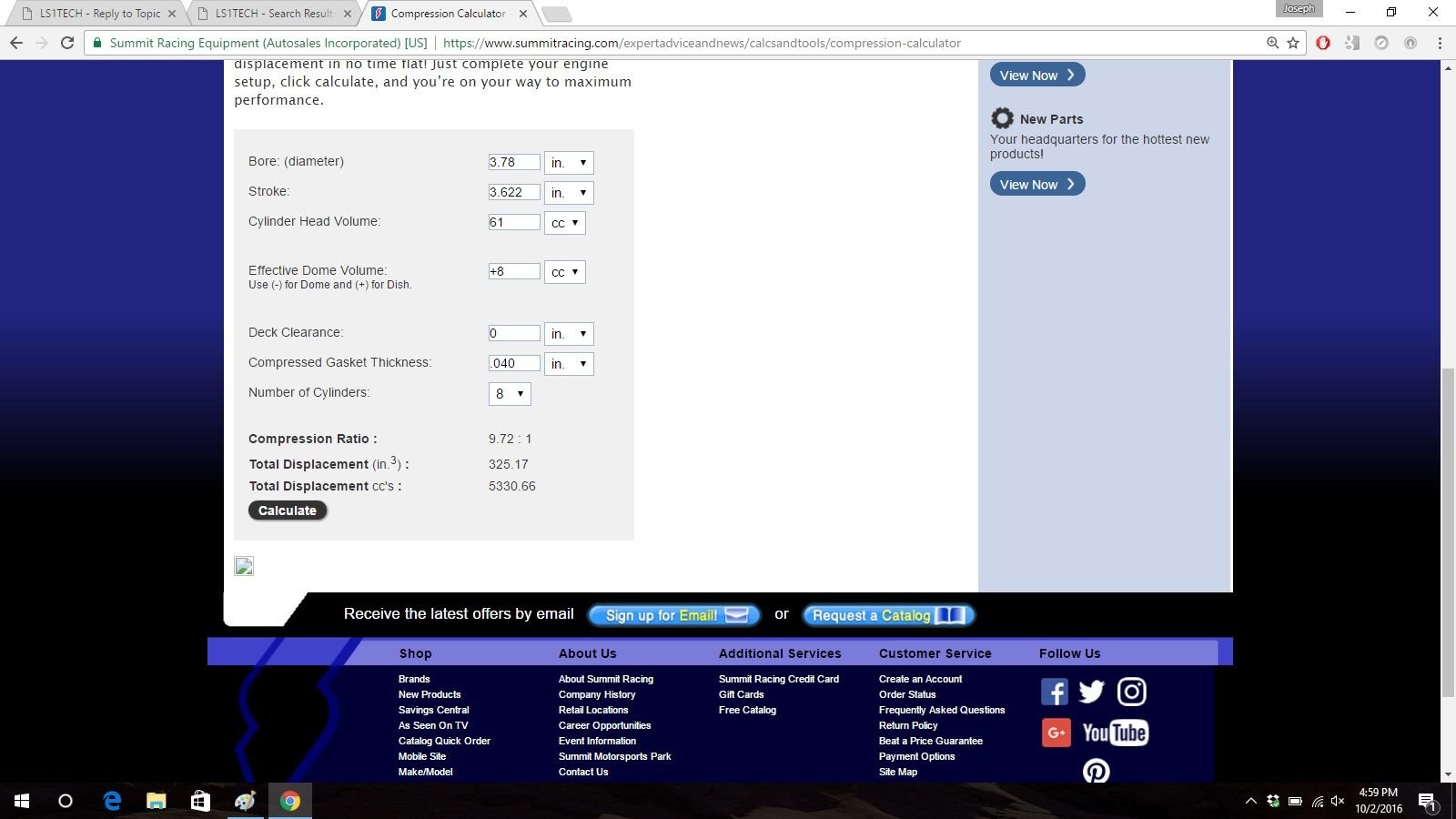

and you dropped to .040 gasket you would achieve 9.72:1 If you milled the 799 to match the 61 CC.

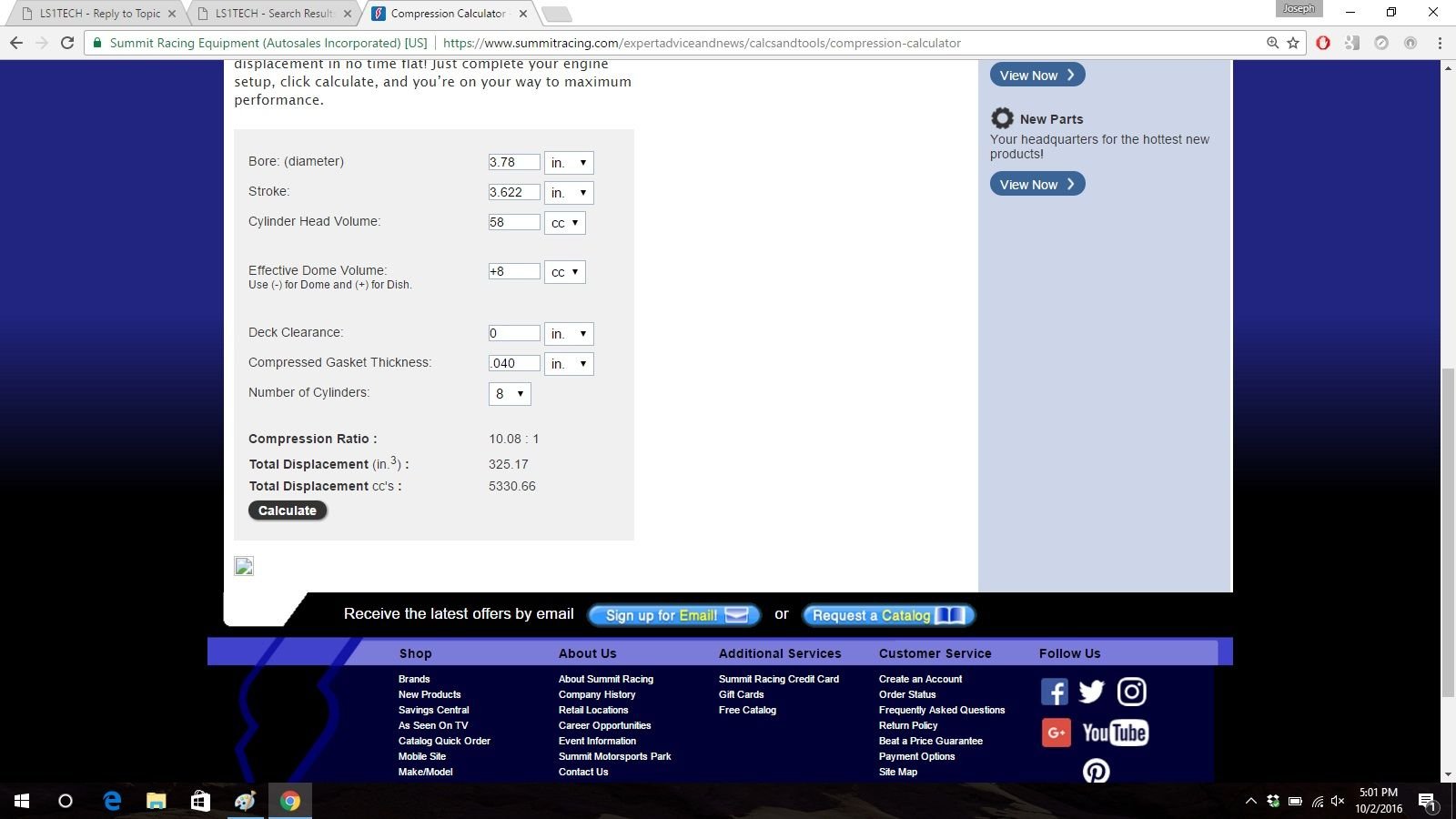

My self, I would try to achieve 58 CC to get over 10:1

You really need to measure the Piston out of the hole measurement. There typically at least +.005 to +.008 out of the hole on most of the Iron Blocks I have measured.

I have an aluminum 5.3L block right now that is +.007 on #1 hole and +.0035 On #8 hole.

You really need to measure PTV clearance based on the cam.

Stock 5.3L

Stock with .040 gasket

Stock with .040 Gasket and 58 CC chamber