The Transmission shop?

#1

Just to help keep this forum going, and my curiosity.

I've read and heard about some of the shops now and in the past that do fast paced rushed overhauls/ rebuilds, and how some techs talk about doing 3 to 5 units a day.

How can all the necessary checks be done at such break neck speed? Don't know about nowadays but many years ago alot of the big chain transmission shops, were in the same category that Earl Shibe and Macco paint jobs were.

I understand going fast, but for me only driving or operating, flying etc. I never go fast putting some machine together, when rushed that is when I do stupid stuff.

If this is not appropriate for this forum please delete it.

I've read and heard about some of the shops now and in the past that do fast paced rushed overhauls/ rebuilds, and how some techs talk about doing 3 to 5 units a day.

How can all the necessary checks be done at such break neck speed? Don't know about nowadays but many years ago alot of the big chain transmission shops, were in the same category that Earl Shibe and Macco paint jobs were.

I understand going fast, but for me only driving or operating, flying etc. I never go fast putting some machine together, when rushed that is when I do stupid stuff.

If this is not appropriate for this forum please delete it.

The following users liked this post:

Tranzman (09-20-2024)

#2

Just to help keep this forum going, and my curiosity.

I've read and heard about some of the shops now and in the past that do fast paced rushed overhauls/ rebuilds, and how some techs talk about doing 3 to 5 units a day.

How can all the necessary checks be done at such break neck speed? Don't know about nowadays but many years ago alot of the big chain transmission shops, were in the same category that Earl Shibe and Macco paint jobs were.

I understand going fast, but for me only driving or operating, flying etc. I never go fast putting some machine together, when rushed that is when I do stupid stuff.

If this is not appropriate for this forum please delete it.

I've read and heard about some of the shops now and in the past that do fast paced rushed overhauls/ rebuilds, and how some techs talk about doing 3 to 5 units a day.

How can all the necessary checks be done at such break neck speed? Don't know about nowadays but many years ago alot of the big chain transmission shops, were in the same category that Earl Shibe and Macco paint jobs were.

I understand going fast, but for me only driving or operating, flying etc. I never go fast putting some machine together, when rushed that is when I do stupid stuff.

If this is not appropriate for this forum please delete it.

But yes many just throw and cheap kit in and hope for the best. It's a gamble but likely still a profitable route . A cheap rebuild kit from amazon with primary bushing and band can be had for 150 , quick fix for PWM 20 dollars , oversized drop in AFL 40, Boost valve 25 , cheap sprag 25 assuming they even go that far charge 1200 and even if they get 1 in 4 back they still make money . Of course that's in brick and mortar shop, That would never fly here, You would get blasted hard. I have seen people here scream over a touch of rust in the threads of the linkage shaft, Of course you pay a premium price you expect a premium product.

And of course with online stuff the customer cant see whats inside normally (Mine they can as i TAKE A PHOTO of every step of every build for each customer) but typically they cannot, So outside appearance is how they are judged and as used car lot people will tell you, You can sell a Sharp looking car all day even if it does not run so well and people will be understanding, But if it looks bad even running great they will forever see it as junk.

The following 3 users liked this post by FranksCustomTrans:

#3

Just to help keep this forum going, and my curiosity.

I've read and heard about some of the shops now and in the past that do fast paced rushed overhauls/ rebuilds, and how some techs talk about doing 3 to 5 units a day.

How can all the necessary checks be done at such break neck speed? Don't know about nowadays but many years ago alot of the big chain transmission shops, were in the same category that Earl Shibe and Macco paint jobs were.

I understand going fast, but for me only driving or operating, flying etc. I never go fast putting some machine together, when rushed that is when I do stupid stuff.

If this is not appropriate for this forum please delete it.

I've read and heard about some of the shops now and in the past that do fast paced rushed overhauls/ rebuilds, and how some techs talk about doing 3 to 5 units a day.

How can all the necessary checks be done at such break neck speed? Don't know about nowadays but many years ago alot of the big chain transmission shops, were in the same category that Earl Shibe and Macco paint jobs were.

I understand going fast, but for me only driving or operating, flying etc. I never go fast putting some machine together, when rushed that is when I do stupid stuff.

If this is not appropriate for this forum please delete it.

I've been told that a few companies that start with M were literally taking 1 out of every 8 transmissions or so and just slapping a fresh coat of paint on a junkyard core and claiming it was a rebuild. The stories are out there of individuals opening up these transmissions upon receipt and seeing nothing was replaced.

I was giving people who I built for a list of all the parts that were put into the unit and copies of all the receipts of what I actually paid for the parts and where they were purchased and when, so that they knew exactly how much they were paying in labor and exactly how much I was actually making on the sale and how long it took me to get the parts. (Not saying a business should ever do this, I'm just saying what I did... I'm not a business)

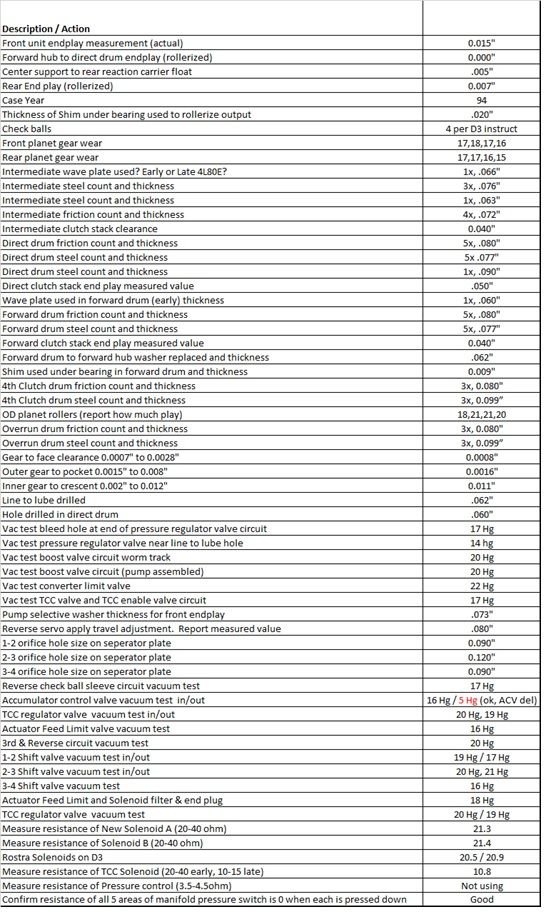

Here's an example of what I was providing to everyone that I built a 4L80E for. Maybe if someone builds one for themselves, they will find value in this. I did it so that if one ever came back, I could see if it was altered from what I did.

If I ever decided built them on the side again, I would NOT provide these sheets to the customer and instead just keep them for my own records. Way too many questions were getting asked just out of curiosity on the specs that were being provided to them LOL!

The following 2 users liked this post by 5.7stroker:

bob4360 (09-19-2024), FranksCustomTrans (09-19-2024)

#4

I also do very similar to the same as far as a build sheet per say. I dont advertise that im a builder because im not. I do it simply for a hobby and I enjoy it mainly doing it for people that I know if they need something done. Theres are a couple guys locally specifically one that I dont want to make it seem like im advertising taking work away from him because I dont claim to be a builder. And really dont want to be

The following 3 users liked this post by 2BFAST:

#6

But all in all and sometimes having to machine pump faces and backs I can have 2-3 days in a unit working 6 to 8 hours a day at it.

but most of these fast build YOUTUBE AND TIKTOKERS also do not show the prep which give the impression it is an easy quick process. And Illusion or not showing and editing.

#7

I will be 75 next month. The more you learn, the more you have to do on the next build. It will always take longer as time goes on. You notice things that maybe were not that important at the time, now are. It is the little things that can make or break a good build. Flat sanding pressure plates is common. As you say, they are rarely flat. I have said for years that most people that call themselves a transmission builder. Are parts changers at best!

The following users liked this post:

FranksCustomTrans (10-17-2024)

Trending Topics

#8

I will be 75 next month. As the cases and external parts keep getting older. They are getting harder to clean. As you state the fixes, modifications, flat sanding the new pressure plates, modifying accumulators, etc. I find the more I have learned, the more I do and it takes more time. You cannot unlearn something. A lot of hours can go into this. I said years ago. The people that build transmissions are parts changers at best. That leaves very few of us...

Last edited by PBA; 10-17-2024 at 12:17 AM.

The following users liked this post:

FranksCustomTrans (10-17-2024)