Anyone use UMI k-member?

#1

My OEM k-member cracked in a few places, so I had my local shop install the UMI RR K-member as I felt it was the only one strong enough for HPDE. Long story short, after installation there is a ton more vibration when not at idle. All mirrors shake horribly and are practically not useful. At idle, it used to shake on the OEM engine mounts and rock when I blipped the throttle cam. Now the engine doesn't shake at all and blipping the throttle cam also doesn't cause it to shake. If I get the RPM up above maybe 3K while driving a lot of the vibration goes away. So it seems as if the rubber in the OEM clam shells are somehow not being utilized.

It gives me flashbacks to when I tried using poly tranny mounts about 20 years ago and pulled them immediately after the test drive. I last installed OEM engine & tranny bushings in 2019 and never had a problem until the K-member swap. An endoscope shows a bolt going through the center of the driver side engine mount, but I couldn't find it on the passenger side from the top. Driver side seems to show the UMI engine stand possibly interfering with the metal shell of the OEM mount.

While I'm waiting answers from UMI, any common experience out there? Other than hating the way it vibrates, any side effects to running it in that condition?

It gives me flashbacks to when I tried using poly tranny mounts about 20 years ago and pulled them immediately after the test drive. I last installed OEM engine & tranny bushings in 2019 and never had a problem until the K-member swap. An endoscope shows a bolt going through the center of the driver side engine mount, but I couldn't find it on the passenger side from the top. Driver side seems to show the UMI engine stand possibly interfering with the metal shell of the OEM mount.

While I'm waiting answers from UMI, any common experience out there? Other than hating the way it vibrates, any side effects to running it in that condition?

#2

TECH Fanatic

iTrader: (1)

I used a UMI k-member when my car still had the LT1, never had a problem. Now I'm using one again with my LS3 swap. I did have a problem with the driver's side stock engine mount making contact with the pedestal which I attribute to poor QC by UMI. I had to remove the mount and hammer it flatter to create clearance. That only ever caused a squeaky noise at idle. I haven't experienced anything like what you've described.

#3

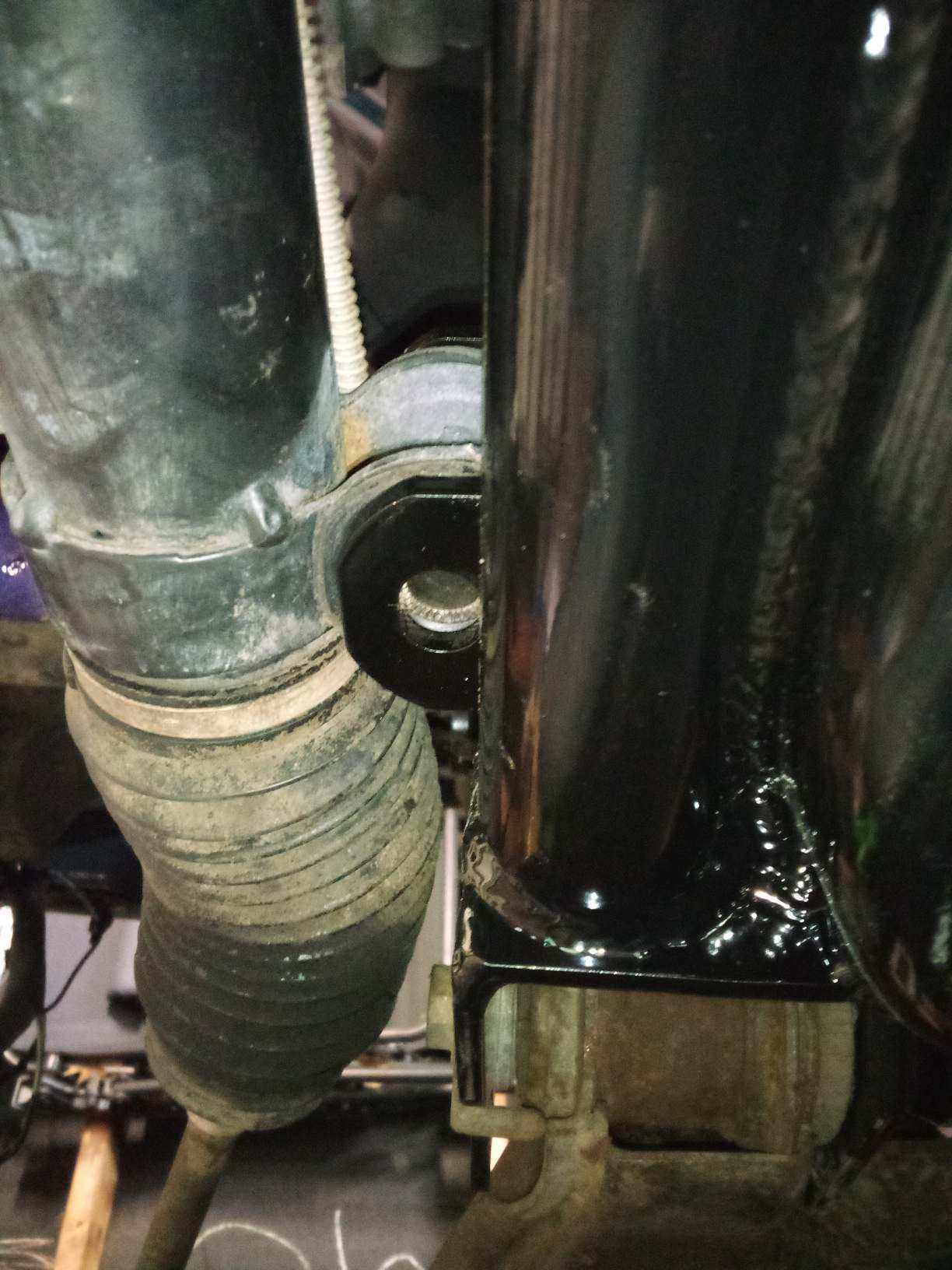

The gussets are riding on the oem engine mount clamshells  I'm not aware that OEM engine mounts can be incorrectly installed, and I see others using the same combination. My shop wants another 8hrs of labor to rectify a problem they didn't cause. I ordered through Stranoparts, waiting to see their proposed resolution.

I'm not aware that OEM engine mounts can be incorrectly installed, and I see others using the same combination. My shop wants another 8hrs of labor to rectify a problem they didn't cause. I ordered through Stranoparts, waiting to see their proposed resolution.

Various photos from the swap here, includung the problem.

https://www.dropbox.com/scl/fo/mcdau...gflap8a1a&dl=0

I'm not aware that OEM engine mounts can be incorrectly installed, and I see others using the same combination. My shop wants another 8hrs of labor to rectify a problem they didn't cause. I ordered through Stranoparts, waiting to see their proposed resolution.

I'm not aware that OEM engine mounts can be incorrectly installed, and I see others using the same combination. My shop wants another 8hrs of labor to rectify a problem they didn't cause. I ordered through Stranoparts, waiting to see their proposed resolution. Various photos from the swap here, includung the problem.

https://www.dropbox.com/scl/fo/mcdau...gflap8a1a&dl=0

#4

12 Second Club

iTrader: (13)

Thanks for posting this up, I'm going to be installing my engine tomorrow with a new UMI K-member ( non road race ) and I didn't even think there would be issues with the mounts not fitting correctly. I'll make sure to mock it up before I try to install it. Sorry you're having this issue, but you should be able to clearance those tabs pretty easily.

Trending Topics

#9

UMI basically said they could see where the gussets may be too close for stock engine mounts and recommended grinding a few thou off the gussets and/or switching to their 2329 poly mounts. They also stated nobody uses stock mounts with the RR kmember and won't pay any labor. However, their public facing information states nothing about choice of kmember, but does say it's a direct bolt-in and no grinding required. Continued frustration on poor quality control and false marketing of various manufacturers.

#10

12 Second Club

iTrader: (13)

Well, I can chime in with another poor quality control issue with UMI. My K-member went in without any issues, that is, until I went to install my steering rack. The passenger side bracket was welded too far back, and the mounting hole was so close to the weld that it made inserting a bolt impossible. They have yet to get back to me after I sent them about 15 pics of the problem. I just took a grinder and elongated the holes forward about .050-.060" and was finally able to install a capscrew and washer. Neither side could use the factory bolts. They have jigs for these things... I cannot fathom how they get welded incorrectly.

The following users liked this post:

Y2K_Frenzy (05-08-2024)