Anyone know of a f-body with a watts link?

#61

Lowering the panhard bar has all kinds of effects on the suspension, as the rear roll center is defined by where the panhard bar crosses the center of the rear end. Lowering it means you need to increase the spring rate and rear sway bar size.

Lowering it just to 'reduce how much the axle moves' isn't the intended use. And besides, I don't know of anyone who has actually had a problem because the axle was moving too much. We aren't talking about a lot of movement here.

Lowering it just to 'reduce how much the axle moves' isn't the intended use. And besides, I don't know of anyone who has actually had a problem because the axle was moving too much. We aren't talking about a lot of movement here.

It’s not the rigidity of the dampers or springs but the isolation of the axle during movement.

Try running 17x10” rims with 315/35/17 on a set of Eibach Pros with an APHR centered perfectly, then have someone in your back seat while hitting a pothole. When you see the tire shredding you will really understand the geometrical movement of the chassis in relation to the axle.

#62

^^^ so true

My drivers side rear tire is shredded and my right tire is untouched. The rear IS centered at ride height. Theres more movement than you might think. Especially when going in and out of driveways and such at an angle.

Watts link does more than just eliminate side to side movement. Theres other benefits. Read the whole thread before you start bashing the idea...

My drivers side rear tire is shredded and my right tire is untouched. The rear IS centered at ride height. Theres more movement than you might think. Especially when going in and out of driveways and such at an angle.

Watts link does more than just eliminate side to side movement. Theres other benefits. Read the whole thread before you start bashing the idea...

#63

I'll would need to see statistical data for me to oppose the simple geometrical math used to justify this mod. If you look at the simple connection points of the PHB, it’s a basic connection that stabilizes the axle during suspension transitions. At no point has ANY aftermarket vendor suggested a higher spring rate due to the increased rigidity of the bushing material or adjustment of the bar to center the axle once lowered. To specify the need for a higher spring rate due to leveling of the PHB would be comparable to saying that you would negate the effects of the control arm relocation brackets with stock spring rates. If anything, relocating the PHB to a more horizontal location would justify the use of softer springs as the offset of axle movement has been reduced. Stiffer spring rates would justify the relocation more so.

It’s not the rigidity of the dampers or springs but the isolation of the axle during movement.

Try running 17x10” rims with 315/35/17 on a set of Eibach Pros with an APHR centered perfectly, then have someone in your back seat while hitting a pothole. When you see the tire shredding you will really understand the geometrical movement of the chassis in relation to the axle.

It’s not the rigidity of the dampers or springs but the isolation of the axle during movement.

Try running 17x10” rims with 315/35/17 on a set of Eibach Pros with an APHR centered perfectly, then have someone in your back seat while hitting a pothole. When you see the tire shredding you will really understand the geometrical movement of the chassis in relation to the axle.

^^^^Learn how the suspension works before bashing other people's posts.^^^^

http://www.frrax.com/rrforum/index.p...dpost&p=125705

Specifically:

Panhard bar lowering brackets

The rear roll center height on 3rd and 4th gen F-bodies is high resulting in an inclined roll axis. When you lower a late model f-body the roll center height in the rear doesn’t drop as much as the front, therefore the roll axis becomes even more inclined. One reason that GM did this perhaps is to allow for softer rear springs so the ride quality would be improved. Since the rear roll center height is determined by where the phb crosses the axle centerline we can very easily change the rear roll center height by lowering the phb. This is accomplished by adding on phb brackets. This is nothing new, although Unbalanced Engineering released their prefabbed kit a few years back which has thrust this controversial issue into the spot light.

As covered under “basic vehicle dynamics”, the roll center height is a basic fundamental of the car’s suspension. A change in the roll center height will change the distance between it and the cg where centripetal force acts upon. Lowering the rear roll center height therefore increases the rear roll couple by increasing the lever arm length. This will increase rear body roll and if made alone the car will push. To counteract this stiffer rear springs and sway bars must be added. Then the shocks must be revalved. The basic goal in revalving them is to lessen compression damping to keep the car compliant over bumps (despite stiffer springs) and to increase rebound damping to control the stiffer springs. Popular shocks for this are Koni DA’s, Bilstein HD’s and other custom valved race shocks such as aluminum bodied Bilsteins or Penskes. Some users have made their brackets adjustable for different roll centers and leveling the panhard bar.

#64

Originally Posted by hpjunky98

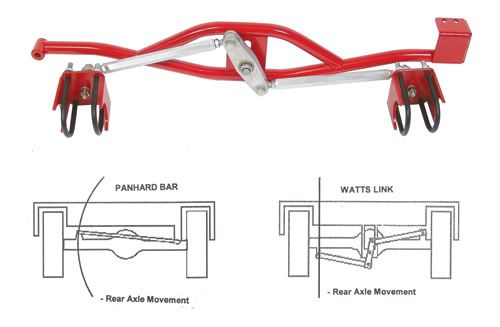

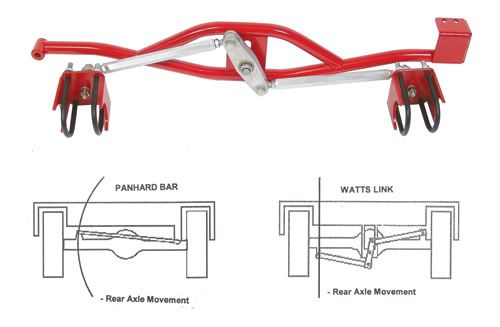

Helpful pic I found online to help understand the effect of a watts inkage vs our traditional set up

Man, what is that for? Who makes that? Looks like it'd be a near perfect fit for an F-body...

Man, what is that for? Who makes that? Looks like it'd be a near perfect fit for an F-body...

#65

OK, I must be missing something. I don't see how a Watts helps that much - at least in my case. Right now, my PHB sits perfectly level and parallel to the ground. I don't know exactly how long a PHB is, but let's say around 4' long. When my rear compresses (or rebounds) by 1", then the 1 side of the PHB moves up 1" in relation to the other, right? That means that the arc comes into play and the rear axle will move side-to-side.

But, what kind of side-to-side distance are we talking about? Well, I used a calculator to find out. It's at http://www.1728.com/circsect.htm. Take a Radius of 48", and an AB Chord of 1". You end up with a Segment Height of 0.0026".

That means, in the first inch that the axle travels vertically, it moves 26 ten-thousandths of an inch sideways. If it moves 2" vertically, it moves 1/100th (0.01") of an inch sideways. At 3", it's 0.023".

First off, I don't think that any of us in the twisty-curvy world are having more than 3" upward or 3" downward (or 6" total vertical) axle travel. Secondly, sidewall flex on even the stiffest race tire is more than 0.023" (more like .5", if my fenderwells are any indication). Finally, unless complete rod-ended setups are used, then the poly bushings will probably compress and allow more than 0.023" of movement.

Again, am I missing something? Is there another component that I don't know of?

But, what kind of side-to-side distance are we talking about? Well, I used a calculator to find out. It's at http://www.1728.com/circsect.htm. Take a Radius of 48", and an AB Chord of 1". You end up with a Segment Height of 0.0026".

That means, in the first inch that the axle travels vertically, it moves 26 ten-thousandths of an inch sideways. If it moves 2" vertically, it moves 1/100th (0.01") of an inch sideways. At 3", it's 0.023".

First off, I don't think that any of us in the twisty-curvy world are having more than 3" upward or 3" downward (or 6" total vertical) axle travel. Secondly, sidewall flex on even the stiffest race tire is more than 0.023" (more like .5", if my fenderwells are any indication). Finally, unless complete rod-ended setups are used, then the poly bushings will probably compress and allow more than 0.023" of movement.

Again, am I missing something? Is there another component that I don't know of?

In a right turn, the chassis mount will move higher with body roll, and, the PHB is in compression. This will cause the PHB to want to "lift" the body (if it's the path of least resistance). This can raise the rear roll center in right hand corners (to a degree) and raise the rear ride height in a corner. I'm not suggesting it's a "ton" of motion, and the sky is not falling. But, that's what a watts link avoids.

On the other hand, a good, stiff PHB works quite well for most cars nearly all of the time. There are some of us who could use it, and many people who can save their money for something else.

#66

Regardless of your reaction, thanks for the info.

#68

I absolutely would NOT run any watts link that is clamped to the axle. If it's not welded or bolted into a proper bolt hole, I'm not using it. There is too much chance of the axle slipping in such a design while under load. I'm not saying it's absolutely going to fail, but if it does, there is a good chance your tire will lock up against the inner fender and you are going to wind up spinning the car (and possibly getting hit). I'll stick with a PHB before I ever consider a design like that.

#69

Griggs (not maximum motorsports as I first posted) also does a modified aluminum rear end cover with their watts link setup mounted to it. I questioned it at first, but I know of "dozens" of actual track cars (driven in competition) that use this setup and I've not seen one fail yet. It does actually work pretty well (though it's like the steel bracket on the back of the cover that someone else showed in this thread, not the Saleen one).

Last edited by trackbird; 06-02-2008 at 12:29 PM.

#70

I'm trying, but it's hard to keep up with what we have to do currently.... and I'm not a fabricator. This is on the radar, I swear... finding time is the issue.

__________________

www.stranoparts.com --814-849-3450

Results matter. Talk is cheap. We are miles beyond the success anyone else has had with the 4th gens, and C5, C6, C7 Corvettes,

10 SCCA Solo National Championships, 2008 Driver of they Year, 2012 Driver of Eminence

13 SCCA Pro Solo Nationals Championships

2023 UMI King of the Mountain Champion

www.stranoparts.com --814-849-3450

Results matter. Talk is cheap. We are miles beyond the success anyone else has had with the 4th gens, and C5, C6, C7 Corvettes,

10 SCCA Solo National Championships, 2008 Driver of they Year, 2012 Driver of Eminence

13 SCCA Pro Solo Nationals Championships

2023 UMI King of the Mountain Champion

#71

A few things. PHB's are not perfect.. but they are dead simple and light and cheap.

For those reading with slammed cars, the more you lower the car the more arc you introduce into the range of motion and the more side to side movement you get. Yet another reason we don't put the cars on the ground. FWIW, my car has the PHB slightly off the to the left to account for the arc in the movement. It took a little messing, but now, dynamically I have not contact issues on either side.

For those reading with slammed cars, the more you lower the car the more arc you introduce into the range of motion and the more side to side movement you get. Yet another reason we don't put the cars on the ground. FWIW, my car has the PHB slightly off the to the left to account for the arc in the movement. It took a little messing, but now, dynamically I have not contact issues on either side.

__________________

www.stranoparts.com --814-849-3450

Results matter. Talk is cheap. We are miles beyond the success anyone else has had with the 4th gens, and C5, C6, C7 Corvettes,

10 SCCA Solo National Championships, 2008 Driver of they Year, 2012 Driver of Eminence

13 SCCA Pro Solo Nationals Championships

2023 UMI King of the Mountain Champion

www.stranoparts.com --814-849-3450

Results matter. Talk is cheap. We are miles beyond the success anyone else has had with the 4th gens, and C5, C6, C7 Corvettes,

10 SCCA Solo National Championships, 2008 Driver of they Year, 2012 Driver of Eminence

13 SCCA Pro Solo Nationals Championships

2023 UMI King of the Mountain Champion

#72

The PHB can flex when it's in compression. Also, body roll will raise and lower the chassis mount. This can cause "jacking" issues due to the angular misalignment of the PHB in the chassis.

In a right turn, the chassis mount will move higher with body roll, and, the PHB is in compression. This will cause the PHB to want to "lift" the body (if it's the path of least resistance). This can raise the rear roll center in right hand corners (to a degree) and raise the rear ride height in a corner. I'm not suggesting it's a "ton" of motion, and the sky is not falling. But, that's what a watts link avoids.

On the other hand, a good, stiff PHB works quite well for most cars nearly all of the time. There are some of us who could use it, and many people who can save their money for something else.

In a right turn, the chassis mount will move higher with body roll, and, the PHB is in compression. This will cause the PHB to want to "lift" the body (if it's the path of least resistance). This can raise the rear roll center in right hand corners (to a degree) and raise the rear ride height in a corner. I'm not suggesting it's a "ton" of motion, and the sky is not falling. But, that's what a watts link avoids.

On the other hand, a good, stiff PHB works quite well for most cars nearly all of the time. There are some of us who could use it, and many people who can save their money for something else.

#73

A few things. PHB's are not perfect.. but they are dead simple and light and cheap.

For those reading with slammed cars, the more you lower the car the more arc you introduce into the range of motion and the more side to side movement you get. Yet another reason we don't put the cars on the ground. FWIW, my car has the PHB slightly off the to the left to account for the arc in the movement. It took a little messing, but now, dynamically I have not contact issues on either side.

For those reading with slammed cars, the more you lower the car the more arc you introduce into the range of motion and the more side to side movement you get. Yet another reason we don't put the cars on the ground. FWIW, my car has the PHB slightly off the to the left to account for the arc in the movement. It took a little messing, but now, dynamically I have not contact issues on either side.

Help me to understand what you are saying. I get a visual that is just the opposite from what you are saying (not to differ but I need clarification).

Let me try to explain how I see it…

Hypothetically, let’s say with stock springs the chassis will have full range motion of 5 inches up and 5 inches down with respect to the axle. With the stock PHB attached, you have a given amount of lateral motion based on the vector angle of the PHB and its length. Now, let’s lower the car reducing the overall full range motion to say, 3 inches up and 3 inches down (reduced by the amount of 4 inches total) and you center the car with an APHB by reducing it’s length say 1 inch to center it properly (I had to). Now the chassis sits lower and the PHB angle to the axle has been reduced effectively making the PHB sit more horizontal/parallel with respect to the axle. With the combination of overall reduced PHB length, reduced chassis to axle clearance and stiffer spring rates, how can the arc possibly be increased? How can the range of lateral motion increase? The vector angle between the axle and chassis would be greatly reduced during full range motion.

Adding in the PHB lowering bracket would only fortify my theory by making the PHB more parallel to the axle.

This is how I see it. Can you please explain how to look at it differently?

Thanks

#74

Maybe I can clarify what Drgnfly is concerned about...

Stock height = PHB angle is 0 = full horizontal length = axle sits evenly

lowered car = PHB connection at axle becomes higher than chassis = shorter horizontal length than stock ride height = axle sits to the right

If PHB relocation kit is added to the axle side (is that where it gets attached?) then you can go back to a 0 degree angle. So I don't think he was disagreeing with you, but just that the PHB length change is minimal and the adjustable PHB is probably sufficient enough for most people to correct the problem as well as being a cheap solution.

Stock height = PHB angle is 0 = full horizontal length = axle sits evenly

lowered car = PHB connection at axle becomes higher than chassis = shorter horizontal length than stock ride height = axle sits to the right

If PHB relocation kit is added to the axle side (is that where it gets attached?) then you can go back to a 0 degree angle. So I don't think he was disagreeing with you, but just that the PHB length change is minimal and the adjustable PHB is probably sufficient enough for most people to correct the problem as well as being a cheap solution.

#75

Maybe I can clarify what Drgnfly is concerned about...

Stock height = PHB angle is 0 = full horizontal length = axle sits evenly

lowered car = PHB connection at axle becomes higher than chassis = shorter horizontal length than stock ride height = axle sits to the right

If PHB relocation kit is added to the axle side (is that where it gets attached?) then you can go back to a 0 degree angle. So I don't think he was disagreeing with you, but just that the PHB length change is minimal and the adjustable PHB is probably sufficient enough for most people to correct the problem as well as being a cheap solution.

Stock height = PHB angle is 0 = full horizontal length = axle sits evenly

lowered car = PHB connection at axle becomes higher than chassis = shorter horizontal length than stock ride height = axle sits to the right

If PHB relocation kit is added to the axle side (is that where it gets attached?) then you can go back to a 0 degree angle. So I don't think he was disagreeing with you, but just that the PHB length change is minimal and the adjustable PHB is probably sufficient enough for most people to correct the problem as well as being a cheap solution.

. The PHB relocation bracket that I was refering to lowers the point of connection at the upper right chassis mount. This mod will bring the PHB lower towards the axle making the PHB more parallel to the axle. That's why I'm trying to say that the more parallel to the axle the PHB is, the less up and down travel it will make when the car is lowered with higher spring rates.

. The PHB relocation bracket that I was refering to lowers the point of connection at the upper right chassis mount. This mod will bring the PHB lower towards the axle making the PHB more parallel to the axle. That's why I'm trying to say that the more parallel to the axle the PHB is, the less up and down travel it will make when the car is lowered with higher spring rates.

Thanks for your feedback.

Last edited by DRGnFLYZ28; 06-04-2008 at 06:22 AM.

#78

Update: We have something in the works. I'll keep you posted.

__________________

www.stranoparts.com --814-849-3450

Results matter. Talk is cheap. We are miles beyond the success anyone else has had with the 4th gens, and C5, C6, C7 Corvettes,

10 SCCA Solo National Championships, 2008 Driver of they Year, 2012 Driver of Eminence

13 SCCA Pro Solo Nationals Championships

2023 UMI King of the Mountain Champion

www.stranoparts.com --814-849-3450

Results matter. Talk is cheap. We are miles beyond the success anyone else has had with the 4th gens, and C5, C6, C7 Corvettes,

10 SCCA Solo National Championships, 2008 Driver of they Year, 2012 Driver of Eminence

13 SCCA Pro Solo Nationals Championships

2023 UMI King of the Mountain Champion

#80

We're not quite there. Working on putting together something, but need some details ironed out first. Patience young Grasshopper... the end is drawing near (I think).

__________________

www.stranoparts.com --814-849-3450

Results matter. Talk is cheap. We are miles beyond the success anyone else has had with the 4th gens, and C5, C6, C7 Corvettes,

10 SCCA Solo National Championships, 2008 Driver of they Year, 2012 Driver of Eminence

13 SCCA Pro Solo Nationals Championships

2023 UMI King of the Mountain Champion

www.stranoparts.com --814-849-3450

Results matter. Talk is cheap. We are miles beyond the success anyone else has had with the 4th gens, and C5, C6, C7 Corvettes,

10 SCCA Solo National Championships, 2008 Driver of they Year, 2012 Driver of Eminence

13 SCCA Pro Solo Nationals Championships

2023 UMI King of the Mountain Champion