Specialty LSx tools, DIY!

#1

Lets see some of your DIY custom LSx tooling!

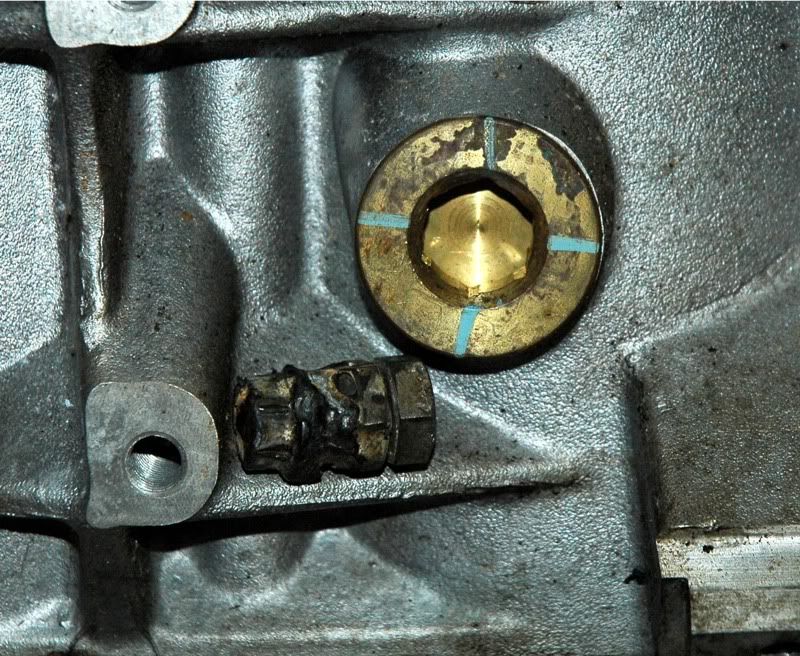

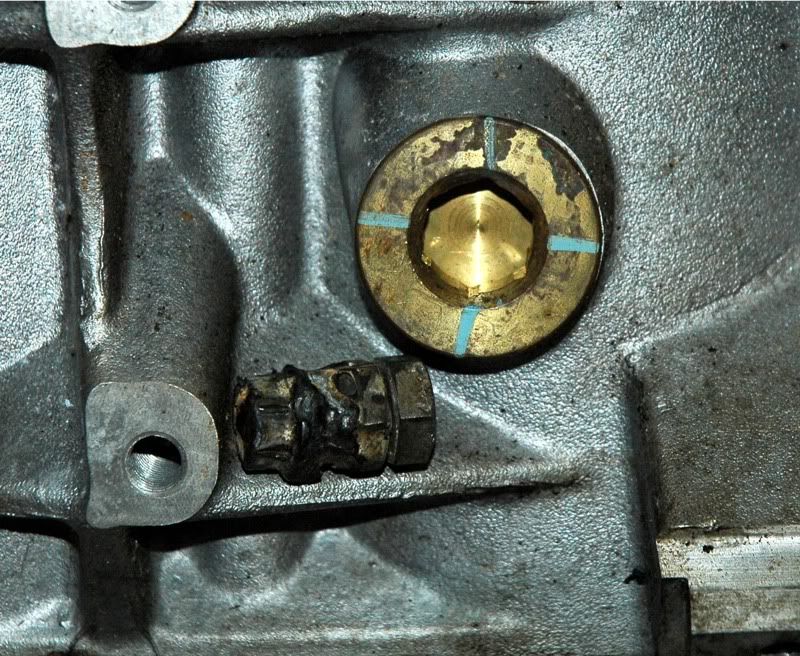

Recently built an uber cheesy 17mm core plug/block drain tool for a quick and dirty plug removal this weekend;

building a little nicer version, again on the cheap. Cutting down this 17mm allen wrench and tacking it in a ½” drive 17mm socket.

Chucked a used damper bolt in the lathe and turned down the head so the damper can slide off past it when using the 3 jaw puller. Even gave it pilot of the pullers centering cone.

haven’t decided whether or not I should get serious about building a front and rear cover alignment tool, more to the point, would such a tool be worth the hassle of building it? Seen pics of the GM version that captures the front cover and works in conjuction with the plate that bolts to the pan rail?...

Recently built an uber cheesy 17mm core plug/block drain tool for a quick and dirty plug removal this weekend;

building a little nicer version, again on the cheap. Cutting down this 17mm allen wrench and tacking it in a ½” drive 17mm socket.

Chucked a used damper bolt in the lathe and turned down the head so the damper can slide off past it when using the 3 jaw puller. Even gave it pilot of the pullers centering cone.

haven’t decided whether or not I should get serious about building a front and rear cover alignment tool, more to the point, would such a tool be worth the hassle of building it? Seen pics of the GM version that captures the front cover and works in conjuction with the plate that bolts to the pan rail?...

#2

TECH Senior Member

iTrader: (1)

Join Date: Nov 2001

Location: Waco, TX

Posts: 6,449

Likes: 0

Received 0 Likes

on

0 Posts

Your drain plug remover looks exactly like my 12-bolt filler plug removal tool. A nut and a bolt with a big glob 'o weld in between.

I like your puller seat bolt. I bought some threaded rod, cut a piece of it for the puller seat, another piece to use as an install tool.

I like your puller seat bolt. I bought some threaded rod, cut a piece of it for the puller seat, another piece to use as an install tool.

#3

In deciding whether or not I should get serious about building a front and rear cover alignment tool, more to the point, would such a tool be worth the hassle of building it, I took my old truck damper, and removed .002”-.003” from the hub by honing it. The cut off the inertia ring, chucked it up in the lathe and turned down the spokes and filed/deburred them for “finger friendly” finish. Maybe this will suffice as it “just” slips over the cranks snout? Guess we’ll see when it comes time to use it.

#6

TECH Senior Member

iTrader: (1)

Join Date: Nov 2001

Location: Waco, TX

Posts: 6,449

Likes: 0

Received 0 Likes

on

0 Posts

I'm diggin' that tranny jack plate. Fantastic. I'm gonna build me one. I don't know how many times I've had the 'ol T56 go wandering around on the jack.

My jack plate consists of an aluminum plate that was formerly a CRT monitor stand (a laptop would sit under the plate, the CRT would sit on top of it). I bolt it to my jack, it makes for a good transmission stand, but sometimes the tranny can get wiggly on me.

I bolt it to my jack, it makes for a good transmission stand, but sometimes the tranny can get wiggly on me.

My jack plate consists of an aluminum plate that was formerly a CRT monitor stand (a laptop would sit under the plate, the CRT would sit on top of it).

Trending Topics

#15

My kids call me an old timer at the ripe young age of 41. In trying to more "current" and in touch with my teenage daughters, I picked up on one of the youngens buzzs words, "uber".

A quick Google search revealed;

http://en.wikipedia.org/wiki/Über

http://www.merriam-webster.com/dictionary/uber

http://news.cnet.com/Google-creates-...3-6184416.html

A quick Google search revealed;

http://en.wikipedia.org/wiki/Über

http://www.merriam-webster.com/dictionary/uber

http://news.cnet.com/Google-creates-...3-6184416.html

#18

Damper installer worked perfectly!

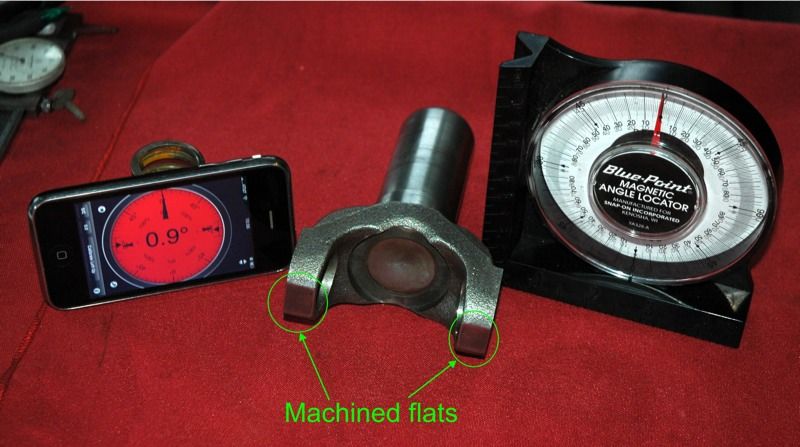

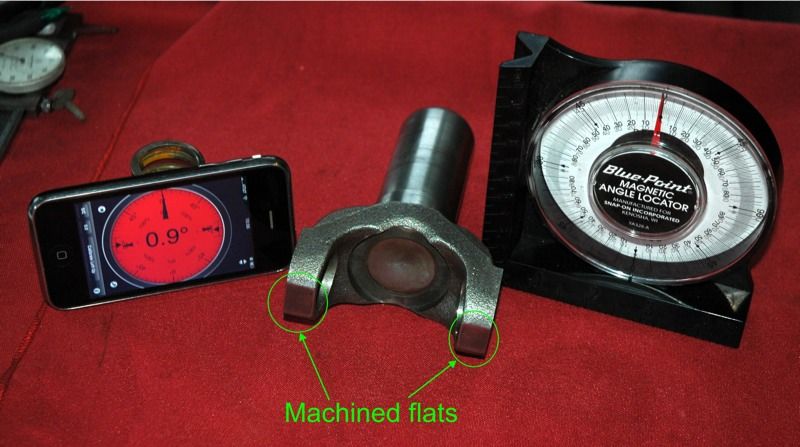

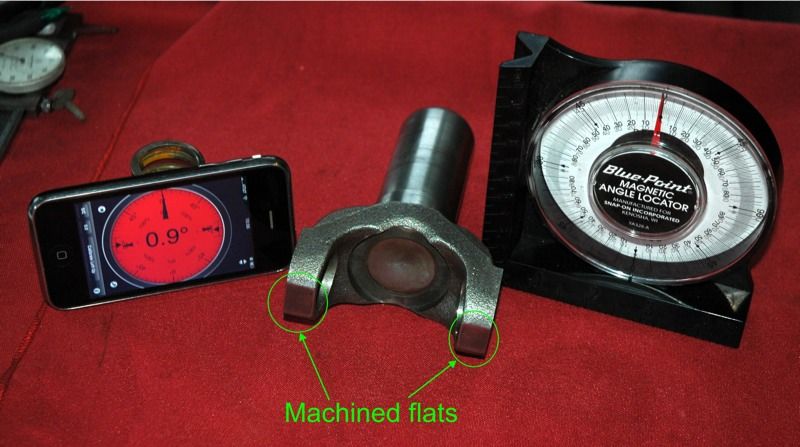

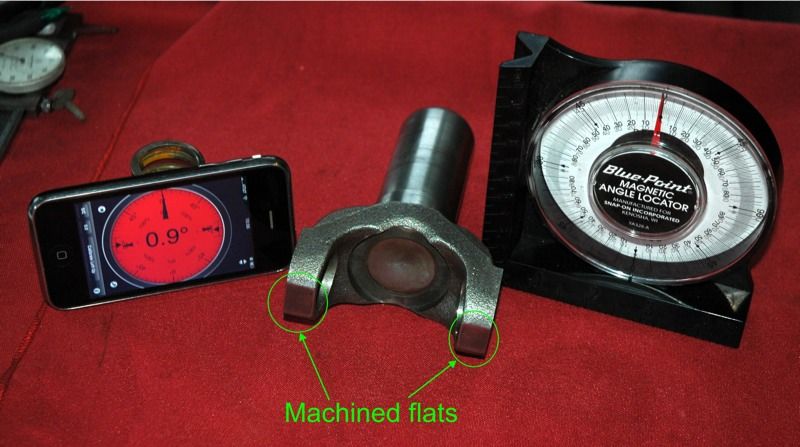

Another new tool. Took a Chevy trans driveshaft yoke that I use as a plug, chucked it up in the lathe, machined flats across the top of the yoke for perfectly square surface when verifying power train angles during engine swaps. You could just as easily measure off the bell housing mating surface if you can get access to it, machined cylinder head surfaces, or the crank damper. This is handy for immediate comparisons to the diff input flange angle.

Also made a power train aiming tool from the advice a good friend, using a Datsun 280-Z steering column tube which just so happens to be within .001” of ideal OD to fit in the tail shaft of the GM T-56, and using a section of schedule 20 PVC pipe that fits oh-so-nicely over that as a telescoping slide, I am able to verify the “aim” of the tail shaft to the diff input during conversions. Sorry no pics of that goodie.

Another new tool. Took a Chevy trans driveshaft yoke that I use as a plug, chucked it up in the lathe, machined flats across the top of the yoke for perfectly square surface when verifying power train angles during engine swaps. You could just as easily measure off the bell housing mating surface if you can get access to it, machined cylinder head surfaces, or the crank damper. This is handy for immediate comparisons to the diff input flange angle.

Also made a power train aiming tool from the advice a good friend, using a Datsun 280-Z steering column tube which just so happens to be within .001” of ideal OD to fit in the tail shaft of the GM T-56, and using a section of schedule 20 PVC pipe that fits oh-so-nicely over that as a telescoping slide, I am able to verify the “aim” of the tail shaft to the diff input during conversions. Sorry no pics of that goodie.

#20

11 Second Club

iTrader: (19)

Damper installer worked perfectly!

Another new tool. Took a Chevy trans driveshaft yoke that I use as a plug, chucked it up in the lathe, machined flats across the top of the yoke for perfectly square surface when verifying power train angles during engine swaps. You could just as easily measure off the bell housing mating surface if you can get access to it, machined cylinder head surfaces, or the crank damper. This is handy for immediate comparisons to the diff input flange angle.

Also made a power train aiming tool from the advice a good friend, using a Datsun 280-Z steering column tube which just so happens to be within .001” of ideal OD to fit in the tail shaft of the GM T-56, and using a section of schedule 20 PVC pipe that fits oh-so-nicely over that as a telescoping slide, I am able to verify the “aim” of the tail shaft to the diff input during conversions. Sorry no pics of that goodie.

Another new tool. Took a Chevy trans driveshaft yoke that I use as a plug, chucked it up in the lathe, machined flats across the top of the yoke for perfectly square surface when verifying power train angles during engine swaps. You could just as easily measure off the bell housing mating surface if you can get access to it, machined cylinder head surfaces, or the crank damper. This is handy for immediate comparisons to the diff input flange angle.

Also made a power train aiming tool from the advice a good friend, using a Datsun 280-Z steering column tube which just so happens to be within .001” of ideal OD to fit in the tail shaft of the GM T-56, and using a section of schedule 20 PVC pipe that fits oh-so-nicely over that as a telescoping slide, I am able to verify the “aim” of the tail shaft to the diff input during conversions. Sorry no pics of that goodie.

I prefer mine to be wiggily. Slides in the much easier when I can maneuver it around some.

I prefer mine to be wiggily. Slides in the much easier when I can maneuver it around some.