Camaro, Firebird, and Corvette: LS Engine Cylinder Head Guide and General Information

If the cam is considered the brains of the operation, then the cylinder heads need to be considered the lungs. Heads can be the single most expensive purchase after the engine you can make when building an engine. It only makes sense to realize what you're doing and what you're spending your money on. Spend your money wisely and enjoy the rewards.

This article applies to Chevrolet Camaro and Pontiac Firebird (1998-2002), as well as all LSx engines.

The cylinder head (or "head") has several main functions. Its first order of business is sealing the top of the cylinder (the piston seals the other end). The second order of business is to provide a way for the air (or air/fuel mixture in an LS engine) to enter the cylinder, provide a sealed space for that air fuel mixture to compress, then burn, and then provide a way to evacuate the exhaust so it can do it all over again. The more efficient the head can do this work, the more horsepower your engine can make. Old school heads you'd find on the Gen I SBC and BBC were mainly made of cast iron. This was because cast iron is durable and can withstand a lot of abuse. It used to be that cast aluminum was an exotic lump of metal, which only those with a large budget could afford. Today, it is the metal of choice and not only for the engine block, but for your heads as well.

LSx heads are considered an "overhead valve" (OHV) configuration with two valves per cylinder. Even though there are only ten head bolts per head, the way they are configured shows the typical LSx head has four bolts per cylinder (four bolts circle each cylinder). Some high performance LS heads have two extra bolts per cylinder (top and bottom) to help hold in the higher cylinder pressures associated with forced induction engines. There are plenty of heads out there which can make your engine and car a winner. Getting the right head for your needs requires you to know a little bit more so you can ask the right questions and get the right answer.

Component Breakdown

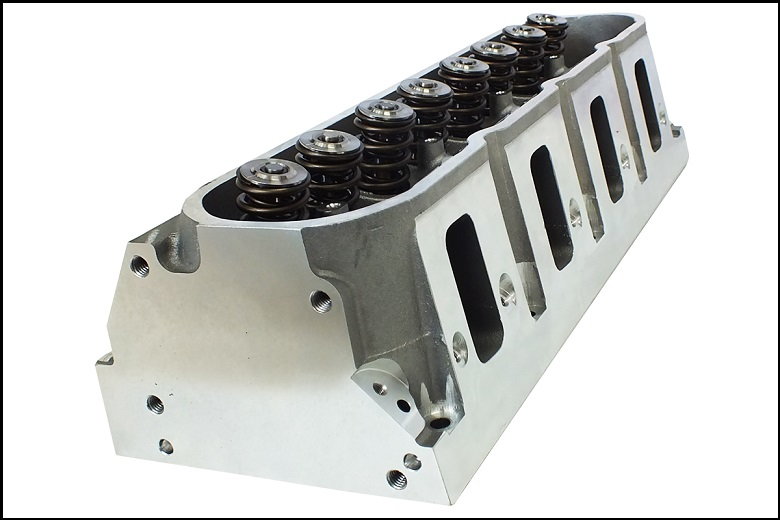

Cylinder Head

LS1 engines come with aluminum heads. Parts and features on the head are the intake and exhaust ports, combustion chambers, seats, valves, springs, retainers, keys, and guides. One of the great features of LS head design is that the intake and exhaust ports are set equally apart unlike previous Chevy small blocks. This makes it very easier to design and port the heads so each cylinder flows equally, which helps make power.

Intake Port

The intake port is where the flow begins. The different port styles can be seen in Figure 2. The LS1 uses the Cathedral Port for the intake. Intake ports are usually measured in CC's to get an idea of how big it is. The intake runner is further measured by how much it can flow in cubic feet per minute (CFM). A general rule of thumb with any head flow measurement is to double the CFM number to come up with the potential horsepower output the head can sustain. Supporting mods are always needed for a head to reach its potential.

Exhaust Port

Exhaust ports are on the opposite side of the head from the intake ports. In Figure 3 you can see how the exhaust ports (left) differ from the intake ports (right). Just like intake ports, exhaust ports come in different varieties. It is good to know what you are getting when looking at heads so you can plan correctly for the headers or exhaust you plan on run.

Combustion Chamber

The combustion chamber is important to several aspects of your engine dynamics. This is where the valves resides (two larger holes) and the spark plug (threaded hole at center bottom). The size is measured in CC's and helps determine the compression ratio of your combination. The shape of the combustion chamber (along with the piston face) direct how the combustion occurs inside the cylinder. A bad design can drastically affect how and engine runs.

Seats

The seats are what the valves rest upon to seal the combustion chamber. In Figure 4 they are the two circular off-colored parts. The seats are where the valves rest against when seated (thus the name). They are most often made out of cast iron for its durability, but can be made of other materials as the design dictates. They are much harder than the surrounding aluminum head to stand up to the continuous abuse dealt out by the valves as they open and close.

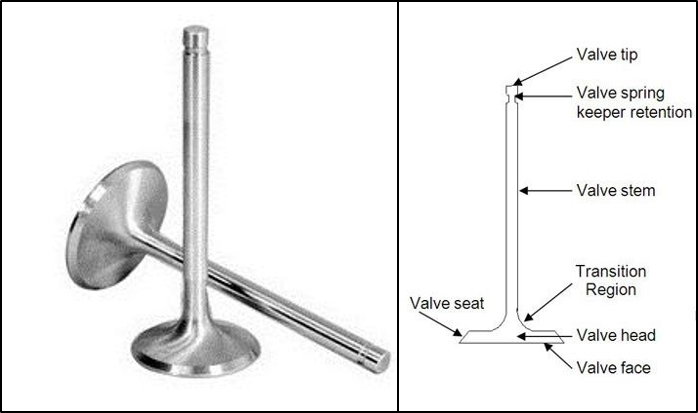

Valves

The valve reside in the combustion chamber and fill the hole of the intake and exhaust ports. The valves can be made of many different materials, including iron, stainless steel, and titanium. Specialized exhaust valves can be hollow and filled with sodium, which helps them withstand higher exhaust temperatures noticed with forced induction applications. The valve head transmits heat away from themselves out to the head, where the cooling system redirects the excess. This allows the valves to withstand the immense heat and pressure, which is found inside the engine.

Springs, Retainers, and Keys

The springs, retainers, and keys (or keepers) are what keeps the valves contained correctly within the head. They are designed to be compressed millions upon millions of times without losing their form or function. In Figure 6 is a normal spring on the left and a beehive spring on the right. With its narrower top, the beehive spring has less mass not only in the spring, but in the retainer as well, which makes it easier for the valve to open and closed. This creates less wear and tare on the valvetrain.

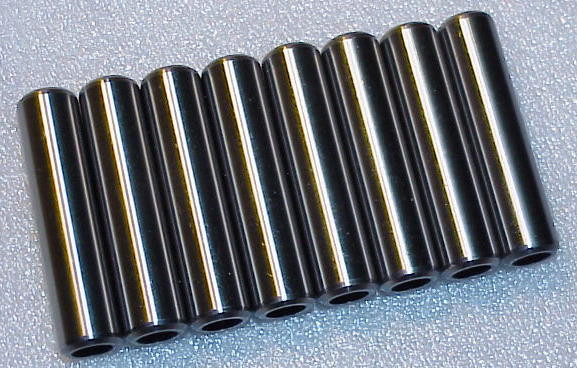

Valve Guides

The valve guide is a piece of metal which can be made out of bronze, cast iron, or many others. It is designed to allow a place for the valve stem to be held in check, thus keeping the valve straight and aligned where it should be. Valve guide wear out over time, but a well maintained engine will probably never need a new set. When installed, these are driven into the head and protrude down into the port runners just above the back of the valve head.

Scheduled Maintenance

If maintained correctly, the heads can last for the life of the engine. The wear parts, such as the guides may need to be replaced if and when you rebuild the engine. The valves lash on stock engines are set, so once rocker arms are torqued down, there's just about nothing else you need to do to them after installation.

Common Questions

How do I clean up my aluminum cylinder heads?

First of all, DO NOT USE A WIRE WHEEL! A wire wheel will damage any of the mating surfaces of the aluminum. This is a very bad idea. It is much better to clean them using a plastic scraper, toothbrush (or hard bristle brush), and brake/carb cleaner. Stay away from the metal gasket scraper, as this, too, can cause scratches in the fragile aluminum.

Is a bigger intake port better?

It can be better, but only if your engine can use the extra port volume. Using too big of a port on an engine which cannot utilize it will usually kill your low end torque. Using the proper sized intake port for your engine's needs will help keep intake flow at speed.

Why is the intake valve bigger than the exhaust valve?

Intake ports are bigger to allow for better flow. Drawing air into the cylinder through the intake is harder than allowing the hot exhaust gases to escape out the exhaust port.

Can I put LS3/L92 heads on my LS1?

Generally no. The LS3/L92 heads were designed and can only be fit on an engine with a 4" or larger bore. This pretty much leaves the LS1 out, unless you want to go to the expense of either putting larger cylinder liners in it, or you procure a block with at least the 4" bore, like an LQ4/9, LS3, L92, or LSx.

Common Issues

Warped Head

A warped head is usually caused by two different things: overheating and/or bad head bolt torque. When this happens, you can either get new heads, or have yours resurfaced at the machine shop to get them back into spec.

(Related Thread: Warped Head?? BAD - LS1Tech.com)

Valve Float

If you have changed out your stock cam for an aftermarket one, you should also have changed out your springs at the same time. If you didn't and you're revving too high, valve float can occur, which is where the spring is no longer able to control the spring at higher engine speeds. Contact your cam manufacturer to get the correct spec for your cam.

Burnt Exhaust Valve

A burnt exhaust valve can happen if some gunk gets trapped between the valve and its seat, not allowing it to close fully, allowing burning gasses to escape during combustion. This will cause a hot spot in the valve and ultimately will ruin it and the seat. If left too long, this can actually damage the head as well. You can check for a burnt valve by doing a leakdown test on the cylinders.

Bad Oil Seals

This is a small seal which fits over the top of the valve stem and valve guide. These keep engine oil out of the combustion chamber. If these are really bad, you can see blue oil smoke during startup and also during hard engine braking (high vacuum event). If you are still running your catalytic converters, get these fixed soon or you'll be replacing them as well.

Related Discussions

- Would 873 Cast Iron Heads Work? - LS1Tech.com

- 241 Heads vs 243 Heads - LS1Tech.com

- 6.0 Head Questions - LS1Tech.com

- Budget LQ4 with 243 Heads - LS1Tech.com

- LQ9 243/799 vs 821/823 Heads? - LS1Tech.com

- Tips on How to Clean Up Cylinder Heads? - LS1Tech.com

- 317 Heads! - LS1Tech.com