Th400 lq4. Converter to flexplate gap.

#21

TECH Fanatic

iTrader: (2)

You'll probably find that your crank hub adapter is too long, and is bottoming out on the face of the converter. It's a simple fix. As was mentioned before, buff the converter pilot so that it spins and moves free. You can put a small dab of grease on it as well, just not too much as it will hydraulic. Seeing if you have your problem fixed is as simple as holding the converter up against the flexplate. No need to reinstall the transmission until you make certain that your issue is resolved.

#22

Moderator

^^^ Exactly.

The very first step in a converter install should be to hold it up to the flexplate to be sure the pilot engages, the mounting pads touch the flexplate and that the mounting holes are aligned.

We've had a bunch of posts where one (or more) of those are not true and then the bleeping trans has to be removed again.

The very first step in a converter install should be to hold it up to the flexplate to be sure the pilot engages, the mounting pads touch the flexplate and that the mounting holes are aligned.

We've had a bunch of posts where one (or more) of those are not true and then the bleeping trans has to be removed again.

#23

Teching In

Thread Starter

Join Date: Oct 2008

Location: Lincoln Nebraska.

Posts: 22

Likes: 0

Received 0 Likes

on

0 Posts

Lol yeah, I should have fit it up before throwing it in. It was one of those drinking nights where I finally had enough help to snug the motor/trans in, so we did it quickly. Live and learn. I will update this when I get it pulled back out. Thanks for the help guys, I really appreciate it.

Here's what it's in btw,

Here's what it's in btw,

#24

Teching In

Thread Starter

Join Date: Oct 2008

Location: Lincoln Nebraska.

Posts: 22

Likes: 0

Received 0 Likes

on

0 Posts

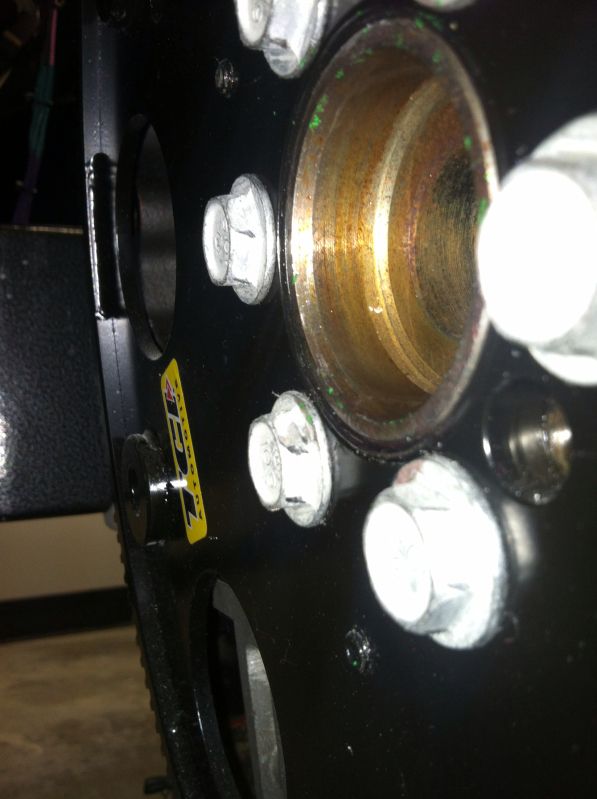

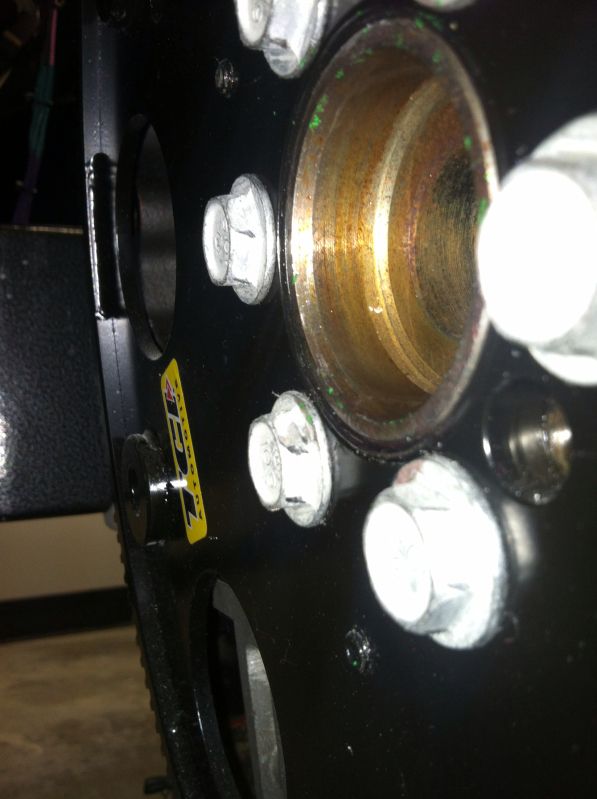

Alright, finally got around to getting it out. After pulling it out, it seemed as the spacer was sitting just a little crooked on the pilot. There seemed to be a bit of paint buildup on the sides that was causing it to sit crooked and not go on all the way. I cleaned that all off, threw some lube on the spacer, and it seated nicely on the converter. I set the converter up to the flexplate, and there was still a little gap between the flexplate and converter mounts. Not nearly as big of a gap as there was, but now maybe 1/8".

Converter pad to converter pilot stick out is .330. With the spacer on, to the pad, is .835. Are my numbers out of wack? Or should I be within range now to shim the 1/8"?

Converter pad to converter pilot stick out is .330. With the spacer on, to the pad, is .835. Are my numbers out of wack? Or should I be within range now to shim the 1/8"?

#25

FormerVendor

iTrader: (21)

Alright, finally got around to getting it out. After pulling it out, it seemed as the spacer was sitting just a little crooked on the pilot. There seemed to be a bit of paint buildup on the sides that was causing it to sit crooked and not go on all the way. I cleaned that all off, threw some lube on the spacer, and it seated nicely on the converter. I set the converter up to the flexplate, and there was still a little gap between the flexplate and converter mounts. Not nearly as big of a gap as there was, but now maybe 1/8".

Converter pad to converter pilot stick out is .330. With the spacer on, to the pad, is .835. Are my numbers out of wack? Or should I be within range now to shim the 1/8"?

Converter pad to converter pilot stick out is .330. With the spacer on, to the pad, is .835. Are my numbers out of wack? Or should I be within range now to shim the 1/8"?

Something like this.....

Chris

#27

Teching In

Thread Starter

Join Date: Oct 2008

Location: Lincoln Nebraska.

Posts: 22

Likes: 0

Received 0 Likes

on

0 Posts

Well, the converter guy had me try to just set the converter up to the flexplate without the spacer, and seemed pretty confident that This would solve my problem. So I tried that. I'm going to use the phrase "set in", because I don't know what to call it, but how much "set in" should the pilot of the converter fit into the back of the crank? What measurement? How critical is this? Right now, if I just take the spacer off, and set the converter on, they mate up flush, But, where the snout goes into the crank, the snout only goes in about .050" where the back of the crank is beveled so it's not a snug fit side to side like you would think you would want.

#29

http://www.jakesperformance.com/Tran..._FAQ_Page.html

How do I know the converter is completely seated?

The old "3 clicks" method is not an accurate way to determine if the converter is correctly installed.

There MUST be clearance between the converter and flexplate when the trans is bolted to the engine.

In a perfect world this would be 1/8" or .125" everytime, and you just bolt it up and go.

In the real world, we have to check it and make adjustments as necessary.

On a typical GM engine, the flexplate mounting pads are 1" away from the bellhousing flange area of the block.

The converter pads when seated completely will be approximately 1 and 1/8th inch ( 1.125")recessed into the bellhousing.

Seat the converter, then measure the distance from the engine block bellhousing mating flange, to the mounting pad on the flexplate.

Then do the same from the transmission bellhousing mating face, to the converter mounting pads.

You should have the converter sitting deeper than the flexplate protrudes from the engine.

If so, you can now bolt the transmission to the engine.

With the trans bolted to the engine, you should be able to turn the converter freely.

Check the distance from the converter to the flexplate with the converter completely seated into the transmission.

You should have 1/8" to 3/16" clearance. (.125"-.187")

If it is more than 3/16", you should use flat ground washers to shim between the flexplate and converter.

How do I know the converter is completely seated?

The old "3 clicks" method is not an accurate way to determine if the converter is correctly installed.

There MUST be clearance between the converter and flexplate when the trans is bolted to the engine.

In a perfect world this would be 1/8" or .125" everytime, and you just bolt it up and go.

In the real world, we have to check it and make adjustments as necessary.

On a typical GM engine, the flexplate mounting pads are 1" away from the bellhousing flange area of the block.

The converter pads when seated completely will be approximately 1 and 1/8th inch ( 1.125")recessed into the bellhousing.

Seat the converter, then measure the distance from the engine block bellhousing mating flange, to the mounting pad on the flexplate.

Then do the same from the transmission bellhousing mating face, to the converter mounting pads.

You should have the converter sitting deeper than the flexplate protrudes from the engine.

If so, you can now bolt the transmission to the engine.

With the trans bolted to the engine, you should be able to turn the converter freely.

Check the distance from the converter to the flexplate with the converter completely seated into the transmission.

You should have 1/8" to 3/16" clearance. (.125"-.187")

If it is more than 3/16", you should use flat ground washers to shim between the flexplate and converter.

Its a 2004 5.3 and TH400 with stock concave flywheel (for now).

Last edited by SniperRacing; 11-09-2021 at 06:12 PM. Reason: Add more detail