Flexplate bolt holes not lining up

#1

TECH Regular

Thread Starter

iTrader: (10)

Join Date: Nov 2009

Posts: 472

Likes: 0

Received 0 Likes

on

0 Posts

Ive got a B&M flexplate on, and a TH400 with a FTI converter. The bolt holes are not lining up for the converter to flexplate. Its the correct flexplate for my application, and Im at a loss here. Im reading that drilling out the mounting holes on the flexplate is sometimes required...is that right?

#2

TECH Enthusiast

iTrader: (17)

Join Date: Sep 2007

Location: Southern NJ

Posts: 634

Likes: 0

Received 0 Likes

on

0 Posts

How far off are they?

I would check with both manufacturers for the proper spec on the hole spacing.

Drilling out by hand might result in the holes not bring properly aligned resulting in a off center wobble. BAD

I would check with both manufacturers for the proper spec on the hole spacing.

Drilling out by hand might result in the holes not bring properly aligned resulting in a off center wobble. BAD

#3

TECH Regular

Thread Starter

iTrader: (10)

Join Date: Nov 2009

Posts: 472

Likes: 0

Received 0 Likes

on

0 Posts

I haven't measured, because Im trying to avoid pulling everything back off the car if its just something stupid Im overlooking...but its starting too look like that's not the case.

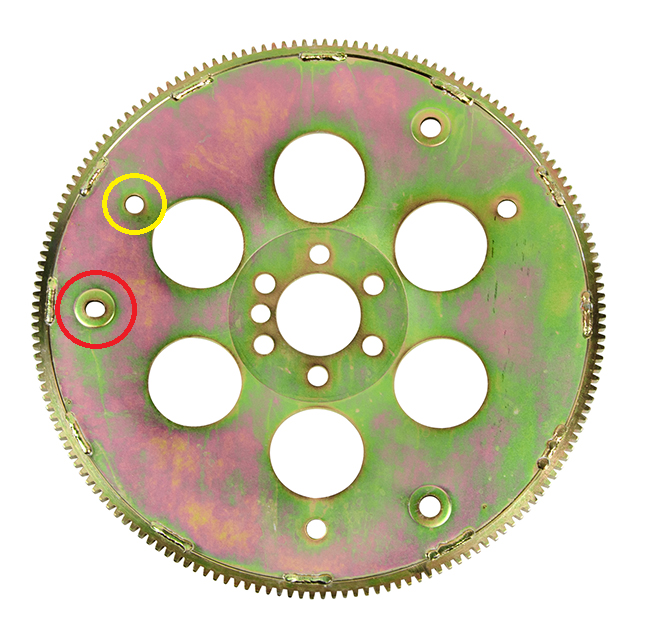

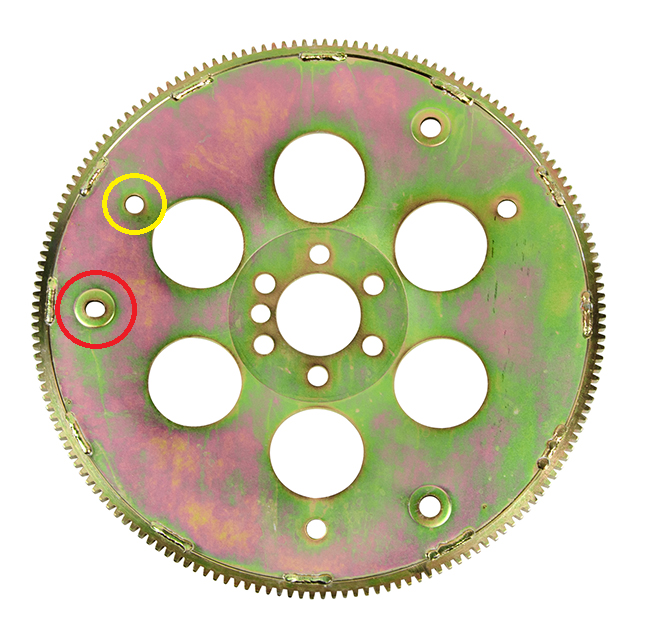

Eyeballing it with everything on the car Id say its off by 1/16-1/8" or so. The flex plate is the LSX plate which should fit my application (iron 5.3 block, TH400, FTI converter specd for my build). Here's a picture of it, Im still trying to figure out which set of holes Im supposed to be using. At this point, the yellow holes are lining up closer, where I can get one in fine, but then the other two are just slightly off. The red holes, with the embossed edges aren't even close.

Eyeballing it with everything on the car Id say its off by 1/16-1/8" or so. The flex plate is the LSX plate which should fit my application (iron 5.3 block, TH400, FTI converter specd for my build). Here's a picture of it, Im still trying to figure out which set of holes Im supposed to be using. At this point, the yellow holes are lining up closer, where I can get one in fine, but then the other two are just slightly off. The red holes, with the embossed edges aren't even close.

#5

The larger pattern on the flexplate is the LS 11.062" bolt circle. The one you have circled in yellow is the LT/th350 10.75" bolt circle. Drilling the bolt holes out slightly larger to fit should not be an issue as there could be a stackup of tolerances with the two aftermarket parts. The converter is centered by the pilot that engages the crankshaft of your motor. The bolts simply secure it to the flexplate. Make sure you use a bolt with a large enough head and proper thread engagement so you don't have issues there.

-Brian

-Brian

#6

TECH Regular

Thread Starter

iTrader: (10)

Join Date: Nov 2009

Posts: 472

Likes: 0

Received 0 Likes

on

0 Posts

The larger pattern on the flexplate is the LS 11.062" bolt circle. The one you have circled in yellow is the LT/th350 10.75" bolt circle. Drilling the bolt holes out slightly larger to fit should not be an issue as there could be a stackup of tolerances with the two aftermarket parts. The converter is centered by the pilot that engages the crankshaft of your motor. The bolts simply secure it to the flexplate. Make sure you use a bolt with a large enough head and proper thread engagement so you don't have issues there.

-Brian

-Brian

Awesome thanks Brian. Odd that I am closer to the yellow holes isn't it? I mean the red holes are nowhere even close to either of the two threaded holes on the converter pad. The converter was built specifically for my application (th400 5.3) I wonder why that is?

Last edited by schmendog; 03-15-2015 at 09:16 AM.

Trending Topics

#9

-Brian

#10

TECH Fanatic

iTrader: (17)

Join Date: Jan 2004

Location: Fayetteville, NC

Posts: 1,069

Likes: 0

Received 0 Likes

on

0 Posts

OP, id take it apart and get the correct flexplate, if you just purchased that one. A good thing to do is lay the flexplate on the ground and put the converter on it to check the alignment before bolting it all up

#11

I just fitted this B&M flexplate and same deal. Lucky for me my Turbo 400 converter has both small and large bolt patterns, so the yellow holes are lining up perfectly. But im paranoid the T350 holes (yellow) are too close to the edge of the plate where the 6 large holes are, and could cause it to eventually crack through. So when I ramp up the engine HP I will remove the plate again and redrill the large T400 bolt pattern fresh, adjacent to all of the other holes, so the new T400 large pattern holes are not close to any edges of where the plate is open/missing.. if that makes sense!

Why can't a part just fit for once without a drill or grinder.

Why can't a part just fit for once without a drill or grinder.

#13

For a cheap plate im not complaining.