Plumbing for My Carbureted 70 Corvette LQ4

#1

On The Tree

Thread Starter

I listed My Corvette swap over in Conversions and Hybrids , but they ain't to interested there . No air conditioning , no power steering , and OMG no Injector = no interest. Lets see what You Guys think .

Starting at the Tank , I added a Competition Engineering C4040 weld on Sump Kit. Weld it on as far forward as possible , if I had to do it over again I would put it at least another 1/4 inch even if it means having to notch the crossmember.

Next a 3/8 pipe to AN-8 90 degree elbow to a braided -8 hose to 90 degree hose end to another 3/8 pipe to AN-8 90 degree elbow to a Fram HPG1 Fuel Filter. From there a 3/8 pipe to -6AN straight adapter to a 90 degree hose end to the fuel pump . I used a Carter P4070 , I always had good luck with them in the past. Then up to another fuel filter , I used a WIX 33481 for GM fuel injection motors with a couple adapters for -6 AN line. From there to the factory hard line with a Swagelock fitting from McMaster Carr.

I hooked into the hard line on top of the frame accessible from the right wheel well , I would of liked to do it in a more accessible area , but I couldn't get My tubing bender in there and kinked the Stainless line, so I had to do it where I did . To bad I didn't know that I was gonna do this when I had the Body off .

That's the back half, Front in the next post.

Starting at the Tank , I added a Competition Engineering C4040 weld on Sump Kit. Weld it on as far forward as possible , if I had to do it over again I would put it at least another 1/4 inch even if it means having to notch the crossmember.

Next a 3/8 pipe to AN-8 90 degree elbow to a braided -8 hose to 90 degree hose end to another 3/8 pipe to AN-8 90 degree elbow to a Fram HPG1 Fuel Filter. From there a 3/8 pipe to -6AN straight adapter to a 90 degree hose end to the fuel pump . I used a Carter P4070 , I always had good luck with them in the past. Then up to another fuel filter , I used a WIX 33481 for GM fuel injection motors with a couple adapters for -6 AN line. From there to the factory hard line with a Swagelock fitting from McMaster Carr.

I hooked into the hard line on top of the frame accessible from the right wheel well , I would of liked to do it in a more accessible area , but I couldn't get My tubing bender in there and kinked the Stainless line, so I had to do it where I did . To bad I didn't know that I was gonna do this when I had the Body off .

That's the back half, Front in the next post.

#2

On The Tree

Thread Starter

For the front half of the plumbing , I started with a Stainless Swedgelock fitting P.N. 8239K23 from McMaster Carr that adapts 3/8 tube to 1/4 pipe thread male. Then a Stainless 1/4 pipe union , to a 1/4 pipe to -6 AN fitting. Then more of E85 Pro's Lite Black Nylon Braided Fuel Line Hose up to the Dual Feed Carburetor Fuel Line with nickel plated fittings . Most of the hoses , AN fittings , and ect I got off e-bay from getfast1.

I also did a return line , in next post.

I also did a return line , in next post.

#3

On The Tree

Thread Starter

For the fuel return , I started with a set of new QFT fuel bowls on My Holley Carb. I used these because they are tapped to run the fuel line into either side , with a block off plug in the side that is not used. First I drilled and tapped one plug for 1/8 pipe thread , then I added a -4 45 degree fitting to that. Then I tapped the inside of the 45 degree fitting for a Holley fuel Jet. This way I can adjust the amount of Fuel that gets returned back to the Tank . Then a -4 braided line back to the Factory return Line. This will keep cool Fuel available at the Secondary's and help with vapor lock .

#5

On The Tree

Thread Starter

#7

Those Carter pumps are relatively popular on here. Guys who have them say they are quiet. They are available everywhere and I feel their flow rate is well matched to a typical N/A LS motor. I thought about running one until I read it has to be mounted the motor below the pump. Wouldn't work in my car.

What filter element are you running in that Fram prefilter? If is a standard 5 micron that is excessive for a prefilter. All you need is 100 micron. I realize the surface area of that big filter will help but you want to minimize the pressure drop before the pump or you risk cavitation and vapor lock. Not to mention it makes the pump louder.

What filter element are you running in that Fram prefilter? If is a standard 5 micron that is excessive for a prefilter. All you need is 100 micron. I realize the surface area of that big filter will help but you want to minimize the pressure drop before the pump or you risk cavitation and vapor lock. Not to mention it makes the pump louder.

Trending Topics

#8

On The Tree

Thread Starter

Those Carter pumps are relatively popular on here. Guys who have them say they are quiet. They are available everywhere and I feel their flow rate is well matched to a typical N/A LS motor. I thought about running one until I read it has to be mounted the motor below the pump. Wouldn't work in my car.

What filter element are you running in that Fram prefilter? If is a standard 5 micron that is excessive for a prefilter. All you need is 100 micron. I realize the surface area of that big filter will help but you want to minimize the pressure drop before the pump or you risk cavitation and vapor lock. Not to mention it makes the pump louder.

What filter element are you running in that Fram prefilter? If is a standard 5 micron that is excessive for a prefilter. All you need is 100 micron. I realize the surface area of that big filter will help but you want to minimize the pressure drop before the pump or you risk cavitation and vapor lock. Not to mention it makes the pump louder.

#9

Teching In

Join Date: Feb 2012

Location: los altos hills

Posts: 49

Likes: 0

Received 0 Likes

on

0 Posts

I know you said "let's see what you guys think" but I don't know that I have any wisdom to impart. I will say your plumbing looks nice and neat. I don't pretend to understand the concept for your return from the fuel bowls. It doesn't look like any regulation is involved there other than playing around with different jet sizes.

In picture number 8, I put a fuel filter between the head and the water pump. I never thought about it until just now, but it might be smart of me to check the temps (see later discussion however).

Anyway since you showed us yours I'll show you mine which does provide some basis for comparison to what you did.

And this is very timely because I am working on some changes to my setup. Like you, I wish I knew some of this stuff while the body was off. What I have is new stock sized lines in stainless steel. 3/8" and 5/16" I believe. Anyway, first up, I have this quote off the internet pasted up in my garage.

Rule #3. NO ELBOWS ON THE SUCTION INLET It is never acceptable to install an elbow on a suction flange! There is always an uneven flow in an elbow. When it is installed at the suction inlet of the pump, it introduces an uneven flow into the eye of the impeller. This can introduce turbulence and air entrainment, which may result in impeller damage and vibration. The only thing worse than an elbow on inlet of a pump is two elbows. As mentioned above, the established method of ensuring a laminar flow to the inlet of the pump is using the 10D rule, straight pipe into the pump. This also means no valves, reducers, tees, etc

Part of my redo will be to honor this caveat. My pump looks like this right now (Edlebrock):

Noise is not at all a problem, the pump being right above the Magnaflow. Don't have a picture of the other side but there is an elbow there. Am looking at replacing this pump with a Holley GEROTOR simply because it looks like such an elegant concept. AND because this pump is unregulated and is at times all over the place pressure-wise. It is nominally set to 6 psi at the carb. Have an AEM fuel pressure gauge installed in the cluster so I can verify the pressure.

I've been auto crossing with down to a quarter tank with this setup and have no starvation with the standard Corvette swing arm tank pickup. No added sump seems to be necessary.

On to the front of the motor.

With regards to regulation, I had first tried a Mallory fuel log which purports to have a built in regulator. It also has a tap for fuel pressure and that's the brass fitting with the wires leading to my gauge.

It never worked right with the stock lines and I tried two of the logs. Pressure went down to about 3psi, couldn't get it much higher and I really don't know why. Best explanation I got was the the smaller return line size created a back pressure which changed the adjustable range of whatever spring is in there. I don't really know if that's a valid explanation but all the installation instructions say to use at least the same diameter or larger return line. Am not going to pull the body and tank to make that happen. I replaced the Mallory with a Quickfuel log (no regulator) and plugged up the return temporarily.

OK, now for the fun stuff.

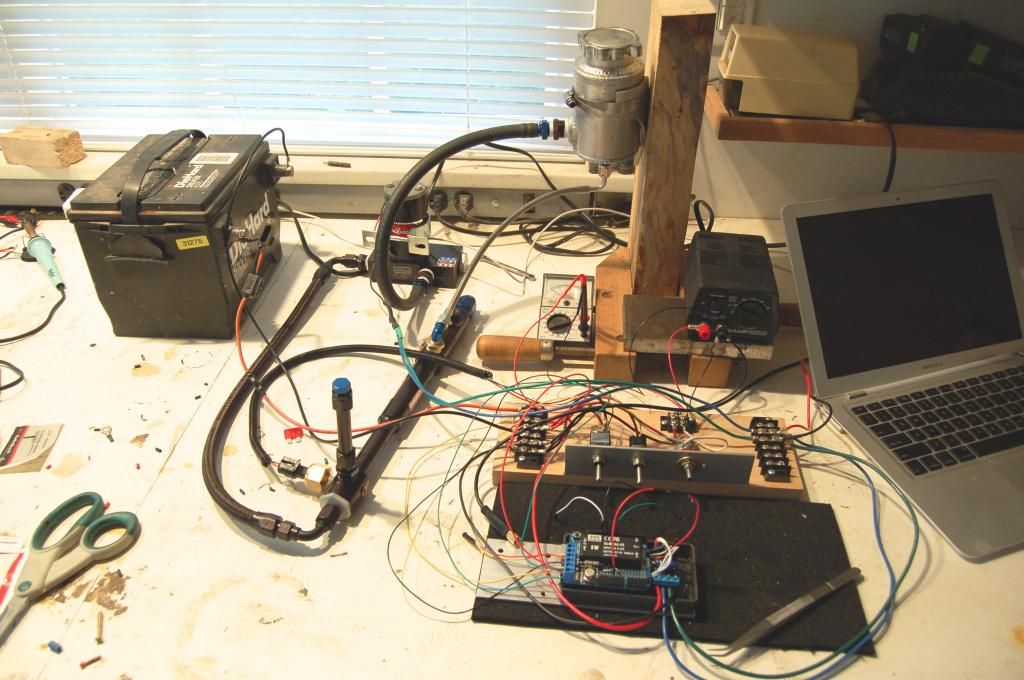

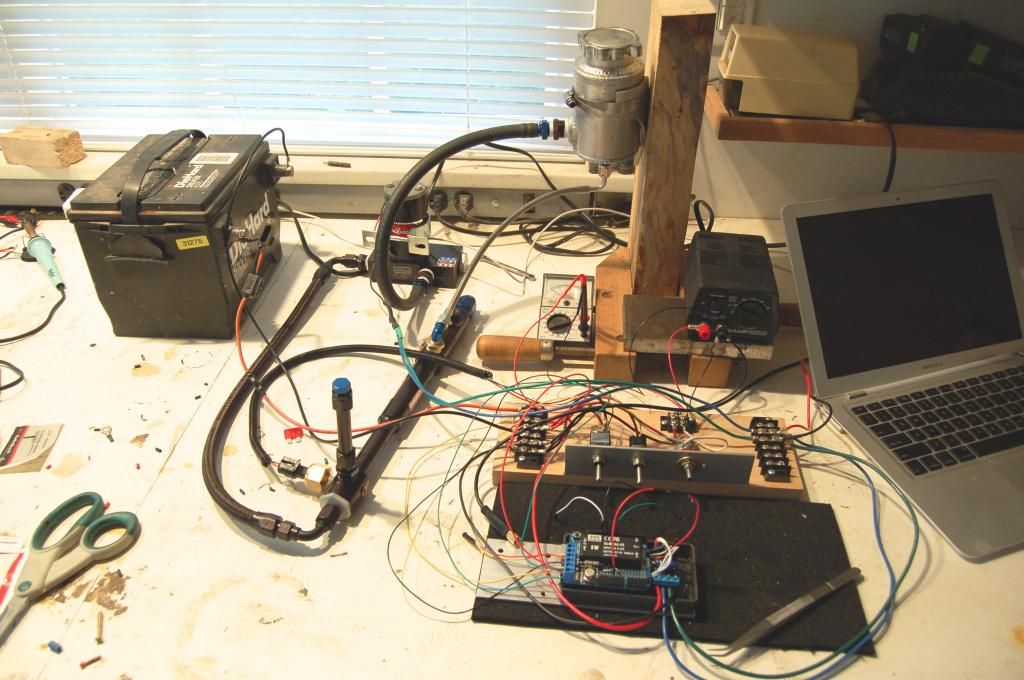

I decide that it wouldn't be all that hard to electronically regulate a higher pressure pump that had a wide open return line.

Here's what's on my bench top right now

That's another Edlebrock pump with a higher capacity and the previously mentioned fuel log (I seem to be accumulating pumps and other stuff).

I've bypassed the regulator and plumbed into a Canton catch can that I had which simulates the fuel tank. Running hydraulic fluid around and around, not gasoline.

The interesting part here is an Arduino micro controller and a Pulse-Width-Modulated pump driver. Granted, this is not everybody's skill set but it is mine and some others on this forum as well. I'm using an AEM pressure sensor for feedback and have built in a simple control loop to maintain constant pressure. Other data input is whether the motor is being cranked and whether or not I have oil pressure via a pressure switch. Plus a little blue blinking light that goes on the dash to warn me if things are out of limits. The nice thing about mechanical pumps is that they stop when the motor stops, not so electric pumps. I figure this logic is the nearest thing to that behavior.

I did mentioned the fuel filter placement earlier. I originally figured if I'm recirculating fuel, that's going to keep everything cooler so my placement may eventually be OK.

This seems to work pretty well on my bench top. I'm also figuring that it will be easier on the pump since it won't always be at maximum capacity 100% of the time. The bench top is running about 50%.

I think I am close to ready to install this and see how it works on the car. I do have to ruggedize my setup, shield the electronics and find a place to mount this.

In picture number 8, I put a fuel filter between the head and the water pump. I never thought about it until just now, but it might be smart of me to check the temps (see later discussion however).

Anyway since you showed us yours I'll show you mine which does provide some basis for comparison to what you did.

And this is very timely because I am working on some changes to my setup. Like you, I wish I knew some of this stuff while the body was off. What I have is new stock sized lines in stainless steel. 3/8" and 5/16" I believe. Anyway, first up, I have this quote off the internet pasted up in my garage.

Rule #3. NO ELBOWS ON THE SUCTION INLET It is never acceptable to install an elbow on a suction flange! There is always an uneven flow in an elbow. When it is installed at the suction inlet of the pump, it introduces an uneven flow into the eye of the impeller. This can introduce turbulence and air entrainment, which may result in impeller damage and vibration. The only thing worse than an elbow on inlet of a pump is two elbows. As mentioned above, the established method of ensuring a laminar flow to the inlet of the pump is using the 10D rule, straight pipe into the pump. This also means no valves, reducers, tees, etc

Part of my redo will be to honor this caveat. My pump looks like this right now (Edlebrock):

Noise is not at all a problem, the pump being right above the Magnaflow. Don't have a picture of the other side but there is an elbow there. Am looking at replacing this pump with a Holley GEROTOR simply because it looks like such an elegant concept. AND because this pump is unregulated and is at times all over the place pressure-wise. It is nominally set to 6 psi at the carb. Have an AEM fuel pressure gauge installed in the cluster so I can verify the pressure.

I've been auto crossing with down to a quarter tank with this setup and have no starvation with the standard Corvette swing arm tank pickup. No added sump seems to be necessary.

On to the front of the motor.

With regards to regulation, I had first tried a Mallory fuel log which purports to have a built in regulator. It also has a tap for fuel pressure and that's the brass fitting with the wires leading to my gauge.

It never worked right with the stock lines and I tried two of the logs. Pressure went down to about 3psi, couldn't get it much higher and I really don't know why. Best explanation I got was the the smaller return line size created a back pressure which changed the adjustable range of whatever spring is in there. I don't really know if that's a valid explanation but all the installation instructions say to use at least the same diameter or larger return line. Am not going to pull the body and tank to make that happen. I replaced the Mallory with a Quickfuel log (no regulator) and plugged up the return temporarily.

OK, now for the fun stuff.

I decide that it wouldn't be all that hard to electronically regulate a higher pressure pump that had a wide open return line.

Here's what's on my bench top right now

That's another Edlebrock pump with a higher capacity and the previously mentioned fuel log (I seem to be accumulating pumps and other stuff).

I've bypassed the regulator and plumbed into a Canton catch can that I had which simulates the fuel tank. Running hydraulic fluid around and around, not gasoline.

The interesting part here is an Arduino micro controller and a Pulse-Width-Modulated pump driver. Granted, this is not everybody's skill set but it is mine and some others on this forum as well. I'm using an AEM pressure sensor for feedback and have built in a simple control loop to maintain constant pressure. Other data input is whether the motor is being cranked and whether or not I have oil pressure via a pressure switch. Plus a little blue blinking light that goes on the dash to warn me if things are out of limits. The nice thing about mechanical pumps is that they stop when the motor stops, not so electric pumps. I figure this logic is the nearest thing to that behavior.

I did mentioned the fuel filter placement earlier. I originally figured if I'm recirculating fuel, that's going to keep everything cooler so my placement may eventually be OK.

This seems to work pretty well on my bench top. I'm also figuring that it will be easier on the pump since it won't always be at maximum capacity 100% of the time. The bench top is running about 50%.

I think I am close to ready to install this and see how it works on the car. I do have to ruggedize my setup, shield the electronics and find a place to mount this.

#10

On The Tree

Thread Starter

Ignatz , I like the idea of a Pulse-Width-Modulated pump looks like a good idea , at least in theory . Whats not to like , big strong pump that is more than adequate and only running just enuf to keep at 6PSI regardless of load. But the added complication is what I don't want . The wiring doesn't intimidate Me but potential failures down the Road does. What does One do a hundred Miles away from Home when a Module fails ? Not Knocking , I just like things simple and trouble free , and if I do have trouble I want something OEM or redally available aftermarket.

I do agree about the elbows in the suction line , on some hi-volume race fuel system . I really don't think it will matter much on this one. Besides the smooth radius bends used in these AN fittings won't introduce much turbulence. I'm not running a fuel pressure regulator because the pump that I'm using only puts out 6 PSI .

You may want to re-think Your setup to include a return line and route some fuel back to the Tank , this will help with Vapor lock. Even the Factory did this , sometimes at the pump or sometime at the Fuel filter . My setup just went one step further and did it off the secondary bowl inlet.

One more thing with a Name like Ignatz , are You Croation ? the reason I ask is My Grandpap was from the "Old Country " and had the same Name.

I do agree about the elbows in the suction line , on some hi-volume race fuel system . I really don't think it will matter much on this one. Besides the smooth radius bends used in these AN fittings won't introduce much turbulence. I'm not running a fuel pressure regulator because the pump that I'm using only puts out 6 PSI .

You may want to re-think Your setup to include a return line and route some fuel back to the Tank , this will help with Vapor lock. Even the Factory did this , sometimes at the pump or sometime at the Fuel filter . My setup just went one step further and did it off the secondary bowl inlet.

One more thing with a Name like Ignatz , are You Croation ? the reason I ask is My Grandpap was from the "Old Country " and had the same Name.

#11

Teching In

Join Date: Feb 2012

Location: los altos hills

Posts: 49

Likes: 0

Received 0 Likes

on

0 Posts

Interesting about your grandfather. MY Grandfather (Polish) called me Ignatz when I was a little tyke. Ignatz was a nasty little brick throwing mouse in a cartoon called Krazy Kat way back when. I thought I was a good kid.

You've correctly pointed out what worries me about inserting a custom built piece of electronics in a critical subsystem. If it fails I don't want to have to put the car on a trailer. Probably throw a toggle switch with some inline resistor to run in a degraded mode.

Yes I definitely want to use the return line for all the usual reasons. I did not see in your pix where the return line is plumbed into your system but it sounds very close to the way the fuel log is plumbed. In the Mallory picture the blue fitting is a 4AN leading back to the tank. Same setup with the QuickFuel.

Hard to know if the fittings introduce any turbulence. Like I said, the Edlebrock pump pressure is sometimes erratic.

Thanks for the reply, you do nice work. I was very impressed with the headers you built and showed in another thread.

You've correctly pointed out what worries me about inserting a custom built piece of electronics in a critical subsystem. If it fails I don't want to have to put the car on a trailer. Probably throw a toggle switch with some inline resistor to run in a degraded mode.

Yes I definitely want to use the return line for all the usual reasons. I did not see in your pix where the return line is plumbed into your system but it sounds very close to the way the fuel log is plumbed. In the Mallory picture the blue fitting is a 4AN leading back to the tank. Same setup with the QuickFuel.

Hard to know if the fittings introduce any turbulence. Like I said, the Edlebrock pump pressure is sometimes erratic.

Thanks for the reply, you do nice work. I was very impressed with the headers you built and showed in another thread.

#12

On The Tree

Thread Starter

Thanks for the compliments Ignatz. 41 Years ago when I started as a Mechanic I wanted to build Motors and work on Corvettes , instead I ended up fixin Peoples junks for 41 Years. When I see the needless complication on most Cars I just wonder what kind of over educated ******* designed this . Especially on Eurotrash Cars. That's why I try to keep things as simple as possible.

Especially on Eurotrash Cars. That's why I try to keep things as simple as possible.

I don't remember Ignatz the Mouse , must of not been allowed to watch Him. If You ever get out this way look Me up , My Wife is also Polish and She makes the best Peroghis and Halushki this side of Warsaw.

Especially on Eurotrash Cars. That's why I try to keep things as simple as possible.

Especially on Eurotrash Cars. That's why I try to keep things as simple as possible.I don't remember Ignatz the Mouse , must of not been allowed to watch Him. If You ever get out this way look Me up , My Wife is also Polish and She makes the best Peroghis and Halushki this side of Warsaw.

#14

On The Tree

Thread Starter

#15

On The Tree

Thread Starter

Last Week , got a couple of reasonably warm Days , so I finished the Crankcase Vent System . First I had to disassemble it down to the Billet Valley Cover. Then took the Hole saw and cut two holes in it for the old style Mopar Oil Separators. From there I hooked them up to a 5/8 "T" fitting that I added an elbow fitting for the 10MM hose to the right Valve Cover , then a 3/4-1" reducing elbow to the Air Cleaner. Reducing elbow only comes in 3/4 on the small end and I needed 5/8 , so a piece of shrink tubing for the wire harness to the 5/8 fitting on the "T" and = perfect fit. I also used the heat shrink Hose Clamps , seem to work great and have a clean look.

#16

On The Tree

Thread Starter

Now that the weather is getting warm again , time to get back to work. The Motor in My Car has the bat wing oil pan from a C5 , what I wanted was a C5 LS-6 oil pan . I found a new one for $40.00 about 10 years ago , and it's been hanging on the wall ever since. Took it apart the other day and washed all the Mouse turds and Mud Dauber wasp nests out of it. Then removed the casting flash and polished the inside nice and smooth so Oil will drain good. I stopped at 320 grit , figured that is good enuf

Next warm Day I'll get this bolted up and the Oil system primed and finally get to hear this baby run !

Next warm Day I'll get this bolted up and the Oil system primed and finally get to hear this baby run !