Installing a LS1 in my 1977 Camaro

#1

My SBC had a problem. Ever since I owned the car, I have said that if the SB came out, a LS motor was going back in. I found a '99 LS1 out of a Firebird with 32K miles about a month ago. I have been stripping down the old motor and selling off the parts. So far I have collected nearly $6k from old motor parts which goes a long way towards paying for the LS swap.

I had a Billet Specialties front runner on the old motor and really liked it so I bought the LS front runner from them. It cost more that what I paid for the motor!!! However, I really like the way it looks and, if I am lucky, I may be able to use my existing AC and power steering lines. The compressor and the PS pump are placed in very similar positions.

I also have a set of Billet Coil Covers from Taylor Industries. They are for Gen IV Camaro's and Firebirds. They are beautifully made from billet and then polished. The only problem is that the passenger side is about 1 1/2" shorter than the driver's side which leaves the last coil exposed. There is evidently an obstruction on the Gen IV F bodies which is why they make them this way. I have talked to them about making a full length passenger side cover and they are considering it. I told them they should market a set for swap situations like mine where there are no obstructions. There are tons of us in this same situation.

In doing some reading, I found that the LS6 intake and throttle body flows better than the LS1. In doing a search, I found the LS6 manifold below that had a Carbon Fiber look done to it. It should look good and work well on the motor.

At this point, I am planning on a twin snorkel air intake. I bought one designed for C5 Vettes. I feel pretty confident it will work but won't know for sure until the motor is in the engine bay. Speaking of which, I am having the guy who painted my car clean up the engine bay and plan on smoothing the firewall.

I found some adjustable engine adapters by Dirty Dingo that will allow me to use my exising clamshell and engine mounts. I can move the engine 2 1/2" front to rear which should allow me to place my Richmond 6 speed in the same location and use my exising crossmember. Assuming all that works, I should be able to use the existing drive shaft.

I have an aluminum bellhousing from Keisler coming which will allow me to mate the Richmond with the engine. I also have an adapter coming so I can hook up my Z bar for the clutch.

I had the wiring harness modified and a tune put to the computer. It appears the computer will fit in my glove box. I cut a hole today in the glove box and test fitted it. It will be tight with the plugs installed but it looks like it will work.

Lots to do but it should be nice when done.

www.jerryforthofer.wordpress.com

We hauled the car to the body shop this morning to have the engine bay cleaned up. I am also having him smooth out the firewall. Should look much better.

I have been talking with Kooks headers about using my car as a guinea pig to design a header/exhaust system for LS swaps. Earlier this week, I talked with the sales manager who said he would get back with me. I had not heard back from him. Today my buddy and I were planning a bike ride. We are always looking for a destination, so I told him let's drive the 30 miles to Statesville and visit Kooks. The salesman (owns a '72 Camaro) took us on a tour of their two year old building. I was not very familiar with Kooks, but they have been in business since 1962 in Long Island, NY and only moved to Statesville two years ago. I was impressed with the quality of their stainless headers and it was an interesting tour.

Once we got back into the office, he hooked us up with the sales manager who drags a 2nd gen which does low 8's in the quarter at around 170!! He asked me why I thought there would be a market for this header and I asked him if he ever visited NastyZ28 or Pro-Touring.com. I told him if he went there and did a search about LS swaps, he would be surprised at how many threads there were. Plus, I told him, on Pro-Touring, he would see not only Camaros, but GTO's, Chevelles, Buicks, Olds, etc.

He then started asking me questions about my car and I showed him my blog. He liked what he saw there and said he need to talk with his boss. About ten minutes later he came back and offered me a sweet deal if I would get both the headers and the full stainless exhaust. I immediately said yes and we are scheduled to take the car there towards the end of June.

They have a digitizer so they will map the all the hard points on my car and feed that into the computer. Once they have done that, they can generate the entire system. Then they will actually make it to make sure the computer is accurate. Once they have all the dimensions nailed, they would make a jig for the production line. They said they would have my car for two or three weeks. Once they have everything done, the system will be available in their product line.

www.jerryforthofer.wordpress.com

I got the Billet Specialties front runner installed this week. I used some of the Kent-Moore tools from their LS tool kit to remove the harmonic balancer. Sure makes it easier when you have the correct tools. The bolt for the harmonic balancer must be torqued to 240 ft lb. I was concerned about tipping over the engine stand so I raised my lift, slid the engine stand under two of the arms and then lowered the arms over the engine stand legs. It worked.

I will be getting the car back from the body shop Monday or Tuesday. Stopped in there today and the engine bay is looking great. I'll post some pics of it next week.

I am waiting for some parts to install the LS6 manifold on the motor. The coolant lines must change and the correct ones are on the way. I also found at Speedway Motors the adapters I need for my oil pressure and water temp senders. These adapters will screw into the block in the factory locations and convert to 1/8NPT so my senders from my old motor will work.

I also replaced the rear main seal and am getting ready to install the rear cover and the oil pan. I found a thread showing how to use one of the tools in the Kent-Moore LS tool kit for aligning the covers with the oil pan.

I also bought a 11' piece of 2" x 6" box steel section and a chain hoist. I am going to place it in my attic across five joists and then drop a chain through the ceiling so I can use a chain hoist to lift the engine among other things. The cherry picker I have was too short to reach the engine and we had to lift the engine out from the side. By having the chain hoist, I can lift the engine up, move the car under the engine and then lower it into place directly from above. My buddy seems to think this will work great. We will see.

www.jerryforthofer.wordpress.com

Got the 3 ton hoist installed in the ceiling of my garage on Saturday. Works like a charm. Here is a pic of it lifting my engine and the stand. This should make it easier to drop the motor into the engine bay.

Should get the car back from the body shop tomorrow.

www.jerryforthofer.wordpress.com

Got the car back today from the body shop. He smoothed out my firewall with four separate, removable panels. There are two main panels on the firewall, a large one that goes to the wiper motor area and a smaller one behind the brake booster. There is also a cover for the wiper motor and a cover for the heater and AC hookups at the firewall. He also cleaned up the crossmember and the frame rails. The trick is going to be getting the motor installed without scratching anything!!! I have a number of moving blankets and am going to cut one of them up to make covers for the firewall and inner fender liners.

Next up is cleaning up the bottom of the car from the firewall back. I lined my walls and floor with plastic and plan on using engine degreaser and my pressure washer to clean it up. A dirty job!!!

www.jerryforthofer.wordpress.com

I had a Billet Specialties front runner on the old motor and really liked it so I bought the LS front runner from them. It cost more that what I paid for the motor!!! However, I really like the way it looks and, if I am lucky, I may be able to use my existing AC and power steering lines. The compressor and the PS pump are placed in very similar positions.

I also have a set of Billet Coil Covers from Taylor Industries. They are for Gen IV Camaro's and Firebirds. They are beautifully made from billet and then polished. The only problem is that the passenger side is about 1 1/2" shorter than the driver's side which leaves the last coil exposed. There is evidently an obstruction on the Gen IV F bodies which is why they make them this way. I have talked to them about making a full length passenger side cover and they are considering it. I told them they should market a set for swap situations like mine where there are no obstructions. There are tons of us in this same situation.

In doing some reading, I found that the LS6 intake and throttle body flows better than the LS1. In doing a search, I found the LS6 manifold below that had a Carbon Fiber look done to it. It should look good and work well on the motor.

At this point, I am planning on a twin snorkel air intake. I bought one designed for C5 Vettes. I feel pretty confident it will work but won't know for sure until the motor is in the engine bay. Speaking of which, I am having the guy who painted my car clean up the engine bay and plan on smoothing the firewall.

I found some adjustable engine adapters by Dirty Dingo that will allow me to use my exising clamshell and engine mounts. I can move the engine 2 1/2" front to rear which should allow me to place my Richmond 6 speed in the same location and use my exising crossmember. Assuming all that works, I should be able to use the existing drive shaft.

I have an aluminum bellhousing from Keisler coming which will allow me to mate the Richmond with the engine. I also have an adapter coming so I can hook up my Z bar for the clutch.

I had the wiring harness modified and a tune put to the computer. It appears the computer will fit in my glove box. I cut a hole today in the glove box and test fitted it. It will be tight with the plugs installed but it looks like it will work.

Lots to do but it should be nice when done.

www.jerryforthofer.wordpress.com

We hauled the car to the body shop this morning to have the engine bay cleaned up. I am also having him smooth out the firewall. Should look much better.

I have been talking with Kooks headers about using my car as a guinea pig to design a header/exhaust system for LS swaps. Earlier this week, I talked with the sales manager who said he would get back with me. I had not heard back from him. Today my buddy and I were planning a bike ride. We are always looking for a destination, so I told him let's drive the 30 miles to Statesville and visit Kooks. The salesman (owns a '72 Camaro) took us on a tour of their two year old building. I was not very familiar with Kooks, but they have been in business since 1962 in Long Island, NY and only moved to Statesville two years ago. I was impressed with the quality of their stainless headers and it was an interesting tour.

Once we got back into the office, he hooked us up with the sales manager who drags a 2nd gen which does low 8's in the quarter at around 170!! He asked me why I thought there would be a market for this header and I asked him if he ever visited NastyZ28 or Pro-Touring.com. I told him if he went there and did a search about LS swaps, he would be surprised at how many threads there were. Plus, I told him, on Pro-Touring, he would see not only Camaros, but GTO's, Chevelles, Buicks, Olds, etc.

He then started asking me questions about my car and I showed him my blog. He liked what he saw there and said he need to talk with his boss. About ten minutes later he came back and offered me a sweet deal if I would get both the headers and the full stainless exhaust. I immediately said yes and we are scheduled to take the car there towards the end of June.

They have a digitizer so they will map the all the hard points on my car and feed that into the computer. Once they have done that, they can generate the entire system. Then they will actually make it to make sure the computer is accurate. Once they have all the dimensions nailed, they would make a jig for the production line. They said they would have my car for two or three weeks. Once they have everything done, the system will be available in their product line.

www.jerryforthofer.wordpress.com

I got the Billet Specialties front runner installed this week. I used some of the Kent-Moore tools from their LS tool kit to remove the harmonic balancer. Sure makes it easier when you have the correct tools. The bolt for the harmonic balancer must be torqued to 240 ft lb. I was concerned about tipping over the engine stand so I raised my lift, slid the engine stand under two of the arms and then lowered the arms over the engine stand legs. It worked.

I will be getting the car back from the body shop Monday or Tuesday. Stopped in there today and the engine bay is looking great. I'll post some pics of it next week.

I am waiting for some parts to install the LS6 manifold on the motor. The coolant lines must change and the correct ones are on the way. I also found at Speedway Motors the adapters I need for my oil pressure and water temp senders. These adapters will screw into the block in the factory locations and convert to 1/8NPT so my senders from my old motor will work.

I also replaced the rear main seal and am getting ready to install the rear cover and the oil pan. I found a thread showing how to use one of the tools in the Kent-Moore LS tool kit for aligning the covers with the oil pan.

I also bought a 11' piece of 2" x 6" box steel section and a chain hoist. I am going to place it in my attic across five joists and then drop a chain through the ceiling so I can use a chain hoist to lift the engine among other things. The cherry picker I have was too short to reach the engine and we had to lift the engine out from the side. By having the chain hoist, I can lift the engine up, move the car under the engine and then lower it into place directly from above. My buddy seems to think this will work great. We will see.

www.jerryforthofer.wordpress.com

Got the 3 ton hoist installed in the ceiling of my garage on Saturday. Works like a charm. Here is a pic of it lifting my engine and the stand. This should make it easier to drop the motor into the engine bay.

Should get the car back from the body shop tomorrow.

www.jerryforthofer.wordpress.com

Got the car back today from the body shop. He smoothed out my firewall with four separate, removable panels. There are two main panels on the firewall, a large one that goes to the wiper motor area and a smaller one behind the brake booster. There is also a cover for the wiper motor and a cover for the heater and AC hookups at the firewall. He also cleaned up the crossmember and the frame rails. The trick is going to be getting the motor installed without scratching anything!!! I have a number of moving blankets and am going to cut one of them up to make covers for the firewall and inner fender liners.

Next up is cleaning up the bottom of the car from the firewall back. I lined my walls and floor with plastic and plan on using engine degreaser and my pressure washer to clean it up. A dirty job!!!

www.jerryforthofer.wordpress.com

#2

I am glad this job is done!! Very messy cleaning up the bottom of the car. I spent Friday using engine degreaser and my pressure washer to get the bottom of the car at least respectable. As most of you know, when you do this type of cleaning, you are really only transferring the dirt. Part of it went onto the plastic and the rest went on me!! I don't have a mirror in my garage. If I had, I would not have gone out to get the mail as my face was pretty black. It took me nearly as long to clean up the mess as it did to clean the car.

Today I masked everything off and used three rattle cans to at least make it all the same color. While it won't pass a white glove inspection, it sure looks better than when I began this project.

Now I can concentrate on getting the motor ready for installation. Should happen this week.

www.jerryforthofer.wordpress.com

Today I masked everything off and used three rattle cans to at least make it all the same color. While it won't pass a white glove inspection, it sure looks better than when I began this project.

Now I can concentrate on getting the motor ready for installation. Should happen this week.

www.jerryforthofer.wordpress.com

#4

I got a lot done on the motor today. First I installed the rear coolant line plugs and the front LS6 coolant line so I could mount the intake. Got the intake mounted and then decided I did not like the army green color of the fuel rails. Painted them satin black.

Next I mounted the Dirty Dingo slider motor mounts. First a plate is attached to the motor, then the factory elephant ear collar is attached to the other plate. The second plate is then loosely attached to the plate on the motor. There are slots and you can slide the motor back and forth 2 1/2".

I am getting close to putting the motor in. I need to align the bellhousing and can't decide whether it would be best to do it out of the car or in the car. Not sure how I can stabilize the engine and turn the crank outside the car.

www.jerryforthofer.wordpress.com

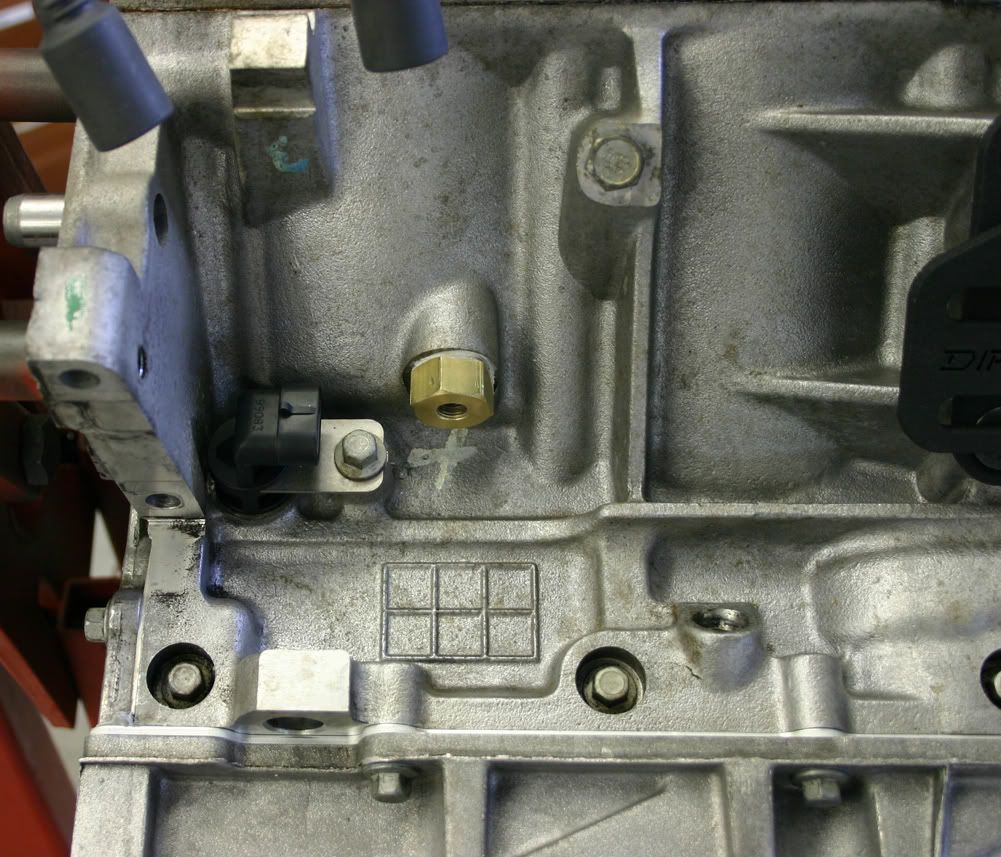

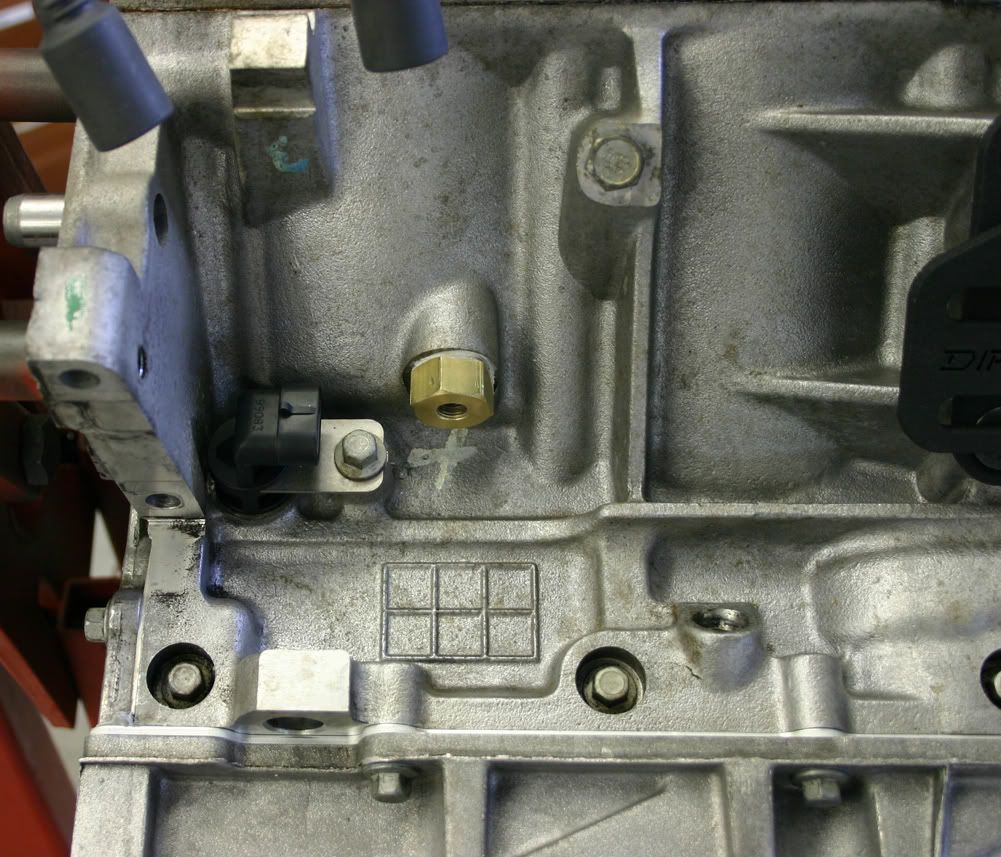

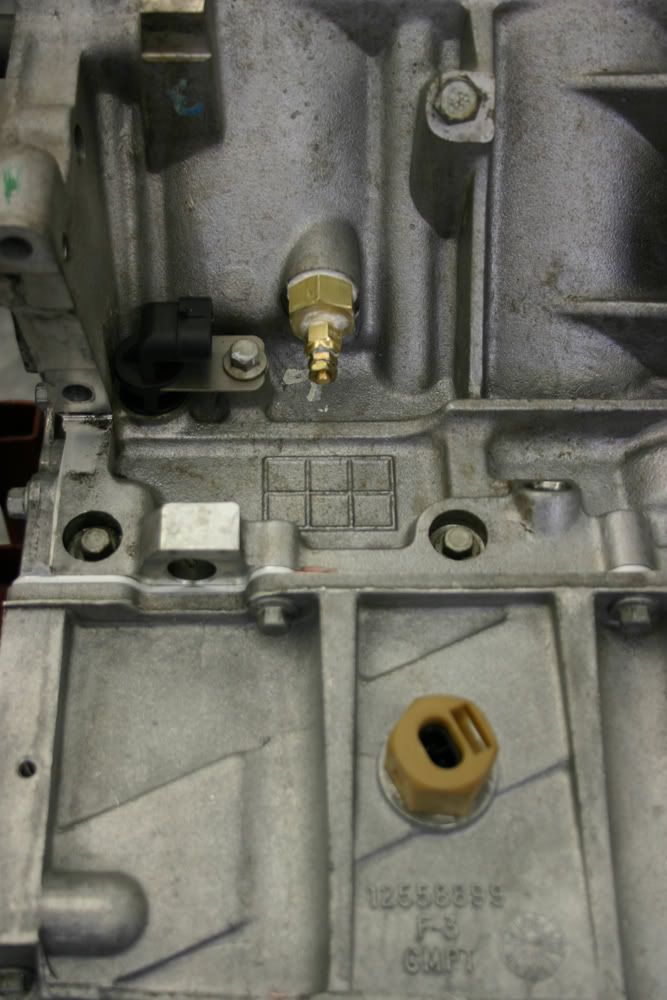

Had to mow the lawn today but still had some time to work on the motor. I removed the plate above the oil filter, drilled the hole through, tapped it for 1/8 NPT 27, and mounted my oil pressure sender for my gauges there.

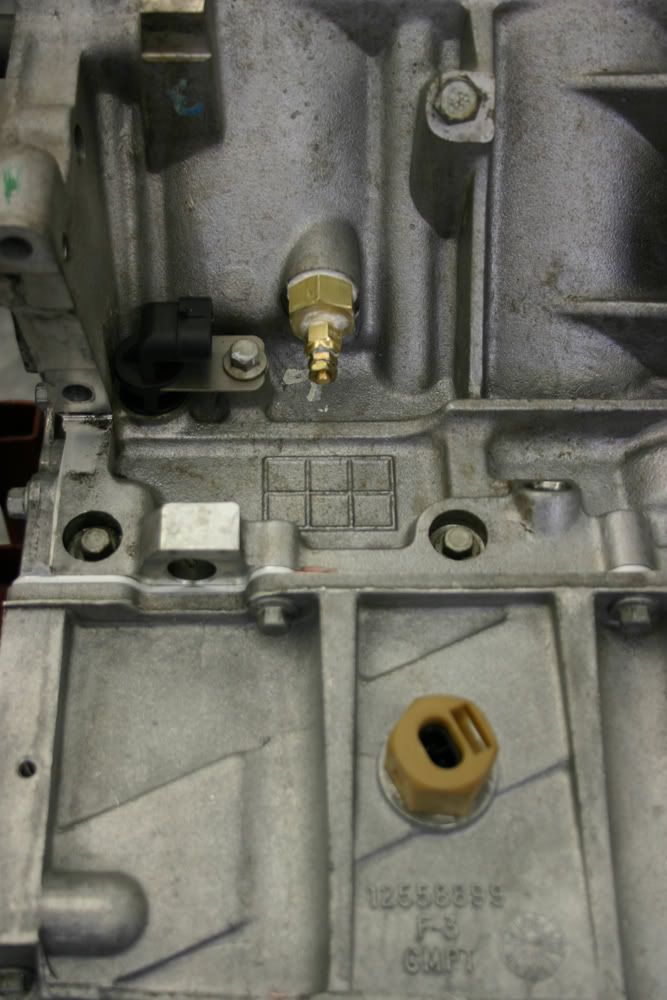

After doing a search for places to put the water temp sender for my gauges, some people recommended removing the drain plug above the starter and mounting it there. After removing the plug, I found an adapter to go to 1/8 NPT 27 thread. I talked to Autometer and they have a 1/8NPT sender that will work with my gauges. It is on the way from Summit and appears to be compact enough to clear the starter.

www.jerryforthofer.wordpress.com

The Edelbrock polished coil covers arrived late yesterday. The coil packs install directly to the rear of the covers which allows them to sit lower. I am not wild about the Edelbrock script, but, overall, it was the look I was going for. I had to cut the support for the fuel line so I can bend it up to clear the coil covers.

My water temp sender with 1/8 NPT threads arrived today and if fit perfectly with plenty of clearance with the starter.

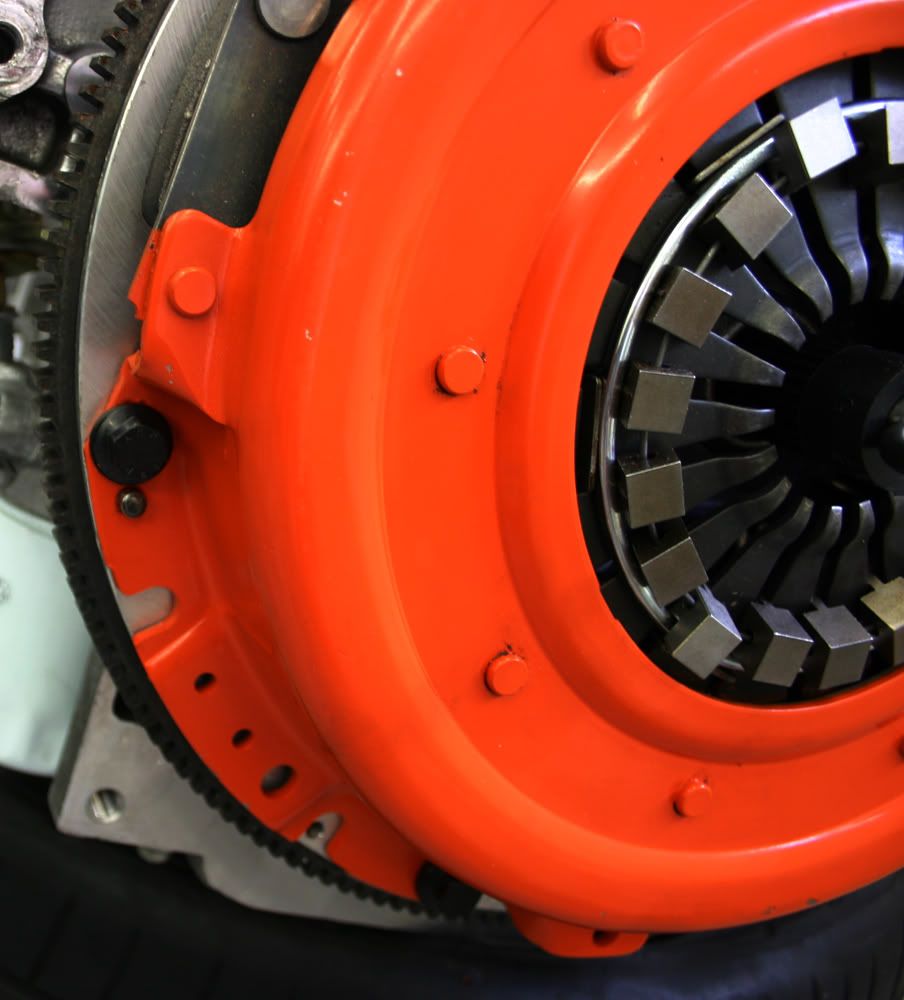

I also installed the correct pilot bearing for my transmission. I also mounted the flywheel and the bellhousing and used my son's gauge to begin the alignment procedure. I did not finish this as time ran out but will sort this out tomorrow. Once I have the bellhousing aligned, I am ready to put the motor in the car.

www.jerryforthofer.wordpress.com

After lunch, I finished up the alignment of the bellhousing. Based on the readings, I had to use a "14 adjustable dowel. I set it in place with my best guess of where it should be to get the bellhousing within spec and it worked. I was within 4 thousandths vertically and less than 2 thousandths horizontally.

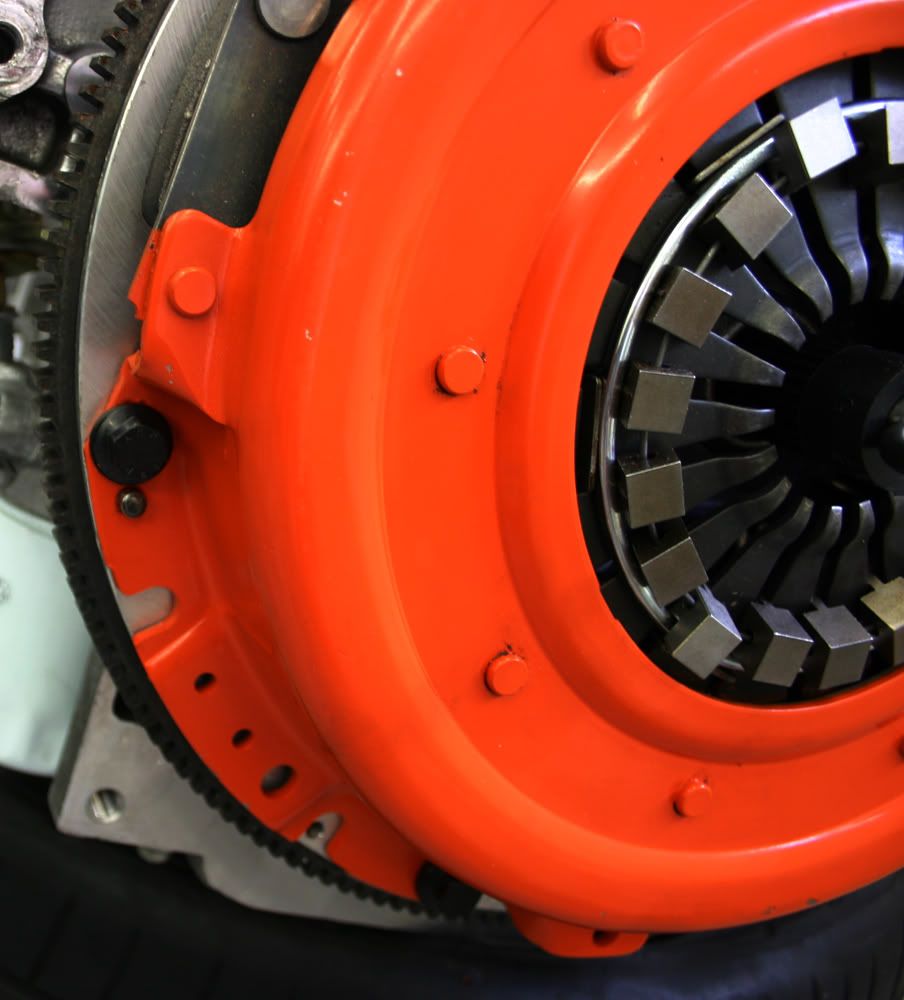

After removing the bellhousing, I installed the clutch. The LS1 flywheels have two dowel pins that must be lined up on the pressure plate for balance purposes.

I installed the clutch pivot ball in the bellhousing and have to adjust the height. Based on my late in the day measurements, I think I need a taller ball.

I also turned the car around in the garage to get the nose facing my ceiling hoist. My driveway is uphill outside the garage so turning it around there is not an option. I bought these dollies from Northern Tool some years ago and they have come in handy. I was able to easily turn the car around by myself. Once I get the pivot ball adjusted correctly, I am ready to put the motor in the car.

Getting close.

www.jerryforthofer.wordpress.com

The motor will go in tomorrow!!! I got the pivot ball adjusted and prepared the engine bay with lots of padding. Hopefully, everything fits tomorrow. My buddy and I decided to keep the car on the dollies. Since the hoist cannot be moved, this will make it easier to move the car to line up the engine mounts.

www.jerryforthofer.wordpress.com

Next I mounted the Dirty Dingo slider motor mounts. First a plate is attached to the motor, then the factory elephant ear collar is attached to the other plate. The second plate is then loosely attached to the plate on the motor. There are slots and you can slide the motor back and forth 2 1/2".

I am getting close to putting the motor in. I need to align the bellhousing and can't decide whether it would be best to do it out of the car or in the car. Not sure how I can stabilize the engine and turn the crank outside the car.

www.jerryforthofer.wordpress.com

Had to mow the lawn today but still had some time to work on the motor. I removed the plate above the oil filter, drilled the hole through, tapped it for 1/8 NPT 27, and mounted my oil pressure sender for my gauges there.

After doing a search for places to put the water temp sender for my gauges, some people recommended removing the drain plug above the starter and mounting it there. After removing the plug, I found an adapter to go to 1/8 NPT 27 thread. I talked to Autometer and they have a 1/8NPT sender that will work with my gauges. It is on the way from Summit and appears to be compact enough to clear the starter.

www.jerryforthofer.wordpress.com

The Edelbrock polished coil covers arrived late yesterday. The coil packs install directly to the rear of the covers which allows them to sit lower. I am not wild about the Edelbrock script, but, overall, it was the look I was going for. I had to cut the support for the fuel line so I can bend it up to clear the coil covers.

My water temp sender with 1/8 NPT threads arrived today and if fit perfectly with plenty of clearance with the starter.

I also installed the correct pilot bearing for my transmission. I also mounted the flywheel and the bellhousing and used my son's gauge to begin the alignment procedure. I did not finish this as time ran out but will sort this out tomorrow. Once I have the bellhousing aligned, I am ready to put the motor in the car.

www.jerryforthofer.wordpress.com

After lunch, I finished up the alignment of the bellhousing. Based on the readings, I had to use a "14 adjustable dowel. I set it in place with my best guess of where it should be to get the bellhousing within spec and it worked. I was within 4 thousandths vertically and less than 2 thousandths horizontally.

After removing the bellhousing, I installed the clutch. The LS1 flywheels have two dowel pins that must be lined up on the pressure plate for balance purposes.

I installed the clutch pivot ball in the bellhousing and have to adjust the height. Based on my late in the day measurements, I think I need a taller ball.

I also turned the car around in the garage to get the nose facing my ceiling hoist. My driveway is uphill outside the garage so turning it around there is not an option. I bought these dollies from Northern Tool some years ago and they have come in handy. I was able to easily turn the car around by myself. Once I get the pivot ball adjusted correctly, I am ready to put the motor in the car.

Getting close.

www.jerryforthofer.wordpress.com

The motor will go in tomorrow!!! I got the pivot ball adjusted and prepared the engine bay with lots of padding. Hopefully, everything fits tomorrow. My buddy and I decided to keep the car on the dollies. Since the hoist cannot be moved, this will make it easier to move the car to line up the engine mounts.

www.jerryforthofer.wordpress.com

#5

The motor is in but it took about four hours of finagling to get it to line up with the engine mounts. For awhile, we thought that there was an alignment issue. However, time and patience eventually got everything to line up. We did have to take the driver's side mount off the motor and spread it apart a bit as it was too narrow to fit over the mount. We got a piece of threaded 1/2" rod and, using placing bolts in the middle as well as on the outside, we were able to spread it about 1/4" which was enough.

After getting it mounted on the mounts, if you let the motor hang, it wanted to rest against the brake line on the rear of the front crossmember. So I tied the front of the motor down to the front swaybar to keep it up until we install the tranny.

As you can see in some of the photos, I do have some adjustment on the mounting plates and can move the motor an inch or so to the rear. It cannot go any further forward of the oil pan will hit the crossmember.

Big job done!! Should get the tranny installed next week and then it is a matter of hooking everything up.

www.jerryforthofer.wordpress.com

After getting it mounted on the mounts, if you let the motor hang, it wanted to rest against the brake line on the rear of the front crossmember. So I tied the front of the motor down to the front swaybar to keep it up until we install the tranny.

As you can see in some of the photos, I do have some adjustment on the mounting plates and can move the motor an inch or so to the rear. It cannot go any further forward of the oil pan will hit the crossmember.

Big job done!! Should get the tranny installed next week and then it is a matter of hooking everything up.

www.jerryforthofer.wordpress.com

#6

The transmission is in!!! My buddy has a very nice transmission jack that I have used nearly as many times as he has. Nevertheless, it was the usual fight getting it to mate with the motor. All's well that ends well.

After getting it bolted up, the bolt on the rear crossmember was a little over an inch forward of the bolt hole. The adjustable motor mounts helped out here. I wasn't quite able to get all of it, but I did get within less than 1/2".

When I installed the driveshaft, I still had plenty of spline left so it should work fine. After putting the car down, I hooked up the shifter and that part was done.

While the car was apart, I had the radiator cleaned and tested for leaks. I cleaned up my fan and installed both the radiator and fan.

Because of needing to use a bolt hole on the front of the head to lift the motor, I had not been able to install the alternator. Got it installed and then installed the belt and tensioner.

Now that I had all of that in place, I could work on the air intake. Problems here!! I tried a connector from the throttle body to the MAF in a straight line. Now I did not have enough room for the twin snorkel. It was nearing the end of the day, but I did try installing the snorkel directly to the throttle body with the MAF at one end of the snorkel. Once I add the filter to both ends, I will have an unbalanced look. I plan on working on this tomorrow to see if I can come up with a solution that both looks good and will work. Any suggestions?

www.jerryforthofer.wordpress.com

After getting it bolted up, the bolt on the rear crossmember was a little over an inch forward of the bolt hole. The adjustable motor mounts helped out here. I wasn't quite able to get all of it, but I did get within less than 1/2".

When I installed the driveshaft, I still had plenty of spline left so it should work fine. After putting the car down, I hooked up the shifter and that part was done.

While the car was apart, I had the radiator cleaned and tested for leaks. I cleaned up my fan and installed both the radiator and fan.

Because of needing to use a bolt hole on the front of the head to lift the motor, I had not been able to install the alternator. Got it installed and then installed the belt and tensioner.

Now that I had all of that in place, I could work on the air intake. Problems here!! I tried a connector from the throttle body to the MAF in a straight line. Now I did not have enough room for the twin snorkel. It was nearing the end of the day, but I did try installing the snorkel directly to the throttle body with the MAF at one end of the snorkel. Once I add the filter to both ends, I will have an unbalanced look. I plan on working on this tomorrow to see if I can come up with a solution that both looks good and will work. Any suggestions?

www.jerryforthofer.wordpress.com

#7

Had a bunch of running around to do today so not much accomplished. I did get the coil covers mounted and installed one of the air cleaners so I could get a feel for how the motor will look.

As you can see in the photo below, the passenger side of the snorkel is very close to the compressor. To move the snorkel out, I have a 1" throttle body spacer on the way. I found a used MAF for little money and I am planning on installing both of them with only one hooked up. Now I have to figure out the best way to block one side of the snorkel.

The Edelbrock water pump that came with the front runner kit takes the late model LS thermostat housing from 2004 up. I test fitted it today and it angles away from the motor which would make for a very weird hose to get it to the radiator. I have a housing that is straight out from the front of the motor on the way. Since the water pump works in the reverse of one on a small block, the hose from the thermostat housing goes to the bottom of the radiator while the return is at the top. I may have to custom make that hose as it must wind around the air intake and the front runner kit.

www.jerryforthofer.wordpress.com

As you can see in the photo below, the passenger side of the snorkel is very close to the compressor. To move the snorkel out, I have a 1" throttle body spacer on the way. I found a used MAF for little money and I am planning on installing both of them with only one hooked up. Now I have to figure out the best way to block one side of the snorkel.

The Edelbrock water pump that came with the front runner kit takes the late model LS thermostat housing from 2004 up. I test fitted it today and it angles away from the motor which would make for a very weird hose to get it to the radiator. I have a housing that is straight out from the front of the motor on the way. Since the water pump works in the reverse of one on a small block, the hose from the thermostat housing goes to the bottom of the radiator while the return is at the top. I may have to custom make that hose as it must wind around the air intake and the front runner kit.

www.jerryforthofer.wordpress.com

Trending Topics

#8

Had a good day today!! I had a Billet Specialties front runner kit on my old motor. When I looked at their front runner kit for the LS motor, I noticed that the compressor and the power steering pump were in basically the same locations as on my small block. With any luck, my existing lines would work.

They did!! Based on a discussion with Billet Specialties, I was pretty sure my AC lines would fit. The PS lines were more of a question mark. The reality was that they fit perfectly. Major victory here. The remote reservoir and the lines fit exactly as they did on the old motor.

One of the key features I really like on the Billet Specialties front runner is the AC manifold that places the hookup for the lines near the bottom of the compressor. Because of this, you do not have the lines conspicuously placed on the top of the motor. This allowed me to run my AC and heater hose lines above the inner fender liner under the fender to keep the engine bay clear. The lines fit as I guessed they would.

Because the heater hose hookup location is quite a bit different, I had to cut off about 6" of each line to make them work. Even cleaner installation here than on the old motor where the hookups were on top of the water pump.

I also re-installed the radiator overflow tank and line.

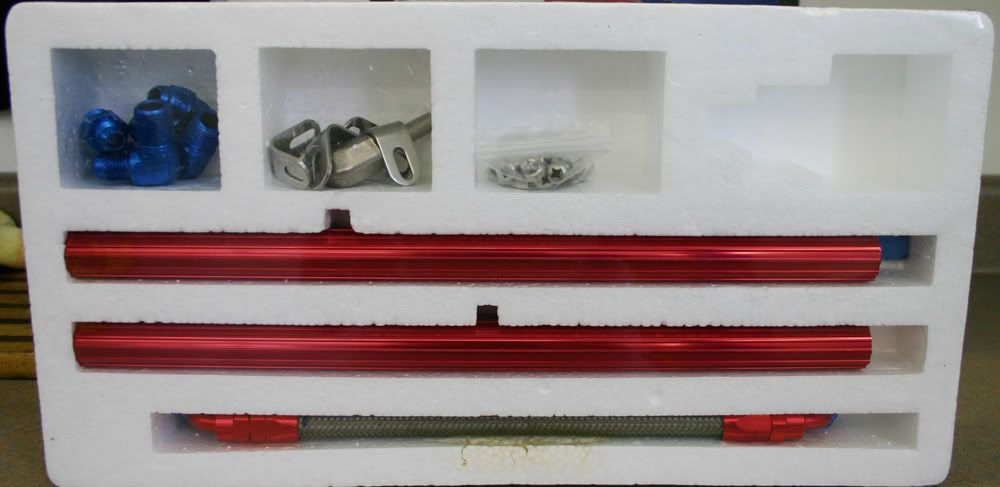

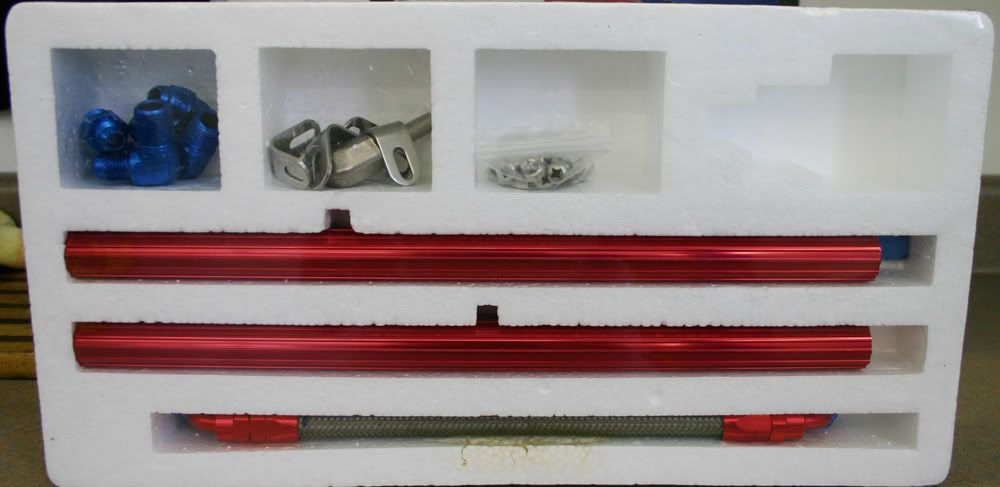

Some research showed that to make my existing fuel lines work, I would need to change the fuel rail. One is on the way.

I got a lot done today.

www.jerryforthofer.wordpress.com

They did!! Based on a discussion with Billet Specialties, I was pretty sure my AC lines would fit. The PS lines were more of a question mark. The reality was that they fit perfectly. Major victory here. The remote reservoir and the lines fit exactly as they did on the old motor.

One of the key features I really like on the Billet Specialties front runner is the AC manifold that places the hookup for the lines near the bottom of the compressor. Because of this, you do not have the lines conspicuously placed on the top of the motor. This allowed me to run my AC and heater hose lines above the inner fender liner under the fender to keep the engine bay clear. The lines fit as I guessed they would.

Because the heater hose hookup location is quite a bit different, I had to cut off about 6" of each line to make them work. Even cleaner installation here than on the old motor where the hookups were on top of the water pump.

I also re-installed the radiator overflow tank and line.

Some research showed that to make my existing fuel lines work, I would need to change the fuel rail. One is on the way.

I got a lot done today.

www.jerryforthofer.wordpress.com

#9

The photo above says it all for recent activity. Some other things had to be done so no car work for a few days. As of the last post, I was waiting for the new fuel rails. Not here yet.

I did get the spacer for the throttle body, but, while it did solve the clearance problem with the compressor, on the other end the filter sat exactly where I needed to put the radiator hose. In searching for an answer to this problem, I discovered that I will need a different radiator. The LS radiator hose sizes are different from the SBC. I have a Griffin radiator coming that has both of the hose hookups on the passenger side. It also has provisions hooking up the steam release hose.

The downside is that all of these hookups preclude any intake going to the passenger side. I have had to give up on the twin snorkel. I was at Autozone and found a very small filter. I did mount it, but I am afraid it will not flow enough air.

Plus, according to my son, the MAF works best when the air has some distance to flow into the throttle body after the MAF. I have a K & N intake designed for late model GTO's on the way.

The car is going to Kooks Custom Headers in Statesville, NC on June 27th. So I have been getting the car ready to be transported by securing the wires and installing the Z-bar. I am still waiting for the Z-Bar ball adapter that mounts to the bellhousing. It has been over 8 weeks. The guy says he has 12 people waiting for them. Their supplier keeps telling them they will be shipped but, as of today, still no adapter.

I sold my old clutch to a guy in south Charlotte. He asked if I had anything else and I mentioned that I had removed the Competition Engineering Slide-a-Link traction bars. He is a drag racer and was interested in them. I told him that the rear mounts that doubled as the lower spring plate and shock mount were still on the car. He said he had a set of stock plates which he sent to me.

The traction bar plates had the left rear shock mounted inside the spring. It was in kind of a strange position and rubbed on the exhaust. The stock plates place both shocks outside the spring. I mounted the right plate first and everything bolted in place as it should.

When I tried to mount the left plate, I had interference problems with the brake caliper. I assume this was because the car did not originally have rear disc brakes. I had to do some custom work on that piece to make it work. I am glad I did this before they fit the exhaust as the location of that left shock was strange.

I also installed a set of Koni shocks. I have used Koni's for years and prefer them to other shocks. One advantage to these shocks compared the Bilsteins that I removed is that they are not as big around. I needed that extra clearance on the left side to clear the brake line. It will be interesting to see if there is any difference in the shocks as well as having the shock back in its stock location.

I cleaned up the car today and it is ready to get some headers and exhaust next week. They will have the car for 2-3 weeks so I will have some time to do some other projects around the house.

www.jerryforthofer.wordpress.com

#10

Took the car to Kooks Custom Headers today. They had me meet with some of the techs to go over how the exhaust system was to be installed. Very nice people. They had a number of interesting cars in their work bay. Everything from drag cars to street rods to SCCA race cars. Clint Boyer's '69 Camaro was there for an exhaust.

They asked if I had brought a car cover. Hadn't thought of that so, after driving home and helping my buddy unhook his trailer, I drove back with the car cover. I ended up in the sales manager's office talking about the car. We were discussing the exit for the exhaust and I told him I wanted it like my old exhaust where it exited straight down inside the rear fender areas. We went to my blog so he could see what the rear end looked like with my old exhaust.

I was also telling him about my thread on Nasty Z28 about the LS1 install. As he was scrolling down the photos, he came to the picture of the K & N intake in one of the posts above. "That's ugly" he said and I told him I felt the same but was having a difficult time coming up with something that will work. "Hell, let's build one for you!!" was his next comment. We then went out to the car, he grabbed some 3 1/2" pipe and we talked about how it should fit. He had one of his fabricators come over, talked to him a bit, and we had a plan. I am riding my motorcycle over there in the morning to take him the cone filter and the connectors. It will be polished stainless steel!! Should be pretty cool!!

By the way, this is George's, the sales manager, car.

www.jerryforthofer.wordpress.com

They asked if I had brought a car cover. Hadn't thought of that so, after driving home and helping my buddy unhook his trailer, I drove back with the car cover. I ended up in the sales manager's office talking about the car. We were discussing the exit for the exhaust and I told him I wanted it like my old exhaust where it exited straight down inside the rear fender areas. We went to my blog so he could see what the rear end looked like with my old exhaust.

I was also telling him about my thread on Nasty Z28 about the LS1 install. As he was scrolling down the photos, he came to the picture of the K & N intake in one of the posts above. "That's ugly" he said and I told him I felt the same but was having a difficult time coming up with something that will work. "Hell, let's build one for you!!" was his next comment. We then went out to the car, he grabbed some 3 1/2" pipe and we talked about how it should fit. He had one of his fabricators come over, talked to him a bit, and we had a plan. I am riding my motorcycle over there in the morning to take him the cone filter and the connectors. It will be polished stainless steel!! Should be pretty cool!!

By the way, this is George's, the sales manager, car.

www.jerryforthofer.wordpress.com

#11

Recently I received the billet fuel rails from Professional Products. The price was reasonable, but, unfortunately, they only come in red with red and blue fittings. I am considering using my buddy's bead blaster to take them back to their natural aluminum finish.

My buddy also mentioned powdercoating them black.

Any opinions?

www.jerryforthofer.wordpress.com

My buddy also mentioned powdercoating them black.

Any opinions?

www.jerryforthofer.wordpress.com

#13

It had the carbon fiber finish when I bought it. You can get it done on ebay at: http://cgi.ebay.com/ebaymotors/LS1-L...fAudioQ5fVideo

They charge $175.

#14

TECH Enthusiast

iTrader: (4)

Thanks.

It had the carbon fiber finish when I bought it. You can get it done on ebay at: http://cgi.ebay.com/ebaymotors/LS1-L...fAudioQ5fVideo

They charge $175.

It had the carbon fiber finish when I bought it. You can get it done on ebay at: http://cgi.ebay.com/ebaymotors/LS1-L...fAudioQ5fVideo

They charge $175.

I had a 74 and a 76 they were great cars.

#15

#16

Launching!

Join Date: Jun 2009

Location: The Woodlands,Texas/New Orleans

Posts: 299

Likes: 0

Received 1 Like

on

1 Post

My SBC had a problem. Ever since I owned the car, I have said that if the SB came out, a LS motor was going back in. I found a '99 LS1 out of a Firebird with 32K miles about a month ago. I have been stripping down the old motor and selling off the parts. So far I have collected nearly $6k from old motor parts which goes a long way towards paying for the LS swap.

I had a Billet Specialties front runner on the old motor and really liked it so I bought the LS front runner from them. It cost more that what I paid for the motor!!! However, I really like the way it looks and, if I am lucky, I may be able to use my existing AC and power steering lines. The compressor and the PS pump are placed in very similar positions.

http://i188.photobucket.com/albums/z...rontrunner.jpg

I also have a set of Billet Coil Covers from Taylor Industries. They are for Gen IV Camaro's and Firebirds. They are beautifully made from billet and then polished. The only problem is that the passenger side is about 1 1/2" shorter than the driver's side which leaves the last coil exposed. There is evidently an obstruction on the Gen IV F bodies which is why they make them this way. I have talked to them about making a full length passenger side cover and they are considering it. I told them they should market a set for swap situations like mine where there are no obstructions. There are tons of us in this same situation.

In doing some reading, I found that the LS6 intake and throttle body flows better than the LS1. In doing a search, I found the LS6 manifold below that had a Carbon Fiber look done to it. It should look good and work well on the motor.

http://i188.photobucket.com/albums/z...berintake2.jpg

http://i188.photobucket.com/albums/z...iberintake.jpg

At this point, I am planning on a twin snorkel air intake. I bought one designed for C5 Vettes. I feel pretty confident it will work but won't know for sure until the motor is in the engine bay. Speaking of which, I am having the guy who painted my car clean up the engine bay and plan on smoothing the firewall.

I found some adjustable engine adapters by Dirty Dingo that will allow me to use my exising clamshell and engine mounts. I can move the engine 2 1/2" front to rear which should allow me to place my Richmond 6 speed in the same location and use my exising crossmember. Assuming all that works, I should be able to use the existing drive shaft.

I have an aluminum bellhousing from Keisler coming which will allow me to mate the Richmond with the engine. I also have an adapter coming so I can hook up my Z bar for the clutch.

I had the wiring harness modified and a tune put to the computer. It appears the computer will fit in my glove box. I cut a hole today in the glove box and test fitted it. It will be tight with the plugs installed but it looks like it will work.

Lots to do but it should be nice when done.

www.jerryforthofer.wordpress.com

I had a Billet Specialties front runner on the old motor and really liked it so I bought the LS front runner from them. It cost more that what I paid for the motor!!! However, I really like the way it looks and, if I am lucky, I may be able to use my existing AC and power steering lines. The compressor and the PS pump are placed in very similar positions.

http://i188.photobucket.com/albums/z...rontrunner.jpg

I also have a set of Billet Coil Covers from Taylor Industries. They are for Gen IV Camaro's and Firebirds. They are beautifully made from billet and then polished. The only problem is that the passenger side is about 1 1/2" shorter than the driver's side which leaves the last coil exposed. There is evidently an obstruction on the Gen IV F bodies which is why they make them this way. I have talked to them about making a full length passenger side cover and they are considering it. I told them they should market a set for swap situations like mine where there are no obstructions. There are tons of us in this same situation.

In doing some reading, I found that the LS6 intake and throttle body flows better than the LS1. In doing a search, I found the LS6 manifold below that had a Carbon Fiber look done to it. It should look good and work well on the motor.

http://i188.photobucket.com/albums/z...berintake2.jpg

http://i188.photobucket.com/albums/z...iberintake.jpg

At this point, I am planning on a twin snorkel air intake. I bought one designed for C5 Vettes. I feel pretty confident it will work but won't know for sure until the motor is in the engine bay. Speaking of which, I am having the guy who painted my car clean up the engine bay and plan on smoothing the firewall.

I found some adjustable engine adapters by Dirty Dingo that will allow me to use my exising clamshell and engine mounts. I can move the engine 2 1/2" front to rear which should allow me to place my Richmond 6 speed in the same location and use my exising crossmember. Assuming all that works, I should be able to use the existing drive shaft.

I have an aluminum bellhousing from Keisler coming which will allow me to mate the Richmond with the engine. I also have an adapter coming so I can hook up my Z bar for the clutch.

I had the wiring harness modified and a tune put to the computer. It appears the computer will fit in my glove box. I cut a hole today in the glove box and test fitted it. It will be tight with the plugs installed but it looks like it will work.

Lots to do but it should be nice when done.

www.jerryforthofer.wordpress.com

#17

Hopefully, I will get the car back from the exhaust place next week. We have a big car show at the Charlotte Motor Speedway at the end of August and I plan on being there.

#18

Good news today from SD Parts. My pivot ball adapter for my Zbar has finally shipped. I have had this on order for nearly 3 months. SD was having a problem getting them from their supplier. If it didn't come soon, I was going to have to install a hydraulic clutch.

Not so good news on getting the correct radiator. Amazon, by far, had the best price, but they have sent the wrong radiator...twice!! The radiator part number is 8-00019-LS but they have twice sent radiator 8-00019 without the LS. The last one had the correct part number on the box but still had the wrong radiator. In their defense, they have been great to work with but, since they are not car people, it is hard to explain to them why the one I got will not work. I have some time yet so I will give them another chance. The difference in price is over $60.

I drove over to Kooks Custom Headers today. Not a whole lot to report there as their digitizer had been down. They have it repaired, but it has put them behind. I watched their guy entering data on another car. Pretty interesting to watch how they can plot all of the hard points and then design the header around those. It will be another couple weeks before my car is finished.

It was good that I stopped as they did have a question for me. They wanted to know if I was OK with their changing the motor mount adapters. They want to sell a complete swap kit including the motor mount adapters so they are sure their headers will work. They showed me a typical mount in another car. I told them as long as the motor uses the factory mounts, I was OK with this. I also asked them to, if possible, move the tranny towards the rear about 1/2" which would place it in exactly the same location as when it was behind the SBC.

I took a couple photos but had to leave suddenly when I got a somewhat alarming call from my wife. She had not been feeling well when I left, and, when she called, she wasn't very coherent. I immediately called my neighbors who checked on her while I drove the forty minutes to the house.

After calling her doctor and explaining how she had nearly fainted and was nauseous, they recommended taking her to the emergency room. They gave her an electrocardiogram and did a scat scan of her head. As they suspected, she had a severe case of vertigo which, according to the scat scan, was probably caused by the sinusitis they discovered. She was feeling much better by the time we left the emergency room and now has a couple prescriptions that will make her better yet.

Not the way you want to spend an afternoon, but some time you have to do what you have to do. Fortunately, it wasn't very serious but she said, at the height of her attack, it was pretty scary!! Thank God for cell phones.

Not so good news on getting the correct radiator. Amazon, by far, had the best price, but they have sent the wrong radiator...twice!! The radiator part number is 8-00019-LS but they have twice sent radiator 8-00019 without the LS. The last one had the correct part number on the box but still had the wrong radiator. In their defense, they have been great to work with but, since they are not car people, it is hard to explain to them why the one I got will not work. I have some time yet so I will give them another chance. The difference in price is over $60.

I drove over to Kooks Custom Headers today. Not a whole lot to report there as their digitizer had been down. They have it repaired, but it has put them behind. I watched their guy entering data on another car. Pretty interesting to watch how they can plot all of the hard points and then design the header around those. It will be another couple weeks before my car is finished.

It was good that I stopped as they did have a question for me. They wanted to know if I was OK with their changing the motor mount adapters. They want to sell a complete swap kit including the motor mount adapters so they are sure their headers will work. They showed me a typical mount in another car. I told them as long as the motor uses the factory mounts, I was OK with this. I also asked them to, if possible, move the tranny towards the rear about 1/2" which would place it in exactly the same location as when it was behind the SBC.

I took a couple photos but had to leave suddenly when I got a somewhat alarming call from my wife. She had not been feeling well when I left, and, when she called, she wasn't very coherent. I immediately called my neighbors who checked on her while I drove the forty minutes to the house.

After calling her doctor and explaining how she had nearly fainted and was nauseous, they recommended taking her to the emergency room. They gave her an electrocardiogram and did a scat scan of her head. As they suspected, she had a severe case of vertigo which, according to the scat scan, was probably caused by the sinusitis they discovered. She was feeling much better by the time we left the emergency room and now has a couple prescriptions that will make her better yet.

Not the way you want to spend an afternoon, but some time you have to do what you have to do. Fortunately, it wasn't very serious but she said, at the height of her attack, it was pretty scary!! Thank God for cell phones.

#19

My buddy and I took another motorcycle ride to Kooks today. We saw the guy welding my headers on the bench. They also still had the reference point attached to the front crossmember for the digitizer. I also took a photo of their mailbox!! Pretty slick!!

If all goes well, I should have the car back this week.

If all goes well, I should have the car back this week.