After seeing this several times, I thought I would raise awareness

#1

11 Second Club

Thread Starter

iTrader: (11)

Join Date: Jul 2007

Location: Kentucky

Posts: 316

Likes: 0

Received 0 Likes

on

0 Posts

First off- This is NOT an advertisement in any way shape or form, this is just simply to raise awareness about somethings that are happening in the lsx conversion aftermarket community these days.

I have re-wired several harnesses, and from time to time I get calls from guys wanting me to look at the stand alone harness that someone either done for them, or that came with their vehicle. Some of the things that I have found are nothing less than shocking. This thread was inspired by my most recent inspection. Keep in mind someone done this harness for a 1960 Corvette. It is beyond me why someone would skimp on something as important as the engine harness.

I see a lot of advice around here that ends in "Its always worked for me" and other statements like that. When it comes to your engine harness you should NEVER cut any corners, this can lead to gremlins later down the road that will be a NIGHTMARE to troubleshoot. This thread may be long and full of pictures, this will be because I will show a picture of what the shortfalls of this harness were, and what it should have looked like if done correctly.

Here is a picture of the harness I was sent. This first picture is a before picture, the second is an AFTER picture

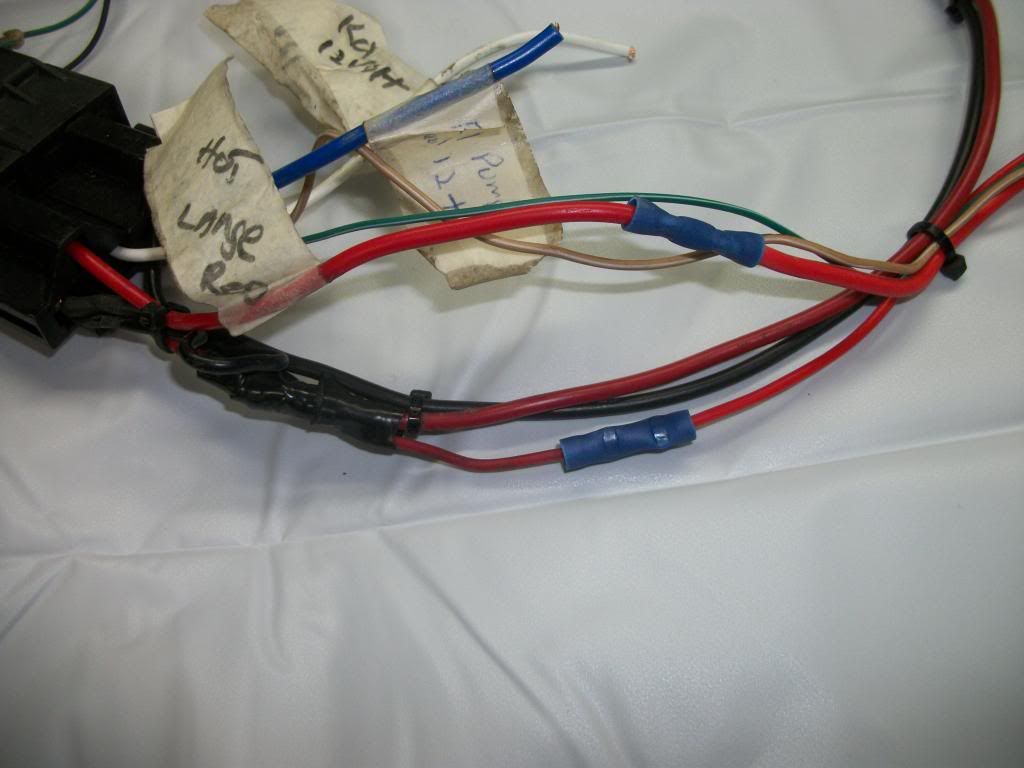

As Im sure you noticed, the harness had plenty of electrical tape on it. Which at normal engine operating temperatures will become gooey and fall off. In the next picture you will find how all of the solder joints (if you could call them that) were just simply taped with electrical tape.

Here is what it could have looked like with adhesive lined heat shrink

As you can see in the picture that Automotive Primary Wire was used, which melts under high temperature. TXL wire is the high temp wire that should be used.

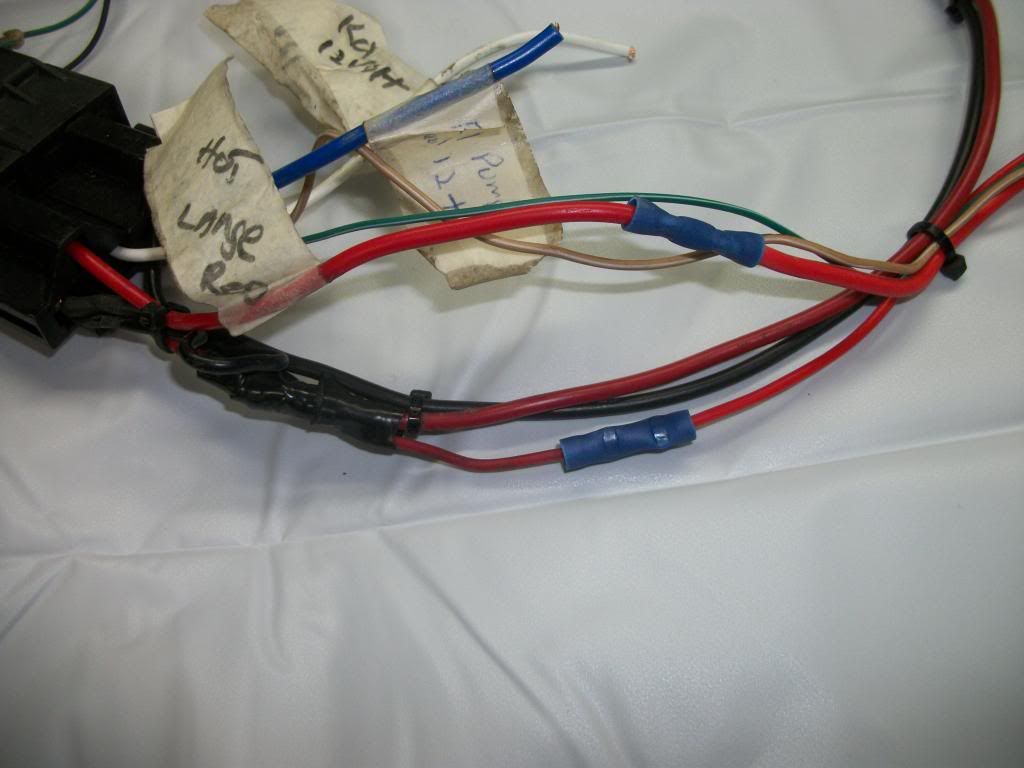

Cheap relay connectors with undersized wire. Cheap China made relays. Unsealed butt connectors.

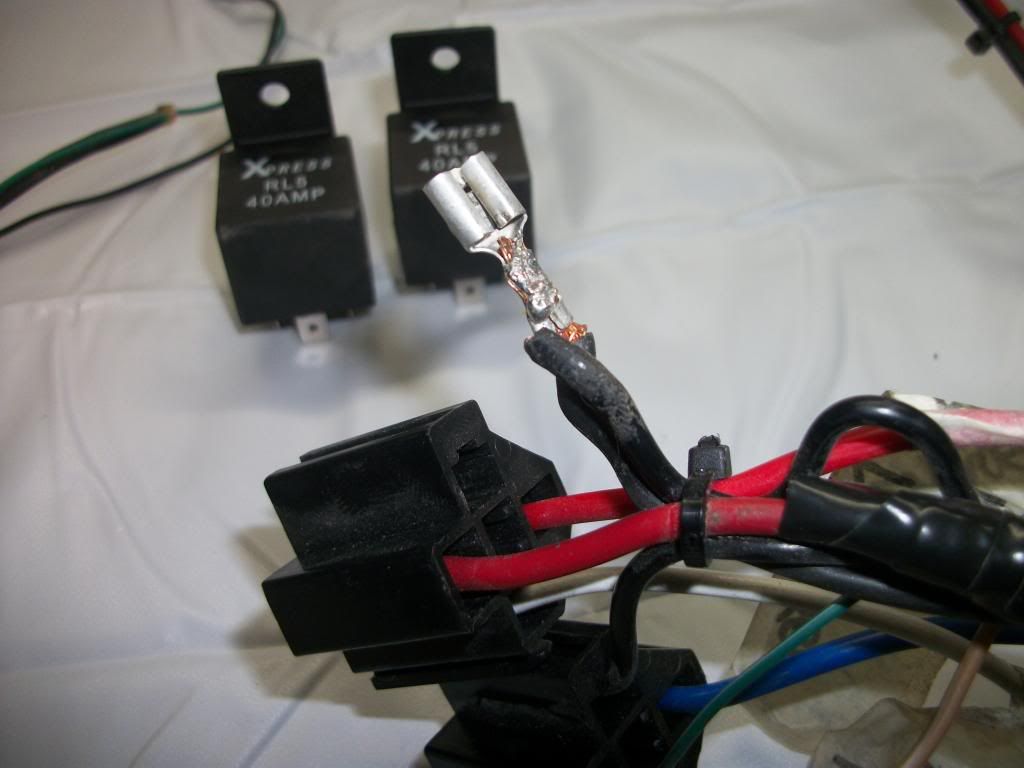

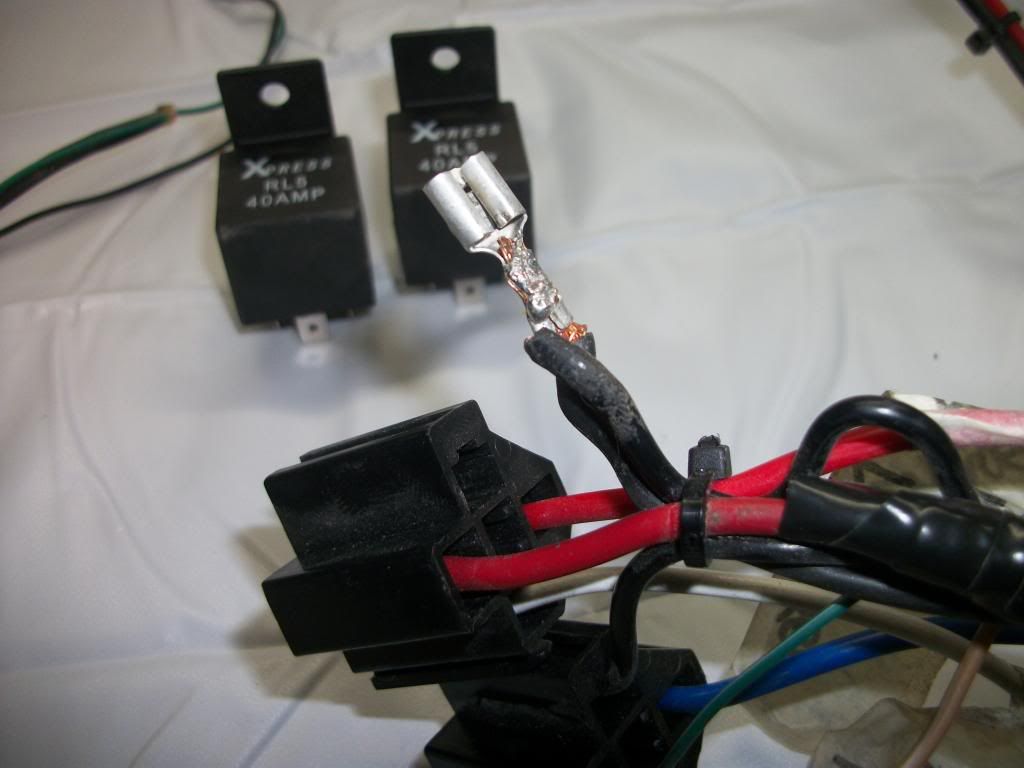

Then I decided to de-pin one of the terminals on the relay connector to inspect the crimp. This is what I found. At least they made an attempt at soldering the connection.

This is what it should have looked like

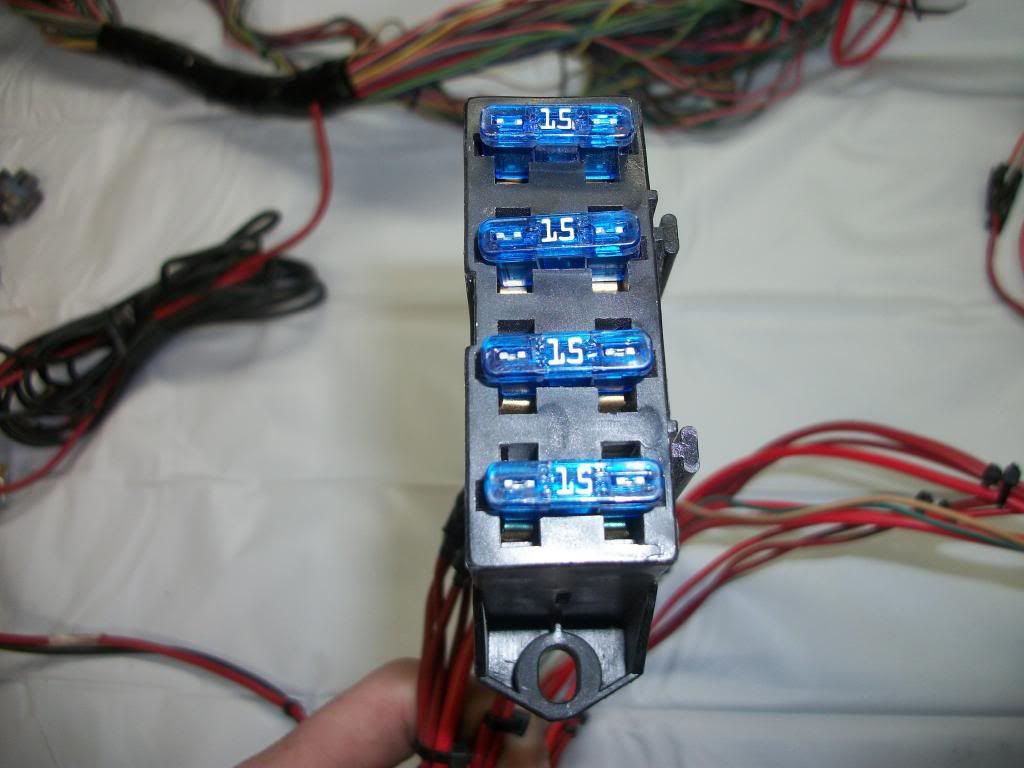

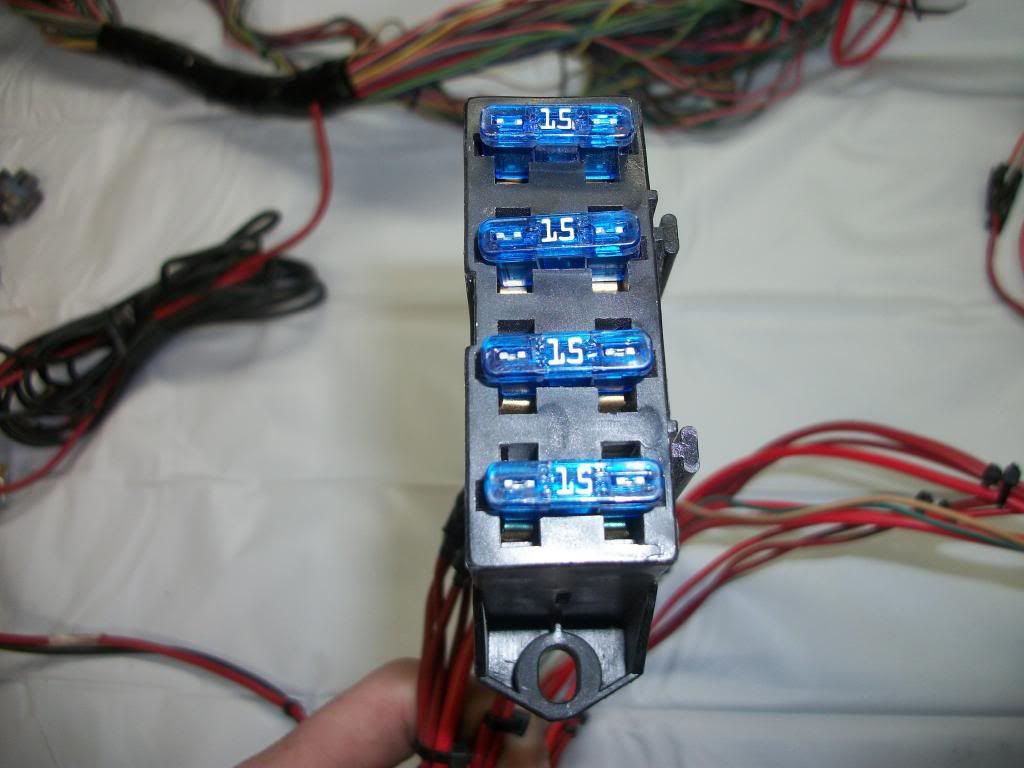

15 Amp Fuse Fits all circuits!! The ignition circuits weren't even separated correctly. I.E. Bank 1, Bank 2, Sensor.....

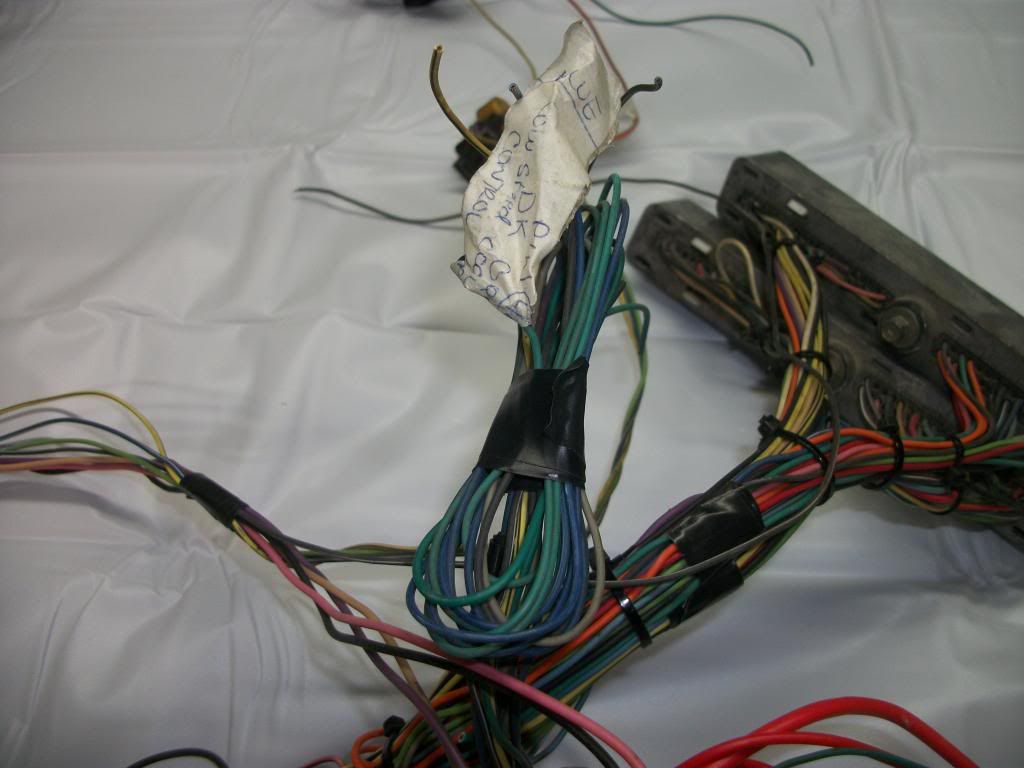

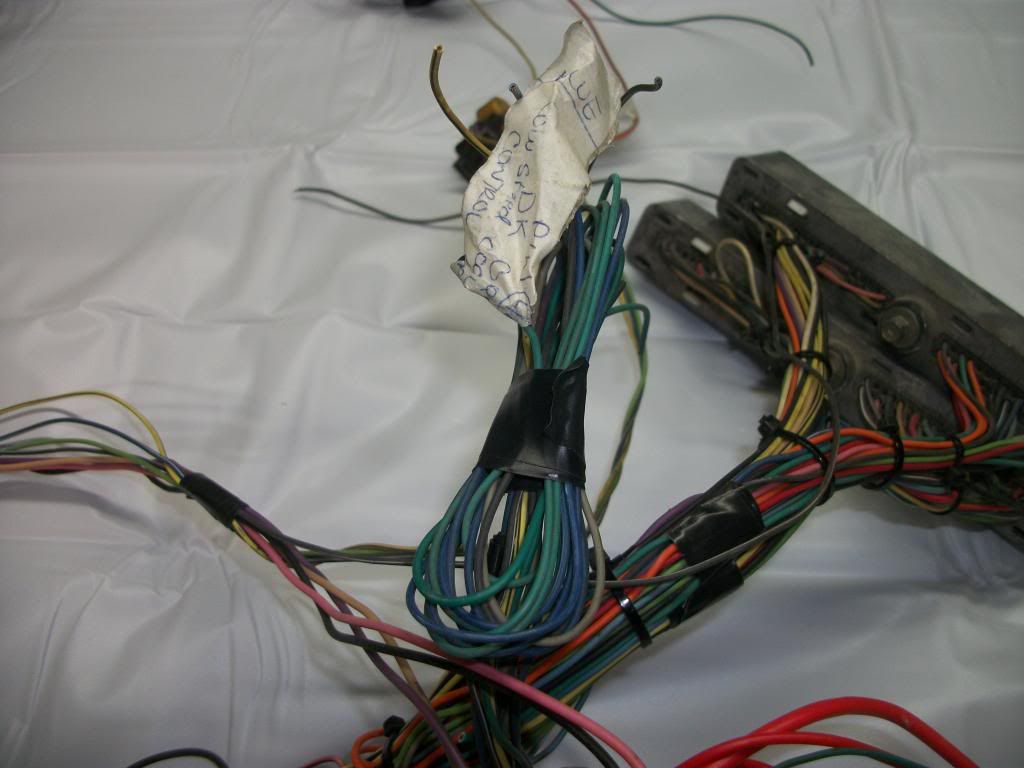

Dash Wiring

I have re-wired several harnesses, and from time to time I get calls from guys wanting me to look at the stand alone harness that someone either done for them, or that came with their vehicle. Some of the things that I have found are nothing less than shocking. This thread was inspired by my most recent inspection. Keep in mind someone done this harness for a 1960 Corvette. It is beyond me why someone would skimp on something as important as the engine harness.

I see a lot of advice around here that ends in "Its always worked for me" and other statements like that. When it comes to your engine harness you should NEVER cut any corners, this can lead to gremlins later down the road that will be a NIGHTMARE to troubleshoot. This thread may be long and full of pictures, this will be because I will show a picture of what the shortfalls of this harness were, and what it should have looked like if done correctly.

Here is a picture of the harness I was sent. This first picture is a before picture, the second is an AFTER picture

As Im sure you noticed, the harness had plenty of electrical tape on it. Which at normal engine operating temperatures will become gooey and fall off. In the next picture you will find how all of the solder joints (if you could call them that) were just simply taped with electrical tape.

Here is what it could have looked like with adhesive lined heat shrink

As you can see in the picture that Automotive Primary Wire was used, which melts under high temperature. TXL wire is the high temp wire that should be used.

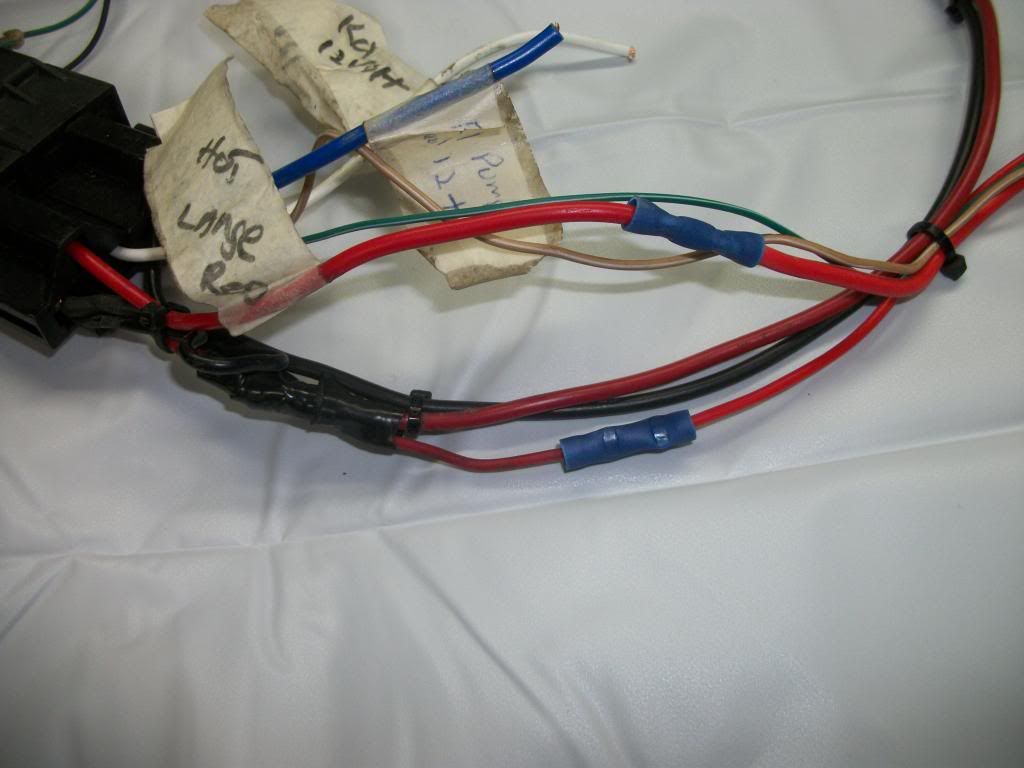

Cheap relay connectors with undersized wire. Cheap China made relays. Unsealed butt connectors.

Then I decided to de-pin one of the terminals on the relay connector to inspect the crimp. This is what I found. At least they made an attempt at soldering the connection.

This is what it should have looked like

15 Amp Fuse Fits all circuits!! The ignition circuits weren't even separated correctly. I.E. Bank 1, Bank 2, Sensor.....

Dash Wiring

#2

11 Second Club

Thread Starter

iTrader: (11)

Join Date: Jul 2007

Location: Kentucky

Posts: 316

Likes: 0

Received 0 Likes

on

0 Posts

It was partially labeled, although you couldn't read some of the handwriting on the masking tape.

Could have been labeled like this

As I said before, this is not an advertisement in any way. I have just become amazed at the work I am seeing, our hard earned money demands more than what we see here. In the end, and old saying really has faded from society today. "If its worth doing, its worth doing right."

If you are paying someone to do your harness, or you are doing you own you should expect nothing but the best-especially from yourself. I hear people saying butt connectors work fine, but soldering is by far better. Why settle for work fine? If small things like that were fine you would find that in OEM harnesses. However, you will NOT find a single butt connector in a GM harness.

I know it was a LONG read- but I had to hop on the soap box before I exploded.

Last edited by green96ta; 11-24-2012 at 11:13 PM.

#7

11 Second Club

Thread Starter

iTrader: (11)

Join Date: Jul 2007

Location: Kentucky

Posts: 316

Likes: 0

Received 0 Likes

on

0 Posts

I sell on ebay, and my re-wire price for even the best kit that I sell which comes with everything imaginable is less than $400

- Ignition Power Relay

- Starter Relay

- Fuel Pump Relay

- A/C Compressor Relay

- A/C Fan Relay (forces a fan on when A/C is active

- Two Fan Relays

- 12 way fuse block

- Covers Labeled for easy id.

Here is a picture of the Convenience center I build and use, 100% brand new.

I have no idea how anyone would thing that the work they done on that harness was worth $400. He is still selling on EBAY too.....Looks like he changed some things up and lowered his price some.

Last edited by green96ta; 11-27-2012 at 09:19 PM.

Trending Topics

#9

11 Second Club

Thread Starter

iTrader: (11)

Join Date: Jul 2007

Location: Kentucky

Posts: 316

Likes: 0

Received 0 Likes

on

0 Posts

https://ls1tech.com/forums/lt1-lt4-m...onversion.html

as for the attention to detail you mentioned, that is something that the Marine Corps. beat into me, lol.

#10

Bill did my harness, I Will have pics up as soon as it gets here. After speaking with him and seeing his work, there is simply no reason to have anyone else do it. This is the most important part of my swap and well worth the money for the effort and customer service bill provides. He also flashes the emissions out of the computer as well. It's a one stop deal

#12

TECH Fanatic

iTrader: (2)

Man that is nice work, I hope to do mine just as nice as you did and not get frustrated and say F it and make it ugly but works attitude. I have quite a few truck harnesses and one fbody. I'd like to have a harness ready to run to check a swap/setup and then the final for the vehicle. Do you think that's a good idea? Making a harness to just get it running and make sure all works then you take it off and put your final harness for the vehicle?

#13

There was one post on here where a guy rewired an entire car with the same spool of red wire. Every single wire was the same gauge of red wire. FWIW he otherwise seemed to do a good job.

When I tried to suggest what he did was a nightmare in the making, his reply was something along the lines of the circuit doesn't care what color the wire is. I gave up trying to make him understand that was exactly the problem.

By the way, I am pretty sure those Omron relays are made in China. No getting away from it these days.

When I tried to suggest what he did was a nightmare in the making, his reply was something along the lines of the circuit doesn't care what color the wire is. I gave up trying to make him understand that was exactly the problem.

By the way, I am pretty sure those Omron relays are made in China. No getting away from it these days.

#14

11 Second Club

Thread Starter

iTrader: (11)

Join Date: Jul 2007

Location: Kentucky

Posts: 316

Likes: 0

Received 0 Likes

on

0 Posts

Man that is nice work, I hope to do mine just as nice as you did and not get frustrated and say F it and make it ugly but works attitude. I have quite a few truck harnesses and one fbody. I'd like to have a harness ready to run to check a swap/setup and then the final for the vehicle. Do you think that's a good idea? Making a harness to just get it running and make sure all works then you take it off and put your final harness for the vehicle?

There was one post on here where a guy rewired an entire car with the same spool of red wire. Every single wire was the same gauge of red wire. FWIW he otherwise seemed to do a good job.

When I tried to suggest what he did was a nightmare in the making, his reply was something along the lines of the circuit doesn't care what color the wire is. I gave up trying to make him understand that was exactly the problem.

By the way, I am pretty sure those Omron relays are made in China. No getting away from it these days.

When I tried to suggest what he did was a nightmare in the making, his reply was something along the lines of the circuit doesn't care what color the wire is. I gave up trying to make him understand that was exactly the problem.

By the way, I am pretty sure those Omron relays are made in China. No getting away from it these days.

The big Omron relays are made in America, the smaller ones are assembled in China, like that makes any sense. I bought them in bulk and when the mini relays run out I will probably move to another brand that is made and assembled here in America.

#15

as judging by the fuse block style, the style of crimps, and relay/connectors that is straight from LT1 swap. The parts work great (when used correctly), but I think I see a 14ga wire for batter power .. yikes.

#18

On The Tree

iTrader: (11)

Join Date: Aug 2012

Location: Chicago, IL

Posts: 187

Likes: 0

Received 0 Likes

on

0 Posts

Nice work....I had issues on previous vehicles with shitty harnesses that were made by "reputable" sellers. They used smaller then stock gauge wire that was all the same green color....cough* boomslang cough*.....it was a nightmare. I had issues with voltage drop, the pins began to fall apart and break they were so thin, etc. I ended up having a forum member such as yourself make me one that was of exceptional quality such as the work you have done here.

#19

11 Second Club

Thread Starter

iTrader: (11)

Join Date: Jul 2007

Location: Kentucky

Posts: 316

Likes: 0

Received 0 Likes

on

0 Posts

Nice work....I had issues on previous vehicles with shitty harnesses that were made by "reputable" sellers. They used smaller then stock gauge wire that was all the same green color....cough* boomslang cough*.....it was a nightmare. I had issues with voltage drop, the pins began to fall apart and break they were so thin, etc. I ended up having a forum member such as yourself make me one that was of exceptional quality such as the work you have done here.

Thanks so much. I hope to be moving from forum member to forum sponsor here soon! Its expensive, but I believe it will be worth it. Just gotta get my website built up a little better!

On everything I do, its the same color code as GM and the wire sizing is the same or bigger in some cases. (fuel pump supply wire) and obviously TXL wire is used.

I also use production crimp tools, not the repair stuff. There are somethings that they dont make production dies for so I have to use a repair crimper and solder the terminal. Most people dont know that even the ratcheting Delphi hand crimpers are just for repair and you are supposed to solder the connection as well as crimp. The production hand frame and dies are the only reliable solderless crimp. Here is a link to the tooling I use, Im am very picky about what has my name on it, so I use the best tools and products I can.

http://www.eficonnection.com/eficonn...spx?ItemId=893

#20

10 Second Club

iTrader: (10)

Nice tutorial on this. I have seen so many swaps that **** away the reliability these new engines have to offer by half assed wiring.

Interesting note on the hand crimpers. I don't have one but I would recommend solder too. There is really no reason not to solder any homebuilt electrical connection.

Interesting note on the hand crimpers. I don't have one but I would recommend solder too. There is really no reason not to solder any homebuilt electrical connection.