Old School LSx 1967 Camaro

#21

More parts...

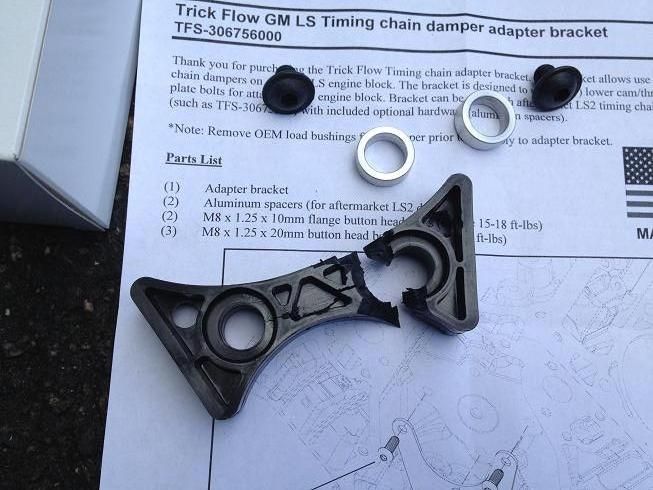

I got a nice shipment from Total Engine Airflow today. I got new timing cover gasket, valve cover gaskets, head gaskets, ARP head bolts, crank bolt, push rods, LS2/7 lifters, ported high volume LS6 oil pump, lifter trays, and the Trick Flow timing chain damper and bracket.

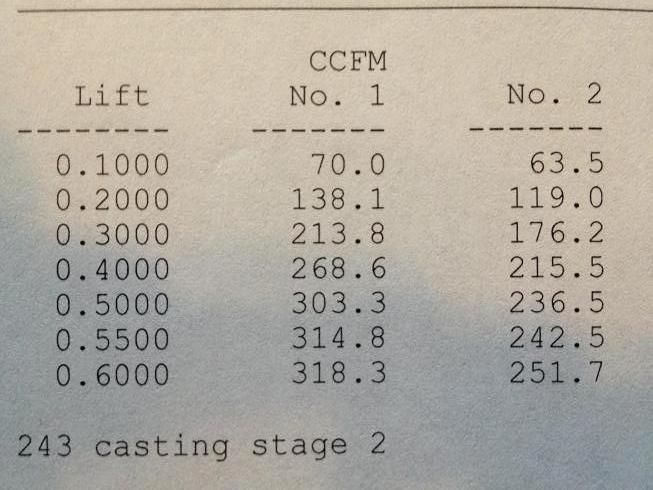

And of course I got my 243 heads back from TEA all cleaned up, ported and polished. I'm heading to Mexico for a week, won't be able to do any assembly until I get back, but I here's some shots before they go on. The new custom cam should arrive from Comp Cams tomorrow and I'll post the specs when I get them.

#22

The progress continues...

I just got back from the Mexico trip, plane got delayed then cxl'd, slept on the airport floor for about an hour. I ended up getting home a day late, so Saturday was a wash.

I was hoping to install the new cam and heads, but my new timing chain set didn't arrive, so I couldn't do much. I finished cleaning the firewall and wheel wells and painting them. No pics yet. The new timing set should be here tomorrow.

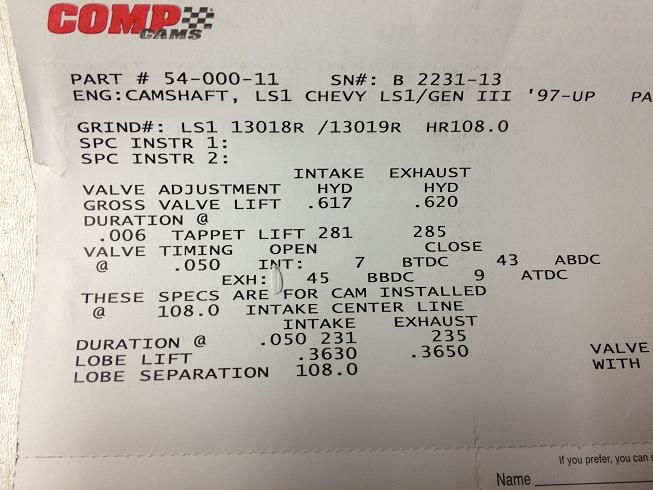

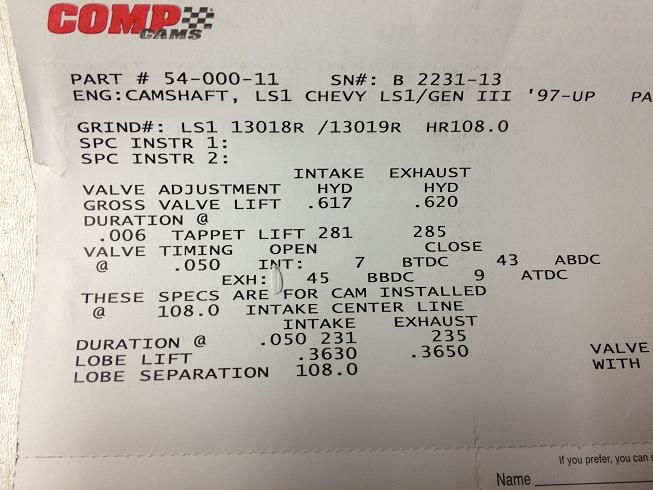

My new camshaft arrived from Comp Cams and I'm including a photo of the cam card. This should take full advantage of the newly ported heads and .650 lift springs. It should also have a nice lump to it. It's a custom grind, and I went with a 108 LSA due to the intake choice.

231/235 @.050 with .617/.620 lift on a 108 LSA.

I was hoping to install the new cam and heads, but my new timing chain set didn't arrive, so I couldn't do much. I finished cleaning the firewall and wheel wells and painting them. No pics yet. The new timing set should be here tomorrow.

My new camshaft arrived from Comp Cams and I'm including a photo of the cam card. This should take full advantage of the newly ported heads and .650 lift springs. It should also have a nice lump to it. It's a custom grind, and I went with a 108 LSA due to the intake choice.

231/235 @.050 with .617/.620 lift on a 108 LSA.

Well, I got my new timing chain set, and I thought I was going to install the new cam/timing chain/oil pump/heads/pushrods/lifters,etc, but as I was starting to tear down the engine I realized that I never ordered a new cam retaining plate. The retaining plate has a gasket on the back of it and if it goes bad, you lose oil pressure. I found out you can't just pick up a new gasket at the dealership, so I'll be waiting until that arrives to carry on. I'd rather not have to tear down the engine over not installing a new $18 part.

Anyways, I finished cleaning up and re-assembling the engine bay. And I degreased and painted the valve covers, valley cover and re-painted the timing chain cover as well since I chipped the edges taking it off.

Here's what the valve covers looked like when I got them:

and here it is with a fresh coat of paint:

Anyways, I finished cleaning up and re-assembling the engine bay. And I degreased and painted the valve covers, valley cover and re-painted the timing chain cover as well since I chipped the edges taking it off.

Here's what the valve covers looked like when I got them:

and here it is with a fresh coat of paint:

I made a little more progress. If my new cam retainer plate arrives by the weekend, then the new cam, timing chain, oil pump and heads are going on. Today I pulled the old heads, cleaned up the old head gasket and cleaned the pistons. I used brake cleaner and a soft bristled cup brush on my dremel, and they came out nice and clean. I taped everything off so I wouldn't end up with any debris in the engine. The flat top pistons confirm that this is an LQ9 motor. The LQ4 would have had dished pistons and lower compression.

And I forgot I put this bolt in when I was removing the crankshaft bolt last time. I put it there so the bolt would catch on the engine stand and allow me to loosen the crank bolt. Well, when I went to turn over the engine to clean the pistons, I got about a half revolution and the motor felt like it was seized. I backed it off and tried again and had the same result. I went into panic mode for a second, but remembered it turned over fine a few months ago. Well, long story short, the bolt was still there and doing exactly what it was supposed to do. Doh!:o

And I forgot I put this bolt in when I was removing the crankshaft bolt last time. I put it there so the bolt would catch on the engine stand and allow me to loosen the crank bolt. Well, when I went to turn over the engine to clean the pistons, I got about a half revolution and the motor felt like it was seized. I backed it off and tried again and had the same result. I went into panic mode for a second, but remembered it turned over fine a few months ago. Well, long story short, the bolt was still there and doing exactly what it was supposed to do. Doh!:o

#23

Hydraulic clutch conversion...

Another package arrived today, this one's from Jegs. This is the 1967-1969 Hydraulic Clutch Conversion Package from McLeod Racing (and Wilwood). Part # 1434002: http://www.mcleodracing.com/info/?id=5514. It's a complete kit to convert from a mechanical to a hydraulic clutch for our cars (master cylinder, reservoir, bracket, bolts, hydraulic line, hose, clamps, etc.)

Here's where I started:

The Wilwood brake master cylider had to come off, and since it's pretty tight under the dash, I pulled the steering column as well:

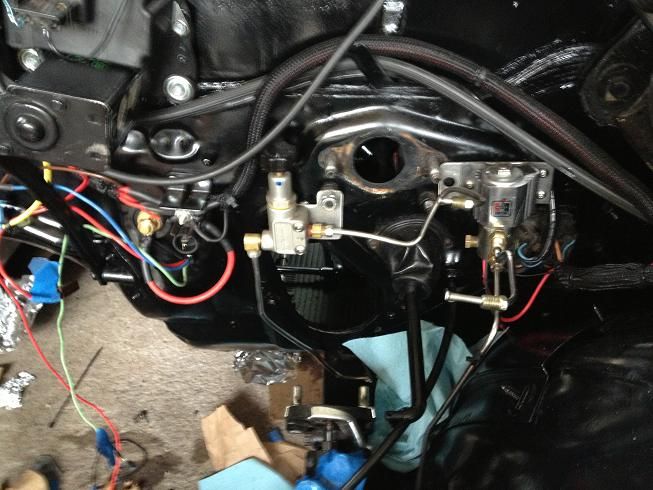

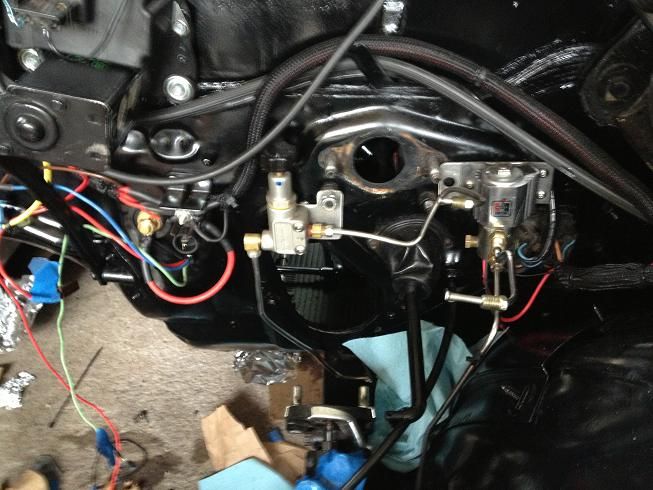

I moved the Wilwood proportioning valve and Hurst Roll Control out of the way. Then I attached the clutch MC to the supplied bracket and mounted it to the firewall:

Everything's back together. I'll put the steering column back in tomorrow. I was getting thirsty...:beers:

Here's where I started:

The Wilwood brake master cylider had to come off, and since it's pretty tight under the dash, I pulled the steering column as well:

I moved the Wilwood proportioning valve and Hurst Roll Control out of the way. Then I attached the clutch MC to the supplied bracket and mounted it to the firewall:

Everything's back together. I'll put the steering column back in tomorrow. I was getting thirsty...:beers:

#24

Cam Swap...

Finally 10 days after I ordered my replacement cam retainer plate, it arrived from gmpartsdirect.com. I don't think I'll use these guys again, I found a lot of bad reviews after ordering from them. Anyways, now I can start the cam swap.

Here's the cam retainer plate and bolts. The new plate has recessed bolts, so the old ones can't be re-used:

Comp Cams custom grind, 231/235 .617"/.621" on a 108 LSA. Should be lumpy.

New cam going in, I used the water pump mounting bolts as a handle:

With the retainer plate:

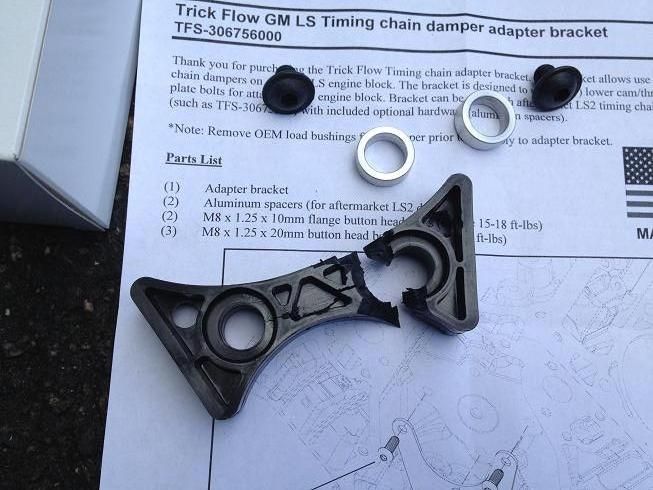

The 6.0 LQ engines don't have any bolt hole provisions for a timing belt tensioner, but the LS2 engines do. I wanted to use an LS2 damper, so I got an adapter bracket and damper from Trick Flow:

The kit requires you to knock out the metal oem load bushings and replace them with newly supplied bushings:

The LS2 damper was very tight going onto the bracket studs, so I used a block of wood and a rubber mallet to gently tap it into place. Just when I thought it seated, I heard a pop and a piece of plastic ricocheted off my leg:

I called Trick Flow and they said the tolerances were extremely tight and while they hadn't had any break, they didn't blame me. I called TEA where I got the damper from, and he's sending a new one out, to be here before the weekend:

Here's the Yank LS2 adjustable timing chain set. They modify a stock timing chain gear, by drilling out where the cam dowel goes and supply a number of inserts to adjust the timing. All the changes are made to the cam gear, and not the crank sprocket. This way if you need to advance or retard the cam, you don't have to remove the oil pump.

Close up of the inserts:

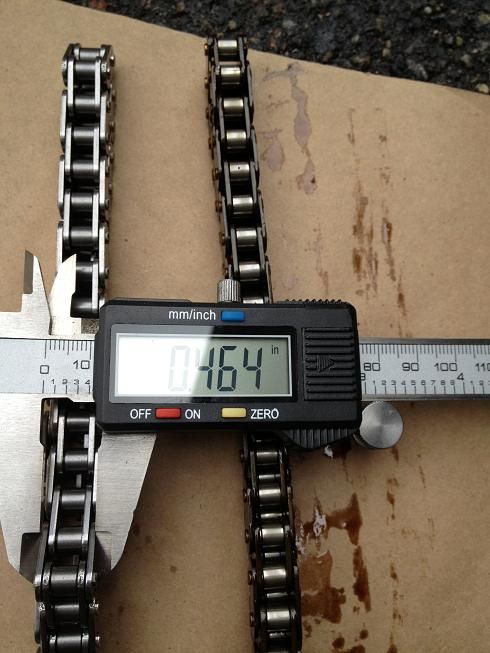

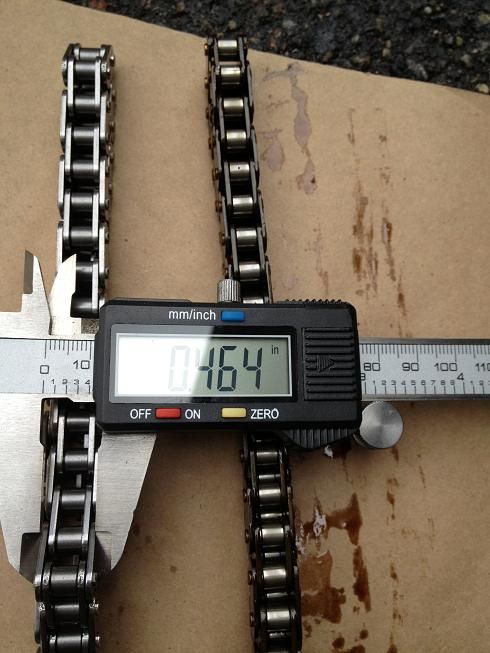

Here's the LS2 chain on the left next to the LS1/LQ9 chain on the right. The LQ9 chain was .433 thick vs the LS2's .464. It's a much stronger chain, without going to a double roller (added mass):

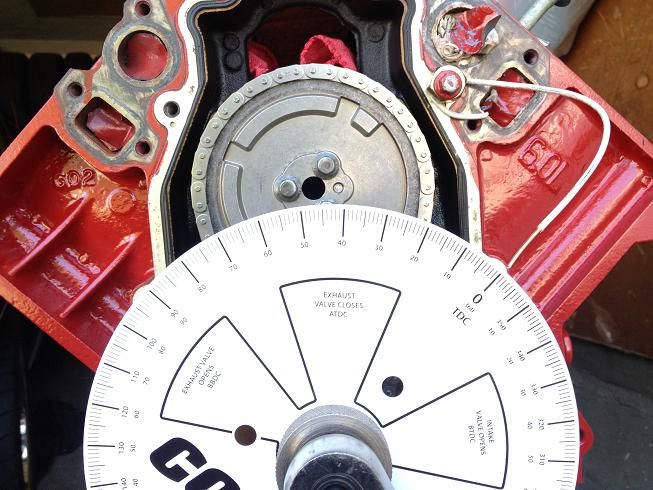

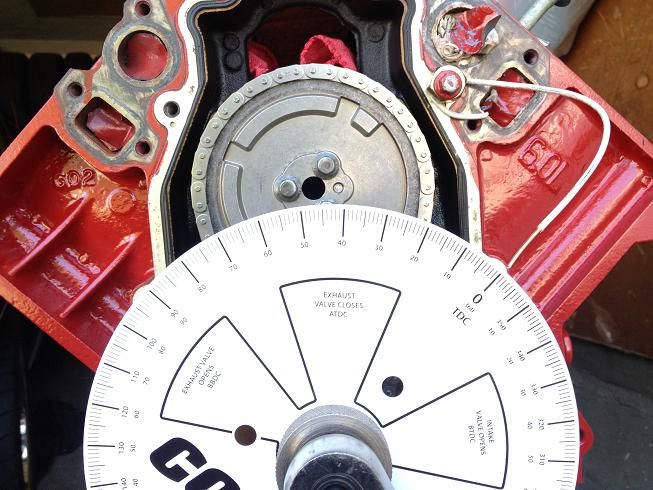

I degreed the cam, and it was within 1 degree of where it was supposed to be, so I'm happy with that:

Here's the cam retainer plate and bolts. The new plate has recessed bolts, so the old ones can't be re-used:

Comp Cams custom grind, 231/235 .617"/.621" on a 108 LSA. Should be lumpy.

New cam going in, I used the water pump mounting bolts as a handle:

With the retainer plate:

The 6.0 LQ engines don't have any bolt hole provisions for a timing belt tensioner, but the LS2 engines do. I wanted to use an LS2 damper, so I got an adapter bracket and damper from Trick Flow:

The kit requires you to knock out the metal oem load bushings and replace them with newly supplied bushings:

The LS2 damper was very tight going onto the bracket studs, so I used a block of wood and a rubber mallet to gently tap it into place. Just when I thought it seated, I heard a pop and a piece of plastic ricocheted off my leg:

I called Trick Flow and they said the tolerances were extremely tight and while they hadn't had any break, they didn't blame me. I called TEA where I got the damper from, and he's sending a new one out, to be here before the weekend:

Here's the Yank LS2 adjustable timing chain set. They modify a stock timing chain gear, by drilling out where the cam dowel goes and supply a number of inserts to adjust the timing. All the changes are made to the cam gear, and not the crank sprocket. This way if you need to advance or retard the cam, you don't have to remove the oil pump.

Close up of the inserts:

Here's the LS2 chain on the left next to the LS1/LQ9 chain on the right. The LQ9 chain was .433 thick vs the LS2's .464. It's a much stronger chain, without going to a double roller (added mass):

I degreed the cam, and it was within 1 degree of where it was supposed to be, so I'm happy with that:

Nice day today, so I cut out of work a little early. I'm hoping that LS2 tensioner arrives by the weekend, so I can really start the re-assembly. I stopped by the local Chevy dealer to see if they had the part in stock, which they didn't, but the closest part is about 40 minutes away. I may make a road trip on Saturday if I don't get the replacement in the mail.

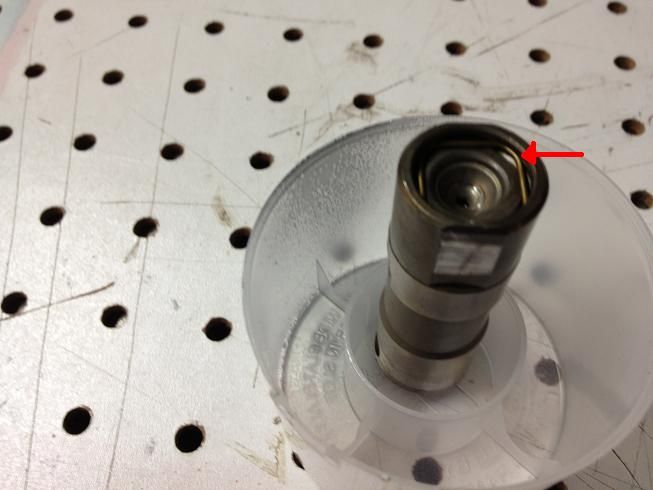

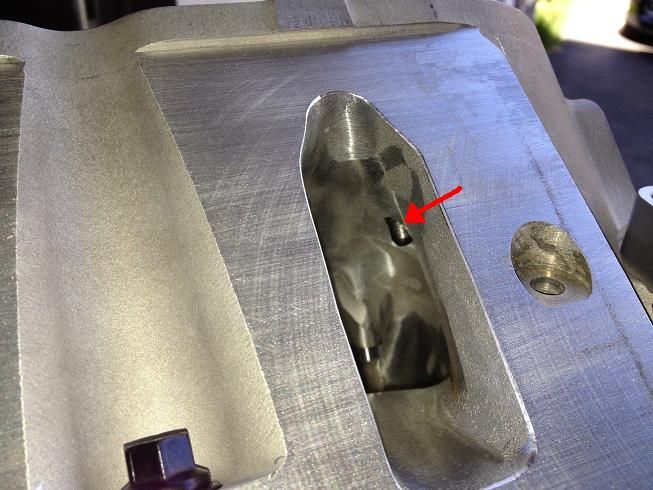

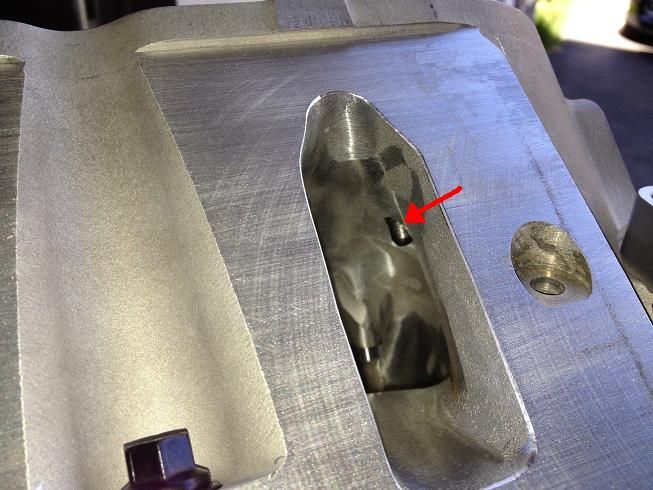

In the meantime, I decided to check my piston to valve (PTV) clearance, since I had the heads milled a little, and I'm running a decent sized cam. I made a couple of solid lifters out of the old LQ9 hydraulic lifters. I just dissasembled them, removed the springs, and then filled them with some QuikSteel epoxy (same as Steel-Stick).

Remove this retaining clip:

Here's what the lifters look like pulled apart:

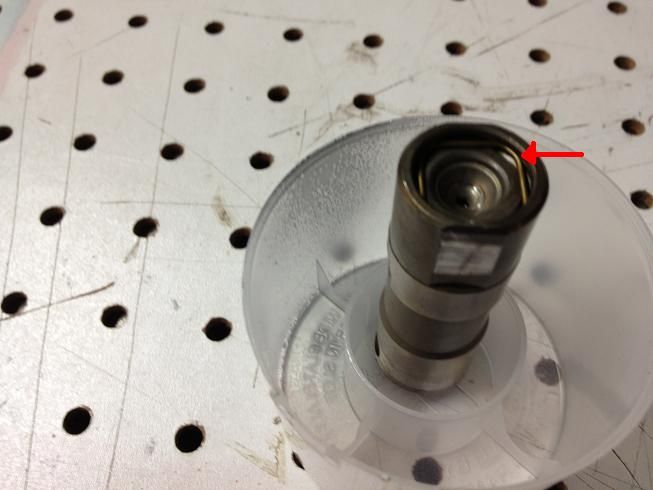

Here they are re-assembled, you can see a little of the steel epoxy by the arrow:

I re-used my old head gaskets for the test, since the new ones are the same thickness. (they look nasty, but I degreased and scrubbed them, and cleaned them with brake cleaner.) And then added a lump of modeling clay to the area where I thought the valves would hit, and rubbed a little oil on the top so it would release from the valve. I had to mix some white and gray clay to get enough for the test. At least I didn't use the bright orange:

Here's one of the new ported TEA 243 heads going on and torqued down to 30 lb/ft for the test:

7.4" pushrods:

I forgot to take a pic with the rocker arms on, but they go on and set to zero lash. Then I rotated the engine over 2 full revolutions and pulled the heads back off:

In the meantime, I decided to check my piston to valve (PTV) clearance, since I had the heads milled a little, and I'm running a decent sized cam. I made a couple of solid lifters out of the old LQ9 hydraulic lifters. I just dissasembled them, removed the springs, and then filled them with some QuikSteel epoxy (same as Steel-Stick).

Remove this retaining clip:

Here's what the lifters look like pulled apart:

Here they are re-assembled, you can see a little of the steel epoxy by the arrow:

I re-used my old head gaskets for the test, since the new ones are the same thickness. (they look nasty, but I degreased and scrubbed them, and cleaned them with brake cleaner.) And then added a lump of modeling clay to the area where I thought the valves would hit, and rubbed a little oil on the top so it would release from the valve. I had to mix some white and gray clay to get enough for the test. At least I didn't use the bright orange:

Here's one of the new ported TEA 243 heads going on and torqued down to 30 lb/ft for the test:

7.4" pushrods:

I forgot to take a pic with the rocker arms on, but they go on and set to zero lash. Then I rotated the engine over 2 full revolutions and pulled the heads back off:

Then I cut the modeling clay half and used a micrometer to measure the thickness at the thinnest point. You want a minimum of .080" on the intake side and .100" on the exhaust side to ensure you won't have any PTV issues. Some people have run as little as .050"-.060" and gotten away with it, but it's a little risky. Too little PTV and you'll have to flycut the pistons or risk piston to valve kiss and the mayhem that ensues. I ordered my cam as large as possible without having to flycut the pistons or having to use a thicker head gasket.

.084 on the intake:

.104 on the exhaust:

I wouldn't want it any tighter.....

.084 on the intake:

.104 on the exhaust:

I wouldn't want it any tighter.....

#25

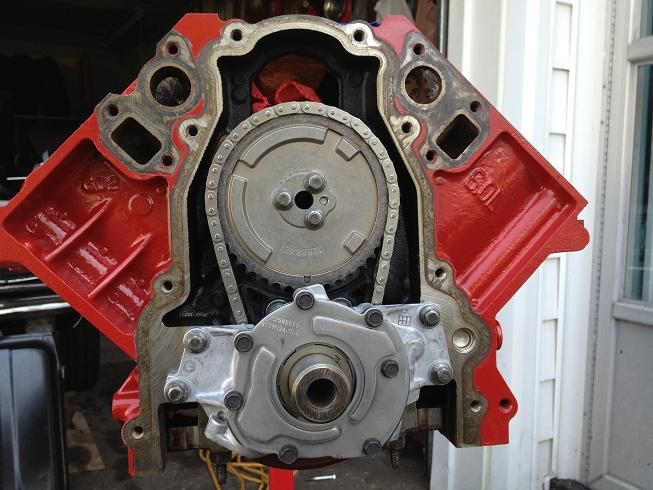

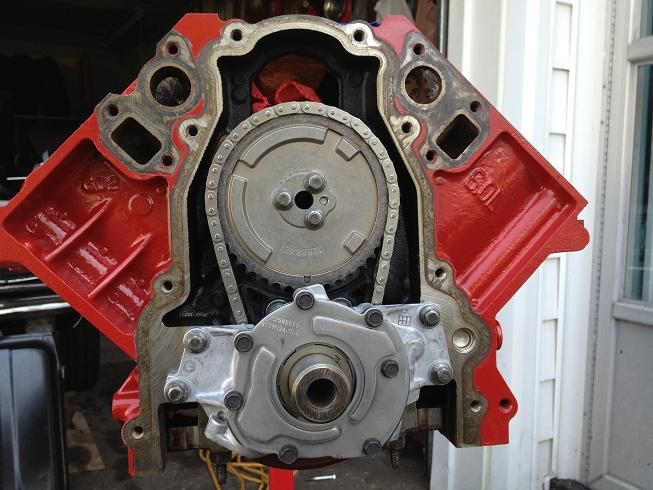

Timing chain tensioner, oil pump, etc...

Made some progress, took more pics along the way.

My new timing chain tensioner arrived from Trick Flow. I tried to fit it and it fit as poorly as the last one I broke. The bolt holes on the tensioner don't line up with the bracket. The bracket's posts are spaced a little too wide. Interesting, since both parts come from the same company. I had to clearance the tensioner a little by boring the holes out towards the midline. I wrapped some 220 grit around a Sharpie and filed away until it would fit:

Here it is mounted to the engine:

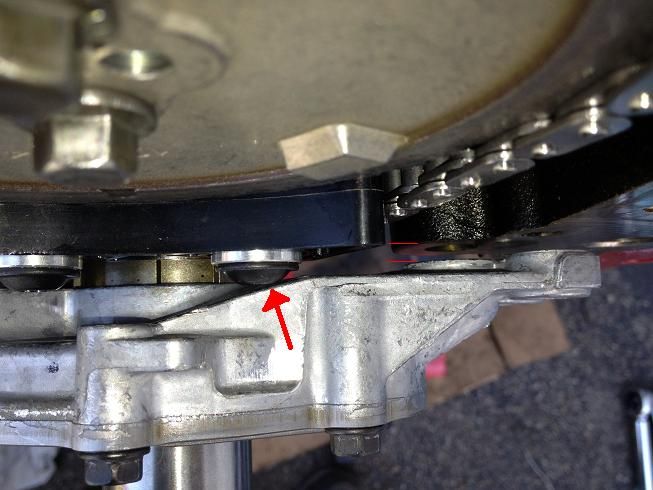

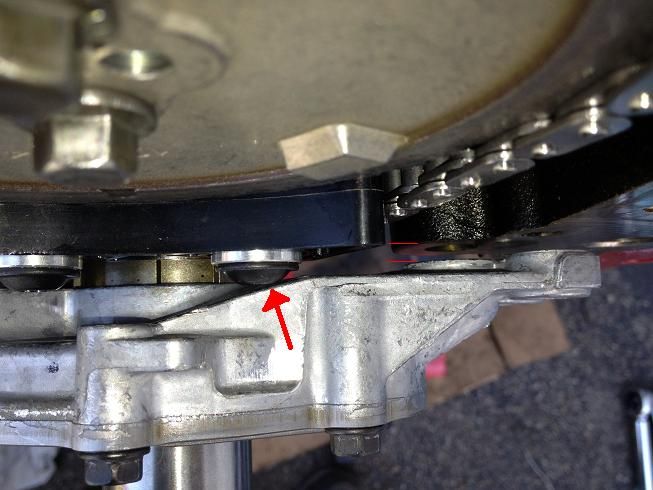

The bracket is tight against the engine, the tensioner is tight against the bracket, the bushings are seated all the way and when I went to bolt up the new oil pump, I had major clearance issues:

I had to drill the bushing recess a little deeper. I started with a step bit, but switched to a forstner bit. I went about 3/16".

Finally the oil pump fit tight against the engine:

Here's a shot of the port work done on the oil pump:

And here it is mounted:

My new timing chain tensioner arrived from Trick Flow. I tried to fit it and it fit as poorly as the last one I broke. The bolt holes on the tensioner don't line up with the bracket. The bracket's posts are spaced a little too wide. Interesting, since both parts come from the same company. I had to clearance the tensioner a little by boring the holes out towards the midline. I wrapped some 220 grit around a Sharpie and filed away until it would fit:

Here it is mounted to the engine:

The bracket is tight against the engine, the tensioner is tight against the bracket, the bushings are seated all the way and when I went to bolt up the new oil pump, I had major clearance issues:

I had to drill the bushing recess a little deeper. I started with a step bit, but switched to a forstner bit. I went about 3/16".

Finally the oil pump fit tight against the engine:

Here's a shot of the port work done on the oil pump:

And here it is mounted:

#26

Oil pan...

Next it was on to the new Holley LS Retrofit oil pan. Old oil pan removed, pick up tube removed and windage tray cleaned up:

Holley says you may have to modify your windage tray if the pick up tube doesn't mount flush. Why wouldn't you have to clearance it right? I mean, it's not like you're buying a retrofit part specifically designed for your car right? Oh, yeah, it is...

Doesn't sit flush, I used a razor blade to mark where I'd need to cut:

Then went over it with a sharpie:

A dremel with a cutoff wheel and then a couple whacks with a hammer:

Assembled on the engine:

Here's the baffle inside the Holley pan:

And this is where I left off, front cover gasket and oil pan gasket in place with a little RTV sealant along the edges where the front cover and rear cover meet the engine. Oil pan bolted on, front cover on. Tomorrow I can start on the heads:

Holley says you may have to modify your windage tray if the pick up tube doesn't mount flush. Why wouldn't you have to clearance it right? I mean, it's not like you're buying a retrofit part specifically designed for your car right? Oh, yeah, it is...

Doesn't sit flush, I used a razor blade to mark where I'd need to cut:

Then went over it with a sharpie:

A dremel with a cutoff wheel and then a couple whacks with a hammer:

Assembled on the engine:

Here's the baffle inside the Holley pan:

And this is where I left off, front cover gasket and oil pan gasket in place with a little RTV sealant along the edges where the front cover and rear cover meet the engine. Oil pan bolted on, front cover on. Tomorrow I can start on the heads:

#28

Engine reassembly...

I'm on my final push ordering parts. The CC to a big hit this week. I just ordered all new sensors for the engine, along with a new alternator (don't ask what happened to the perfectly good one that I removed, tried to disasemble and took a 5lb BFH to...), gaskets, bolts, hoses, new Monster level 2 clutch, slave cylinder, speed bleeder, and probably some other goodies that will be a surprise when they arrive.

Installed the new knock sensors and wiring harness in the valley cover. These engines seem to have an issue with water leaking in around the big black rubber grommets, and mine was no exception. This results in rusted out knock sensors. I layed down a bead of black RTV before installing the grommets to prevent this in the future:

LS2 lifter trays, these hold the roller lifters in the right direction and are a nice upgrade from the LS1/LQ9 stuff. You can see the tops of the LS7 lifters that I upgraded to as well:

OOOO, head gasket is on, you know what that means...

ARP head bolts:

Installed the new knock sensors and wiring harness in the valley cover. These engines seem to have an issue with water leaking in around the big black rubber grommets, and mine was no exception. This results in rusted out knock sensors. I layed down a bead of black RTV before installing the grommets to prevent this in the future:

LS2 lifter trays, these hold the roller lifters in the right direction and are a nice upgrade from the LS1/LQ9 stuff. You can see the tops of the LS7 lifters that I upgraded to as well:

OOOO, head gasket is on, you know what that means...

ARP head bolts:

Installed the pushrods, rocker arms and torqued the bolts down today. GM recommends torquing to 22 lb/ft for a stock setup, but with a bigger cam the recommendation is 24-26 lb/ft from many builders. So I went with 25 lb/ft.

With cylinder 1 at TDC on the compression stroke, I torqued down the intake rockers for cylinders 1, 3, 4 and 5; as well as the exhaust rockers for cylinders 1, 2, 7 and 8. Just remember that the LS engine has a different IEIEIEIE pattern than the SBC's EIIEEIIE.

For quick reference these are the drivers side rocker arms you torque down with cyl 1 at TDC on the compression stroke:

And these are the passenger side rocker arms you torque down:

With any ported head, you need to look down the intake port to see if the port work has left the rocker arm bolt holes exposed. If so, you need to add a little RTV to the rocker arm bolts before installing. I added the RTV to both the intake and exhaust rocker arm bolts so my torque readings would be consistent. Here's a bolt showing through the intake side:

And here's the finished product:

With cylinder 1 at TDC on the compression stroke, I torqued down the intake rockers for cylinders 1, 3, 4 and 5; as well as the exhaust rockers for cylinders 1, 2, 7 and 8. Just remember that the LS engine has a different IEIEIEIE pattern than the SBC's EIIEEIIE.

For quick reference these are the drivers side rocker arms you torque down with cyl 1 at TDC on the compression stroke:

And these are the passenger side rocker arms you torque down:

With any ported head, you need to look down the intake port to see if the port work has left the rocker arm bolt holes exposed. If so, you need to add a little RTV to the rocker arm bolts before installing. I added the RTV to both the intake and exhaust rocker arm bolts so my torque readings would be consistent. Here's a bolt showing through the intake side:

And here's the finished product:

Last edited by 67rally; 01-02-2014 at 05:47 PM.

#29

Slave Cylinder...

Well, can't really blame anyone other than myself here. Once again I'm waiting on some parts, but it's my own fault for not ordering in the right order. I have my new engine wiring harness coming from PSI conversions, a new 6 cylinder gas pedal so I can convert to cable rather than mechanical linkage, a new alternator relocation bracket, a new oil fill tube, and some other loose end. Well, I did order a bunch of gaskets, seals and sensors that USPS lost for 4 days, and once they arrived, the bag of 8 intake gaskets was opened and taped back up with one gasket missing...but I probably won't install the intake until I drop the engine into the bay anyways.

So in the meantime, lots of pics without much excitement.

New GM GTO slave cylinder (bottom) and old (top):

I'm adding a speed bleeder from Tick Performance so I can bleed the clutch from the engine bay. Old bleeder comes off:

Here's the new Tick bleeder:

The copper washer is shipped on the wrong side of the fitting so it does't get lost, just make sure to move the copper washer so it sits between the fitting and the slave cylider:

Attaches with two 10mm bolts torqued to 71 inch pounds:

So in the meantime, lots of pics without much excitement.

New GM GTO slave cylinder (bottom) and old (top):

I'm adding a speed bleeder from Tick Performance so I can bleed the clutch from the engine bay. Old bleeder comes off:

Here's the new Tick bleeder:

The copper washer is shipped on the wrong side of the fitting so it does't get lost, just make sure to move the copper washer so it sits between the fitting and the slave cylider:

Attaches with two 10mm bolts torqued to 71 inch pounds:

#30

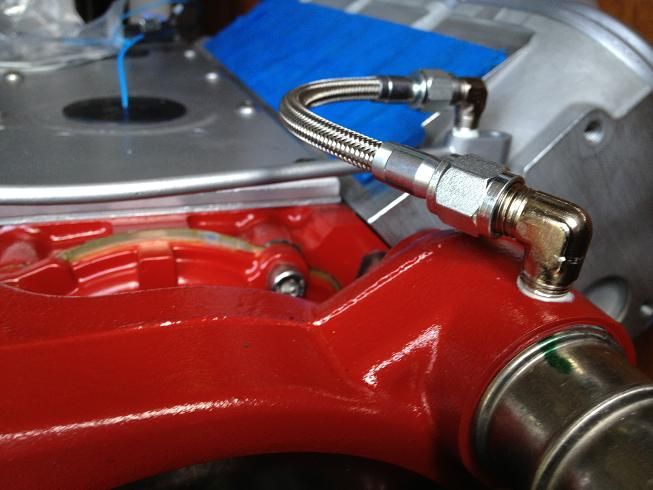

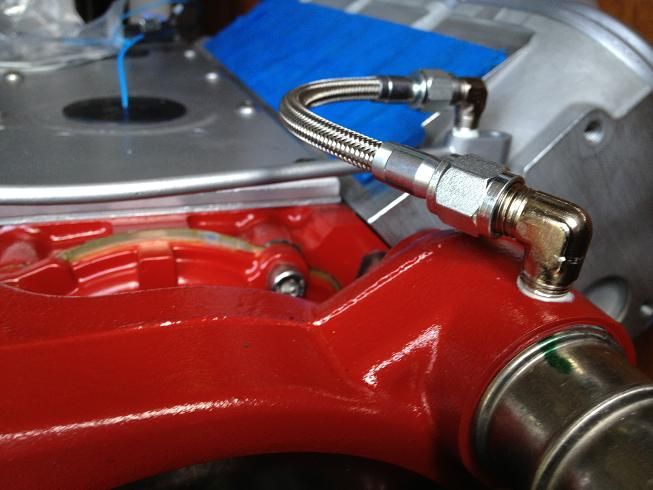

Steam tube crossover...

Here's an issue that you don't have on the sbc's. The LS engines have a steam tube vent (crossover tube) that connects the water passages on the both heads to a small line and ties back into the cooling system. It's recommended that you tie into the highest point in the system to prevent air pockets in the system.

Here's the tube in question:

Here it is removed and all cruddy (and backwards):

Before I knew what I was doing with it, I cleaned it up and painted it:

Then I cut the tube off the top of the driver's side and drilled a 11/32" hole:

Then I drilled an 11/32 hole through the top of my brand new water pump:

Tapped both holes with a 1/4" NPT tap:

Installed a 90 degree 1/4"NPT to -4AN fitting and sealed it with ARP thread sealer, and attached a 6" long -4AN stainless steel PTFE hose to it (I'm still waiting on the seals that go between the vent tubes and the heads, along with the correct bolts, so this is just for mockup):

Here's the tube in question:

Here it is removed and all cruddy (and backwards):

Before I knew what I was doing with it, I cleaned it up and painted it:

Then I cut the tube off the top of the driver's side and drilled a 11/32" hole:

Then I drilled an 11/32 hole through the top of my brand new water pump:

Tapped both holes with a 1/4" NPT tap:

Installed a 90 degree 1/4"NPT to -4AN fitting and sealed it with ARP thread sealer, and attached a 6" long -4AN stainless steel PTFE hose to it (I'm still waiting on the seals that go between the vent tubes and the heads, along with the correct bolts, so this is just for mockup):

#37

I am waiting to see what you did with the console. I am looking at modifying the trans with the forward inspection cover shift relocation so I can use my original console. I would rather keep the stock shifter location and put a modern console on which is what it looks like you did. Nice build so far.

#38

Thanks Guys!

Pics coming soon...

I am waiting to see what you did with the console. I am looking at modifying the trans with the forward inspection cover shift relocation so I can use my original console. I would rather keep the stock shifter location and put a modern console on which is what it looks like you did. Nice build so far.

#39

Starting to come together...

Actually, I didn't take a pic with the heads bolted on. This is the teaser pic I took when I mocked everything up on Sunday.

My goal (as with everything on my Camaro) was to keep an old school, updated look. I think this engine build fits perfectly with the rest of the design. I'm going with an Edelbrock Vic Jr. EFI intake manifold. And on top of it sits an Accufab 4150 4 barrel throttle body. The TB looks like a carb, but acts just like any other LS TB. I will be converting from drive by wire to drive by cable, so it will really look the part. I'll bolt a traditional air cleaner on and it should really finish the look (and yes, I have a plan for that as well...)

That's a far cry from where I started:

My goal (as with everything on my Camaro) was to keep an old school, updated look. I think this engine build fits perfectly with the rest of the design. I'm going with an Edelbrock Vic Jr. EFI intake manifold. And on top of it sits an Accufab 4150 4 barrel throttle body. The TB looks like a carb, but acts just like any other LS TB. I will be converting from drive by wire to drive by cable, so it will really look the part. I'll bolt a traditional air cleaner on and it should really finish the look (and yes, I have a plan for that as well...)

That's a far cry from where I started:

#40

.......

I installed a new gas pedal today. I'm using one designed for a 6 cyl. '67 Camaro, which is the same as the crossram accelerator pedal. It is set up for a cable rather than mechanical linkage. The arm is inside the passenger compartment rather than in the engine bay. If you're going to do this swap, make sure to do it when the engine is out.

New (cable) on the left, Old (linkage) on the right:

My adjustable crossmember for my T56 arrived from BMR Suspension. I figured something wouldn't fit right, but this thing has a ton of adjustability. It bolts up to the old crossmember bolt holes and allows for quite a bit of front to back as well as side to side movement. It also comes with an Energy Suspension tranny mount and all the hardware. The aluminum spacer (with 3 holes) is only used for an automatic transmission, so it will get tossed. Overall it's a very nicely built piece and comes in black hammertone finish. I'd rather it be gloss black, but no one is ever going to see it, so it's staying the way it is.

The only thing I don't like is that it only uses the center hole of the trans mount to bolt up to. I decided to modify it to use the outer two holes. I just used the aluminum spacer to mark my holes and drilled them out on the drill press:

Then I used a Dremel with a cutoff wheel to hack away the rest, it looked pretty good until I realized that I was off a hair on my spacing, so I had to go back and grind a little more away. Not the prettiest work, but it'll do. I touched up the raw edges with some Roll Bar & Chassis black paint:

And here's a quick pic when I mocked it up. Just showing how tight it runs to the floor pan. I should have plenty of clearance exhaust.

New (cable) on the left, Old (linkage) on the right:

My adjustable crossmember for my T56 arrived from BMR Suspension. I figured something wouldn't fit right, but this thing has a ton of adjustability. It bolts up to the old crossmember bolt holes and allows for quite a bit of front to back as well as side to side movement. It also comes with an Energy Suspension tranny mount and all the hardware. The aluminum spacer (with 3 holes) is only used for an automatic transmission, so it will get tossed. Overall it's a very nicely built piece and comes in black hammertone finish. I'd rather it be gloss black, but no one is ever going to see it, so it's staying the way it is.

The only thing I don't like is that it only uses the center hole of the trans mount to bolt up to. I decided to modify it to use the outer two holes. I just used the aluminum spacer to mark my holes and drilled them out on the drill press:

Then I used a Dremel with a cutoff wheel to hack away the rest, it looked pretty good until I realized that I was off a hair on my spacing, so I had to go back and grind a little more away. Not the prettiest work, but it'll do. I touched up the raw edges with some Roll Bar & Chassis black paint:

And here's a quick pic when I mocked it up. Just showing how tight it runs to the floor pan. I should have plenty of clearance exhaust.

I cut a 2" hole through the firewall for my wiring harness today, but forgot to take pics. I'll snap one tomorrow to show where it goes through. I just used a 2" hole saw, deburred the edges with a dremel and painted the raw edges so they won't rust.

I also installed a shorter oil filler neck. Here's the old long LQ9 one next to the new LS1/LS6 shorty.

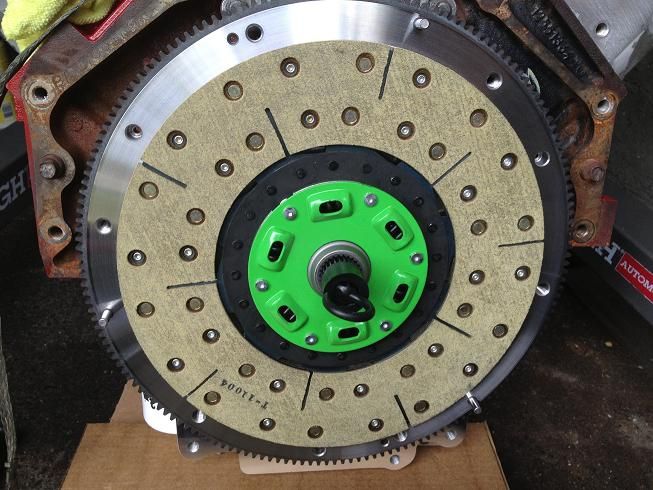

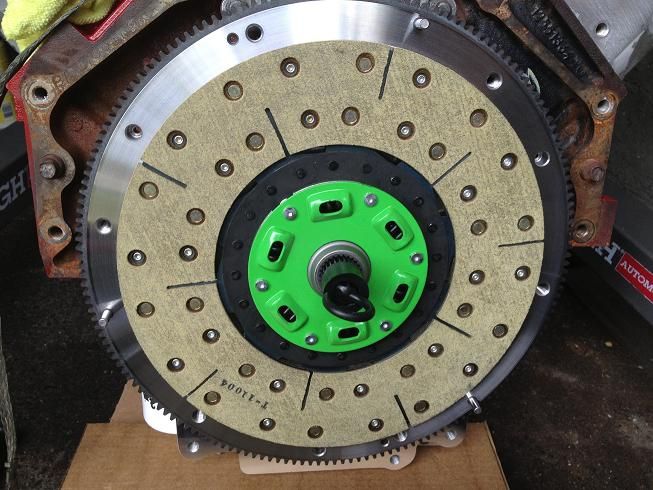

I got the motor off the stand and hanging on the engine hoist. I installed a new pilot bearing and the new Monster Level 2 clutch today along with a new GTO starter and the bell housing. If the weather cooperates tomorrow, I'm going to bolt up the tranny and try dropping her in.

Flywheel:

Clutch plate and alignment tool:

12" Pressure Plate:

All bolted up:

I also installed a shorter oil filler neck. Here's the old long LQ9 one next to the new LS1/LS6 shorty.

I got the motor off the stand and hanging on the engine hoist. I installed a new pilot bearing and the new Monster Level 2 clutch today along with a new GTO starter and the bell housing. If the weather cooperates tomorrow, I'm going to bolt up the tranny and try dropping her in.

Flywheel:

Clutch plate and alignment tool:

12" Pressure Plate:

All bolted up: