For you DIY 5.3 guys

#1

I got tired of looking for a camaro or corvette accessory setup, so what i did was chop it up with out having to weld, so it can be usd on the A-body or what have you, no need for spending more money ill have more pics up tommorow these are just some rough cuts..lol

ill have more pics up tommorow these are just some rough cuts..lol

ill have more pics up tommorow these are just some rough cuts..lol

ill have more pics up tommorow these are just some rough cuts..lol

#3

well for A-body (chevelles,Tempest...etc..) Truck acc brackets makes The alternator sit to damn high and the PS pump (saginaw style) hot the power steering gearbox, most of us have to convert to a F-body or corvette acc. mount setup to get around this problem what i did was chop it so the alternator dosent sit so high and the ps pump pulley will clear the PS gear box, if you have saw zaw and drill bit's this can be done in very little time.

#5

the ALT wont hit come to find out but the PS pump cover where the pulley hits on the belt was ground down a little, and the PS bracket was slighlty drilled out so i could the clearnece i needed, I also made the truck manifolds work here some pics

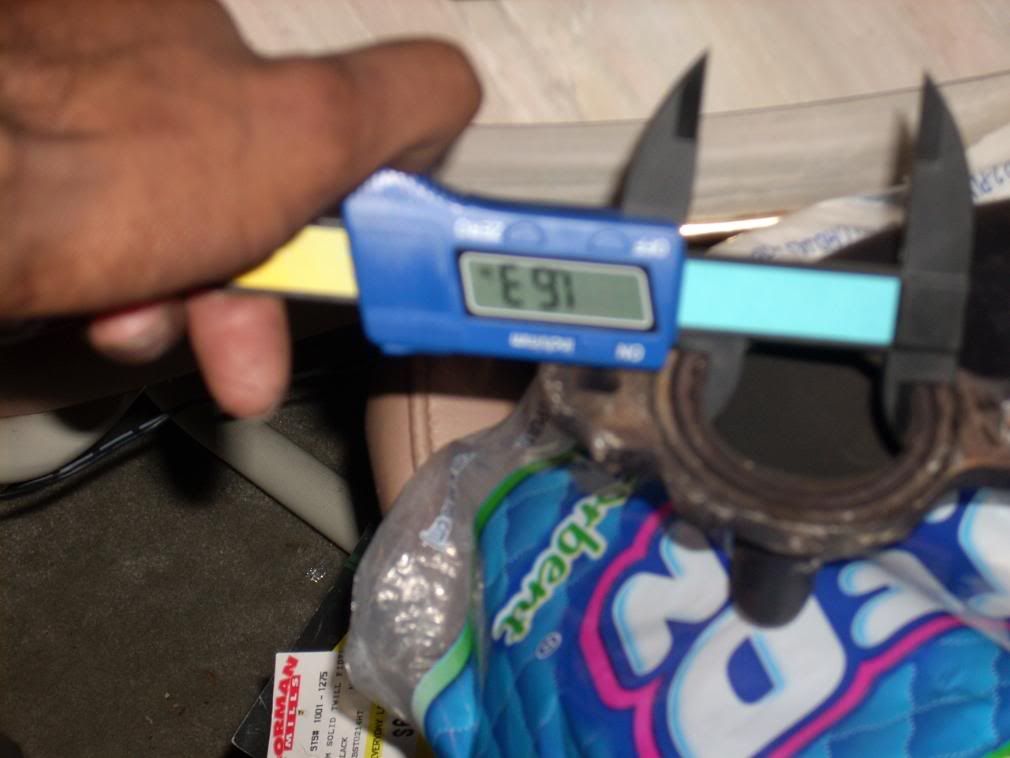

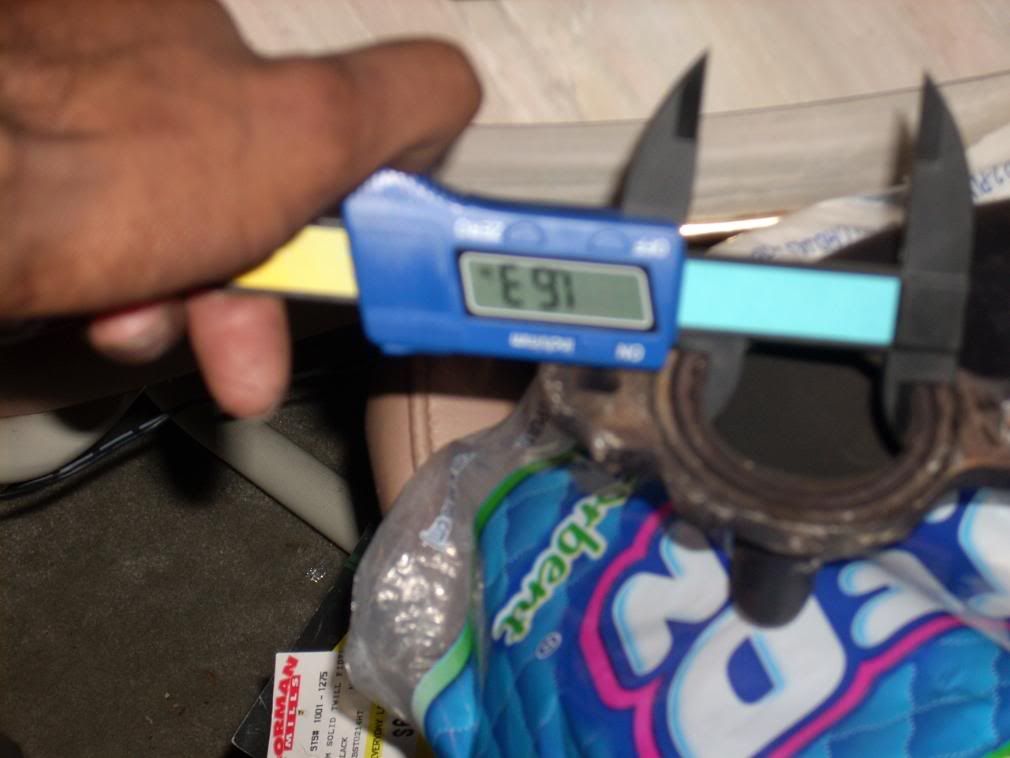

and if anybody ever wondered about the truck mani's primaries and outlet they are 1.63 across and 1.59 up, the outlet specs at 2.25, Comparing the manifolds to the corvette ones, Truck manifolds actually have a bigger I.D primary and same size collector outlet, I will port the Exaust manifold slighlty after i reposition the 02 bung and other things.

Truck mani's.

Corvette mani's

Outer portion measured at 2.55, i couldnt hold the camera and keep my caliper inside but the inner "sleeve" is 2.25

and if anybody ever wondered about the truck mani's primaries and outlet they are 1.63 across and 1.59 up, the outlet specs at 2.25, Comparing the manifolds to the corvette ones, Truck manifolds actually have a bigger I.D primary and same size collector outlet, I will port the Exaust manifold slighlty after i reposition the 02 bung and other things.

Truck mani's.

Corvette mani's

Outer portion measured at 2.55, i couldnt hold the camera and keep my caliper inside but the inner "sleeve" is 2.25

Trending Topics

#9

I heard that somewhere to, but i tried anyway thats the main reason my bead is so thick though, had to make sure my weld penetrated, but im going to get some 2.5' pipe today and weld that instead of using the factory 2.25 piece as pictured. will post later on tonight or tommorow.

#11

welded the 2.5 inch pipe in had to hammer the end to make it oval shape to "fit" the shape of the manifold but this should help it breathe alot better throughout the powerband and clear the frame rails with no problem...which is why i hacked them up in the first place lol...call me cheap

Last edited by 91parkave; 03-17-2008 at 02:37 PM.