How did you mount your Rear AFCOs??

#1

I got some Madman brackets with my shocks your supposed to weld to the shock mounting bracket on the axle then bolt the shock to the madman bracket. I really didnt want to weld it on so I just tuned the shock and mounted it up the normal way with a grade 8 bolt and a spacer. The adjustment **** on the shock does clear the UMI drag bar but its kinda close. Do I need to be worried about side to side movement on the sway bar hitting the ****?

Trending Topics

#16

Ya I just decided I didnt want to weld them. The only welder I had available was a flux wire welder and I just didnt trust it to penetrate deep enough. Then I just started thinking about a bolt in application.

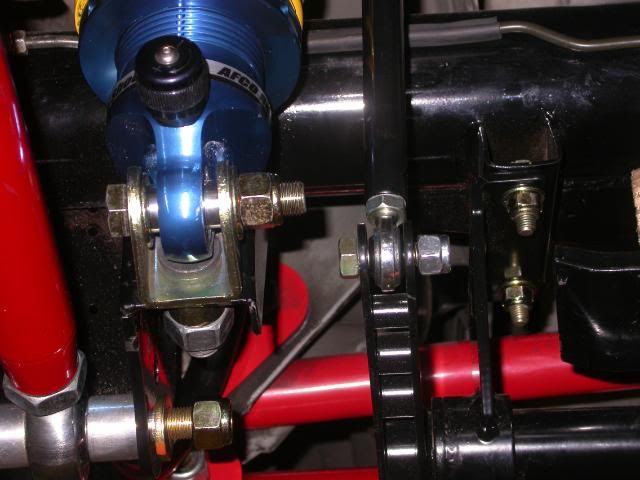

Heres the bracket b4 the final adjustments and mounting. We had to mill down the bolt head and the inside of the bracket just a bit so the shock body didnt hit anything.

Heres the bracket b4 the final adjustments and mounting. We had to mill down the bolt head and the inside of the bracket just a bit so the shock body didnt hit anything.

#20

We had a MIG and TIG at the shop but no way to get the car there, or the welder to the garage. Plus I decided I wanted a bolt in application. The machine shop owner thinks the alum will be strong enough thats why we went so much thicker with it over the supplied steel brackets.