416 LS3 heading to the engine dyno....(UPDATED WITH VIDEO)

#1

Hi Guys,

Just thought I would post a quick summary of the engine I built for a customer in Florida who plans to install it in his road race/autoX C5....its strictly a track car but I set it up for a max effort 93 octane application (about 11.8 to 1). In the heat I suggested he splash some race gas just for a little extra insurance (it can be brutal racing in the Florida summers).

While we are obviously always trying to put up a number, a road race car needs more low and middle RPM power and torque to accelerate off a corner so the cam timing is of course a bit on the light side in an effort to build more area under the curve (243/243 on a 113 + 2), Truthfully this would make a phenomenal street engine for a guy who valued a more "balanced" package, versus a more drag oriented set-up with more cam timing and a better top end charge (at the expense of low/mid-range torque of course). We are trying to make 500+ ft/lbs extremely early in the curve and have a usable very flat wide power band from 3500 - 7K.

Opted for a set of AFR 230 "V2" heads which are very capable out of the box but you guys already know most of the complete engine builds I get involved place an emphasis on optimizing everything....I dont leave many stones unturned in search of "more".

So we "Mamofied" the 230's including the installation of some larger 2.100 lighter weight intake valves coaxing the intake port to almost 340 CFM when I was finished while still retaining a moderate cross section (only 233 cc's finished volume) ideal for the RPM and power curve we are looking for. If this was more a drag race car I might have opted for the larger 245 heads we offer. With the high airspeed design, conservative cam timing, and long runner (ported of course) 102 FAST, it should come on early but hang on due to all the airflow available to process with the high flowing heads and intake.

Im running a SCAT crank and Callies Compstar rods with a trick set of Wiseco pistons including their GFX ring package, and the customer also opted for a dry sump oiling system in search of more reliability under the heavy G's this car will be capable of (its lightened, with coil overs, and has lots of trick suspension work). I enlisted ARE for the dry sump conversion and was very impressed with the fit and finish of the kit. Its an expensive upgrade though but its also worth a little power in actual racing conditions because you don't have 6 quarts of oil wanting to climb up the crank (costing you power from heavy windage losses) and alot of extra oil getting on the cylinder walls making the oil rings work alot harder to remove the excess so the compression rings can do a better job. Also, another bonus is the dry sump pump will actually create some crankcase vacuum.....also beneficial and worth a few horsepower as well.

So lets see what she does tomorrow.....in the mean time here are a couple of pics of the engine as well as the dry sump stand I built to facilitate all the oil line plumbing (and remote filter which is convenient) when the engine mounted on the dyno.

Cheers,

Tony

Just thought I would post a quick summary of the engine I built for a customer in Florida who plans to install it in his road race/autoX C5....its strictly a track car but I set it up for a max effort 93 octane application (about 11.8 to 1). In the heat I suggested he splash some race gas just for a little extra insurance (it can be brutal racing in the Florida summers).

While we are obviously always trying to put up a number, a road race car needs more low and middle RPM power and torque to accelerate off a corner so the cam timing is of course a bit on the light side in an effort to build more area under the curve (243/243 on a 113 + 2), Truthfully this would make a phenomenal street engine for a guy who valued a more "balanced" package, versus a more drag oriented set-up with more cam timing and a better top end charge (at the expense of low/mid-range torque of course). We are trying to make 500+ ft/lbs extremely early in the curve and have a usable very flat wide power band from 3500 - 7K.

Opted for a set of AFR 230 "V2" heads which are very capable out of the box but you guys already know most of the complete engine builds I get involved place an emphasis on optimizing everything....I dont leave many stones unturned in search of "more".

So we "Mamofied" the 230's including the installation of some larger 2.100 lighter weight intake valves coaxing the intake port to almost 340 CFM when I was finished while still retaining a moderate cross section (only 233 cc's finished volume) ideal for the RPM and power curve we are looking for. If this was more a drag race car I might have opted for the larger 245 heads we offer. With the high airspeed design, conservative cam timing, and long runner (ported of course) 102 FAST, it should come on early but hang on due to all the airflow available to process with the high flowing heads and intake.

Im running a SCAT crank and Callies Compstar rods with a trick set of Wiseco pistons including their GFX ring package, and the customer also opted for a dry sump oiling system in search of more reliability under the heavy G's this car will be capable of (its lightened, with coil overs, and has lots of trick suspension work). I enlisted ARE for the dry sump conversion and was very impressed with the fit and finish of the kit. Its an expensive upgrade though but its also worth a little power in actual racing conditions because you don't have 6 quarts of oil wanting to climb up the crank (costing you power from heavy windage losses) and alot of extra oil getting on the cylinder walls making the oil rings work alot harder to remove the excess so the compression rings can do a better job. Also, another bonus is the dry sump pump will actually create some crankcase vacuum.....also beneficial and worth a few horsepower as well.

So lets see what she does tomorrow.....in the mean time here are a couple of pics of the engine as well as the dry sump stand I built to facilitate all the oil line plumbing (and remote filter which is convenient) when the engine mounted on the dyno.

Cheers,

Tony

Last edited by Tony Mamo @ AFR; 03-23-2011 at 08:32 PM.

#2

I was wondering why you require race gas with 11.8-1 compression in the heat? Is this the norm? The reason I am asking is because the motor I am building at the time is LS2 402ci that will have around 12.2-1 compression. The tuner said who also speced the cam said it would work. Now I am running a bigger cam then you have speced for this motor with the Trick Flow 215cnc's opened up to a 4" bore size and a larger diam intake valve. 2.055. The cam spec are 246/255-605/632@113+2 comp cam. Any help is appreciated.

Thanks

Thanks

Trending Topics

#12

It was simply a recommendation to err on the side of caution in high heat extended WOT racing conditions. Oil temps, air inlet temps, and combustion chamber temps are all alot hotter in those conditions and the chance of detonation is higher. Splashing a little race gas doesn't add much to your weekends allowance of gas and offers a little peace of mind from the heat.

Odarabla, IMO 12.2 is very aggressive and doesn't leave you with much safety margin from a bad tank of gas, partially clogged injector....whatever. You better have your tune really dialed in as well.

This installation of this pump does eliminate your A/C compressor but they make a different version that mounts higher in front of your passenger side head. At the end of the day the dry sump really didn't show any power advantage sitting on a dyno (whatever gains from crankcase vacuum and slightly better windage looked to be offset by the power required to drive the pump), however, it adds measurably to reliability, especially in a car that has high G-loads and is worth power in a dynamic state where the wetsump system would have oil sloshing all over the rotating assembly.

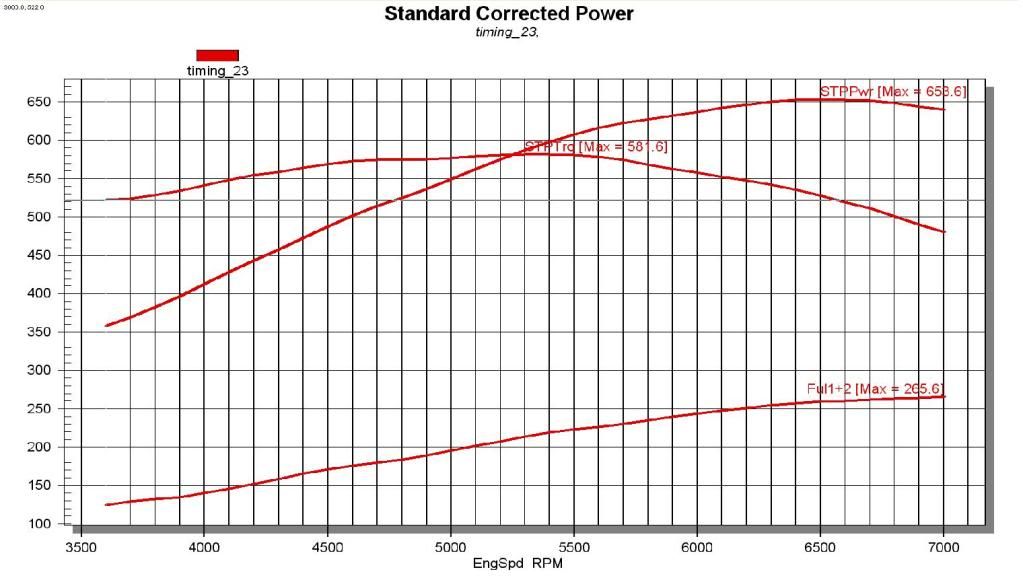

Guys its been a LONG day so Im going to just post the results which I was very pleased with (a very fat and very flat torque curve) that was already making 525 ft/lbs of torque at the beginning of the pull (3500 RPM's)! That used to be a pretty stout peak number for a 454 big block Chevy not that long ago! We made 582 - 583 ft/lbs of peak torque and still managed to produce a peak of 654 HP with minimal "roll over" at the top.

Here is the curve.....

And here is a quick shot of it on the Westech 902 SuperFlow dyno.....

I will upload a vid or two in the next couple of days!

Cheers,

Tony

Last edited by Tony Mamo @ AFR; 03-17-2011 at 12:22 PM.

#19

Extremely efficient combustion chamber. Needs less time (timing) to get the flame across the piston after TDC. The more timing you put in the sonner the plug starts to fire before TDC. With a good chamber like the AFR's have the flame travels very well.

#20

Actually that was the 23rd (and final) dyno pull of the day. We changed the timing a little the last few runs looking for a few more ponies. Truth is it was not very sensitive to timing past 25' because the engine combination and chamber design is/was very efficient. It did like 27 ish at peak torque and 28 at peak power but it was only a few HP and Ft/lbs of torque better than when we were running a 25/24 combination in the engine and creeping up on the proper fueling (A/F ratio).

Good question though....I would have probably thought the same reading the name of the run (Steve @ Westech enters most of the data and changes we are making thru out the day in the notes as well as a quickie footnote in the name of the run to keep track of what we are changing/manipulating along the way!)

Thanks for all the positive comments guys....it will be fun to see what this engine is capable in Brian's C5 race car!

Cheers,

Tony

Good question though....I would have probably thought the same reading the name of the run (Steve @ Westech enters most of the data and changes we are making thru out the day in the notes as well as a quickie footnote in the name of the run to keep track of what we are changing/manipulating along the way!)

Thanks for all the positive comments guys....it will be fun to see what this engine is capable in Brian's C5 race car!

Cheers,

Tony

Anyways logging on the post for the results.

Anyways logging on the post for the results.