Rear mount large a/r and quick spool valve

#1

I'm looking for constructive ideas here guys. I understand the rear mount isn't optimal. My car is an LS swapped BMW. I had to choose front mounted turbo without a/c, or a/c with rear mounted turbo. The car is getting a/c.

I tried to PM Zombie about this as he's the only one that seems to have tried a QSP, but I haven't heard back.

I'm curious about thoughts on a quick spool valve and a large a/r housing on a rear mount. I'm using a Comp oil less turbo on my 6.0 / 4L80 rear mount combo. Currently I have an open .96 exhaust housing with 3" down pipe that I have stepped up to 4". I also have a 1.59 dual scroll housing that is a 4" v-band down pipe and a quick spool valve. I understand the QSV will effectively make the larger housing act as a ~.80 a/r when it's closed, which will help with the initial spool.

Would the 1.59 housing be too big once the turbo gets into boost? I'm trying to avoid the problem most rear mounts have in regard to either slow spool (housing too big) or power falling off early (housing too small). I doubt the .96 will cause the issue, but the 1.59 seems like it could be the key to better spool and it should pull a lot harder once the QSP opens up under boost.

Any thoughts or tips are greatly appreciated!

I tried to PM Zombie about this as he's the only one that seems to have tried a QSP, but I haven't heard back.

I'm curious about thoughts on a quick spool valve and a large a/r housing on a rear mount. I'm using a Comp oil less turbo on my 6.0 / 4L80 rear mount combo. Currently I have an open .96 exhaust housing with 3" down pipe that I have stepped up to 4". I also have a 1.59 dual scroll housing that is a 4" v-band down pipe and a quick spool valve. I understand the QSV will effectively make the larger housing act as a ~.80 a/r when it's closed, which will help with the initial spool.

Would the 1.59 housing be too big once the turbo gets into boost? I'm trying to avoid the problem most rear mounts have in regard to either slow spool (housing too big) or power falling off early (housing too small). I doubt the .96 will cause the issue, but the 1.59 seems like it could be the key to better spool and it should pull a lot harder once the QSP opens up under boost.

Any thoughts or tips are greatly appreciated!

#2

TECH Apprentice

iTrader: (11)

Join Date: Nov 2008

Location: Federal Way, Wa

Posts: 381

Likes: 0

Received 0 Likes

on

0 Posts

just pick the right size turbo for what you want. My rear mount spools super fast. make sure to use a shorty header or manifold and wrap the full hot side from.heads to turbo. mine has been a stock 5.3 with a billet pt7175 .81 journal and now a built motor billet pt7675 ball bearing. Mines a stick so you have the auto to help also.

#3

just pick the right size turbo for what you want. My rear mount spools super fast. make sure to use a shorty header or manifold and wrap the full hot side from.heads to turbo. mine has been a stock 5.3 with a billet pt7175 .81 journal and now a built motor billet pt7675 ball bearing. Mines a stick so you have the auto to help also.

#5

8 Second Club

iTrader: (4)

I’ll throw in my .02. Been wanting to make a remote mount for years “the math way”. Never have. This is all just opinion, some will disagree…

I’ve yet to see a remote mount system with the mathematically “correct” hot side piping size. I hear many claims from others that have largish piping and a smallish turbo claiming how well it works. Yet there are no smaller diameter setups with larger turbos for comparison that I’ve seen.

Depending on motor size, NA HP, amount of bends etc… A single 2” pipe pre-turbo is sufficient for most turbo builds moving 450 CFM of air or under 300hp and under NA. To a point, smaller pipe should allow a larger AR housing to spool as quickly as a smaller housing with less overall backpressure. Allowing you to run a larger cam and make more power per lb of boost. Most can’t grasp the concept of running tiny piping the length of the car. It’s been ground into our brains that larger exhaust is better.

Most T4 scroll housings exits are TINY. If I remember correctly, a 1.10AR T4 housings scroll exit diameter is right around 1” per side. Then you have to factor in the restriction of the wheel. This almost always makes the turbo the bottle neck in the system. A 5” pipe pre-bottle neck (turbo) will flow no more than a 2” pipe. Larger pipe will only slow velocity. Slower velocity = slower spool. It is also possible to get the piping so small the exhaust gasses will exceed the speed of sound and cause all sorts of turbulence/restrictions. Running 3” pipe the length of the car pre-turbo on a motor displacing 450cfm of air or less is overkill and totally unnecessary. Not that it won’t work, but it could work better.

For a basic JY long block 5.3 build shooting for 600-700 fly wheel hp in boost:

I’d step the collectors down to 2” and plumb them to a “Y”. Then run a single 2.25” pipe the length of the car. A 70/75 ‘ish turbo with 1.25 T4 housing would be my choice. With the right cam, I think this would make for a potent quick spooling remote kit. I’d look at the 72/86 1.10 T6 AR if you want to run the spool valve.

In general the turbine to compressor ratio plays a big part too. Running something like a 70/75 is much better than the typical 75/65 turbos out there. The larger exhaust wheel has leverage over the smaller compressor wheel making it “spool” more quickly. The small exh. wheels coupled with larger compressors make for a lazy turbo in my experience.

Good luck!

I’ve yet to see a remote mount system with the mathematically “correct” hot side piping size. I hear many claims from others that have largish piping and a smallish turbo claiming how well it works. Yet there are no smaller diameter setups with larger turbos for comparison that I’ve seen.

Depending on motor size, NA HP, amount of bends etc… A single 2” pipe pre-turbo is sufficient for most turbo builds moving 450 CFM of air or under 300hp and under NA. To a point, smaller pipe should allow a larger AR housing to spool as quickly as a smaller housing with less overall backpressure. Allowing you to run a larger cam and make more power per lb of boost. Most can’t grasp the concept of running tiny piping the length of the car. It’s been ground into our brains that larger exhaust is better.

Most T4 scroll housings exits are TINY. If I remember correctly, a 1.10AR T4 housings scroll exit diameter is right around 1” per side. Then you have to factor in the restriction of the wheel. This almost always makes the turbo the bottle neck in the system. A 5” pipe pre-bottle neck (turbo) will flow no more than a 2” pipe. Larger pipe will only slow velocity. Slower velocity = slower spool. It is also possible to get the piping so small the exhaust gasses will exceed the speed of sound and cause all sorts of turbulence/restrictions. Running 3” pipe the length of the car pre-turbo on a motor displacing 450cfm of air or less is overkill and totally unnecessary. Not that it won’t work, but it could work better.

For a basic JY long block 5.3 build shooting for 600-700 fly wheel hp in boost:

I’d step the collectors down to 2” and plumb them to a “Y”. Then run a single 2.25” pipe the length of the car. A 70/75 ‘ish turbo with 1.25 T4 housing would be my choice. With the right cam, I think this would make for a potent quick spooling remote kit. I’d look at the 72/86 1.10 T6 AR if you want to run the spool valve.

In general the turbine to compressor ratio plays a big part too. Running something like a 70/75 is much better than the typical 75/65 turbos out there. The larger exhaust wheel has leverage over the smaller compressor wheel making it “spool” more quickly. The small exh. wheels coupled with larger compressors make for a lazy turbo in my experience.

Good luck!

#6

That's great info. I have run into a lot of hatred for the Comp turbo because the intake and exhaust wheels are so close in size, apparently causing back pressure issues. I have found 2 rear mount builds that used this turbo and both seemed to work really well. Maybe the 78/79 wheel combo is better matched for the rear mount.

I struggled with deciding on the exhaust diameter going to the turbo. As stated, mathematically it makes more sense to run the smaller diameter piping to keep the velocity. While researching this, there wasn't a clear cut "winner" when it came to exhaust diameter. The common theme was avoiding long tube headers and wrapping the exhaust pipe. I haven't been able to find a back to back test showing spool characteristics of a 2.25" system changed 3" or visa-versa. People have changed from one to the other and claimed they had better spool. I suspect the turbo itself will react a lot different depending on the wheel size/ combo.

One interesting thing I did find was an actual back to back test on swapping the exhaust housing a/r. The smaller housing had better spool, the larger housing was "laggy." The actual dyno numbers showed very similar power #'s up to the point where the small housing choked off and stopped making power. The large housing kept making power. This is what I would expect based on how a turbo normally reacts.

Enter the question of the spool valve... A large a/r cut in half should equal a decent spooling turbo. When you open the spool valve and take advantage of the other half of the housing, it should pull nicely on the top end. I fear this thing will have a dyno graph that looks like a Supra with a big single, but there will always be trade offs.

I struggled with deciding on the exhaust diameter going to the turbo. As stated, mathematically it makes more sense to run the smaller diameter piping to keep the velocity. While researching this, there wasn't a clear cut "winner" when it came to exhaust diameter. The common theme was avoiding long tube headers and wrapping the exhaust pipe. I haven't been able to find a back to back test showing spool characteristics of a 2.25" system changed 3" or visa-versa. People have changed from one to the other and claimed they had better spool. I suspect the turbo itself will react a lot different depending on the wheel size/ combo.

One interesting thing I did find was an actual back to back test on swapping the exhaust housing a/r. The smaller housing had better spool, the larger housing was "laggy." The actual dyno numbers showed very similar power #'s up to the point where the small housing choked off and stopped making power. The large housing kept making power. This is what I would expect based on how a turbo normally reacts.

Enter the question of the spool valve... A large a/r cut in half should equal a decent spooling turbo. When you open the spool valve and take advantage of the other half of the housing, it should pull nicely on the top end. I fear this thing will have a dyno graph that looks like a Supra with a big single, but there will always be trade offs.

Trending Topics

#9

8 Second Club

iTrader: (4)

People that actually race professionally and record track data have proven it is beneficial to keep velocity up in the hot-side. Phil99vette’s 438” LS motor Revving to 8500 RPM at 40lbs of boost runs a 2.5” hotside. This allowed him to run a much larger AR housing with less back pressure improving overall performance with no negative effects to "spool-up". To suggest 3” pipe is needed or beneficial on most of these little turd motors barely revving past 6k is ridiculous IMO.

#10

TECH Apprentice

iTrader: (11)

Join Date: Nov 2008

Location: Federal Way, Wa

Posts: 381

Likes: 0

Received 0 Likes

on

0 Posts

Not made it to the track yet due to some set backs motor related. But ill tell you i have beat on the street some fast cars. Including a built ttx c6z making more power and tq 875/900 vs my 840/840. So its working amazingly well. That was on the baby turbo 7175 and the stock motor. Is it 100% optimal Maybe not. But for someone planing to build around about the same size turbo as myself. I cant see spending all that time and money on it. Unless a huge shop with money to blow on changing piping size and swapping out turbos left and right. I see boost as low as 2000rpms on the street with the street with the 7175 a couple hundred later on the 7675. Pretty damn good throttle response. Not trying to get in a argument. Just offering up what works better then 90% of the rear mount setup i have seen tossed together.

We did plan to make more power down the road which was why the 3 in pipe. If planning 6-700 yeah maybe stay a little smaller for spool. But who doesn't turn it up down the road? I dont know anything about the math as you were posting about. I'm just tossing in my personal experience.

http://www.corvetteforum.com/forums/...unt-c5z06.html

here is my build thread for any info you want. For some reason the pics vanished so i had to post them back in the first page missing some for sure.

We did plan to make more power down the road which was why the 3 in pipe. If planning 6-700 yeah maybe stay a little smaller for spool. But who doesn't turn it up down the road? I dont know anything about the math as you were posting about. I'm just tossing in my personal experience.

http://www.corvetteforum.com/forums/...unt-c5z06.html

here is my build thread for any info you want. For some reason the pics vanished so i had to post them back in the first page missing some for sure.

#11

TECH Apprentice

iTrader: (11)

Join Date: Nov 2008

Location: Federal Way, Wa

Posts: 381

Likes: 0

Received 0 Likes

on

0 Posts

With all due respect your setup/car are awesome. But what are you basing your statement on? What other setups have you tried? Have you ever had your car to an actual track? Or are you basing it all off dyno numbers? I don’t see how you can say your setup is “as good as your going to see” when you’ve never tried a smaller hot-side coupled with a larger housing.

People that actually race professionally and record track data have proven it is beneficial to keep velocity up in the hot-side. Phil99vette’s 438” LS motor Revving to 8500 RPM at 40lbs of boost runs a 2.5” hotside. This allowed him to run a much larger AR housing with less back pressure improving overall performance with no negative effects to "spool-up". To suggest 3” pipe is needed or beneficial on most of these little turd motors barely revving past 6k is ridiculous IMO.

People that actually race professionally and record track data have proven it is beneficial to keep velocity up in the hot-side. Phil99vette’s 438” LS motor Revving to 8500 RPM at 40lbs of boost runs a 2.5” hotside. This allowed him to run a much larger AR housing with less back pressure improving overall performance with no negative effects to "spool-up". To suggest 3” pipe is needed or beneficial on most of these little turd motors barely revving past 6k is ridiculous IMO.

Is that a rear mount? So he is shoving all that 438CI of air 15 feet through on little 2.5 pipe? Thats nuts.

#13

TECH Apprentice

iTrader: (11)

Join Date: Nov 2008

Location: Federal Way, Wa

Posts: 381

Likes: 0

Received 0 Likes

on

0 Posts

Then that isnt a good comparison cause mine has 2.5 in pipes too. Off the manifolds that merge into a single 3 in pipe. Shove all that air threw a small pipe for the length of the car. Im sure the back pressure will be huge.

I do believe i read Zombie went from 2.5 to 3 in piping on his rear mount and it was beneficial to his setup.

I do believe i read Zombie went from 2.5 to 3 in piping on his rear mount and it was beneficial to his setup.

#14

8 Second Club

iTrader: (4)

Then that isnt a good comparison cause mine has 2.5 in pipes too. Off the manifolds that merge into a single 3 in pipe. Shove all that air threw a small pipe for the length of the car. Im sure the back pressure will be huge.

I do believe i read Zombie went from 2.5 to 3 in piping on his rear mount and it was beneficial to his setup.

I do believe i read Zombie went from 2.5 to 3 in piping on his rear mount and it was beneficial to his setup.

Pressurized exhaust gas pre-turbine is of far less volume than exhaust on your typical NA engine. Because of this, it doesn't need nearly as much flow area. The added restriction for the longer pipe would need to be factored in. I've done the math and it's not as much of a concern as you think. I'll dig out the formula and post it.

The turbine housing exit volute size dictates the flow and your piping size determines the speed of the exhaust gasses. You want your exh gas to be traveling as fast as possible without going sonic. (1100 FPS) Running larger pipe nets ZERO flow gains if the turbo is the bottle neck.

#15

I thought I saw somewhere on here (might have been phil's thread) that ounces gasses get over 450fps they start to act a little strange. Could be wrong though (not looked it up).

Also would it not be better to go for a t6 housing with a smaller AR? I think that was discussed in Phil's thread and was what some were able to do whilst not I lacking spool thanks to smaller pipes. Just a thought.

Would love to see someone develop a rear mount kit that worked with a given power requirement. You should effectively be able to size the system I. The peak power requirement (not engine size) as that's what roughly determines airflow. After all it's peak flow numbers that matter. A v8 can run fine with a 2i ch exhaust if you do t rev it and only ever ask for 50bhp!

Also would it not be better to go for a t6 housing with a smaller AR? I think that was discussed in Phil's thread and was what some were able to do whilst not I lacking spool thanks to smaller pipes. Just a thought.

Would love to see someone develop a rear mount kit that worked with a given power requirement. You should effectively be able to size the system I. The peak power requirement (not engine size) as that's what roughly determines airflow. After all it's peak flow numbers that matter. A v8 can run fine with a 2i ch exhaust if you do t rev it and only ever ask for 50bhp!

#16

8 Second Club

iTrader: (4)

Mach speed changes drastically with temperature. (and altitude). If your EGT is 1500* @ sea level... Mach is now 2169 FPS (not 1100fps) So .4 mach at 1500* is 867 FPS.

So I'm twisting Corkys words and assuming 867FPS is a good do not cross point for a 1500* exhaust pipe. Phil99vette used his own formula and cam up with very similar pipe sizes...

If your dealing with a 400HP/600CFM engine NA...

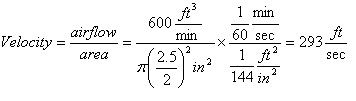

This formula is calculating the FPS for 2.5" piping on a 600CFM motor.

If we factor in the 1500* exh temp this is what I ended up with.

3.0” piping will have velocity at 390FPS. (.18 mach)

2.5” will be 585FPS. (.26 mach)

2.25” will be 694FPS (.32 mach)

2.0” will be 867FPS. (.40 mach)

So 2" piping appears to be right on the edge for a motor flowing 600CFM.

Most 4.8/5.3's aren't flowing anywhere near 600 cfm. So 2" piping would be my choice for a typical turbo kit on SBE motors. This is why I suggested 2.25 for a remote setup.

When dealing with cold side piping, most go overboard as well. According to the formula above most of us should be using 2"-2.25" intercooler piping!

Assuming 68* and sea level...

3.0” piping will have velocity at 203FPS. (.18 mach)

2.5” will be 293FPS. (.26 mach)

2.25” will be 361FPS (.32 mach)

2.0” will be 457FPS. (.40 mach)

This is all just to get a basic idea of the piping requirements. I also make no claims any of this is "correct".

I'd sure like to see how a remote mounted 5.3/4.8 with a 2.25 hot and cold side with a moderately large AR housing would compare to something like ZGLASS's car when he first built it.

Last edited by Forcefed86; 12-09-2014 at 01:53 PM.