Anyone using FT-350 Fuel Tech ECU?

#1

Picked up a car recently with one installed. (car not running).

I'm looking for the correct crank/cam settings to use for sequential fuel and spark. I have the 24/1 gen3 LS setup. I do see a "24-1" setting and I believe I could batch fire the inj/coils form this alone.

I'd like to use it in sequential fuel/spark mode. But the crank/cam setting choices don't correspond with the 1 tooth cam and 24t crank.

Any clues here? I tried FuelTech's online help. Sent 4 messages made 3 calls and used their "online support chat". Over the past 4 days I've had zero luck contacting anyone.

Thanks

I'm looking for the correct crank/cam settings to use for sequential fuel and spark. I have the 24/1 gen3 LS setup. I do see a "24-1" setting and I believe I could batch fire the inj/coils form this alone.

I'd like to use it in sequential fuel/spark mode. But the crank/cam setting choices don't correspond with the 1 tooth cam and 24t crank.

Any clues here? I tried FuelTech's online help. Sent 4 messages made 3 calls and used their "online support chat". Over the past 4 days I've had zero luck contacting anyone.

Thanks

#3

TECH Apprentice

If there was a 24 tooth setting, and you could trigger on the falling edge, you could get it to work, once you setup a cam sensor to trigger on falling or rising edge of the cam sensor

I bet there isn't tho.

If you had a gen 4 engine in there(or just the crank) and it had a 60-2 setting, it could do wasted spark pretty easily. 60-2 is very common, so maybe they (fueltech) supports that mode.

Scott(dieselgeek) would definately be the go to guy for those ECUs(and most other MODERN ecus)

Larson's S-10 on Dragweek this year, was running their top of the line one(FT500), and Scott was heavily involved in that project.

They seem pretty cool, I wouldn't mind getting one to mess with at some point.

They(fueltech ECUs) are very capable, but the 24x wheel on the 3 gen engines(and northstar engines) are a complicated animal.

I bet there isn't tho.

If you had a gen 4 engine in there(or just the crank) and it had a 60-2 setting, it could do wasted spark pretty easily. 60-2 is very common, so maybe they (fueltech) supports that mode.

Scott(dieselgeek) would definately be the go to guy for those ECUs(and most other MODERN ecus)

Larson's S-10 on Dragweek this year, was running their top of the line one(FT500), and Scott was heavily involved in that project.

They seem pretty cool, I wouldn't mind getting one to mess with at some point.

They(fueltech ECUs) are very capable, but the 24x wheel on the 3 gen engines(and northstar engines) are a complicated animal.

Last edited by atomic 6; 02-06-2015 at 11:13 PM.

#4

If there was a 24 tooth setting, and you could trigger on the falling edge, you could get it to work, once you setup a cam sensor to trigger on falling or rising edge of the cam sensor

I bet there isn't tho.

If you had a gen 4 engine in there(or just the crank) and it had a 60-2 setting, it could do wasted spark pretty easily. 60-2 is very common, so maybe they (fueltech) supports that mode.

Scott(dieselgeek) would definitely be the go to guy for those ECUs(and most other MODERN ecus)

Larson's S-10 on Dragweek this year, was running their top of the line one(FT500), and Scott was heavily involved in that project.

They seem pretty cool, I wouldn't mind getting one to mess with at some point.

They(fueltech ECUs) are very capable, but the 24x wheel on the 3 gen engines(and northstar engines) are a complicated animal.

I bet there isn't tho.

If you had a gen 4 engine in there(or just the crank) and it had a 60-2 setting, it could do wasted spark pretty easily. 60-2 is very common, so maybe they (fueltech) supports that mode.

Scott(dieselgeek) would definitely be the go to guy for those ECUs(and most other MODERN ecus)

Larson's S-10 on Dragweek this year, was running their top of the line one(FT500), and Scott was heavily involved in that project.

They seem pretty cool, I wouldn't mind getting one to mess with at some point.

They(fueltech ECUs) are very capable, but the 24x wheel on the 3 gen engines(and northstar engines) are a complicated animal.

It was already running on the previous gen 3 engine car. (or so seller claimed) The Ft400-500 can do sequential fuel/spark, but this unit can batch fire. It has the rising and falling edge options and I think I have the teeth settings input correctly at this point. Was a little confusing, they list it as "24(crank) or 48(cam)"

I can get it to crank over and even backfire, or try to kick the eng backwards. Def not timed correctly.

It's also asking my for the "Crank Index Position" Which was set at 16* (tune that came with car and supposedly ran the old 6.0 motor.)

configure the alignment of the trigger wheel

used in the engine, informing in which tooth the sensor is positioned when

the engine is on TDC (cylinder 1 on TDC). The teeth are counted from the

fault reference point (open space with no teeth), counter wise to the engine

RPM.

used in the engine, informing in which tooth the sensor is positioned when

the engine is on TDC (cylinder 1 on TDC). The teeth are counted from the

fault reference point (open space with no teeth), counter wise to the engine

RPM.

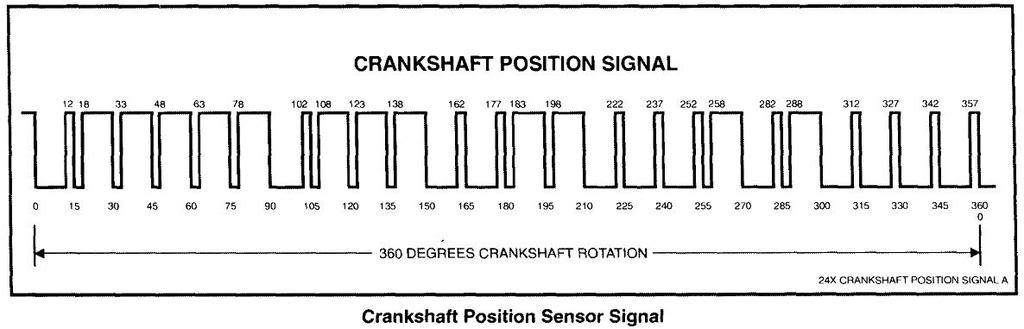

The primary trigger has 24 pulses per revolution where the falling edge of the trigger signal is at 15 deg intervals and the pulse length of the logical '0' is 12 or 3 degrees. As the pulse density is high and the difference is fairly large I think that we can detect this reliably even when cranking. The sync is possible in 90 deg.

Thanks!

#6

As I was saying these are suppose to work with the gen3 LS engine. Just not sure how to set it up properly to do so.

#7

9 Second Club

24-1 is common on some old Toyotas, Hondas, and not the same as the LS24x

BUt....whilst the rising edge on the 24x is all over the place, apparently the falling edge is a regular pattern and should be able to be used universally by most decent ecu's

As the image above shows there is a falling edge every 15deg of crank rotation.

But you would still need to configure the cam trigger properly to give the ecu a TDC reference, and a cyl 1 reference.

The reason you see 12 crank or 24 cam...is some engines, again Toyota, Nissan, Honda etc do this, they run a dizzy or trigger off the cam, so 12 teeth here rotating at cam speed, is essentially seen as 24 teeth for one full 720 cycle of the engine, but there are actually only 12 teeth seen per 360 deg crank rotation.

Looks like a lot of what you're paying for there is the fact it is a display, as the tech spec of the ecu itself is very very basic.

BUt....whilst the rising edge on the 24x is all over the place, apparently the falling edge is a regular pattern and should be able to be used universally by most decent ecu's

As the image above shows there is a falling edge every 15deg of crank rotation.

But you would still need to configure the cam trigger properly to give the ecu a TDC reference, and a cyl 1 reference.

The reason you see 12 crank or 24 cam...is some engines, again Toyota, Nissan, Honda etc do this, they run a dizzy or trigger off the cam, so 12 teeth here rotating at cam speed, is essentially seen as 24 teeth for one full 720 cycle of the engine, but there are actually only 12 teeth seen per 360 deg crank rotation.

Looks like a lot of what you're paying for there is the fact it is a display, as the tech spec of the ecu itself is very very basic.

Last edited by stevieturbo; 02-07-2015 at 02:09 PM.

Trending Topics

#8

9 Second Club

If you did 24 at crank, 48 cam, falling edge that should work.

You'd need to determine where either the rising or falling edge of the cam trigger ( assuming older single tooth ) falls to enter that value.

You may get the engine to start via trial and error here, but this MUST be final checked with a timing light.

It seems they are calling the cam trigger position the "First Tooth Alignment"...strange term for it.

You'd need to determine where either the rising or falling edge of the cam trigger ( assuming older single tooth ) falls to enter that value.

You may get the engine to start via trial and error here, but this MUST be final checked with a timing light.

It seems they are calling the cam trigger position the "First Tooth Alignment"...strange term for it.

#9

9 Second Club

If this thread is right, you could try rising edge for the cam and approx 350deg...that should get you started enough to hook up a timing light and set it accurately.

https://ls1tech.com/forums/pcm-diagn...ank-scope.html

https://ls1tech.com/forums/pcm-diagn...ank-scope.html

Last edited by stevieturbo; 02-07-2015 at 02:27 PM.

#10

Nothing is listed as "LS1". But they have the popular 24-1, 24-2 60-2 etc... Then they list separately the "12 (crank) or 24 (cam)" and "24 (crank) or 48 (cam)" and the ability to choose magnetic or HALL sensors with rising or falling edge.

As I was saying these are suppose to work with the gen3 LS engine. Just not sure how to set it up properly to do so.

As I was saying these are suppose to work with the gen3 LS engine. Just not sure how to set it up properly to do so.

I'm installing a FT500 and like to know about...

I have a GENIII LR4 with 24x sensor