C5 Custom APS upgrades

#1

Like (almost) everyone else with an APS TT setup, it was only a matter of time until it was necessary to replace the original turbos that came with the kit. I know there are a few good options out there already for upgrading these turbos, but I decided to build my own upgrade based on the GT35R turbos. I went this route because the GT35R's are ball bearing, retain the water cooled feature and leave room for plenty more hp (especially with the new GTX wheels). The kicker of the whole deal is the turbine housings, they are custom to the APS kit. My solution is pictured above. They are a bit more compact than the originals, 1.06 A/R, 100% 304 stainless steel and 100% made in the USA! Lots of fun to be had with these beauties!

#4

Thanks!

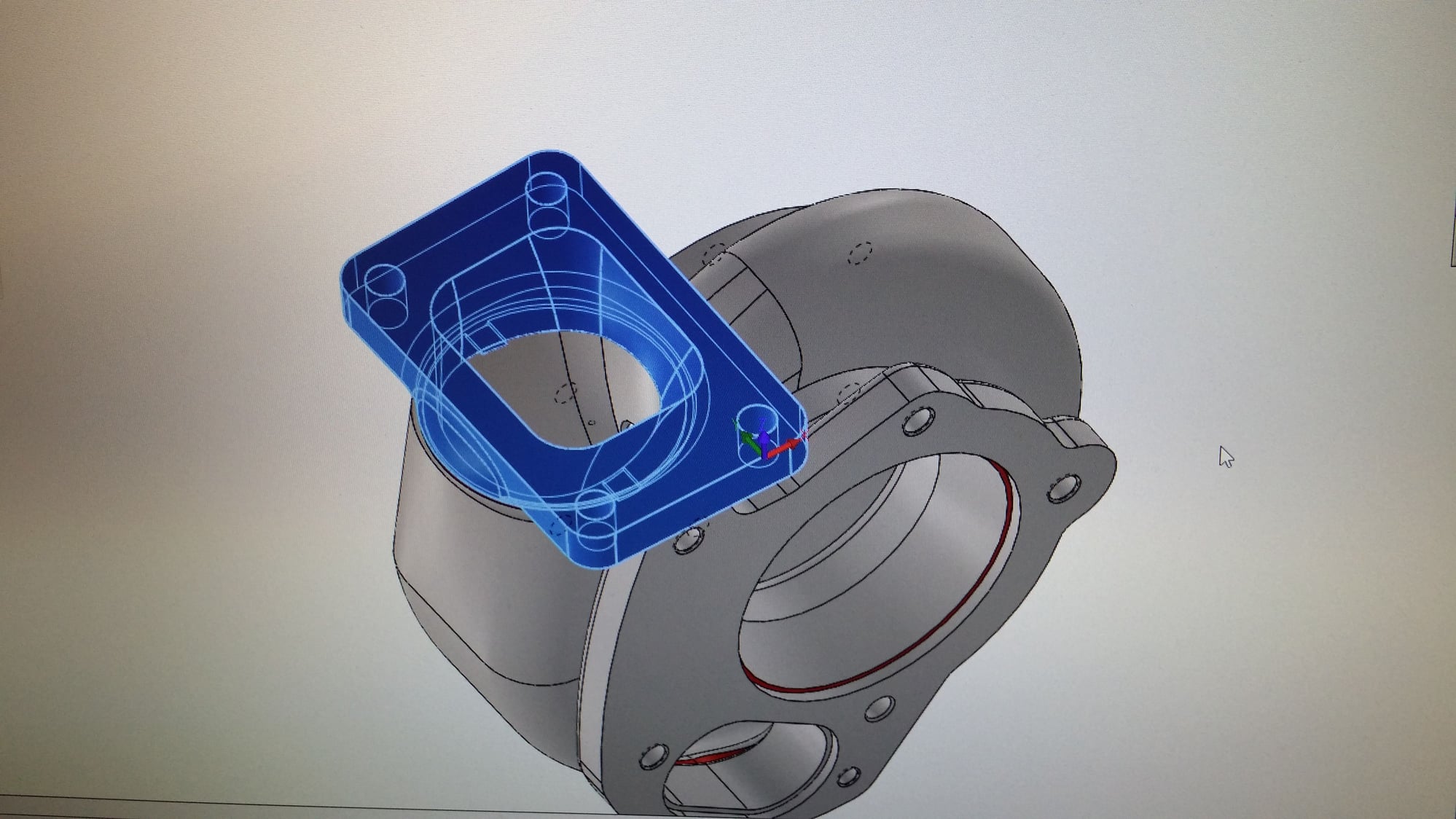

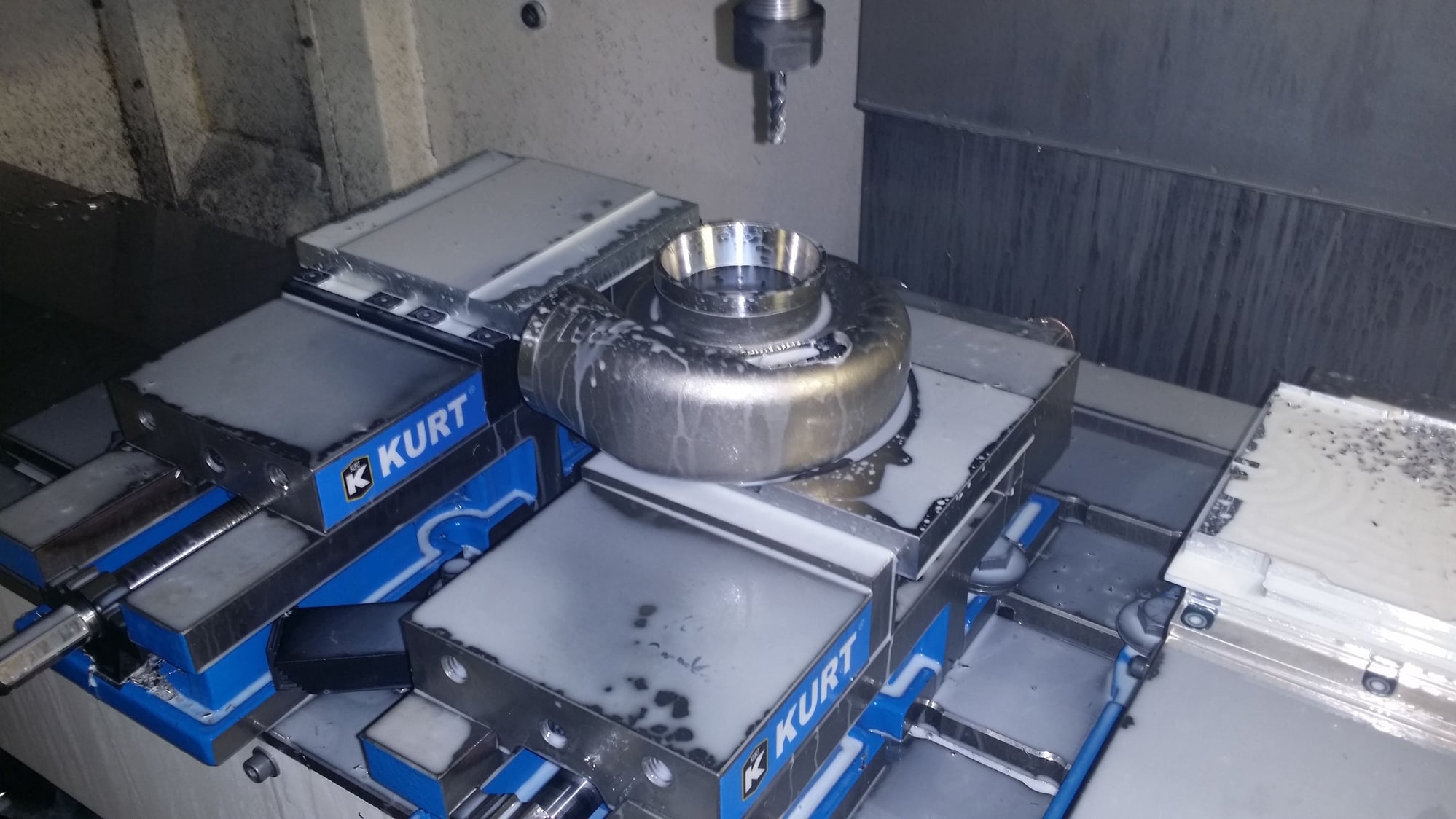

How much did it cost????...well the true costs of this are a little blurry, but I can tell you that there were countless hours in CMM time, 3d modeling, 3d printing (for mockup), fixture building, CNC machining, and welding. On the other hand, I own a CNC machine shop and enjoy doing this kind of stuff on the side, so it really only cost me the materials to do it. I take pride in the fact that I built them, and the quality of these are second to none! The benefits of using these turbos with a stainless turbine housing are, in my opinion, worth the extra time and expense compared to the other options out there.

If I had to price out the cost of building another set, it would be around $4,700 for both turbos. Each turbo sells for about $1750 on atpturbo.com with the tial stainless housing (need to order it with the T04B compressor cover) and it would run about $1200 to modify the Tial housings to bolt up to the APS exhaust. By no means did I expect this project to ever go into production, but I'd be willing to help out anyone else that is looking to do the same if needed.

How much did it cost????...well the true costs of this are a little blurry, but I can tell you that there were countless hours in CMM time, 3d modeling, 3d printing (for mockup), fixture building, CNC machining, and welding. On the other hand, I own a CNC machine shop and enjoy doing this kind of stuff on the side, so it really only cost me the materials to do it. I take pride in the fact that I built them, and the quality of these are second to none! The benefits of using these turbos with a stainless turbine housing are, in my opinion, worth the extra time and expense compared to the other options out there.

If I had to price out the cost of building another set, it would be around $4,700 for both turbos. Each turbo sells for about $1750 on atpturbo.com with the tial stainless housing (need to order it with the T04B compressor cover) and it would run about $1200 to modify the Tial housings to bolt up to the APS exhaust. By no means did I expect this project to ever go into production, but I'd be willing to help out anyone else that is looking to do the same if needed.

#7

Thanks guys!

I have a 427 LSX in the works that will be able to handle the bigger 1.06 a/r housings, but the 6.0 does alright for now at 14psi :-) I did notice a difference in low end torque with the bigger housings/garrett turbine design over the APS ones.

I was actually ready to go down the billet housing road until I found these Tial housings. The main reasons I used them is because they are 304 stainless (which welds up a lot nicer than cast!), they are very compact and lightweight, and I'm guessing that there is a little bit of science that I am unaware of that goes into shaping a turbine housing. They are spendy...but very nice!

I have a 427 LSX in the works that will be able to handle the bigger 1.06 a/r housings, but the 6.0 does alright for now at 14psi :-) I did notice a difference in low end torque with the bigger housings/garrett turbine design over the APS ones.

I was actually ready to go down the billet housing road until I found these Tial housings. The main reasons I used them is because they are 304 stainless (which welds up a lot nicer than cast!), they are very compact and lightweight, and I'm guessing that there is a little bit of science that I am unaware of that goes into shaping a turbine housing. They are spendy...but very nice!

Trending Topics

#9

12 Second Club

iTrader: (13)

Me and SM105K are still going to the "APS Anonymous" meetings, but I still like to check out other APS user's builds. But it looks like you went the correct route and have gone to the correct turbos that won't blow. I was just tired of putting money into mine. I probably could have done 2 front mount builds with my APS dramas. lol

#11

Me and SM105K are still going to the "APS Anonymous" meetings, but I still like to check out other APS user's builds. But it looks like you went the correct route and have gone to the correct turbos that won't blow. I was just tired of putting money into mine. I probably could have done 2 front mount builds with my APS dramas. lol

I know exactly what you mean....I have the car on the road now but the little voice in the back of my head is telling me that I still need to re-do the intake plumbing. It's endless.

#12

On The Tree

Thanks!

How much did it cost????...well the true costs of this are a little blurry, but I can tell you that there were countless hours in CMM time, 3d modeling, 3d printing (for mockup), fixture building, CNC machining, and welding. On the other hand, I own a CNC machine shop and enjoy doing this kind of stuff on the side, so it really only cost me the materials to do it. I take pride in the fact that I built them, and the quality of these are second to none! The benefits of using these turbos with a stainless turbine housing are, in my opinion, worth the extra time and expense compared to the other options out there.

If I had to price out the cost of building another set, it would be around $4,700 for both turbos. Each turbo sells for about $1750 on atpturbo.com with the tial stainless housing (need to order it with the T04B compressor cover) and it would run about $1200 to modify the Tial housings to bolt up to the APS exhaust. By no means did I expect this project to ever go into production, but I'd be willing to help out anyone else that is looking to do the same if needed.

How much did it cost????...well the true costs of this are a little blurry, but I can tell you that there were countless hours in CMM time, 3d modeling, 3d printing (for mockup), fixture building, CNC machining, and welding. On the other hand, I own a CNC machine shop and enjoy doing this kind of stuff on the side, so it really only cost me the materials to do it. I take pride in the fact that I built them, and the quality of these are second to none! The benefits of using these turbos with a stainless turbine housing are, in my opinion, worth the extra time and expense compared to the other options out there.

If I had to price out the cost of building another set, it would be around $4,700 for both turbos. Each turbo sells for about $1750 on atpturbo.com with the tial stainless housing (need to order it with the T04B compressor cover) and it would run about $1200 to modify the Tial housings to bolt up to the APS exhaust. By no means did I expect this project to ever go into production, but I'd be willing to help out anyone else that is looking to do the same if needed.

So 1200 is just for modding the tial housings ??.......what if I just wanted to modify the footprint to match the aps manifolds and use v bands for the exhaust.

#14

The Tial housing is very close to the footprint of the aps housing. I could just mod the housing and make you a new inlet plate. The vband on the outlet would match right up. What about the waste gate port? Would you still need a hole cut for a tube to be welded in? I could also just make the parts and you could weld them together if you want.

#15

#16

I know on the TTix corvette kits people have taken the weastgate port directly off the bottom of the turbine housing. It seemed to work for them lretty well. If you could mid the APS manifold to take the Vband than you would only need to make the weastagte port on the turbo.

Guess it comes down to where is the best place for the weastgate as to how you do that one.

Guess it comes down to where is the best place for the weastgate as to how you do that one.

#17

Thanks guys!

I have a 427 LSX in the works that will be able to handle the bigger 1.06 a/r housings, but the 6.0 does alright for now at 14psi :-) I did notice a difference in low end torque with the bigger housings/garrett turbine design over the APS ones.

I was actually ready to go down the billet housing road until I found these Tial housings. The main reasons I used them is because they are 304 stainless (which welds up a lot nicer than cast!), they are very compact and lightweight, and I'm guessing that there is a little bit of science that I am unaware of that goes into shaping a turbine housing. They are spendy...but very nice!

I have a 427 LSX in the works that will be able to handle the bigger 1.06 a/r housings, but the 6.0 does alright for now at 14psi :-) I did notice a difference in low end torque with the bigger housings/garrett turbine design over the APS ones.

I was actually ready to go down the billet housing road until I found these Tial housings. The main reasons I used them is because they are 304 stainless (which welds up a lot nicer than cast!), they are very compact and lightweight, and I'm guessing that there is a little bit of science that I am unaware of that goes into shaping a turbine housing. They are spendy...but very nice!

Final result are both stunning and should be much better than the originals.

#19

On The Tree

The Tial housing is very close to the footprint of the aps housing. I could just mod the housing and make you a new inlet plate. The vband on the outlet would match right up. What about the waste gate port? Would you still need a hole cut for a tube to be welded in? I could also just make the parts and you could weld them together if you want.

#20

Thanks. Yeah cutting into the first one was definitely a nail biting experience!

how much did it cost ?

how much did it cost ?