How is everyone building brace supports for their turbo?

#1

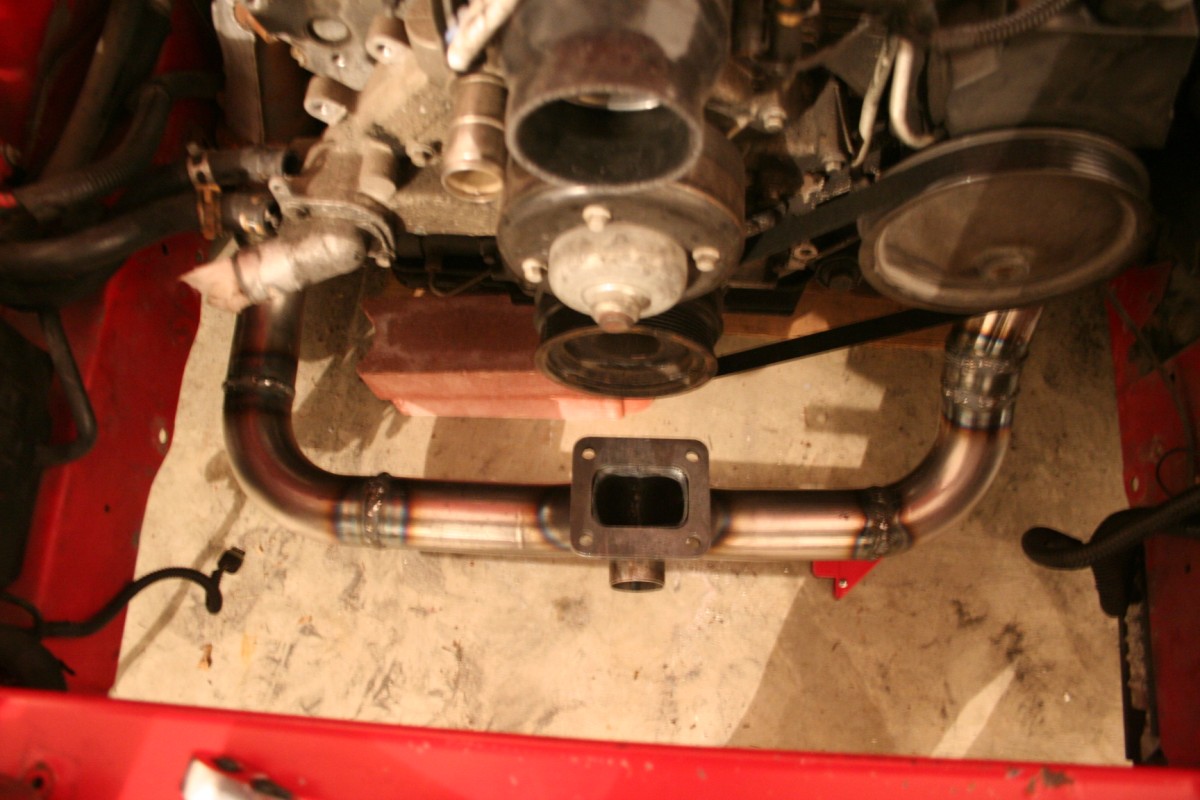

Looking around at everyone's setup and cant really see how yall are supporting the weight of the turbo. Could we get some undershots to see where you are mounting your braces to the turbo and to what part of the engine bay (or engine if mounted directly)

I am going to mount mine where the battery used to go and was trying to figure out how to brace it and also what to do about the pipes flexing as the engine moves, just probably stick a couple of flex joints somewhere?

I am going to mount mine where the battery used to go and was trying to figure out how to brace it and also what to do about the pipes flexing as the engine moves, just probably stick a couple of flex joints somewhere?

#6

looks good, i would rather mount it to the exhaust housing being that it is cast iron rather than softer aluminum. Besides exhaust housing are cheaper to replace if they do crack.

The following users liked this post:

Homer_Simpson (08-31-2023)

Trending Topics

#10

I've seen a few manifolds/turbo's braced to the chassis like this crack the manifold, when the motor rocks there isnt any give for the manifold.

#13

11 Second Club

iTrader: (8)

Join Date: Nov 2006

Location: Round Lake, NY

Posts: 1,217

Likes: 0

Received 0 Likes

on

0 Posts

well I would think it would help avoid cracking...since their is pivot joints in there and when the motor torques back and forth, the points take away the stress...So I would think it would be good to go.

#15

9 Second Club

iTrader: (22)

I know it wont do any good for you reject since your keeping ac, but i was going to use some roundbar and flat iron and put some bolts in the motor where the ac used to bolt up. IF i make it symmetrical and do it on both sides, we could do one on the alternator side to..

Chris

#17

#19

9 Second Club

iTrader: (22)

My source of info happens to be the shop that builds the fastest toyota supra's in the country. They have been in business almost 20 yrs, and they told me if you have solid mounts you can go to the body, otherwise go to the motor. Im sure the flex could work, but it would all depend on how much the flex can move. Also i kind of like the idea of having the turbo supported by the merge/and a support. Meaning if 1 fails the other is still there. If all you have is the support, then if something happens, how much does the flex move and where does the turbo go?

I also dont know your setup, but on my 240 that was turbo, the flex is always blowing out. It has happened to alot of friends with wrx's to.

Just telling you my experience, and what i have been told. Im sure it could be made to work just fine.

Chris