Changing 10-bolt axle and bearing. Can it be done at home?

#1

Launching!

Thread Starter

iTrader: (5)

Join Date: Dec 2010

Location: Louisiana

Posts: 235

Likes: 0

Received 0 Likes

on

0 Posts

I've been trying to pin-point some vibration and noise coming from my rear end for a while now. It seems to be coming from the passenger rear. First thing i found out was that the wheel that was on it was badly bent so i bought a good used one and had it mounted and balanced. The noise was still there after the new wheel.

I jacked up my car and ran the tires at idle while looking down the side of the wheel for a wobble. There could possibly be a slight wobble but no where near the amount when the old bent wheel was on.

I got my girlfriend to run the tires at 30mph while i poked around the rear end with a stethoscope. I checked around the pumpkin and at the end by the wheel bearings. The noise was the loudest closest to the wheel bearings.

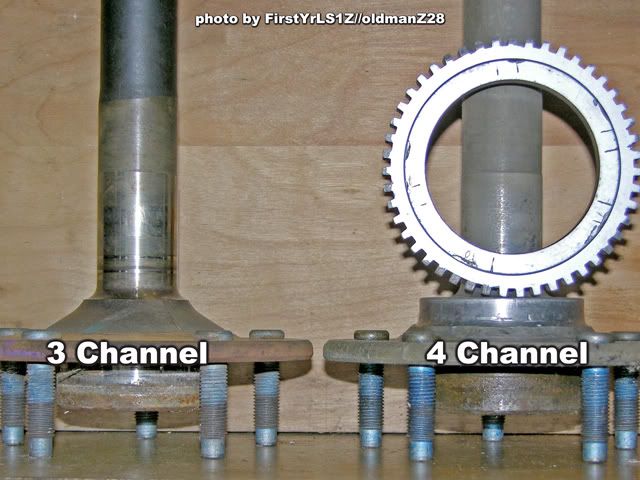

So i plan on getting a used axle and a bearing kit. Will i need any special tools or will i need to bring anything to a machine shop to have anything pressed off/on? It's a 4-channel rear.

I jacked up my car and ran the tires at idle while looking down the side of the wheel for a wobble. There could possibly be a slight wobble but no where near the amount when the old bent wheel was on.

I got my girlfriend to run the tires at 30mph while i poked around the rear end with a stethoscope. I checked around the pumpkin and at the end by the wheel bearings. The noise was the loudest closest to the wheel bearings.

So i plan on getting a used axle and a bearing kit. Will i need any special tools or will i need to bring anything to a machine shop to have anything pressed off/on? It's a 4-channel rear.

#2

TECH Veteran

iTrader: (4)

Axle bearings ( and seal ) are pressed into the housing and not onto the axle.

Being a 2002,you would have a Torsen differential. Removing the center 'paddle' will allow the axle to move in to be able to remove the 'c-clips'. Axles will slide out then with the bearings and seals still in the housing.

There are 'axle saver bearing kits' that relocate the bearing in a slightly different position on the axle in order to be able to use a 'worn' axle. Using those 'kits' don't allow the axles to go in far enough to re-insert the c-clips. Avoid those 'kits'.

removing the bearings from the housing requires some kind of puller.

Being a 2002,you would have a Torsen differential. Removing the center 'paddle' will allow the axle to move in to be able to remove the 'c-clips'. Axles will slide out then with the bearings and seals still in the housing.

There are 'axle saver bearing kits' that relocate the bearing in a slightly different position on the axle in order to be able to use a 'worn' axle. Using those 'kits' don't allow the axles to go in far enough to re-insert the c-clips. Avoid those 'kits'.

removing the bearings from the housing requires some kind of puller.

#4

On The Tree

iTrader: (2)

Join Date: Jun 2010

Location: Arkansas

Posts: 127

Likes: 0

Received 0 Likes

on

0 Posts

Autozone is your friend. Just did axle bears/seals on mine and its a piece of cake. Autozone rents the bearing puller and the slide hammer. You will also need the bearing/race driver too, but look up the part number online. The guys instore sometimes have trouble finding it. Definitely doable in home though.

-Will

-Will

#6

Launching!

iTrader: (1)

I did one of these outside an auto parts store, and I'd never even seen the inside of a differential, much less removed an axle. Very easy. As stated above, make sure you have all your parts before you start. Axle bearing slide hammer, bearing installation tool, new bearings, new seals, etc. If you were only gonna do one side only, don't. Do both. I don't know much about the reluctor though.

One tip, get a GOOD quality axle bearing puller. I went to rent one and found some of the claws broken off already. You'll likely have to slam that slide hammer hard, so make sure it's a good named puller. You don't want some foreign no name slag metal tool from the clearance bin. The bearing installation tool was actually a mini set. Definately make sure there is more than one or two pieces cause not all bearings/axle tubes are the same size, lol.

One tip, get a GOOD quality axle bearing puller. I went to rent one and found some of the claws broken off already. You'll likely have to slam that slide hammer hard, so make sure it's a good named puller. You don't want some foreign no name slag metal tool from the clearance bin. The bearing installation tool was actually a mini set. Definately make sure there is more than one or two pieces cause not all bearings/axle tubes are the same size, lol.

Trending Topics

#8

Banned

iTrader: (4)

Join Date: Feb 2011

Location: Hinesville GA

Posts: 226

Likes: 0

Received 0 Likes

on

0 Posts

i had the same wabble and a noise coming from my 10 bolt or so i thought, turnout out one of my rear brake calipers was hanging up and not fully releasing..it was easily fixed when i replaced the caliper