Help me better understand lifters

#1

Moderator

Thread Starter

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,836 Likes

on

1,145 Posts

There have been a few lifter threads show up, and prior to reading them I thought I understood lifters. Now I'm not so sure.

For example, I would have thought solid lifters would provide more power than hydraulics on identical cam and valve train. But then I see JakeFusion saying to increase duration of you go to solids. And Jake is a someone whose recommendations you can hang your hat on.

So, what separates good lifters from bad ones? What are the pitfalls to avoid when selecting lifters? Why do so many people use LS7 lifters, which I would have thought are only marginally better than the LS1 lifters?

For example, I would have thought solid lifters would provide more power than hydraulics on identical cam and valve train. But then I see JakeFusion saying to increase duration of you go to solids. And Jake is a someone whose recommendations you can hang your hat on.

So, what separates good lifters from bad ones? What are the pitfalls to avoid when selecting lifters? Why do so many people use LS7 lifters, which I would have thought are only marginally better than the LS1 lifters?

#2

Solid roller cams have a different ramp design and being completely mechanical, their lifter design is quite a bit different than a hydraulic lifter (solid roller lifters are just what their name implies....basically a "solid" lifter which incorporates a cup to hold the pushrod, a link bar typically, and a roller wheel that rides on the cam).

SR lifters have no hyd plungers and moving parts to absorb shock or thermal expansion etc., and they require valve lash to help the valvetrain live and account for cold and hot engines. A tight lash solid in a very cold garage may actually not start or run crappy when it does (till it warms up) based on the fact your .014 lash at operating temp is actually holding the valve open when everything is cold. Cold engines have less lash than hot engines when they warm up because the head and block expand pushing the rocker arms further from the pushrods increasing lash with temperature. Most lash measurements are meant to be set at full operating temps with hot oil.

The biggest issue I think that is confusing to some (and what you also mentioned Darth) is related to the numbers. Its not that you NEED a bigger cam with a solid.....its just that a larger cam on paper in a solid roller acts smaller in the real world because some of the duration is eliminated due to actually having the valve lash which delays the opening of the valve and sets the valve down sooner acting like an HR cam some 8 degrees smaller in actual function.

For instance my 383 SR motor that I built in 2005 or so....I ran a 242/248 (114 LSA) stick in that and it drove really well while still making big power with the rest of the optimized package around it....but its deceiving because in actuality, it has about the same overlap as a 234/240 HR on the same 114 LSA which most would agree is middle of the road at best in aggressiveness for a 383 CID engine.....hence the reason it did drive as well as it did with minimal protest or surging even as low as 1200 RPM's lugging it around a corner in 3rd gear. Point is it does look bigger on paper but it wont act like an HR of the same size.....you have to get your head wrapped around that if your considering a solid roller.

I'm 53 and I have been at this hobby (and loving it) for over 30 years....closer to 35 actually, and back in the day you had no choice but to run a solid if you wanted the serious power potential that RPM always brings to the table.....not to mention the extra lift a solid usually helps with tapping your cylinder heads for more of the bigger peak numbers.....it all added up to a combo that would destroy an HR in yesteryear's world because parts were heavy.....hydraulic roller technology was light-years behind the times.....no limited travel plunger and low bleed down rates to help valve control.....the springs and valves were boat anchors.....really heavy.....you couldn't get much past 6K without serious valve float with an HR grind but a solid would rip to 7K with ease.....especially if you had a good head and manifold and cam combination that all worked together. Back in the day an SR could be worth 50+ HP or more cause you just couldnt get serious with an HR back then.

Fast forward to today.....smaller diameter lighter weight valves....spring pressures that are the same as heavy springs of yesteryear but weigh 40% less and have much smaller footprints/mass....badazz trick hydraulic roller lifters with anti bleed features and limited travel, lightweight rocker gear, etc. etc,....everything to help a good set-up with an HR make big power and have perfect power curves and offer zero maintenance and lash adjustments. It really is awesome what you guys take for granted now and I cant really blame you because if you haven't been on the planet as long you just never experienced as much advancement and technology in the sport.

Bottom line....will a solid roller guarantee a performance increase....it really depends on how well you set up your HR set-up to compare it to. If you don't have ALL your ducks in a row with an HR set-up, its alot easier to have that perfect valve control with a solid but your going to have to get under those valve covers once in a while to adjust them. I know the low lash deal has been the rage of late but IMO its really best suited for the 10% crowd.....most guys want to build there deal and then just drive the ***** off it with little maintenance besides a few oil changes. Honestly Im in the 10% crowd but know how little I would give up with the right HR set-up and even I opted for an HR grind in Vader which was pretty much a see what we can make for power type of build.

Don't forget though.....HR's can suck if you don't get it right and cost you alot of power....the jagged dyno graphs that are almost commonplace are due to valvetrains that aren't completely optimized.....stock lifters that give up the ghost quickly, heavy rockers perhaps, the wrong valve springs, flimsy pushrods.....etc, etc.. In some respects an SR set-up almost forces you to do everything right....beefier rockers, pushrods, springs are all required if your going in that direction.

Anyway....I know I just threw up a bunch of information that wasn't even brought up yet, but its all relevant to the question is an SR right for you and why/how is an SR potentially better than an HR. BUT....also keeping in mind that if you nail the combo with an HR and carefully select all your components properly (optimizing the valvetrain for an HR set-up), then your not really giving up much in regards to power and perfect valve control (see the power curve shape of any one of my builds.....all look like an SR was installed)....not to mention a quieter valvetrain with zero maintenance is a perk most appreciate. If you guys think some of the hyd rollers sound like a "sewing machine" I assure you a solid will certainly get your attention (but I still appreciate and like the sound of an SR with all the lash dialed in perfectly...its kind of a sweet mechanical "whurring" of parts....LOL).

What do you know.....its 3AM again.....LOL

Catch you guys later.....sorry for the ramble....hope some/most of it was helpful!!

Cheers,

Tony

SR lifters have no hyd plungers and moving parts to absorb shock or thermal expansion etc., and they require valve lash to help the valvetrain live and account for cold and hot engines. A tight lash solid in a very cold garage may actually not start or run crappy when it does (till it warms up) based on the fact your .014 lash at operating temp is actually holding the valve open when everything is cold. Cold engines have less lash than hot engines when they warm up because the head and block expand pushing the rocker arms further from the pushrods increasing lash with temperature. Most lash measurements are meant to be set at full operating temps with hot oil.

The biggest issue I think that is confusing to some (and what you also mentioned Darth) is related to the numbers. Its not that you NEED a bigger cam with a solid.....its just that a larger cam on paper in a solid roller acts smaller in the real world because some of the duration is eliminated due to actually having the valve lash which delays the opening of the valve and sets the valve down sooner acting like an HR cam some 8 degrees smaller in actual function.

For instance my 383 SR motor that I built in 2005 or so....I ran a 242/248 (114 LSA) stick in that and it drove really well while still making big power with the rest of the optimized package around it....but its deceiving because in actuality, it has about the same overlap as a 234/240 HR on the same 114 LSA which most would agree is middle of the road at best in aggressiveness for a 383 CID engine.....hence the reason it did drive as well as it did with minimal protest or surging even as low as 1200 RPM's lugging it around a corner in 3rd gear. Point is it does look bigger on paper but it wont act like an HR of the same size.....you have to get your head wrapped around that if your considering a solid roller.

I'm 53 and I have been at this hobby (and loving it) for over 30 years....closer to 35 actually, and back in the day you had no choice but to run a solid if you wanted the serious power potential that RPM always brings to the table.....not to mention the extra lift a solid usually helps with tapping your cylinder heads for more of the bigger peak numbers.....it all added up to a combo that would destroy an HR in yesteryear's world because parts were heavy.....hydraulic roller technology was light-years behind the times.....no limited travel plunger and low bleed down rates to help valve control.....the springs and valves were boat anchors.....really heavy.....you couldn't get much past 6K without serious valve float with an HR grind but a solid would rip to 7K with ease.....especially if you had a good head and manifold and cam combination that all worked together. Back in the day an SR could be worth 50+ HP or more cause you just couldnt get serious with an HR back then.

Fast forward to today.....smaller diameter lighter weight valves....spring pressures that are the same as heavy springs of yesteryear but weigh 40% less and have much smaller footprints/mass....badazz trick hydraulic roller lifters with anti bleed features and limited travel, lightweight rocker gear, etc. etc,....everything to help a good set-up with an HR make big power and have perfect power curves and offer zero maintenance and lash adjustments. It really is awesome what you guys take for granted now and I cant really blame you because if you haven't been on the planet as long you just never experienced as much advancement and technology in the sport.

Bottom line....will a solid roller guarantee a performance increase....it really depends on how well you set up your HR set-up to compare it to. If you don't have ALL your ducks in a row with an HR set-up, its alot easier to have that perfect valve control with a solid but your going to have to get under those valve covers once in a while to adjust them. I know the low lash deal has been the rage of late but IMO its really best suited for the 10% crowd.....most guys want to build there deal and then just drive the ***** off it with little maintenance besides a few oil changes. Honestly Im in the 10% crowd but know how little I would give up with the right HR set-up and even I opted for an HR grind in Vader which was pretty much a see what we can make for power type of build.

Don't forget though.....HR's can suck if you don't get it right and cost you alot of power....the jagged dyno graphs that are almost commonplace are due to valvetrains that aren't completely optimized.....stock lifters that give up the ghost quickly, heavy rockers perhaps, the wrong valve springs, flimsy pushrods.....etc, etc.. In some respects an SR set-up almost forces you to do everything right....beefier rockers, pushrods, springs are all required if your going in that direction.

Anyway....I know I just threw up a bunch of information that wasn't even brought up yet, but its all relevant to the question is an SR right for you and why/how is an SR potentially better than an HR. BUT....also keeping in mind that if you nail the combo with an HR and carefully select all your components properly (optimizing the valvetrain for an HR set-up), then your not really giving up much in regards to power and perfect valve control (see the power curve shape of any one of my builds.....all look like an SR was installed)....not to mention a quieter valvetrain with zero maintenance is a perk most appreciate. If you guys think some of the hyd rollers sound like a "sewing machine" I assure you a solid will certainly get your attention (but I still appreciate and like the sound of an SR with all the lash dialed in perfectly...its kind of a sweet mechanical "whurring" of parts....LOL).

What do you know.....its 3AM again.....LOL

Catch you guys later.....sorry for the ramble....hope some/most of it was helpful!!

Cheers,

Tony

__________________

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

www.mamomotorsports.com

Tony@MamoMotorsports.com

Anything worth doing is worth doing well. Build it right the first time....its alot cheaper than building it twice!!

Last edited by Tony @ Mamo Motorsports; 07-10-2015 at 03:11 PM.

#3

TECH Senior Member

iTrader: (4)

What separates a good lifter from a less expensive lifter is typically materials, machining tolerances, oiling, etc. Also, some of the aftermarket lifter manufacturers have taken into account that an aftermarket cam with a smaller base circle places the lifter lower in the oil gallery and its lift will be higher. Their designs assure that there won't be oil starvation issues.

GM specifies their lifter for stock springs and lift, and if you think about it, they last a very long time in a stock car. I have not had any stock GM products in recent years that I have sent to the dump with a crapload of miles that had a lifter problem. As a matter of fact, my Suburban still ran great at 250K but the frame/body rotted out due to the New England winter salt bath every year.

Also, as Tony stated, there are a number of components that need to be well thought out within the valve train. My pet peeve is the pushrods where most think hardened pushrods are stiffer than stock. They are marginally stiffer since they typically have a thicker wall, but to truly increase the stiffness and decrease the flex you need a larger OD. I went from 5/16" pushrods to 3/8 double taper and it really altered the shape of the curve above 6K RPM indicating that there was some instability in my valve train. This instability could have led to other issues over time with other components in the valve train.

#4

Moderator

Thread Starter

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,836 Likes

on

1,145 Posts

Thanks both of you. That helps. I mean, it sounds like a heads/cam thing where the combination matters more than the individual pieces?

So for example, I may not get much benefit to throwing in a set of Johnson or morels without also looking at rockers and pushrods?

So if I want to put 3/8 rods in, would the boss in the heads need to be drilled out? I have 5/16 .080" in now. Also, it seems the pushrods being heavier makes no difference due to it being on the short side of the lever? Let's be stupi and say each one weighs a half pound. No measurable effect on the valve train, because it's not on the sprung side anyway? Light over the valve and heavy over the lifter is ok?

And Tony, your replies are quite lucid at 3am.

So for example, I may not get much benefit to throwing in a set of Johnson or morels without also looking at rockers and pushrods?

So if I want to put 3/8 rods in, would the boss in the heads need to be drilled out? I have 5/16 .080" in now. Also, it seems the pushrods being heavier makes no difference due to it being on the short side of the lever? Let's be stupi and say each one weighs a half pound. No measurable effect on the valve train, because it's not on the sprung side anyway? Light over the valve and heavy over the lifter is ok?

And Tony, your replies are quite lucid at 3am.

#5

TECH Veteran

iTrader: (14)

Hey Darth, basically its what vette nuts said the ls7 lifter is just what it is, a stock replacement. When you get into springs with a lot of pressure the ls7's start to bleed down in the various rpm ranges. Better lifters like johnson or morel use a disk based plunger over a ball one likke the ls7 uses. Tolerances, metal, bleed down rate and springs inside the lifter are all upgraded as well as in some cases the travel reduced of the actual lifter plunger. An ls7 lifter has .200" of travel in the plunger, a morel 5315 is also .200" but go to a johnson 2110 and you get only .150" or the 2116 which has .093 or even then to the reduced travel 2116 which is .05.

Naturally as you get less and less travel things like preload become more and more sensitive, but the lifter can take more abuse. If you have stock heads the holes have to be machined for 3/8 pr's 9/10 times. The biggest that will reliably fit in there is a 3/8-5/16 double taper which are expensive lol however if I had a cam thats what I would run. If i was just going for stock replacements 11/32 would be fine. Weight still plays a role on that side of the valve but its much less critical than it is over the valve. Basically get the biggest pushrod you can in there lol which in a stock head case is the double taper. You want the lightest things you can on the valve side and beefy as possible on the other.

In your case I dont think you would gain much by going to a good johnson or higher end morel...I say that because the 5315 is very similar to an ls7 but is still a better lifter although just not as good as the higher end drop-ins. Better lifters wont add power by themselves, if the stock lifter is functioning normally then going to a different one wont do anything. However the problem is that violent cam lobes, and heavy springs dont make the lifters job easy and its there that people see an increase in stability and thus a better power curve.

IF i was building a mild cam only setup and had the funds I would go right to the 2110 its extra security saying you wont have any issues in the future whereas an ls7 lifter might get tired down the line. Then also if I wanted to go with a bigger cam/spring/rocker combo I wouldnt need to tear the heads off again. If I was on an extreme budget then the 5315 would be fine. Morel only rates the 5315 to 6300 rpm, I know everyone spins them higher but nonetheless thats what they're rated to. The 2110 is in the copo that sees 8500 rpm 1/4 mile at a time and was chosen by gm for the application. That right there is a testament to quality, theres a reason they didnt use the ls7 in it lol

Naturally as you get less and less travel things like preload become more and more sensitive, but the lifter can take more abuse. If you have stock heads the holes have to be machined for 3/8 pr's 9/10 times. The biggest that will reliably fit in there is a 3/8-5/16 double taper which are expensive lol however if I had a cam thats what I would run. If i was just going for stock replacements 11/32 would be fine. Weight still plays a role on that side of the valve but its much less critical than it is over the valve. Basically get the biggest pushrod you can in there lol which in a stock head case is the double taper. You want the lightest things you can on the valve side and beefy as possible on the other.

In your case I dont think you would gain much by going to a good johnson or higher end morel...I say that because the 5315 is very similar to an ls7 but is still a better lifter although just not as good as the higher end drop-ins. Better lifters wont add power by themselves, if the stock lifter is functioning normally then going to a different one wont do anything. However the problem is that violent cam lobes, and heavy springs dont make the lifters job easy and its there that people see an increase in stability and thus a better power curve.

IF i was building a mild cam only setup and had the funds I would go right to the 2110 its extra security saying you wont have any issues in the future whereas an ls7 lifter might get tired down the line. Then also if I wanted to go with a bigger cam/spring/rocker combo I wouldnt need to tear the heads off again. If I was on an extreme budget then the 5315 would be fine. Morel only rates the 5315 to 6300 rpm, I know everyone spins them higher but nonetheless thats what they're rated to. The 2110 is in the copo that sees 8500 rpm 1/4 mile at a time and was chosen by gm for the application. That right there is a testament to quality, theres a reason they didnt use the ls7 in it lol

#6

TECH Veteran

iTrader: (14)

Hey Darth, basically its what vette nuts said the ls7 lifter is just what it is, a stock replacement. When you get into springs with a lot of pressure the ls7's start to bleed down in the various rpm ranges. Better lifters like johnson or morel use a disk based plunger over a ball one likke the ls7 uses. Tolerances, metal, bleed down rate and springs inside the lifter are all upgraded as well as in some cases the travel reduced of the actual lifter plunger. An ls7 lifter has .200" of travel in the plunger, a morel 5315 is also .200" but go to a johnson 2110 and you get only .150" or the 2116 which has .093 or even then to the reduced travel 2116 which is .05.

Naturally as you get less and less travel things like preload become more and more sensitive, but the lifter can take more abuse. If you have stock heads the holes have to be machined for 3/8 pr's 9/10 times. The biggest that will reliably fit in there is a 3/8-5/16 double taper which are expensive lol however if I had a cam thats what I would run. If i was just going for stock replacements 11/32 would be fine. Weight still plays a role on that side of the valve but its much less critical than it is over the valve. Basically get the biggest pushrod you can in there lol which in a stock head case is the double taper. You want the lightest things you can on the valve side and beefy as possible on the other.

In your case I dont think you would gain much by going to a good johnson or higher end morel...I say that because the 5315 is very similar to an ls7 but is still a better lifter although just not as good as the higher end drop-ins. Better lifters wont add power by themselves, if the stock lifter is functioning normally then going to a different one wont do anything. However the problem is that violent cam lobes, and heavy springs dont make the lifters job easy and its there that people see an increase in stability and thus a better power curve.

IF i was building a mild cam only setup and had the funds I would go right to the 2110 its extra security saying you wont have any issues in the future whereas an ls7 lifter might get tired down the line. Then also if I wanted to go with a bigger cam/spring/rocker combo I wouldnt need to tear the heads off again. If I was on an extreme budget then the 5315 would be fine. Morel only rates the 5315 to 6300 rpm, I know everyone spins them higher but nonetheless thats what they're rated to. The 2110 is in the copo that sees 8500 rpm 1/4 mile at a time and was chosen by gm for the application. That right there is a testament to quality, theres a reason they didnt use the ls7 in it lol

Naturally as you get less and less travel things like preload become more and more sensitive, but the lifter can take more abuse. If you have stock heads the holes have to be machined for 3/8 pr's 9/10 times. The biggest that will reliably fit in there is a 3/8-5/16 double taper which are expensive lol however if I had a cam thats what I would run. If i was just going for stock replacements 11/32 would be fine. Weight still plays a role on that side of the valve but its much less critical than it is over the valve. Basically get the biggest pushrod you can in there lol which in a stock head case is the double taper. You want the lightest things you can on the valve side and beefy as possible on the other.

In your case I dont think you would gain much by going to a good johnson or higher end morel...I say that because the 5315 is very similar to an ls7 but is still a better lifter although just not as good as the higher end drop-ins. Better lifters wont add power by themselves, if the stock lifter is functioning normally then going to a different one wont do anything. However the problem is that violent cam lobes, and heavy springs dont make the lifters job easy and its there that people see an increase in stability and thus a better power curve.

IF i was building a mild cam only setup and had the funds I would go right to the 2110 its extra security saying you wont have any issues in the future whereas an ls7 lifter might get tired down the line. Then also if I wanted to go with a bigger cam/spring/rocker combo I wouldnt need to tear the heads off again. If I was on an extreme budget then the 5315 would be fine. Morel only rates the 5315 to 6300 rpm, I know everyone spins them higher but nonetheless thats what they're rated to. The 2110 is in the copo that sees 8500 rpm 1/4 mile at a time and was chosen by gm for the application. That right there is a testament to quality, theres a reason they didnt use the ls7 in it lol

#7

TECH Enthusiast

Join Date: Jun 2005

Location: Wichita, KS

Posts: 546

Likes: 0

Received 0 Likes

on

0 Posts

Semi-Random question -- but relates to lifters.

Right now to do a cam swap without removing the heads, you can spin the camshaft and the lifters get captured in the lifter trays. Then you can slide in your dowel rods, and remove the cam.

If you had tie bar lifters installed, which negate the lifter trays, would you have to remove the heads to do a cam swap, or when you spin the cam would the tie bar lifters be captured in the head?

Right now to do a cam swap without removing the heads, you can spin the camshaft and the lifters get captured in the lifter trays. Then you can slide in your dowel rods, and remove the cam.

If you had tie bar lifters installed, which negate the lifter trays, would you have to remove the heads to do a cam swap, or when you spin the cam would the tie bar lifters be captured in the head?

Trending Topics

#8

TECH Regular

iTrader: (3)

I bought the Morel 5315 for my build. I liked the circlip holding the axle in instead of the swedged LS7 design. Can anyone tell me what the 5315 wheel is made out of and what the LS7 wheel is made out of ?

When asking for a custom cam from Cam Motion, they ask for the wheel diameter, .700 vs .750 , does anyone know what they do differently for the larger wheel ? Is it a way I can get more aggressive than 55 (.006 to .050) by lying and saying I have a .750 lifter wheel ?

For Tie Bar lifters, could 5_litre_eater pull each lifter up with a pen magnet to insert the dowel rods ?

When asking for a custom cam from Cam Motion, they ask for the wheel diameter, .700 vs .750 , does anyone know what they do differently for the larger wheel ? Is it a way I can get more aggressive than 55 (.006 to .050) by lying and saying I have a .750 lifter wheel ?

For Tie Bar lifters, could 5_litre_eater pull each lifter up with a pen magnet to insert the dowel rods ?

#10

Moderator

Thread Starter

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,836 Likes

on

1,145 Posts

Hey Darth, basically its what vette nuts said the ls7 lifter is just what it is, a stock replacement. When you get into springs with a lot of pressure the ls7's start to bleed down in the various rpm ranges. Better lifters like johnson or morel use a disk based plunger over a ball one likke the ls7 uses. Tolerances, metal, bleed down rate and springs inside the lifter are all upgraded as well as in some cases the travel reduced of the actual lifter plunger. An ls7 lifter has .200" of travel in the plunger, a morel 5315 is also .200" but go to a johnson 2110 and you get only .150" or the 2116 which has .093 or even then to the reduced travel 2116 which is .05.

Naturally as you get less and less travel things like preload become more and more sensitive, but the lifter can take more abuse. If you have stock heads the holes have to be machined for 3/8 pr's 9/10 times. The biggest that will reliably fit in there is a 3/8-5/16 double taper which are expensive lol however if I had a cam thats what I would run. If i was just going for stock replacements 11/32 would be fine. Weight still plays a role on that side of the valve but its much less critical than it is over the valve. Basically get the biggest pushrod you can in there lol which in a stock head case is the double taper. You want the lightest things you can on the valve side and beefy as possible on the other.

In your case I dont think you would gain much by going to a good johnson or higher end morel...I say that because the 5315 is very similar to an ls7 but is still a better lifter although just not as good as the higher end drop-ins. Better lifters wont add power by themselves, if the stock lifter is functioning normally then going to a different one wont do anything. However the problem is that violent cam lobes, and heavy springs dont make the lifters job easy and its there that people see an increase in stability and thus a better power curve.

IF i was building a mild cam only setup and had the funds I would go right to the 2110 its extra security saying you wont have any issues in the future whereas an ls7 lifter might get tired down the line. Then also if I wanted to go with a bigger cam/spring/rocker combo I wouldnt need to tear the heads off again. If I was on an extreme budget then the 5315 would be fine. Morel only rates the 5315 to 6300 rpm, I know everyone spins them higher but nonetheless thats what they're rated to. The 2110 is in the copo that sees 8500 rpm 1/4 mile at a time and was chosen by gm for the application. That right there is a testament to quality, theres a reason they didnt use the ls7 in it lol

Naturally as you get less and less travel things like preload become more and more sensitive, but the lifter can take more abuse. If you have stock heads the holes have to be machined for 3/8 pr's 9/10 times. The biggest that will reliably fit in there is a 3/8-5/16 double taper which are expensive lol however if I had a cam thats what I would run. If i was just going for stock replacements 11/32 would be fine. Weight still plays a role on that side of the valve but its much less critical than it is over the valve. Basically get the biggest pushrod you can in there lol which in a stock head case is the double taper. You want the lightest things you can on the valve side and beefy as possible on the other.

In your case I dont think you would gain much by going to a good johnson or higher end morel...I say that because the 5315 is very similar to an ls7 but is still a better lifter although just not as good as the higher end drop-ins. Better lifters wont add power by themselves, if the stock lifter is functioning normally then going to a different one wont do anything. However the problem is that violent cam lobes, and heavy springs dont make the lifters job easy and its there that people see an increase in stability and thus a better power curve.

IF i was building a mild cam only setup and had the funds I would go right to the 2110 its extra security saying you wont have any issues in the future whereas an ls7 lifter might get tired down the line. Then also if I wanted to go with a bigger cam/spring/rocker combo I wouldnt need to tear the heads off again. If I was on an extreme budget then the 5315 would be fine. Morel only rates the 5315 to 6300 rpm, I know everyone spins them higher but nonetheless thats what they're rated to. The 2110 is in the copo that sees 8500 rpm 1/4 mile at a time and was chosen by gm for the application. That right there is a testament to quality, theres a reason they didnt use the ls7 in it lol

When you reduce the HR lifter travel, I'm assuming this makes the lifter behave more like a solid. Do you start to "lose" duration? Do you "gain" duration? I'm assuming you would go to limited travel lifters for improved valve control?

I'm not planning to pull the heads "just" to replace the lifters, BUT I am planning a head swap. A bit of background info. When I had my stock heads ported out by a local shop, not knowing any better, I left the stock lifters in, but I did upgrade the springs and pushrods. Due to a poorly ground cam, I was never able to rev very well (5500 was about it), had other issues. But now that I have a very good cam (Kip) in there, I can easily rev 6500, hitting 7K on occasion, which is no Bueno for the stock lifters (but I didn't know why).

When I do the head swap later this fall (hopefully, sooner), I don't want to leave a time bomb in there. But rather than ask "which lifter should I use? (can I have a fish?)" I thought I'd ask "help me understand lifters (teach me to fish)"

My initial gut reaction was to just throw Johnson 2110's in there or 2116's, but I really want o know exactly why these would be good or bad choices. The explanations on the bleed down rates and design differences has been tremendously helpful. Now I just want to make sure I don't "sacrifice" duration with a shorter travel lifter.

#11

All posts have helped a lot, but this one raised another question I meant to ask -

When you reduce the HR lifter travel, I'm assuming this makes the lifter behave more like a solid. Do you start to "lose" duration? Do you "gain" duration? I'm assuming you would go to limited travel lifters for improved valve control?

I'm not planning to pull the heads "just" to replace the lifters, BUT I am planning a head swap. A bit of background info. When I had my stock heads ported out by a local shop, not knowing any better, I left the stock lifters in, but I did upgrade the springs and pushrods. Due to a poorly ground cam, I was never able to rev very well (5500 was about it), had other issues. But now that I have a very good cam (Kip) in there, I can easily rev 6500, hitting 7K on occasion, which is no Bueno for the stock lifters (but I didn't know why).

When I do the head swap later this fall (hopefully, sooner), I don't want to leave a time bomb in there. But rather than ask "which lifter should I use? (can I have a fish?)" I thought I'd ask "help me understand lifters (teach me to fish)"

My initial gut reaction was to just throw Johnson 2110's in there or 2116's, but I really want o know exactly why these would be good or bad choices. The explanations on the bleed down rates and design differences has been tremendously helpful. Now I just want to make sure I don't "sacrifice" duration with a shorter travel lifter.

When you reduce the HR lifter travel, I'm assuming this makes the lifter behave more like a solid. Do you start to "lose" duration? Do you "gain" duration? I'm assuming you would go to limited travel lifters for improved valve control?

I'm not planning to pull the heads "just" to replace the lifters, BUT I am planning a head swap. A bit of background info. When I had my stock heads ported out by a local shop, not knowing any better, I left the stock lifters in, but I did upgrade the springs and pushrods. Due to a poorly ground cam, I was never able to rev very well (5500 was about it), had other issues. But now that I have a very good cam (Kip) in there, I can easily rev 6500, hitting 7K on occasion, which is no Bueno for the stock lifters (but I didn't know why).

When I do the head swap later this fall (hopefully, sooner), I don't want to leave a time bomb in there. But rather than ask "which lifter should I use? (can I have a fish?)" I thought I'd ask "help me understand lifters (teach me to fish)"

My initial gut reaction was to just throw Johnson 2110's in there or 2116's, but I really want o know exactly why these would be good or bad choices. The explanations on the bleed down rates and design differences has been tremendously helpful. Now I just want to make sure I don't "sacrifice" duration with a shorter travel lifter.

As you reduce the travel you decrease the amount of time it takes for the lifter to recover from shock loads or bleed down. When I say "recover"...I'm meaning recover the area that is underneath the internal piston with oil. 95% of the time duration loss is noticed right after the valve comes off the seat. With full travel lifters (drop-in stuff) you have a greater chance of losing seat duration than you would with a short travel lifter. The piston has more room to "squish" if you will. The other 5% is noticed around peak lift during high RPM pulls, when the lifter can't recover fast enough from the initial "squish" that is happening off the seat.

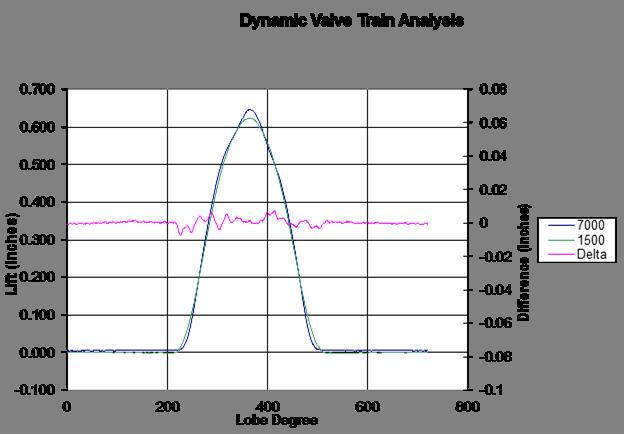

Unfortunately I don't have any SpinTron reports on my computer showing exactly what I'm talking about...but here's one that exhibits weak pushrods. Notice the trace at 1,000 RPM (green line) is wider than the trace at 7,000 RPM (blue line) off the seat. This is essentially what happens when comparing reduced travel and full travel lifters off the seat. The high RPM loft you see here is from the pushrod pole vaulting the valve and lifter.

EDIT: I said all this while not talking about leakdown rates. That is a huge factor here as well...I was just trying to keep the discussion as simple as possible. Just assume leakdown is ideal for either scenario above.

Last edited by Havoc40; 07-10-2015 at 03:10 PM.

#12

TECH Veteran

iTrader: (14)

Semi-Random question -- but relates to lifters.

Right now to do a cam swap without removing the heads, you can spin the camshaft and the lifters get captured in the lifter trays. Then you can slide in your dowel rods, and remove the cam.

If you had tie bar lifters installed, which negate the lifter trays, would you have to remove the heads to do a cam swap, or when you spin the cam would the tie bar lifters be captured in the head?

Right now to do a cam swap without removing the heads, you can spin the camshaft and the lifters get captured in the lifter trays. Then you can slide in your dowel rods, and remove the cam.

If you had tie bar lifters installed, which negate the lifter trays, would you have to remove the heads to do a cam swap, or when you spin the cam would the tie bar lifters be captured in the head?

All posts have helped a lot, but this one raised another question I meant to ask -

When you reduce the HR lifter travel, I'm assuming this makes the lifter behave more like a solid. Do you start to "lose" duration? Do you "gain" duration? I'm assuming you would go to limited travel lifters for improved valve control?

I'm not planning to pull the heads "just" to replace the lifters, BUT I am planning a head swap. A bit of background info. When I had my stock heads ported out by a local shop, not knowing any better, I left the stock lifters in, but I did upgrade the springs and pushrods. Due to a poorly ground cam, I was never able to rev very well (5500 was about it), had other issues. But now that I have a very good cam (Kip) in there, I can easily rev 6500, hitting 7K on occasion, which is no Bueno for the stock lifters (but I didn't know why).

When I do the head swap later this fall (hopefully, sooner), I don't want to leave a time bomb in there. But rather than ask "which lifter should I use? (can I have a fish?)" I thought I'd ask "help me understand lifters (teach me to fish)"

My initial gut reaction was to just throw Johnson 2110's in there or 2116's, but I really want o know exactly why these would be good or bad choices. The explanations on the bleed down rates and design differences has been tremendously helpful. Now I just want to make sure I don't "sacrifice" duration with a shorter travel lifter.

When you reduce the HR lifter travel, I'm assuming this makes the lifter behave more like a solid. Do you start to "lose" duration? Do you "gain" duration? I'm assuming you would go to limited travel lifters for improved valve control?

I'm not planning to pull the heads "just" to replace the lifters, BUT I am planning a head swap. A bit of background info. When I had my stock heads ported out by a local shop, not knowing any better, I left the stock lifters in, but I did upgrade the springs and pushrods. Due to a poorly ground cam, I was never able to rev very well (5500 was about it), had other issues. But now that I have a very good cam (Kip) in there, I can easily rev 6500, hitting 7K on occasion, which is no Bueno for the stock lifters (but I didn't know why).

When I do the head swap later this fall (hopefully, sooner), I don't want to leave a time bomb in there. But rather than ask "which lifter should I use? (can I have a fish?)" I thought I'd ask "help me understand lifters (teach me to fish)"

My initial gut reaction was to just throw Johnson 2110's in there or 2116's, but I really want o know exactly why these would be good or bad choices. The explanations on the bleed down rates and design differences has been tremendously helpful. Now I just want to make sure I don't "sacrifice" duration with a shorter travel lifter.

With a short travel lifter you dont lose duration at all. You simply make sure the lifter is just preloaded correctly and it functions like any normal lifter but it has a smaller fluid cushion to bleed out.

I'll try to explain this another way. Lets say you have a cam pushing on a lifter and thats pushing on a pushrod which actuates the valve. Well if the lifter bleeds down, it causes the plunger to sink into the body of the lifter, thus you have more "slack" in the valvetrain because you just introduced a looser tolerance between the lifter, pushrod and valve.

The 2110 and 2116 are both great lifters and I'm sure randy will chime in with the exact differences. However the 2116 is a shorter travel and is a link bar which will ultimately allow it to be more stable for more radical setups. The 2110 like I said has .150 of travel and the 2116 has .093 now given they are both preloaded correctly they will provide the same duration and lift no matter what. Either will for any setup even stock, it just comes down to which one is too much overkill for you if you dont really need it, understand? lol

On a side note I just noticed that Crower makes a lifter by the number of 66330hp which is a drop in like the 2110 and has pin oiling, but it priced at 230 for a set so I'd like to know the differences between the 2 if Randy could provide some light on that...

EDIT: Randy's response kicks the hell out of mine so read his lmao but read mine too haha

#13

DOH! I remembered that after I posted lol and was coming back to correct it, you beat me to it. LOL thanks Randy.

The 2110 and 2116 are both great lifters and I'm sure randy will chime in with the exact differences. However the 2116 is a shorter travel and is a link bar which will ultimately allow it to be more stable for more radical setups. The 2110 like I said has .150 of travel and the 2116 has .093 now given they are both preloaded correctly they will provide the same duration and lift no matter what. Either will for any setup even stock, it just comes down to which one is too much overkill for you if you dont really need it, understand? lol

On a side note I just noticed that Crower makes a lifter by the number of 66330hp which is a drop in like the 2110 and has pin oiling, but it priced at 230 for a set so I'd like to know the differences between the 2 if Randy could provide some light on that...

EDIT: Randy's response kicks the hell out of mine so read his lmao but read mine too haha

The 2110 and 2116 are both great lifters and I'm sure randy will chime in with the exact differences. However the 2116 is a shorter travel and is a link bar which will ultimately allow it to be more stable for more radical setups. The 2110 like I said has .150 of travel and the 2116 has .093 now given they are both preloaded correctly they will provide the same duration and lift no matter what. Either will for any setup even stock, it just comes down to which one is too much overkill for you if you dont really need it, understand? lol

On a side note I just noticed that Crower makes a lifter by the number of 66330hp which is a drop in like the 2110 and has pin oiling, but it priced at 230 for a set so I'd like to know the differences between the 2 if Randy could provide some light on that...

EDIT: Randy's response kicks the hell out of mine so read his lmao but read mine too haha

Anyway, I don't know anything about Crower's drop-in lifter? Crower buys our 2116 lifters, but not the drop-in stuff. We don't offer the axle oiling drop-in version to the automotive crowd...only Harley's. Reason being is if you're truthfully needing that feature, you need to be in a tie-bar with the reduced travel etc. We also use a pretty expensive bearing and axle...so we're comfortable not offering it in this lifter. From a cost standpoint, it just makes sense to jump into the tie-bars.

#14

Moderator

Thread Starter

iTrader: (4)

Join Date: Jul 2014

Location: My own internal universe

Posts: 10,446

Received 1,836 Likes

on

1,145 Posts

I can't thank you guys enough. Very helpful info. And Havoc, don't worry about the long-nerdy posts. I'm a nerd, so I enjoy the technical details - or I wouldn't have started the thread. That chart showing the valve events was very helpful, and answered my question on duration. Also, I would never have guessed the loft would be so much!

And Redbird, I was assuming the dowel rod trick would work for all lifters, but it is good to have that confirmed.

I could foresee a scenario with very short travel HR lifters that, based on stacking of machine tolerances, one could conceivably end up with slightly different pushrod lengths for each valve. This is probably Tony's 10% level of detail, but if you want it to run right... Anyone seen that happen before?

I know adjustable rockers are typically reserved for solids, but I'll ask the stupid question anyway - could using adjustable rockers compensate for slight variances in desired pushrod lengths, or is that a problematic set up.

Now that I've laid that out there, I can see why Redbird suggests to throw the Johnson 2110's in there - less travel than stock, enough travel to compensate for the stacked machining tolerances and get one size pushrod. The 2116's probably have enough travel at .093, since pushrods are available in .025" increments, anyway. So, assuming you measure for preload correctly, there is no real world difference below 8,000 rpms.

Makes a lot more sense now than it did yesterday, that's for sure!

Those crower lifters you mentioned do sound intriguing, but without evidence, I would stick with a tried and true solution

And Redbird, I was assuming the dowel rod trick would work for all lifters, but it is good to have that confirmed.

I could foresee a scenario with very short travel HR lifters that, based on stacking of machine tolerances, one could conceivably end up with slightly different pushrod lengths for each valve. This is probably Tony's 10% level of detail, but if you want it to run right... Anyone seen that happen before?

I know adjustable rockers are typically reserved for solids, but I'll ask the stupid question anyway - could using adjustable rockers compensate for slight variances in desired pushrod lengths, or is that a problematic set up.

Now that I've laid that out there, I can see why Redbird suggests to throw the Johnson 2110's in there - less travel than stock, enough travel to compensate for the stacked machining tolerances and get one size pushrod. The 2116's probably have enough travel at .093, since pushrods are available in .025" increments, anyway. So, assuming you measure for preload correctly, there is no real world difference below 8,000 rpms.

Makes a lot more sense now than it did yesterday, that's for sure!

Those crower lifters you mentioned do sound intriguing, but without evidence, I would stick with a tried and true solution

#16

TECH Senior Member

iTrader: (4)

Unfortunately I don't have any SpinTron reports on my computer showing exactly what I'm talking about...but here's one that exhibits weak pushrods. Notice the trace at 1,000 RPM (green line) is wider than the trace at 7,000 RPM (blue line) off the seat. This is essentially what happens when comparing reduced travel and full travel lifters off the seat. The high RPM loft you see here is from the pushrod pole vaulting the valve and lifter.

#17

TECH Apprentice

iTrader: (16)

Can you elaborate on that a little more on the cushion or spring affect. I'm still a bit confused because it seems like oil would act like any other fluid, and prevent any compressibility in the cup. Is that not true, or I'm not understanding it correctly?