Just got my 243 Heads from Patriot: Should I do some mild home porting?

#1

Should I home port them before putting them in? Im afraid of doing the intake side because i don't want it TOO smooth and i don't want to take off TOO much material and lose flow, . . unless someone could advise me otherwise, . . . I will probably jus remove some casting irregularities on the exhaust port and smooth it out too, . . anybody have any opinions? any good tips or sites to look up? should i smooth out the combustion chamber?

thanx!

thanx!

#4

11 Second Club

iTrader: (1)

well I ported a set for my LT1 car and working on a set of LS1 heads right now. I can forward you some pics Ive saved along the way to use for reference. one of the best things you can do is clean up all the bowl area's. where the casting lines are and esp. the bad lips that the valve seats make. smooth that out. also, you wont hurt anything by grinding down the valve guides and smoothing them over. I dont mean completly but down to the diam. of the guide at the top and radius it out toward the bottom. infact, im taking pics of the second head step by step I can send you pics of that so you can easily see how ea. step looks like. Im not hoging mine out, just smoothing everything, taking out all the lard, and taking out the bump in the intake wall that ws there to cover the rocker stud bolt at the bottom. I'll try to send you some pics tonight, and the one Im working on currently I'll send tomorrow night. I got the first ports (intake and exh) flow tested at ETPerformance and they thought it came out really good too. not quite PRO quality but I got most of the extra flow up top, and more flow down low then most CNC heads.

chris

chris

Trending Topics

#10

TECH Senior Member

iTrader: (4)

Originally Posted by Studytime

GuitsBoy, what gaskets are you running? what sized valves?

Did you measure PTV clearance for your setup?

Ben T.

Did you measure PTV clearance for your setup?

Ben T.

#11

TECH Fanatic

iTrader: (8)

Originally Posted by Studytime

GuitsBoy, what gaskets are you running? what sized valves?

Did you measure PTV clearance for your setup?

Ben T.

Did you measure PTV clearance for your setup?

Ben T.

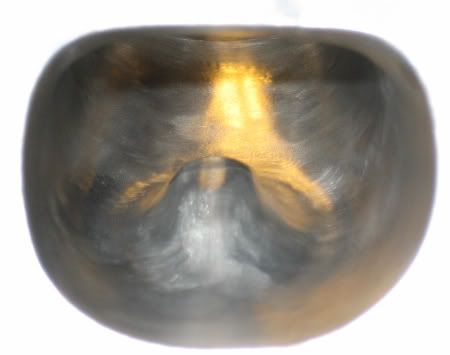

A gasket size of .040 would be great for your application. You want to maximize DCR and the thinner gasket (specificially the .040) does a great job of this. Here are some pics of my 243's.

You'll want to make the intake port a bit rougher than what's pictured though.

Last edited by Xtnct00WS6; 09-12-2006 at 01:18 PM.

#14

TECH Fanatic

iTrader: (8)

Valve guides? Yeah, they've just been blended into the shape of the port. Patriot did the cnc work, and then hand finished them.

When you do the porting, you can keep the exhaust and combustion chamber smooth, but you'll want a little more rough of a texture to the intake port.

Check out this thread to see what a really good port looks like:

https://ls1tech.com/forums/generation-iii-internal-engine/514551-dart-225-after-info.html

When you do the porting, you can keep the exhaust and combustion chamber smooth, but you'll want a little more rough of a texture to the intake port.

Check out this thread to see what a really good port looks like:

https://ls1tech.com/forums/generation-iii-internal-engine/514551-dart-225-after-info.html

#15

i've read that mild smoothing of the intake floor, wall and ceiling is beneficial, just not to TOO smooth, . . . then i've read that rough, rigid is better because it packs in air better, . . . .so, . . .???? . . but yeah, i'll be mildly smoothing the combustion chamber and porting and blending the exhaust ports along with blending in the valve bowls in both intake and exhaust

. . you did them yourself?

. . you did them yourself?