Fast 102mm Intake--Real Results --NO BS

#1

FormerVendor

Thread Starter

iTrader: (4)

Join Date: Nov 2008

Location: Scott, LA

Posts: 504

Likes: 0

Received 0 Likes

on

0 Posts

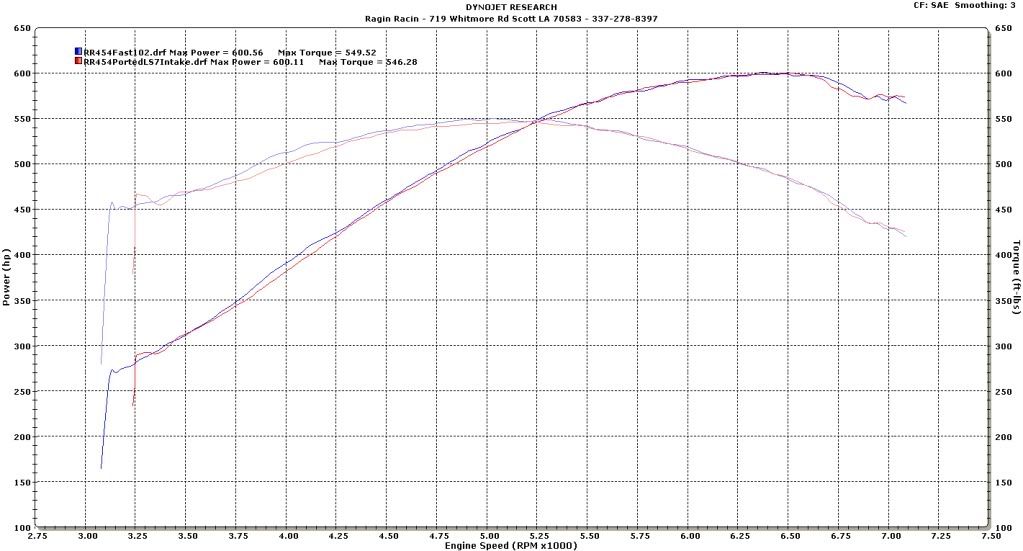

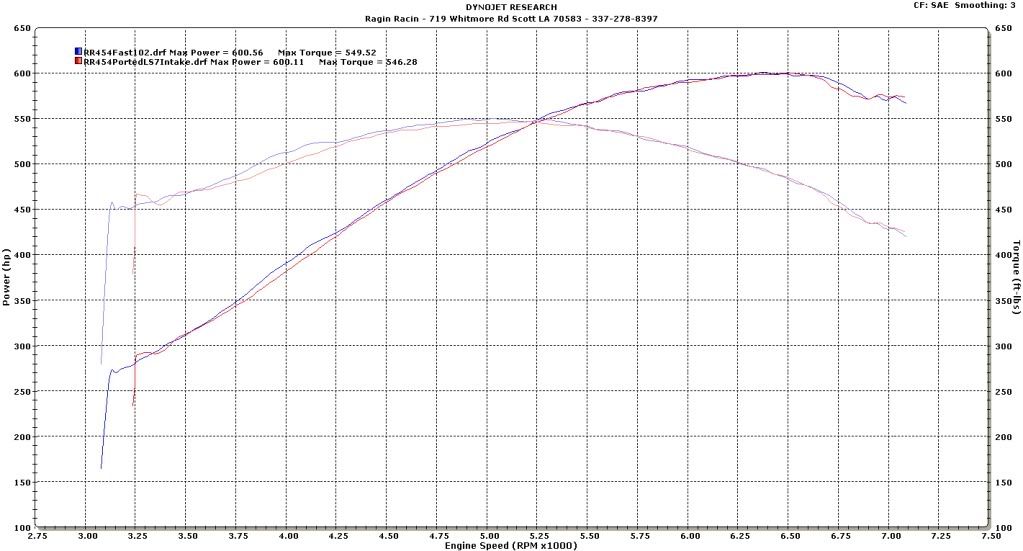

Tired of see BS threads on the new FAST 102. I was on the dyno with this thing all morning yesterday. To say the least I am very dissapointed. We put it on my 454 LSx that is doing 600rwhp expecting it to shine with this motor over our ported LS7 intake. I did everything I could to extract as much power as I could and it was evedent that this intake just didn't have it. We cleaned up the runners on the FAST to get everything as smooth as possible. You couldn't really open it up that much. We matched everything up using a boroscope just to make sure is was perfect. I do have plans to pull it off the car and take the intake apart and really port the whole thing out since cleaning it up didn't help at all. This will be done in the week or so. I will also be testing the use of a 100mm TB as well. Until then you can see there was absolutely no gain.

Last edited by 98Aggie; 06-24-2009 at 11:08 PM.

#2

Don't really think this is a surprise.

But maybe with the bigger TB and you doing an all-out port job on the intake you will get some results.

After taking a closer look, you picked up some between 3800 and 4200 and then again at 6700-6900.

Curious as to the difference in conditions between the 2 runs?

But maybe with the bigger TB and you doing an all-out port job on the intake you will get some results.

After taking a closer look, you picked up some between 3800 and 4200 and then again at 6700-6900.

Curious as to the difference in conditions between the 2 runs?

Last edited by 8ByGoat; 06-23-2009 at 01:15 PM.

Trending Topics

#8

Banned

iTrader: (10)

I suspect that the choke point is the TB. Get a good 95 or 100mm billet on it and see it wake up and show what it can do. I can't imagine the 90mm TB allowing it to work as designed.

Flow#'s are what we all look at, but velocity makes power. You can hog out runners & ports until an elephant could be sucked through and make no power....it all has to work together for maximum velocity & volumetric efficiency to product the max power.

I trust FAST has done their homework on this and Shawn will show us better results with the right TB on the snout.

Flow#'s are what we all look at, but velocity makes power. You can hog out runners & ports until an elephant could be sucked through and make no power....it all has to work together for maximum velocity & volumetric efficiency to product the max power.

I trust FAST has done their homework on this and Shawn will show us better results with the right TB on the snout.

#9

TECH Veteran

iTrader: (12)

Join Date: Dec 2004

Location: Rockville, MD

Posts: 4,354

Likes: 0

Received 0 Likes

on

0 Posts

I suspect that the choke point is the TB. Get a good 95 or 100mm billet on it and see it wake up and show what it can do. I can't imagine the 90mm TB allowing it to work as designed.

Flow#'s are what we all look at, but velocity makes power. You can hog out runners & ports until an elephant could be sucked through and make no power....it all has to work together for maximum velocity & volumetric efficiency to product the max power.

I trust FAST has done their homework on this and Shawn will show us better results with the right TB on the snout.

Flow#'s are what we all look at, but velocity makes power. You can hog out runners & ports until an elephant could be sucked through and make no power....it all has to work together for maximum velocity & volumetric efficiency to product the max power.

I trust FAST has done their homework on this and Shawn will show us better results with the right TB on the snout.

#10

Money well spent Thanks for the honest review. I'm curious what will happen if you decide to go in and shorten the runners (that is possible on this intake right?).

Thanks for the honest review. I'm curious what will happen if you decide to go in and shorten the runners (that is possible on this intake right?).

Larry

Thanks for the honest review. I'm curious what will happen if you decide to go in and shorten the runners (that is possible on this intake right?).

Thanks for the honest review. I'm curious what will happen if you decide to go in and shorten the runners (that is possible on this intake right?).Larry

#13

TECH Apprentice

Join Date: Dec 2008

Location: Westbank of N.O.

Posts: 333

Likes: 0

Received 0 Likes

on

0 Posts

Even though 1 of these intakes has my name on it, don't get too comfy w/ the popcorn. I can tell u now that using the 100mm t-body will drop the torque a tiny bit and produce NO hp gains. Stay tuned just the same, the bashing could get interesting

I know Shawn & Randy personally, they would want this thing to work as much as anyone here, but it is what it is. Katech reported some 12+ hp increase over the LS7 intake on the engine dyno. Shawn was using a ported LS7 (weren't you?) on the baseline 454 pull, and we have seen gains of 10+ porting the stocker, so this is no big surprise. FAST better sell all these damn things FAST

I know Shawn & Randy personally, they would want this thing to work as much as anyone here, but it is what it is. Katech reported some 12+ hp increase over the LS7 intake on the engine dyno. Shawn was using a ported LS7 (weren't you?) on the baseline 454 pull, and we have seen gains of 10+ porting the stocker, so this is no big surprise. FAST better sell all these damn things FAST

#14

9 Second Club

iTrader: (33)

Even though 1 of these intakes has my name on it, don't get too comfy w/ the popcorn. I can tell u now that using the 100mm t-body will drop the torque a tiny bit and produce NO hp gains. Stay tuned just the same, the bashing could get interesting

I know Shawn & Randy personally, they would want this thing to work as much as anyone here, but it is what it is. Katech reported some 12+ hp increase over the LS7 intake on the engine dyno. Shawn was using a ported LS7 (weren't you?) on the baseline 454 pull, and we have seen gains of 10+ porting the stocker, so this is no big surprise. FAST better sell all these damn things FAST

I know Shawn & Randy personally, they would want this thing to work as much as anyone here, but it is what it is. Katech reported some 12+ hp increase over the LS7 intake on the engine dyno. Shawn was using a ported LS7 (weren't you?) on the baseline 454 pull, and we have seen gains of 10+ porting the stocker, so this is no big surprise. FAST better sell all these damn things FAST

#16

TECH Fanatic

I suspect that the choke point is the TB. Get a good 95 or 100mm billet on it and see it wake up and show what it can do. I can't imagine the 90mm TB allowing it to work as designed.

Flow#'s are what we all look at, but velocity makes power. You can hog out runners & ports until an elephant could be sucked through and make no power....it all has to work together for maximum velocity & volumetric efficiency to product the max power.

I trust FAST has done their homework on this and Shawn will show us better results with the right TB on the snout.

Flow#'s are what we all look at, but velocity makes power. You can hog out runners & ports until an elephant could be sucked through and make no power....it all has to work together for maximum velocity & volumetric efficiency to product the max power.

I trust FAST has done their homework on this and Shawn will show us better results with the right TB on the snout.

Did you mean that higher intake/port velocity makes more power?

Please explain how that works.

Thanks in advance,

Jon

#18

Banned

iTrader: (10)

Here is an excerpt from David Reher, owner of Reher Morrison and a family friend:

"What's it flow?"

Whenever a conversation about cylinder heads begins with that question, I cringe. I know where this discussion is going, and it's not good. When a racer wants to distill the performance of a highly developed cylinder head down to a single number, I know I'm dealing with someone who is fixated on the flow bench.

I can speak from hard-earned experience, because there was a time when the flow bench was the center of my universe. When my partners Buddy Morrison and Lee Shepherd constructed our first flow bench in the '70s, it was a revelation – or so we believed. We were addicted to airflow, and like three flow bench junkies, we convinced ourselves that big flow numbers translated to quicker elapsed times. But that was more than 30 years ago, and since then I've learned to avoid the pitfalls of flow bench testing.

Unfortunately many racers coming into the sport haven't been taught the lessons that Buddy, Lee and I learned the hard way. Cylinder head manufacturers, porting shops, and engine builders constantly advertise flow numbers – and I confess that I'm sometimes guilty as well. In this environment, it's understandable that some racers think it's all about maximum airflow. They shop for the biggest cfm number at the lowest price, like finding a screaming bargain on a 52-inch TV at WalMart.

The strategy to win the "Biggest CFM Contest" is simple: Grind the largest port that will physically fit in the head, use the biggest valves that will fit the combustion chambers, and test it on the biggest fixture you can find. That head might win the prize for airflow, but it won't win on the dyno or on the race track.

The factors that determine the performance of a cylinder head are complex. A head that is ported without considering air speed, the size of the engine, the rpm range, the location of the valves, and a dozen other parameters isn't going to be the best head, regardless of its peak airflow. And yet I see racers who are seduced by big cfm numbers bolt a pair of 10,000 rpm cylinder heads on a 7,000 rpm short block and then wonder why the engine won't run.

The most critical area in a competition cylinder head is the valve seat, and the order of importance works its way out from there. There are many questions that are much more important than airflow: How far are the valve heads off the cylinder wall? What's the ratio of valve size to bore diameter? What's the ratio of the airflow to the size of the valve? What's the size of the port, what's its taper, how high is the short-side radius? The answers to these aren't as simple as comparing a flow number, but they are what really make a difference in an engine.

Airflow is simply one measurement among many that influence engine performance. With the availability of affordable flow benches and computer simulation programs, it's easy to fall into the airflow trap. A builder works on a cylinder head, sees some bigger cfm numbers, and keeps working for more flow. But if he doesn't stop and test the engine on a dyno and on the drag strip, it's very likely he's gone down a blind alley. What the manometer on a flow bench sees at a steady 28 inches of depression is not at all what the engine sees in the real world. The pursuit of a big cfm rating has ruined countless cylinder heads in terms of what will actually run on an engine.

I put more faith in dyno pulls and time slips than I do in flow benches. I'll cite an example from back in the day when Buddy, Lee and I were winning Pro Stock championships. Lee came up with an idea for a tuliped exhaust valve. He filled in the back of the valve with Bondo, and tested the new design on our flow bench. It was killer. We instantly saw a tremendous improvement in airflow with a small exhaust port, a nice tight radius below the seat, and much more stable flow. So we had some titanium tulip exhaust valves made and tested them on the dyno – and the engine didn't run well at all. We had great airflow on the bench, but the engine didn't care.

We were working late one night, and Buddy decided to yank the heads off the block and have Lee open up the exhaust throats. Well, Lee kept grinding and Buddy kept taking the heads on and off, and eventually we picked up 30 horsepower that night. We were porting from the dyno and not from the flow bench. When Lee finally flow tested the heads the next day, they were down 30 or 40 cfm, but that's not what that engine saw.

The final test of a cylinder head is on the track. Frank Iaconio was our chief Pro Stock rival, and he was a smart racer. Frankie used to change valves at the track -- he'd make a run, come back to the pits and switch from valves with a 30-degree back angle to a 20-degree back angle. We did similar tests on the dyno, but he did it at the track. I was impressed.

I'm not dismissing flow benches. In fact, we use them daily at Reher-Morrison Racing Engines. But a flow bench is a tool, and it's really not much different than a micrometer. A micrometer can measure the diameter of a piston, but you have to run the engine to learn the correct piston clearance. Knowing the sizes of the piston and cylinder bore doesn't tell you if the piston is going to gall or collapse a skirt until you run it. And knowing the airflow of a cylinder head doesn't tell you whether it will make good power on a given engine until you race it.

Experience is the most important tool in cylinder head development. A person with extensive dyno and track experience has been through it all before, and knows how to avoid the flow bench fallacies.

And more:

Our era is often referred to as the Information Age, but not all of the available information is necessarily useful. I am beginning to think that flow benches should be labeled with a government warning: "Caution! Excessive reliance on flow numbers may be harmful to your engine!"

I'm kidding, of course. Used wisely, a flow bench can be a useful tool in engine development, just like a timing light or a dynamometer. Unfortunately, some racers believe that a flow bench is the ultimate answer machine. When the subject is cylinder heads, the four words I dread to hear are, "What do they flow?" Novice racers and magazine writers share a fixation about airflow. The mistaken belief that "more is better" is often the false assumption that produces an underperforming engine..

(Continued in the next post due to length)........

#19

Banned

iTrader: (10)

(and the rest)...... I learned this lesson myself when my partners Buddy Morrison and Lee Shepherd built our first flow bench in the mid-'70s. It was a great contraption that could just about suck the windows out of our rented shop on Arkansas Lane. While this homebuilt test bench boosted our racing program, it certainly didn't make us engine experts overnight - even though we initially thought we had found the key to the vault of knowledge.

We had been racing 287-cubic-inch small-blocks in various Modified and Comp classes before we decided to make the move to Pro Stock with a 331ci engine. (Students of Pro Stock history will recall that the '70s was the era of weight breaks for various engine and chassis combinations.) We were determined to be "scientific" in our approach, and reasoned that a 15 percent increase in engine displacement demanded a 15 percent increase in airflow. We dutifully enlarged the ports, increased the valve diameters, and hit our airflow targets. We set off to conquer the world of Pro Stock - but our pride and joy was a dog.

After struggling to even qualify in our initial outings, we pulled an old pair of Modified heads off the shelf. Lee worked on the ports for an afternoon, we bolted them on our Pro Stock short-block, and we qualified fifth at Englishtown in our next race.

If you went strictly by the flow numbers, those heads would hardly enough air to satisfy a respectable big-inch bracket racing engine - and yet they were magic on the race track. That was when I realized that cfm isn't everything. It's a lesson that I have seen repeated countless times in the last 25 years.

A flow bench measures air movement in a very rudimentary way - steady-state flow at a constant depression (vacuum). Obviously the conditions that exist inside a running engine are quite different. The flow bench can't simulate the effects of the pistons going up and down, the reversion pulses as the valves open and close, the sonic waves that resonate inside the runners, the inertia of the fuel droplets, and all of the other phenomena that influence engine performance in the real world. When you flow test a cylinder head, you are simply measuring how far you can move the liquid in a manometer.

The bigger you make a port, the more it flows. That's hardly shocking news. Bolt a sewer pipe onto a flow bench and it will generate terrific flow numbers. So should we use ports as big as sewer pipes on our race cars? The flow bench says we should - the time slip says something completely different.

If airflow were everything, we would all use the longest duration camshafts we could find - after all, more duration means more flow. In fact we know that there is a finite limit to how long the valves can be open before performance

suffers. That is because the valve events have to be in harmony with the rest of the engine.

The same principle applies to cylinder heads. Simple airflow capacity should never be the first consideration in evaluating cylinder heads. Characteristics that are far more important include air speed, port cross section, port volume and shape, and the relationship between the size of the throat and the valve seat. If these attributes are wrong, you can work forever on the flow bench and not overcome the fundamental flaws.

Here is a do-it-yourself example: Turn on a garden hose and the water will dribble out a couple of feet. Now put a nozzle on the hose and the water will spray across your backyard. The water pressure and volume haven't changed, but the velocity has increased dramatically. Now think about the air and fuel going into your engine's cylinders. Which would you prefer: slow and lazy or fast and responsive?

An engineer will tell you that an engine requires a prescribed amount of air and fuel to produce "X" horsepower. In a perfect world, that may be true - but we race with imperfect engines. The shape and cross-sectional area of the runners are absolutely critical to performance. For example, I have two sets of Pro Stock cylinder heads that produce nearly identical flow numbers, yet one pair produces nearly 150 more horsepower at 9,200 rpm than the other. The flow bench can't tell the difference between them, but the engine certainly can.

There are software programs that claim to be able to predict an engine's performance based on airflow numbers. Unfortunately, a critical shortcoming of many of these programs is that they are based on inaccurate information or false assumptions. A computer is an excellent calculator, but it is not an experienced engine builder. The software doesn't know whether a port's short-turn radius is shaped properly, whether the flow is turbulent at critical valve lifts, or whether the flame speed is fast enough. Racers have a tendency to believe that computers are infallible, so they accept the software's solutions as gospel, when in fact they may be badly flawed.

Textbooks would lead you to believe that an exhaust to intake flow ratio of 80 percent is ideal - yet a typical Pro Stock head has exhaust ports that flow less than 60 percent of the intake runners. You can improve the exhaust flow

tremendously with about 40 minutes of work with a hand grinder - but the supposed improvements will just about kill the engine's on-track performance. I know because I've been there.

We have also learned that low-lift flow (meaning anything below .400-inch valve lift in a Pro Stock engine with a .900-inch lift camshaft) is relatively unimportant. Think about the valve events in a racing engine: From the point when the valve first moves off its seat until it reaches mid-lift, the piston is either going the wrong way (that is, it is rising in the cylinder) or it's parked near TDC. The piston doesn't begin to move away from the combustion chamber with enough velocity to lower the pressure in the cylinder until the valve is nearly halfway open. Consequently it is high-lift flow that really matters in a drag racing engine.

The shape of the combustion chamber also has a significant impact on performance. A conventional chamber with deep reliefs around the valve seats and a relatively flat valve seat angle can produce terrific flow at .200 to .300-inch valve lift. Today a state-of-the-art chamber typically has 55-degree valve seats and steep walls that guide the air/fuel mixture into the cylinder to enhance high-lift flow This doesn't mean that every racer needs state-of-the-art Pro Stock cylinder heads - along with the high maintenance they require. The heads have to match the application. Conventional combustion chambers and 45-degree valve seats are just fine for a dependable, low-maintenance racing engine that will run a full season between overhauls.

The classic Hemi combustion chamber is capable of producing impressive flow figures, but it's not going to make impressive power. Engine technology in all forms of motorsports is converging around smaller, high-efficiency combustion chamber designs. You can see the result in lower brake specific fuel consumption (BSFC) numbers, which indicate improved engine efficiency. Twenty years ago, a racing engine with a .48 BSFC was considered very good; today's competition engines produce BSFC numbers in the neighborhood of .35. This means that a given quantity of fuel is being atomized and burned more effectively to produce more power. A cylinder head's combustion efficiency can't be measured on a flow bench, yet it has a huge impact on performance.

I am not against flow benches; in fact, we use computerized flow benches daily at Reher-Morrison Racing Engines. What I am against is over reliance on flow numbers as the primary measurement of a cylinder head's performance. A flow bench is a valuable tool that can help a racer fine tune a combination - but it is not the ultimate authority.

This is more info than most were looking for I expect, but invaluable info when seeking to understand the reality behind flow numbers. If the intake charge does not flow with sufficient velocity to move through the entire "air pump" that our motors are, peak power cannot be realized.

As for the FAST 102 being worthwhile, independant testing such as Ragin's and company will be the real test and we may find that adding the 100mm TB may not do the trick.....but with the proper heads, cam profile, and exhaust as long as there is not a bottle neck or restriction in any of the key areas, I suspect we will see these make good power. If not, it will be a first for the FAST line of intake manifolds.

We had been racing 287-cubic-inch small-blocks in various Modified and Comp classes before we decided to make the move to Pro Stock with a 331ci engine. (Students of Pro Stock history will recall that the '70s was the era of weight breaks for various engine and chassis combinations.) We were determined to be "scientific" in our approach, and reasoned that a 15 percent increase in engine displacement demanded a 15 percent increase in airflow. We dutifully enlarged the ports, increased the valve diameters, and hit our airflow targets. We set off to conquer the world of Pro Stock - but our pride and joy was a dog.

After struggling to even qualify in our initial outings, we pulled an old pair of Modified heads off the shelf. Lee worked on the ports for an afternoon, we bolted them on our Pro Stock short-block, and we qualified fifth at Englishtown in our next race.

If you went strictly by the flow numbers, those heads would hardly enough air to satisfy a respectable big-inch bracket racing engine - and yet they were magic on the race track. That was when I realized that cfm isn't everything. It's a lesson that I have seen repeated countless times in the last 25 years.

A flow bench measures air movement in a very rudimentary way - steady-state flow at a constant depression (vacuum). Obviously the conditions that exist inside a running engine are quite different. The flow bench can't simulate the effects of the pistons going up and down, the reversion pulses as the valves open and close, the sonic waves that resonate inside the runners, the inertia of the fuel droplets, and all of the other phenomena that influence engine performance in the real world. When you flow test a cylinder head, you are simply measuring how far you can move the liquid in a manometer.

The bigger you make a port, the more it flows. That's hardly shocking news. Bolt a sewer pipe onto a flow bench and it will generate terrific flow numbers. So should we use ports as big as sewer pipes on our race cars? The flow bench says we should - the time slip says something completely different.

If airflow were everything, we would all use the longest duration camshafts we could find - after all, more duration means more flow. In fact we know that there is a finite limit to how long the valves can be open before performance

suffers. That is because the valve events have to be in harmony with the rest of the engine.

The same principle applies to cylinder heads. Simple airflow capacity should never be the first consideration in evaluating cylinder heads. Characteristics that are far more important include air speed, port cross section, port volume and shape, and the relationship between the size of the throat and the valve seat. If these attributes are wrong, you can work forever on the flow bench and not overcome the fundamental flaws.

Here is a do-it-yourself example: Turn on a garden hose and the water will dribble out a couple of feet. Now put a nozzle on the hose and the water will spray across your backyard. The water pressure and volume haven't changed, but the velocity has increased dramatically. Now think about the air and fuel going into your engine's cylinders. Which would you prefer: slow and lazy or fast and responsive?

An engineer will tell you that an engine requires a prescribed amount of air and fuel to produce "X" horsepower. In a perfect world, that may be true - but we race with imperfect engines. The shape and cross-sectional area of the runners are absolutely critical to performance. For example, I have two sets of Pro Stock cylinder heads that produce nearly identical flow numbers, yet one pair produces nearly 150 more horsepower at 9,200 rpm than the other. The flow bench can't tell the difference between them, but the engine certainly can.

There are software programs that claim to be able to predict an engine's performance based on airflow numbers. Unfortunately, a critical shortcoming of many of these programs is that they are based on inaccurate information or false assumptions. A computer is an excellent calculator, but it is not an experienced engine builder. The software doesn't know whether a port's short-turn radius is shaped properly, whether the flow is turbulent at critical valve lifts, or whether the flame speed is fast enough. Racers have a tendency to believe that computers are infallible, so they accept the software's solutions as gospel, when in fact they may be badly flawed.

Textbooks would lead you to believe that an exhaust to intake flow ratio of 80 percent is ideal - yet a typical Pro Stock head has exhaust ports that flow less than 60 percent of the intake runners. You can improve the exhaust flow

tremendously with about 40 minutes of work with a hand grinder - but the supposed improvements will just about kill the engine's on-track performance. I know because I've been there.

We have also learned that low-lift flow (meaning anything below .400-inch valve lift in a Pro Stock engine with a .900-inch lift camshaft) is relatively unimportant. Think about the valve events in a racing engine: From the point when the valve first moves off its seat until it reaches mid-lift, the piston is either going the wrong way (that is, it is rising in the cylinder) or it's parked near TDC. The piston doesn't begin to move away from the combustion chamber with enough velocity to lower the pressure in the cylinder until the valve is nearly halfway open. Consequently it is high-lift flow that really matters in a drag racing engine.

The shape of the combustion chamber also has a significant impact on performance. A conventional chamber with deep reliefs around the valve seats and a relatively flat valve seat angle can produce terrific flow at .200 to .300-inch valve lift. Today a state-of-the-art chamber typically has 55-degree valve seats and steep walls that guide the air/fuel mixture into the cylinder to enhance high-lift flow This doesn't mean that every racer needs state-of-the-art Pro Stock cylinder heads - along with the high maintenance they require. The heads have to match the application. Conventional combustion chambers and 45-degree valve seats are just fine for a dependable, low-maintenance racing engine that will run a full season between overhauls.

The classic Hemi combustion chamber is capable of producing impressive flow figures, but it's not going to make impressive power. Engine technology in all forms of motorsports is converging around smaller, high-efficiency combustion chamber designs. You can see the result in lower brake specific fuel consumption (BSFC) numbers, which indicate improved engine efficiency. Twenty years ago, a racing engine with a .48 BSFC was considered very good; today's competition engines produce BSFC numbers in the neighborhood of .35. This means that a given quantity of fuel is being atomized and burned more effectively to produce more power. A cylinder head's combustion efficiency can't be measured on a flow bench, yet it has a huge impact on performance.

I am not against flow benches; in fact, we use computerized flow benches daily at Reher-Morrison Racing Engines. What I am against is over reliance on flow numbers as the primary measurement of a cylinder head's performance. A flow bench is a valuable tool that can help a racer fine tune a combination - but it is not the ultimate authority.

This is more info than most were looking for I expect, but invaluable info when seeking to understand the reality behind flow numbers. If the intake charge does not flow with sufficient velocity to move through the entire "air pump" that our motors are, peak power cannot be realized.

As for the FAST 102 being worthwhile, independant testing such as Ragin's and company will be the real test and we may find that adding the 100mm TB may not do the trick.....but with the proper heads, cam profile, and exhaust as long as there is not a bottle neck or restriction in any of the key areas, I suspect we will see these make good power. If not, it will be a first for the FAST line of intake manifolds.

#20

Even though 1 of these intakes has my name on it, don't get too comfy w/ the popcorn. I can tell u now that using the 100mm t-body will drop the torque a tiny bit and produce NO hp gains. Stay tuned just the same, the bashing could get interesting

I know Shawn & Randy personally, they would want this thing to work as much as anyone here, but it is what it is. Katech reported some 12+ hp increase over the LS7 intake on the engine dyno. Shawn was using a ported LS7 (weren't you?) on the baseline 454 pull, and we have seen gains of 10+ porting the stocker, so this is no big surprise. FAST better sell all these damn things FAST

I know Shawn & Randy personally, they would want this thing to work as much as anyone here, but it is what it is. Katech reported some 12+ hp increase over the LS7 intake on the engine dyno. Shawn was using a ported LS7 (weren't you?) on the baseline 454 pull, and we have seen gains of 10+ porting the stocker, so this is no big surprise. FAST better sell all these damn things FAST

In addition like you stated about 12hp on an engine dyno-so what does that translate to at the wheels-about what Ragin showed.