Some advices on front-mount arrangement, please

#1

I'm starting to build my front-mount setup, with single TC78 and truck manifolds. Engine is 9.2:1 CR, 383ci, Patriot Heads, small cam. Everything is extremely on budget. Stock front suspension. Car is daily driver but will be used on track too, so main accent is on top-end power. Final goal is some 800whp.

I'd like to get some advices on arrangement of the whole kit, please

a) on what side should I run downpipe - driver or passenger? What size? Turbo exit is 3", should I immediately expand into 4" and then go 4" all the way? Or first into 3" bend and then expand into 4"?

b) how should I place turbo - exhaust gases coming from bottom, or from top? I guess horizontal direction depends solely on where will I run my DP? Where from do you get fresh air for the turbo?

c) is 2.6" ID tubing OK from manifolds to turbo?

Please give your advices, I need to build this during May

I'd like to get some advices on arrangement of the whole kit, please

a) on what side should I run downpipe - driver or passenger? What size? Turbo exit is 3", should I immediately expand into 4" and then go 4" all the way? Or first into 3" bend and then expand into 4"?

b) how should I place turbo - exhaust gases coming from bottom, or from top? I guess horizontal direction depends solely on where will I run my DP? Where from do you get fresh air for the turbo?

c) is 2.6" ID tubing OK from manifolds to turbo?

Please give your advices, I need to build this during May

#2

2.6" I.D. is fine for your crossover piping, I'm running my tc78 downpipe through the passenger side where the A/C compressor was located. I'm expanding from 3" to 3.5" before the bend and trying to squeeze it between the stock kmember and solid mounts. If you go to the truck manifold sticky and look at Code4's build, this is how I've modeled mine after. I think it looks like a well thought out and efficient design.

EDIT: Code4 Truck Manifold Post

EDIT: Code4 Truck Manifold Post

Last edited by killerinparadise; 05-12-2009 at 11:31 AM.

#3

Yes, saw that, looks nice, although I don't like that only 1 O2 port is used (and after the turbo, not before), and I don't see WG in there

Anyway, what is the largest DP I can fit with stock K-member? And is it easier to put it on drivers on passengers side?

Edit: actually I don't see how oil would drain with turbo sitting that low, is he using dedicated pump for it?

Anyway, what is the largest DP I can fit with stock K-member? And is it easier to put it on drivers on passengers side?

Edit: actually I don't see how oil would drain with turbo sitting that low, is he using dedicated pump for it?

Last edited by Vetal; 05-12-2009 at 12:45 PM.

#4

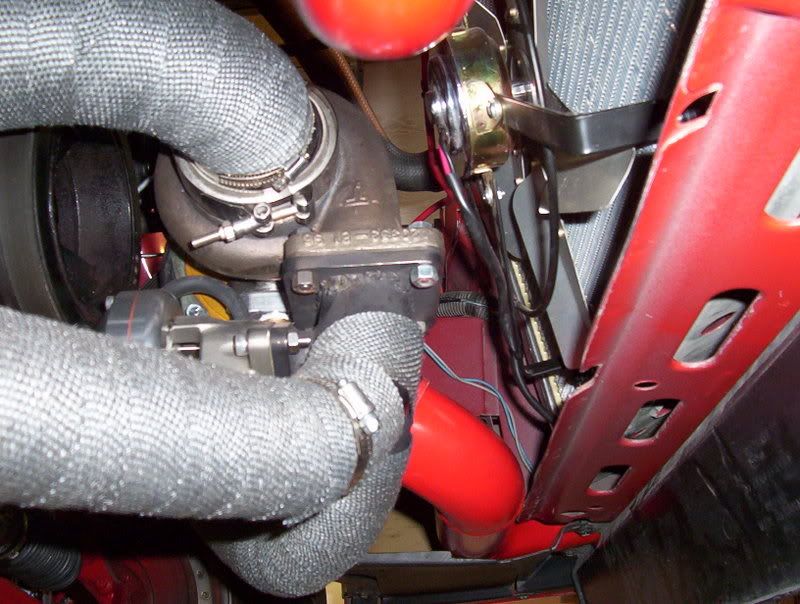

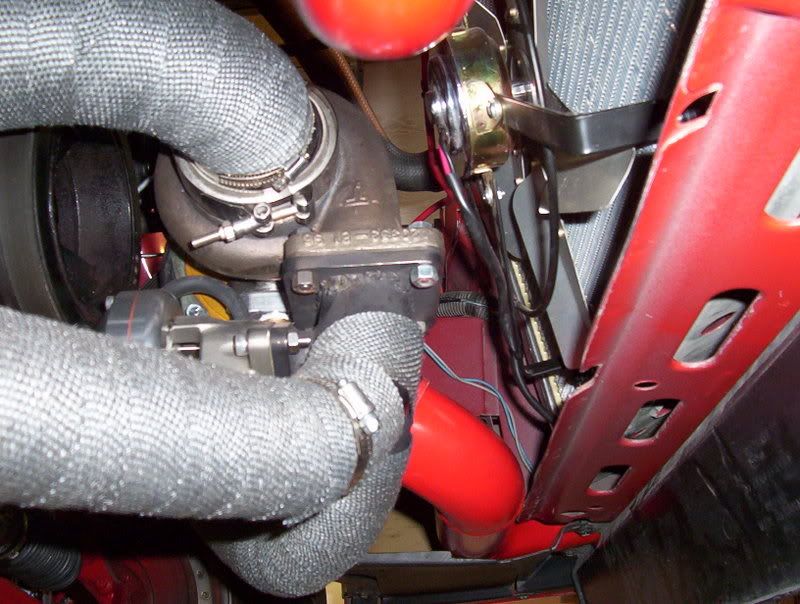

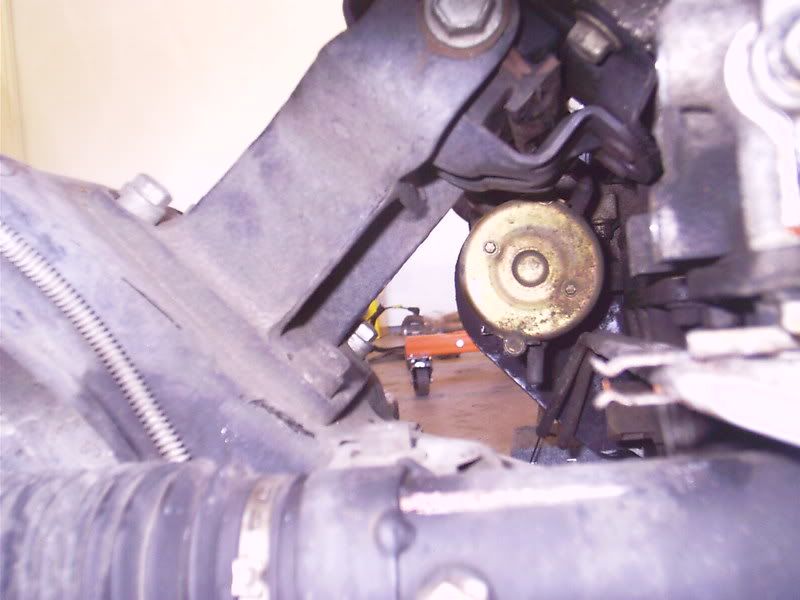

I'm not sure how his oil is being drained but I'll be mounting mine a little higher between the harmonic balancer and water pump and draining to the front of the timing cover. I think the biggest downpipe you can fit through the stock kmember and mounts is 3" I have not tried this myself though, I'm waiting on the solid mounts to get here and then I'm going put the motor back on the kmember and run my 3.5" piping. The reason he only has one O2 sensor after the turbo is because he is running a MAFless Speed Density tune and that is all you need, I'll be doing the same. If you are going to keep the front narrow band O2's you'll want to try to keep them in the same general location/distance as the factory has them and then 1 after the turbo to monitor A/F. In this picture you can see how he has the wastegate mounted between the crossover and harmonic balancer. I'm going to try to keep mine on the otherside (near the radiator).

#5

No matter whether you are running MAF or MAP for the load sensor, only 1 O2 sensor is not enough for V8 imho...

Today I looked again under hood and there was no space between pulleys and fans, let alone for turbo I'll be removing A/C rad tomorrow and see if it helps.

I'll be removing A/C rad tomorrow and see if it helps.

It sucks if all that can be done with stock K-member is 3" downpipe... It will strangle the turbo as hell Maybe there is more space on the drivers' side?

Maybe there is more space on the drivers' side?

Today I looked again under hood and there was no space between pulleys and fans, let alone for turbo

I'll be removing A/C rad tomorrow and see if it helps.

I'll be removing A/C rad tomorrow and see if it helps.It sucks if all that can be done with stock K-member is 3" downpipe... It will strangle the turbo as hell

Maybe there is more space on the drivers' side?

Maybe there is more space on the drivers' side?

#7

TECH Enthusiast

iTrader: (9)

Join Date: Oct 2005

Location: Greenville, Raleigh NC

Posts: 702

Likes: 0

Received 0 Likes

on

0 Posts

Have you mounted the rad. vert. yet? There is no room with the rad. like it is mounted from the factory you have to do a griffin or some vert. radiator mod for a front mount.

Trending Topics

#9

If you're keeping the stock radiator search around for people who have moved it forward and down to fit under the hood like 98Z28CobraKiller did in his thread or switch to slim pusher fans if you can. I'll be doing the later and moving it forward a little since the A/C is removed.

#11

Yeah I searched on this site and thought I found that somewhere. I've still got my wrecked ls1 on the stock kmember and I'm planning on switching the solid mounts and new motor on this weekend so I'll try to find some various sizes of pipe and see how they fit between the stock mounts and motor beforehand. I'll post up my results and pictures Saturday or Sunday.

#13

TECH Resident

iTrader: (13)

Join Date: Mar 2008

Location: On the coast of somewhere

Posts: 779

Likes: 0

Received 1 Like

on

1 Post

Gases do not "re-expand" when released from compression. Gases start cooling immediately, as minute as it may be, from higher psi. If it comes out of a 3" hole, how will 3.5 or 4" pipe, down stream help? Yes, gases will cool faster from surface area but, the cork is at the exhaust housing. Basically, from a physics stand point, don't neck down smaller than the exhaust housing exit size. Jose, please chime in on this. I'm debating the same issue to get the best clearance and flow.

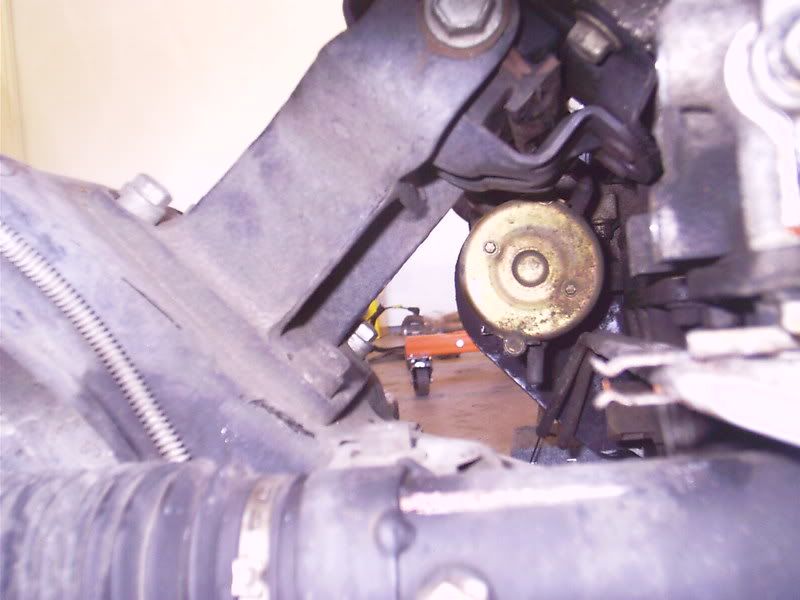

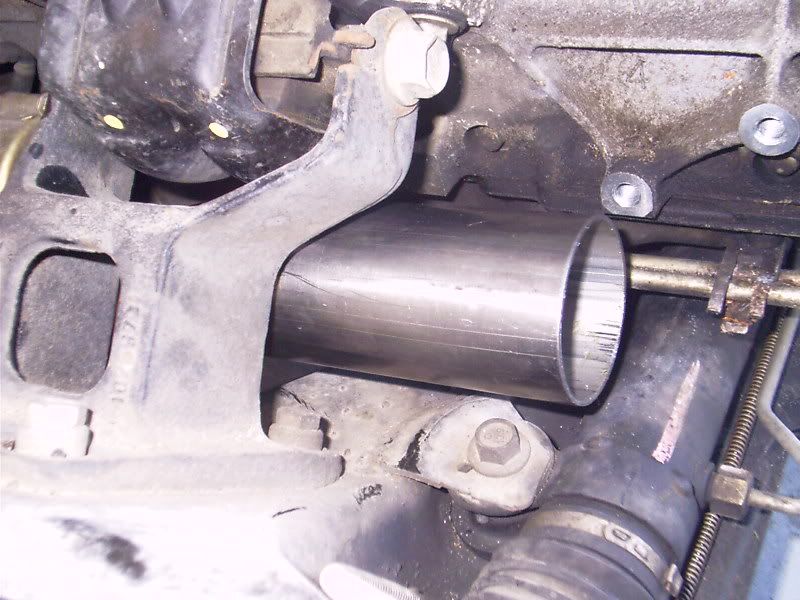

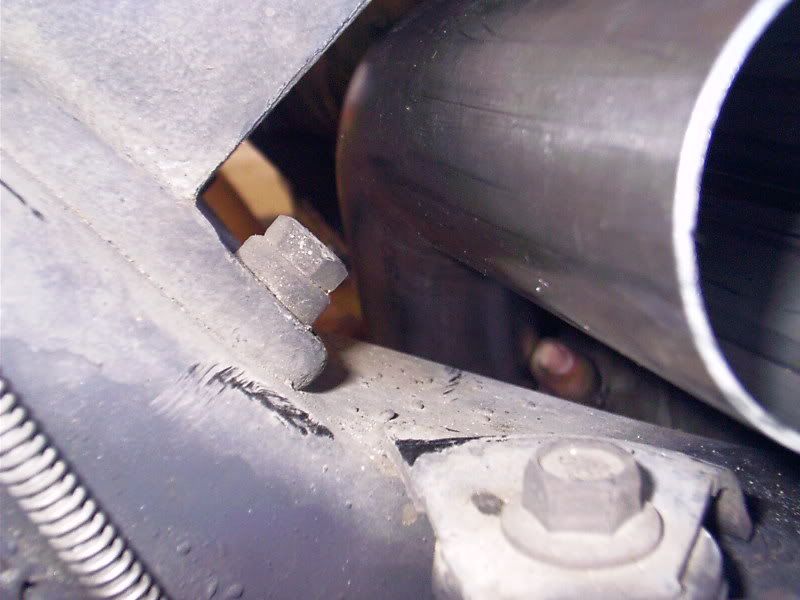

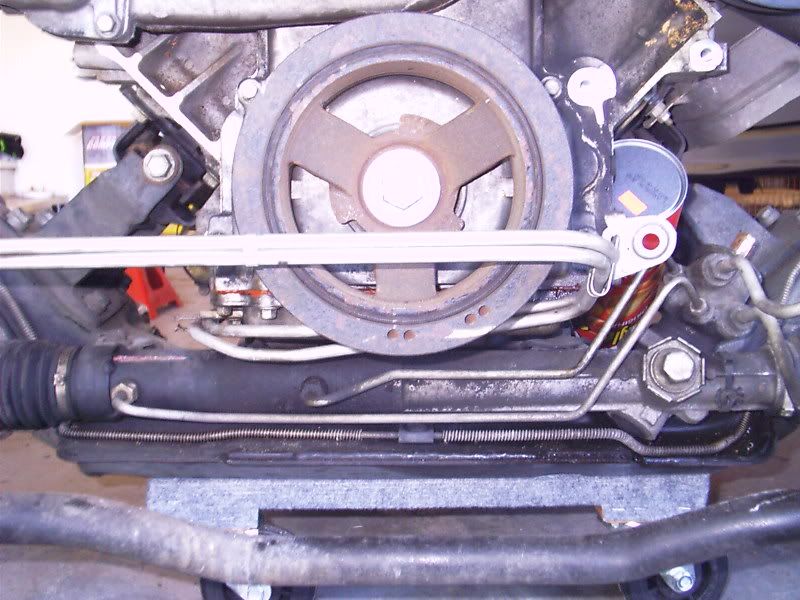

#15

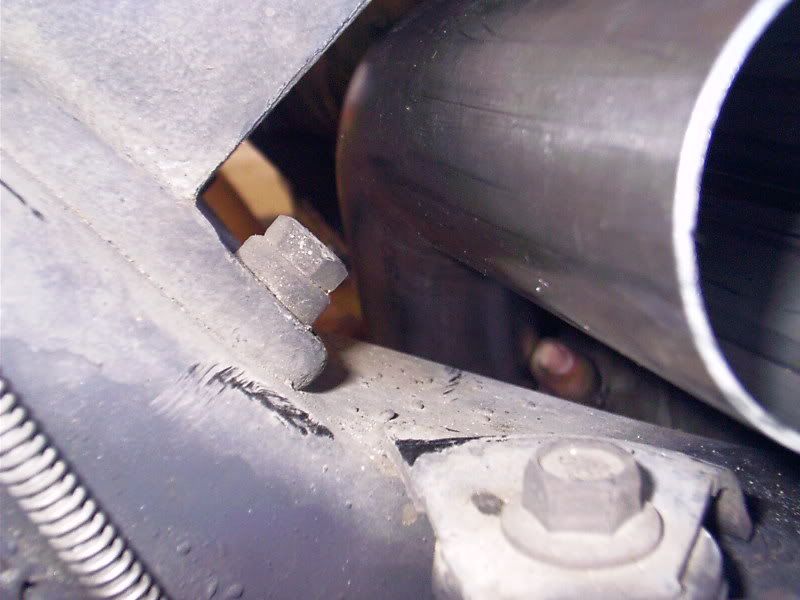

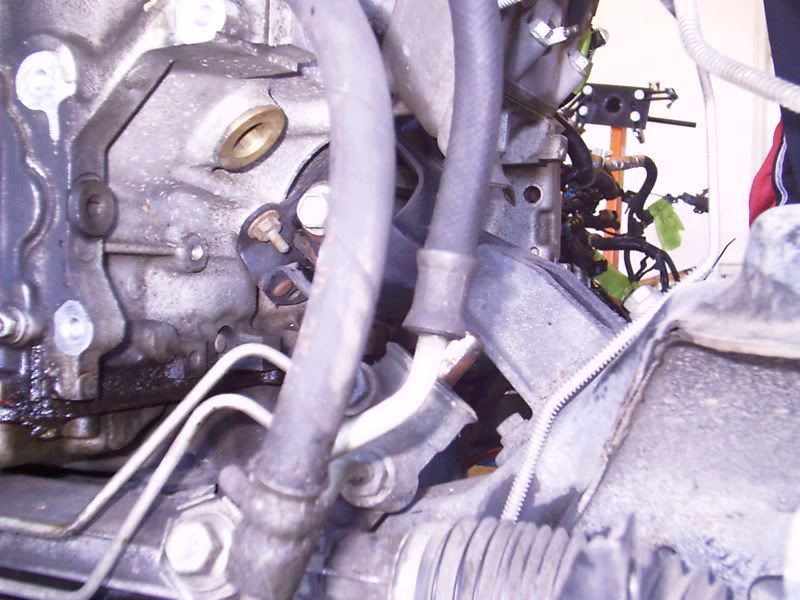

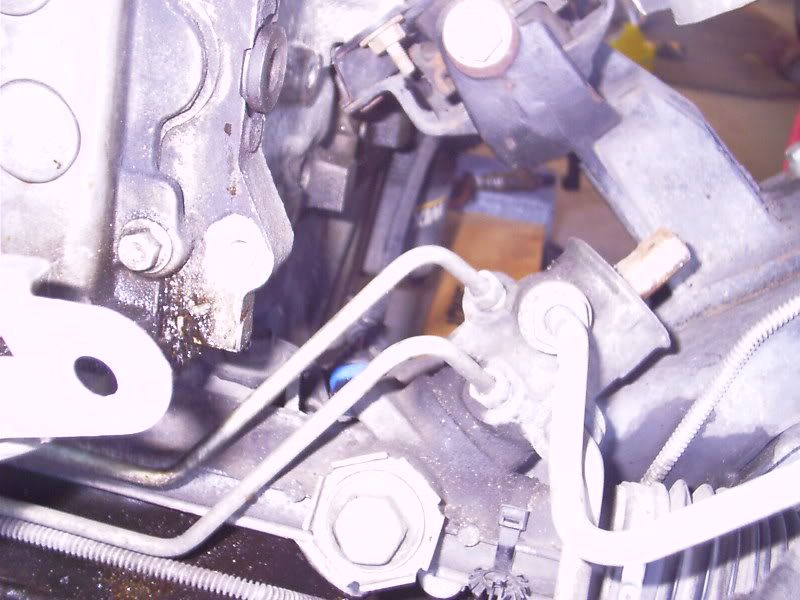

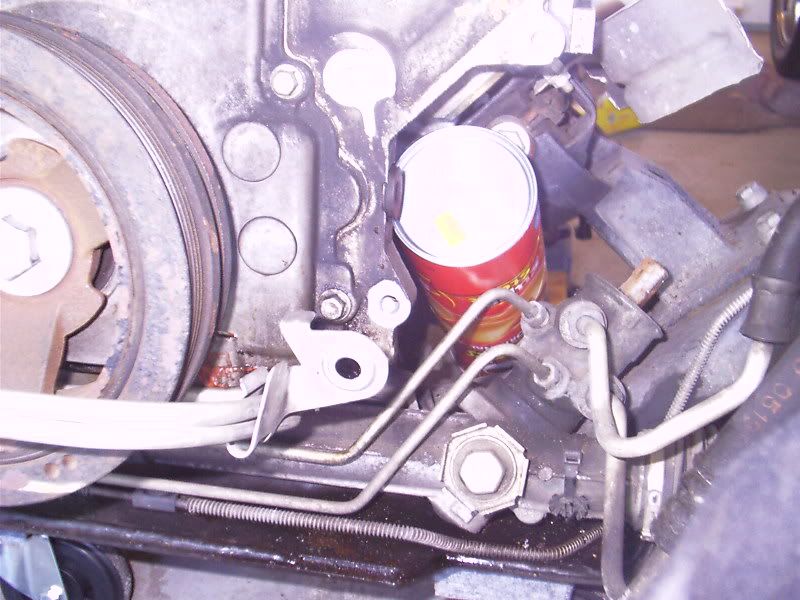

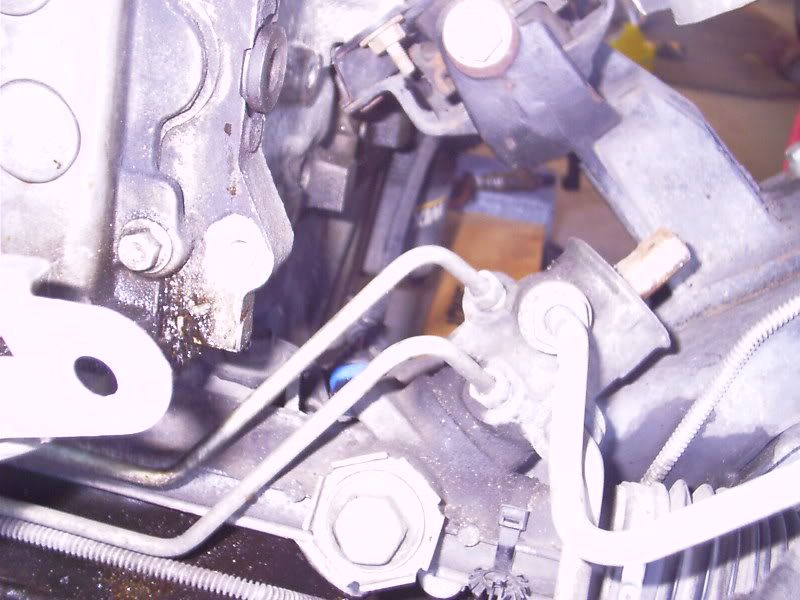

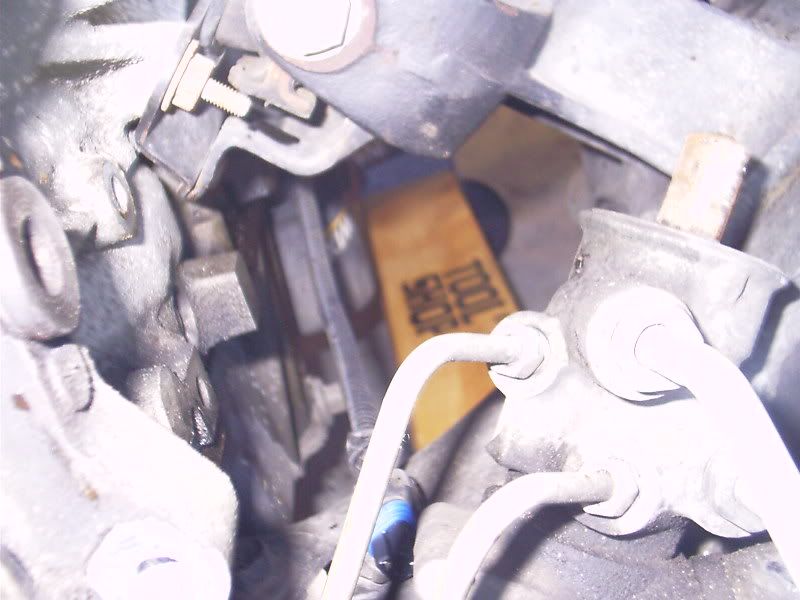

Here are some pictures I took of the space between the stock mounts, kmember and block. The first set is of the passenger side, unfortunately the only piping I had laying around is 2.5" OD for my cross over piping. I grabbed an empty pringles can I had laying around too which has nearly a 3" OD. There seemed to be enough room fit a 3" pipe easily and still be able to turn down before the starter. I think you might be able to squeeze a 3.5" in there but 4" would be very tough if not impossible. In the second group of pics I have are pictures of the drivers side.

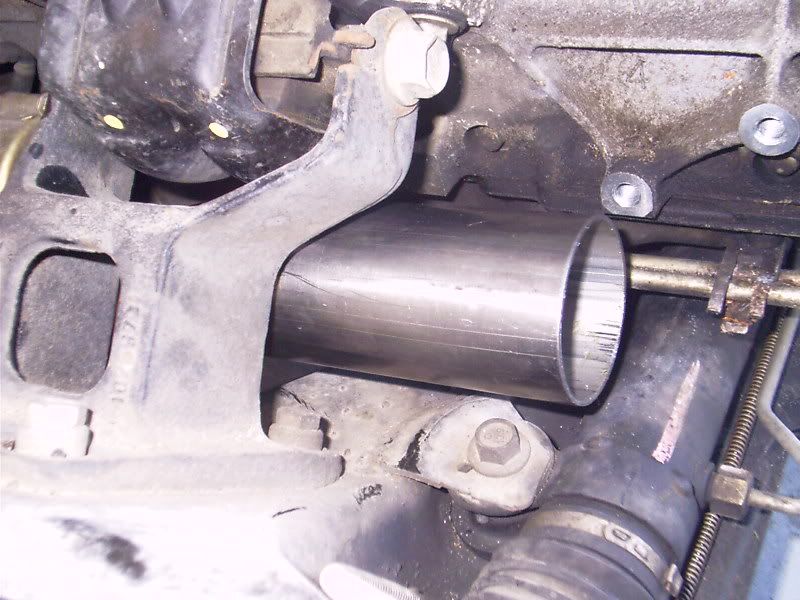

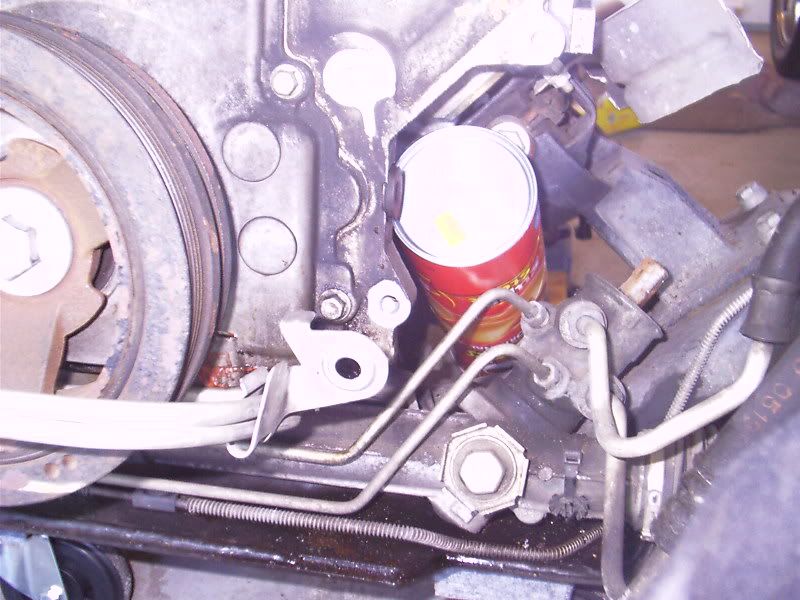

#16

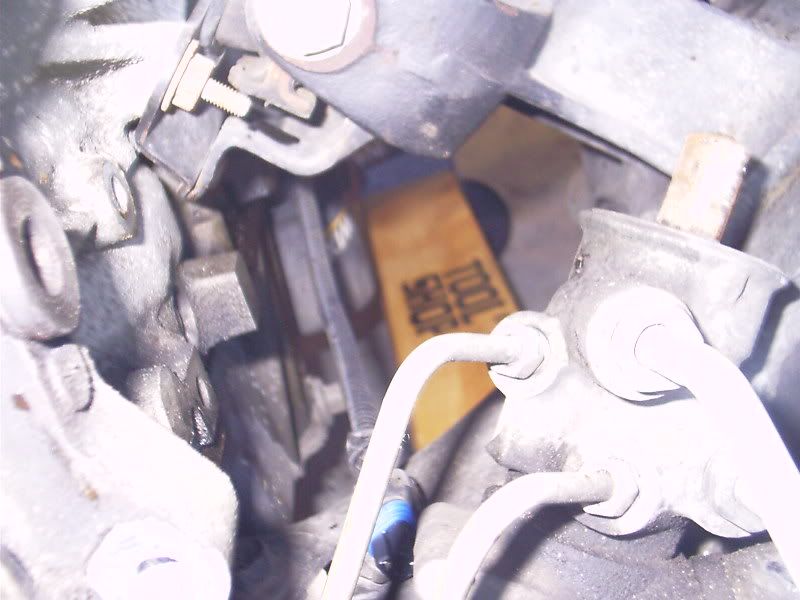

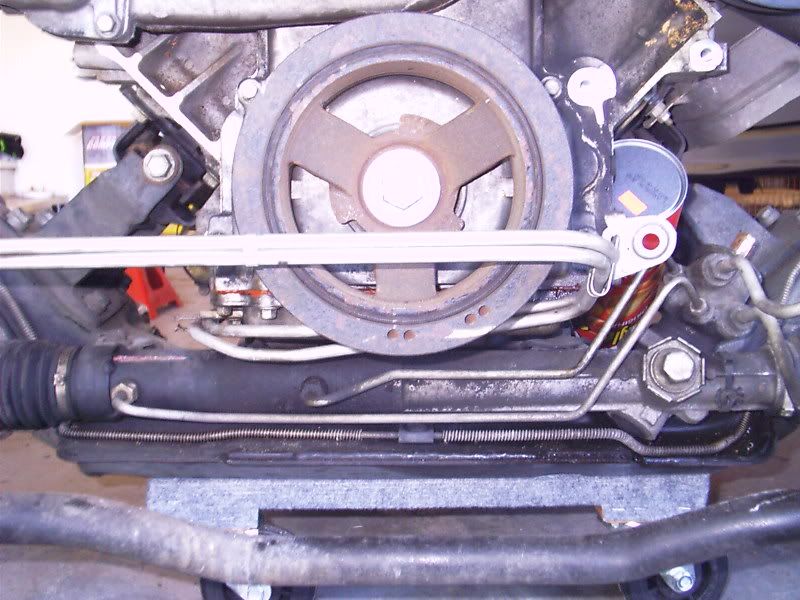

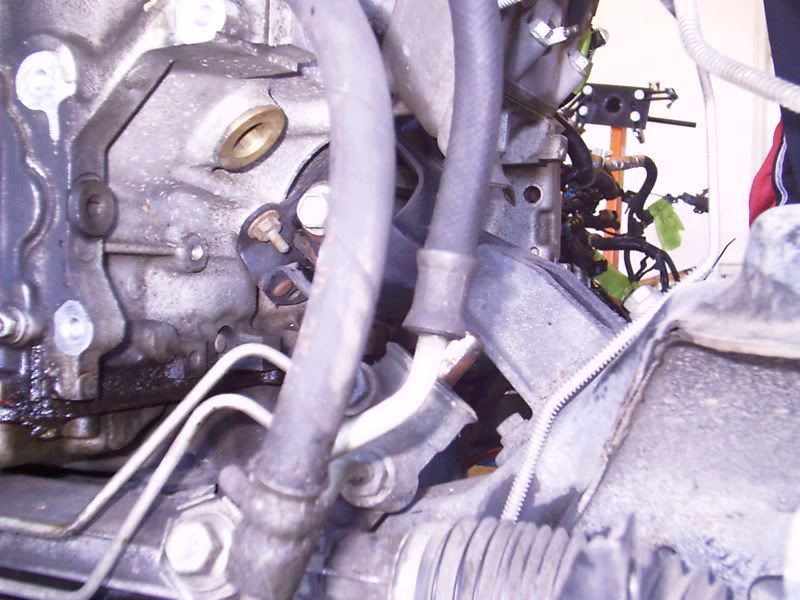

Here is the Drivers side, I think the hardest part about running it on the drivers side will be getting it to clear the power steering rack and lines. I'm not 100% on where the manifold will come down either and if that will cause any interference. Other then rack it seems to be the same as the drivers side but you wont have to turn down around the starter. I may bolt the exhaust manifolds on there later tonight and get some more pictures. Again, the pringles can is almost exactly a 3" OD.

Let me know if you need anything else, the engine will still be on the kmember for a few hours.

Let me know if you need anything else, the engine will still be on the kmember for a few hours.

#19

TECH Resident

iTrader: (13)

Join Date: Mar 2008

Location: On the coast of somewhere

Posts: 779

Likes: 0

Received 1 Like

on

1 Post

I understand your comment but, going to 4" pipe after the k-member(basicaly mid-way) isn't going to make much difference because of the cooling of gases, meaning the volume is much less at that area of the system. I do agree that coming directly off the housing to a larger pipe is optimum for flow(less back pressure)

#20

You do realize that resistance is not only in one hole, but in the whole system, right?

You do realize that resistance is not only in one hole, but in the whole system, right?  I think a 3.5" is possible to fit with some work.

I think a 3.5" is possible to fit with some work.