Spun Rod Bearing

#1

A month ago my motor locked up idling while pulling into a parking spot. I tore the motor down and turns out the oil pump was locked up but everything else looked alright and I threw it back together with a new pump. Car had 75 psi of oil pressure on cold start and 40 at hot idle. Never drove the car, just ran it in the driveway. Once it got hot I revved it up to around 4k rpm and when it started dropping I could hear the slightest knocking. Pulled it apart knowing it has bearing problems and here are pictures of what I found. Just the #6 rod bearing got spun, but doesn't look too bad. I don't think crank can be turned anymore and block can not be line honed or bored anymore. If damage isn't bad is it possible to fix this without getting a complete re-build with another block and crank?

Other Rods (Appear alright to me):

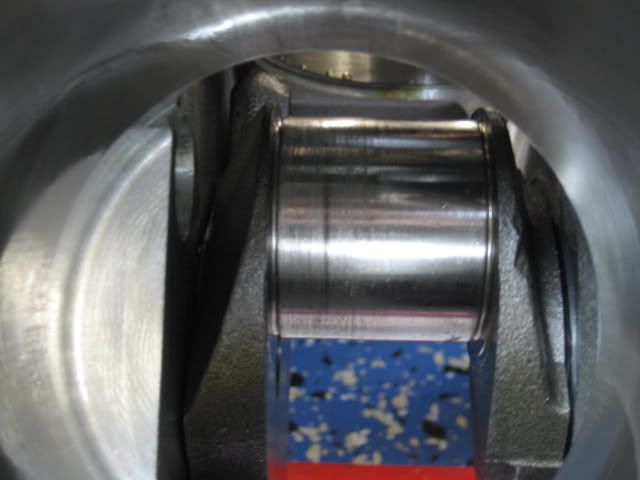

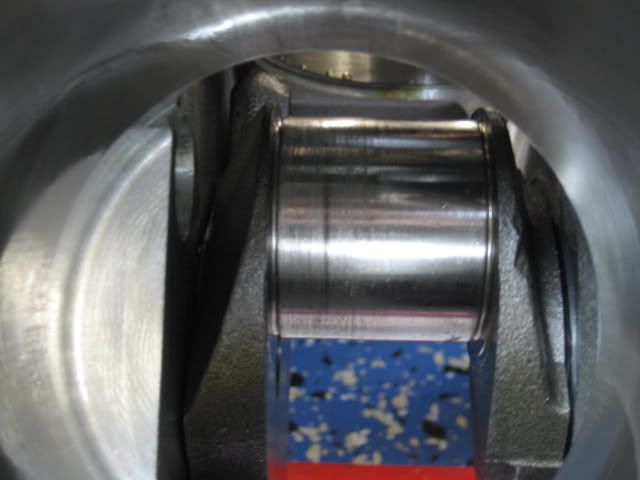

Spun Rod:

Bad Bearings Inside:

Bad Bearings Outside:

Crank Damage:

Other Rods (Appear alright to me):

Spun Rod:

Bad Bearings Inside:

Bad Bearings Outside:

Crank Damage:

#2

TECH Addict

ouch, sorry about the bad luck man. it doesn't look bad but i think it's still enough to need to replace the crank and rod. idk about the block, that's up to you and your machine shop.

#8

TECH Addict

go melling. you will never have a problem with it. GM pumps are all prone to failure, the melling is a completely beefed up redesigned pump. and it's not that expensive to upgrade.

#10

TECH Resident

iTrader: (3)

Take the crank and rods to the machine shop and check them out. Crank might polish out, but it's hard to tell from the pictures. Rod can be resized no problem. I take it the crank has already been turned and the block honed before? You could just turd hone the block to break the glaze and re-ring also. What work has the block and crank already been through?

#11

Plan is to just re-build it with the help of a buddy who works at a local machine shop. I need to remove crank today and see what the main bearings look like and how much that was turned / honed when main studs were added. Bores will be honed at the machine shop and we will balance it and replace all the bearings, rings, and the rod. Figured now is the time and I can get it done for under 1k.

Any suggestions on bearing type or brand? It had Clevite in there but I need to go look at them and try and see what kind.

Any suggestions on bearing type or brand? It had Clevite in there but I need to go look at them and try and see what kind.