Another Nova swap- 70' LQ4/ T56

#1

On The Tree

Thread Starter

iTrader: (3)

Join Date: Aug 2011

Location: WA

Posts: 125

Likes: 0

Received 0 Likes

on

0 Posts

I am bored on my lunch break so I thought I would share the LS swap on my 70' Nova. I have been lurking on this site for ~2 years and following Frojoe's and some of the other swaps. About a year ago I finally got a Nova and this fall I really started tearing into the car. Currently I am mocking up the motor and tranny, checking clearances ect inbetween rust repair and restoration activities. I will do my best to keep this thread updated along with the other one (see link). http://www.stevesnovasite.com/forums...d.php?t=213597

For now the parts list:

03' LQ4, Unknown mileage.

Stock bottom end

LSA Heads with some porting to remove the "wing" on the intake ports.

LS9 Head Gaskets

ARP Head Studs

Custom comp cams camshaft. Very mild grind for a (future) turbo.

3/8" HKE pushrods (I forget the length)

Brian Tooley Dual Valve springs

LS2 Timing set and chain dampner

LS3 Camaro Intake

Holley Swap Oil Pan

Dirty Dingo "double D" motor mount adapters

5.3L truck harness modified for standalone

98' F-body exhaust manifolds

F-body T-56

I still need to decide on an accessory drive, radiator, and pick up some other parts (throttle body, injectors, fuel system, ect). I will add some pictures soon so there is something to oogle.

For now the parts list:

03' LQ4, Unknown mileage.

Stock bottom end

LSA Heads with some porting to remove the "wing" on the intake ports.

LS9 Head Gaskets

ARP Head Studs

Custom comp cams camshaft. Very mild grind for a (future) turbo.

3/8" HKE pushrods (I forget the length)

Brian Tooley Dual Valve springs

LS2 Timing set and chain dampner

LS3 Camaro Intake

Holley Swap Oil Pan

Dirty Dingo "double D" motor mount adapters

5.3L truck harness modified for standalone

98' F-body exhaust manifolds

F-body T-56

I still need to decide on an accessory drive, radiator, and pick up some other parts (throttle body, injectors, fuel system, ect). I will add some pictures soon so there is something to oogle.

#2

On The Tree

iTrader: (5)

Join Date: Mar 2011

Location: Indiana

Posts: 126

Likes: 0

Received 0 Likes

on

0 Posts

Welcome to the club! I am in the process of an LQ9/TH350 swap in my 71 Nova right now. Ive learned lots of things from this site that were helpful in my swap. Let me know if you run into any issues or have any questions and I will share what I am doing with mine if it helps.

#4

LS1Tech Sponsor

iTrader: (5)

We have a 71 with an LS2. If you have any questions please ask. You will find a lot of good information on the board.

Jon

PSI

Jon

PSI

__________________

Your Source for LSX Conversion Parts!

www.psiconversion.com

Ebay Store

Facebook/psiconversion

Instagram/psiconversion

'Dont Let EFI Pass You By!'

Your Source for LSX Conversion Parts!

www.psiconversion.com

Ebay Store

Facebook/psiconversion

Instagram/psiconversion

'Dont Let EFI Pass You By!'

#6

I notched mine.

Click on the link in my sig to see what I did.

I added a reinforced the floor with a 1/4" thick plate that I bent to contour the floor.

I also drilled and tapped it so that I could mount the shifter boot and get a water tight seal.

Click on the link in my sig to see what I did.

I added a reinforced the floor with a 1/4" thick plate that I bent to contour the floor.

I also drilled and tapped it so that I could mount the shifter boot and get a water tight seal.

Trending Topics

#8

On The Tree

iTrader: (5)

Join Date: Mar 2011

Location: Indiana

Posts: 126

Likes: 0

Received 0 Likes

on

0 Posts

I used the truck accessory bracket on mine with a relocated idler pulley, f body pump with spacers, truck alternator and power steering pump. Everything fits nicely together and I drilled the spacer on the water pump to route the coolant crossover to. Nice looking car, btw!

#10

On The Tree

Thread Starter

iTrader: (3)

Join Date: Aug 2011

Location: WA

Posts: 125

Likes: 0

Received 0 Likes

on

0 Posts

Couple of updates. After some head scratching I decided to mount the motor in the original SBC position to get some extra clearance for the exhaust and fan/ radiator. I also built the crossmember. A little rusty with the welder. Not 100% happy with it but after grinding a few more welds I think it will look pretty good. Some have modified the th400 crossmember to work, but with the motor in the original SBC bellhousing position it was not going to be very clean looking. It is made out of 3"x5/16" flat bar. I liked the BMR and ATS cross members but I just couldnt swallow the $300.

#11

On The Tree

Thread Starter

iTrader: (3)

Join Date: Aug 2011

Location: WA

Posts: 125

Likes: 0

Received 0 Likes

on

0 Posts

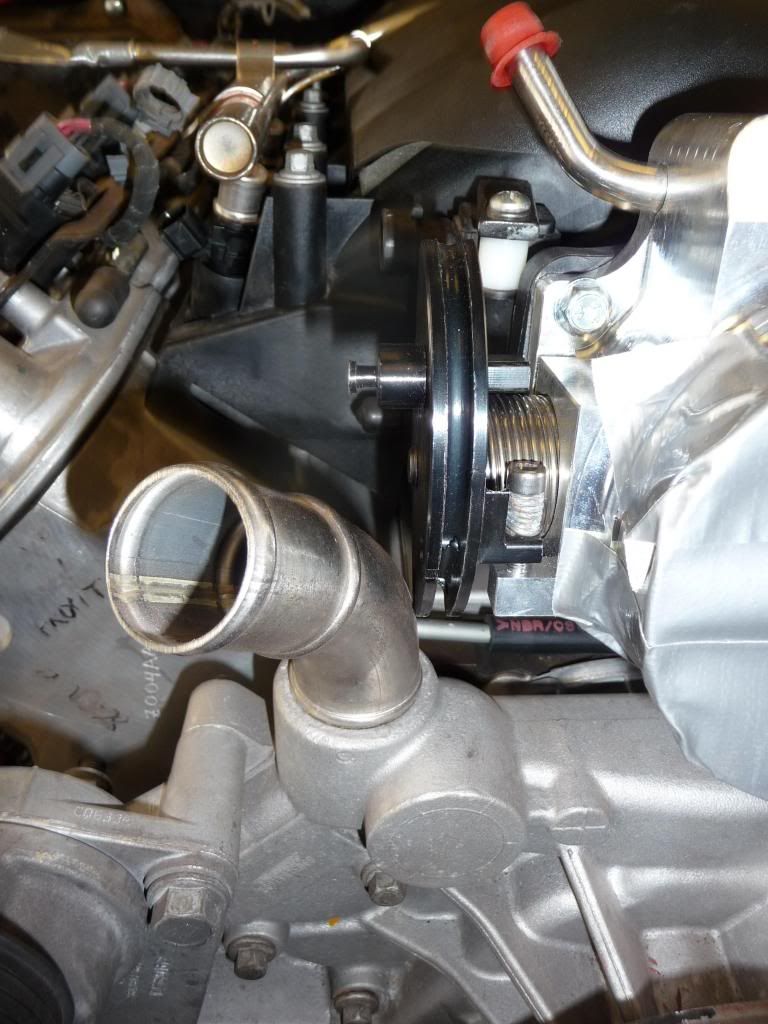

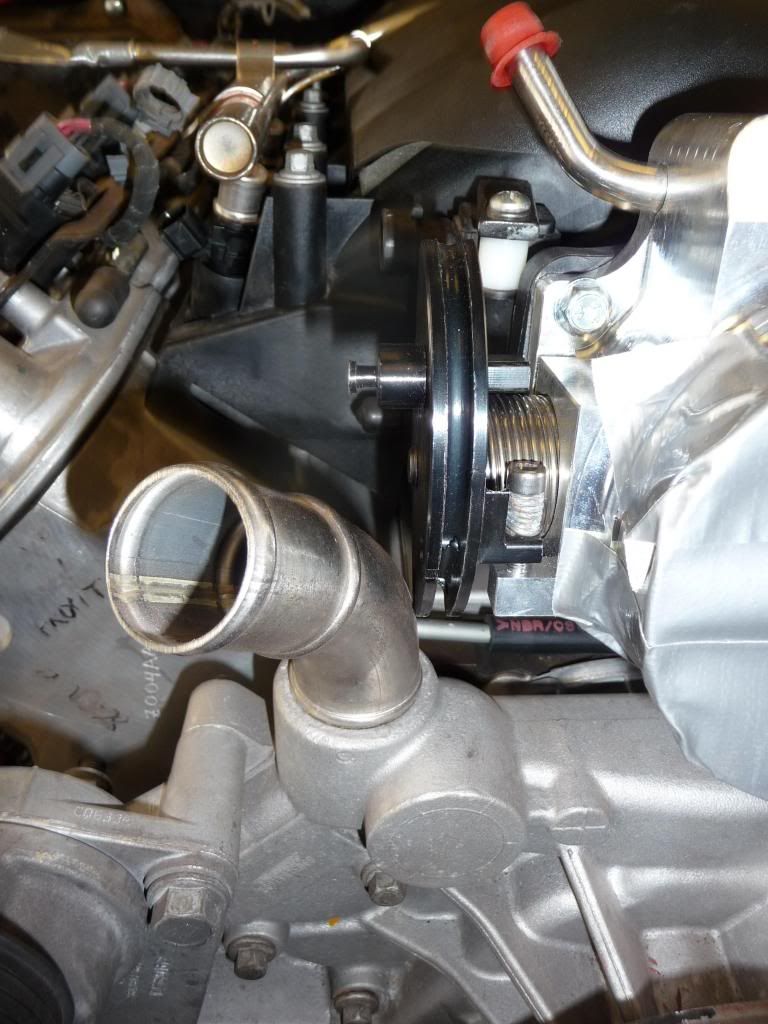

I also got some LS9 injectors off ebay, alper motorsports throttle body, iac/ tps sensors since the ones off the 03' DBW LQ4 throttle body are different than the ones for my 01 truck DBC harness. Unfortunately the truck water pump outlet doesnt clear the cam on the throttle body. Need to figure out if I am going to try and modify the outlet, use a 2010 camaro WP or some other WP with spacers. Also picked up a 2010 camaro steam tube since the truck tube didnt fit the LS3 intake.

#12

I like the build, your making good progress. I have a couple questions for you as I am gathering parts for swapping a 99 LS1/T56 combination in my 70 Nova. I hadn't heard of the particular set of motor mounts you are using. What position do they mount the engine? I have also seen a lot of builds where the trans tunnel is cut all the way to the dash, in order to get the right angle. How much cutting have you had to do, it doesn't appear to be much? One more question. Any issues with the manifold clearance? It looks like it cleared the steering box. Thanks and keep up the good work.

#13

On The Tree

Thread Starter

iTrader: (3)

Join Date: Aug 2011

Location: WA

Posts: 125

Likes: 0

Received 0 Likes

on

0 Posts

I like the build, your making good progress. I have a couple questions for you as I am gathering parts for swapping a 99 LS1/T56 combination in my 70 Nova. I hadn't heard of the particular set of motor mounts you are using. What position do they mount the engine? I have also seen a lot of builds where the trans tunnel is cut all the way to the dash, in order to get the right angle. How much cutting have you had to do, it doesn't appear to be much? One more question. Any issues with the manifold clearance? It looks like it cleared the steering box. Thanks and keep up the good work.

The Dirty Dingo "Double D" adapter plates have three positions, standard SBC, 3/4 forward, and 1-3/4". All the pictures of fiment are with the motor in the 3/4" forward position, but I have since decided to use he standard SBC position.

The tranny clears the tunnel fine, except for the shifter hole ends up right through the floor brace/ crossmember. The only clearancing I may have to do will be around the reverse lockout solenoid, but right now it clears. I honestly cant figure out why most have had to do so much cutting. The only thing I can think would be the half-height subframe bushings many people use, but I have the standard height.

The manifold is tight to the steering box in 3/4" forward position, probably only 3/8-1/2" away. But with the motor in the standard SBC position there is plenty of clearance. Keep in mind I have a manual steering box and the stamped steel 98' F-body manifolds, which are different than the cast iron 99-02 manifolds.

#14

TECH Senior Member

iTrader: (12)

Welcome to the forum. I have a 71' Nova with a 02' LS1/4L60E project going, Its been on the self for a few month as I had some other projects I needed to get done, but it is almost time to get back to it. Project Build Thread in my Sig...

since I am using an 4L60E, I didn't run into the same problem as you are on the T56 and the Crossmember and Floor Support. What Oil pan are you using?

Nice job on the project so far. As stated, much information can be found on this Forum. Just read the many project threads.. Let us know if you need anything else answered.

BC

since I am using an 4L60E, I didn't run into the same problem as you are on the T56 and the Crossmember and Floor Support. What Oil pan are you using?

Nice job on the project so far. As stated, much information can be found on this Forum. Just read the many project threads.. Let us know if you need anything else answered.

BC

#15

The amount of cutting to the tunnel that needs to be done soley depends on the drivetrain inclination angle you are trying to acheive, or should I say willing to live with. If you have installed the Holley pan without having to notch the front crossmember and have only had to do minor modifications to the tunnel, then you are going to have to accept the U-joint working angles that are a result of it.

Your inclination angle with the set-up you have is somewhere between 4 and 6 degrees with the chassis level. If you want 3 degrees (or less) of engine inclination on these cars with a T56 or T56 magnum you will have to notch the crossmember if you want to use the Holley pan, or use a stock F-body pan notched to clear the steering center link to allow you to get the front of the engine low enough AND do major modifications to the tunnel to clear the top of the trans.

The benefits far outweigh the required work (realistic U-joint working angles and tucking the bottom edge of the T56 case up high enough that it barely hangs below the subframe)in my opinion, so it's the route I choose to take.

There are guys running that ultra-expensive CV driveshaft, but it costs more ($800) than it does for me to perform the needed modifications and doesn't get the bottom of the trans case up higher. You'll get different answers here, but I just thought I'd give you a different perspective with the hope that it helps you make a fully informed decision.

Your inclination angle with the set-up you have is somewhere between 4 and 6 degrees with the chassis level. If you want 3 degrees (or less) of engine inclination on these cars with a T56 or T56 magnum you will have to notch the crossmember if you want to use the Holley pan, or use a stock F-body pan notched to clear the steering center link to allow you to get the front of the engine low enough AND do major modifications to the tunnel to clear the top of the trans.

The benefits far outweigh the required work (realistic U-joint working angles and tucking the bottom edge of the T56 case up high enough that it barely hangs below the subframe)in my opinion, so it's the route I choose to take.

There are guys running that ultra-expensive CV driveshaft, but it costs more ($800) than it does for me to perform the needed modifications and doesn't get the bottom of the trans case up higher. You'll get different answers here, but I just thought I'd give you a different perspective with the hope that it helps you make a fully informed decision.

#17

TECH Resident

iTrader: (24)

Join Date: Jun 2005

Location: Houston, TX

Posts: 860

Likes: 0

Received 0 Likes

on

0 Posts

The amount of cutting to the tunnel that needs to be done soley depends on the drivetrain inclination angle you are trying to acheive, or should I say willing to live with. If you have installed the Holley pan without having to notch the front crossmember and have only had to do minor modifications to the tunnel, then you are going to have to accept the U-joint working angles that are a result of it.

Your inclination angle with the set-up you have is somewhere between 4 and 6 degrees with the chassis level. If you want 3 degrees (or less) of engine inclination on these cars with a T56 or T56 magnum you will have to notch the crossmember if you want to use the Holley pan, or use a stock F-body pan notched to clear the steering center link to allow you to get the front of the engine low enough AND do major modifications to the tunnel to clear the top of the trans.

The benefits far outweigh the required work (realistic U-joint working angles and tucking the bottom edge of the T56 case up high enough that it barely hangs below the subframe)in my opinion, so it's the route I choose to take.

There are guys running that ultra-expensive CV driveshaft, but it costs more ($800) than it does for me to perform the needed modifications and doesn't get the bottom of the trans case up higher. You'll get different answers here, but I just thought I'd give you a different perspective with the hope that it helps you make a fully informed decision.

Your inclination angle with the set-up you have is somewhere between 4 and 6 degrees with the chassis level. If you want 3 degrees (or less) of engine inclination on these cars with a T56 or T56 magnum you will have to notch the crossmember if you want to use the Holley pan, or use a stock F-body pan notched to clear the steering center link to allow you to get the front of the engine low enough AND do major modifications to the tunnel to clear the top of the trans.

The benefits far outweigh the required work (realistic U-joint working angles and tucking the bottom edge of the T56 case up high enough that it barely hangs below the subframe)in my opinion, so it's the route I choose to take.

There are guys running that ultra-expensive CV driveshaft, but it costs more ($800) than it does for me to perform the needed modifications and doesn't get the bottom of the trans case up higher. You'll get different answers here, but I just thought I'd give you a different perspective with the hope that it helps you make a fully informed decision.

#18

On The Tree

Thread Starter

iTrader: (3)

Join Date: Aug 2011

Location: WA

Posts: 125

Likes: 0

Received 0 Likes

on

0 Posts

Welcome to the forum. I have a 71' Nova with a 02' LS1/4L60E project going, Its been on the self for a few month as I had some other projects I needed to get done, but it is almost time to get back to it. Project Build Thread in my Sig...

since I am using an 4L60E, I didn't run into the same problem as you are on the T56 and the Crossmember and Floor Support. What Oil pan are you using?

Nice job on the project so far. As stated, much information can be found on this Forum. Just read the many project threads.. Let us know if you need anything else answered.

BC

since I am using an 4L60E, I didn't run into the same problem as you are on the T56 and the Crossmember and Floor Support. What Oil pan are you using?

Nice job on the project so far. As stated, much information can be found on this Forum. Just read the many project threads.. Let us know if you need anything else answered.

BC

A lot of truth mentioned here. In order to achieve a driveline angle of less than 4 degrees you will have to raise the tunnel. I had similar results as you upon initial mockup with no clearance issues until I tried to get the 3-4 degrees that is recommended. Ride height plays a factor as well.... If you don't mind putting a little money into the trans you can run a viper tailshaft with the beefier viper output as it moves the shifter position forward several inches. I have a few pics I will add once I can get to a computer.

Found this in a quick google search:

http://www2.dana.com/pdf/J3311-1-DSSP.pdf

Not worried about the ground clearance, I have about the same clearance as the original TH400 and the trans is probably less than 3/4" below the crossmember at the lowest point. I wont be lowering this car anywhere near as much as many do.

#19

An LS/4L60 combo is installable in a 3rd gen Nova without cutting the floor and being able to acheive 2.5-3 degrees eng/trans inclination angle...but not with the Holley oil pan, which is more than an inch deeper across the front of the pan than a stock F-body pan.

If you are willing to notch the front crossmember, then the Holley pan can be used successfully. Others here have used the Holley pan in a Nova swap without notching the crossmember, but I assure you their U-joint working angles are nowhere near what you can acheive if you start out with the standard 3 degree engine inclination being your objective, which also means you're less likely to need to shim your rear end to adjust pinion angle.

As a side note, with the engine low enough to obtain a 3 degree inclination angle a low-mount F-body alternator will not install with this setup unless you notch the crossmember or move the engine forward 3/4"-1" from the stock position, which I am against from a handling perspective and from reducing the area available in front of the engine for radiators, fans, intake tubing etc... You can keep the the motor in a low/rear position and use low-cost bracket options available from Holley and others to upper-mount the alternator while using either the stock truck or F-body balancer/water pump spacings.

There's also A/C compressor relocation brackets for upper mounting the compressor high on the passenger head if you want to run A/C. Things have really improved over the last few years from an affordable parts supply standpoint and will make your swap much easier than those done previously by others here.

If you are willing to notch the front crossmember, then the Holley pan can be used successfully. Others here have used the Holley pan in a Nova swap without notching the crossmember, but I assure you their U-joint working angles are nowhere near what you can acheive if you start out with the standard 3 degree engine inclination being your objective, which also means you're less likely to need to shim your rear end to adjust pinion angle.

As a side note, with the engine low enough to obtain a 3 degree inclination angle a low-mount F-body alternator will not install with this setup unless you notch the crossmember or move the engine forward 3/4"-1" from the stock position, which I am against from a handling perspective and from reducing the area available in front of the engine for radiators, fans, intake tubing etc... You can keep the the motor in a low/rear position and use low-cost bracket options available from Holley and others to upper-mount the alternator while using either the stock truck or F-body balancer/water pump spacings.

There's also A/C compressor relocation brackets for upper mounting the compressor high on the passenger head if you want to run A/C. Things have really improved over the last few years from an affordable parts supply standpoint and will make your swap much easier than those done previously by others here.