Head Removal way to avoid cleaning bolt holes

#1

Going to do a H/C swap. I understand that cleaning the head bolt holes is a no fun but a must do. Going to install ARP studs as well.

Here is the idea that came to me,while removing the head bolts. If a stud(stud only) was installed one at a time, in place of the bolt that was removed, would this be a safe way to avoid any contamination to the holes, prior to lifting the head.

Here is the idea that came to me,while removing the head bolts. If a stud(stud only) was installed one at a time, in place of the bolt that was removed, would this be a safe way to avoid any contamination to the holes, prior to lifting the head.

#2

TECH Senior Member

Pointless as you will still need to clean out the sealant remains in the holes trapped in the threads.

I suck the water with a wet vac and a home made tube contraption, then I use a gun cleaning kit to clean the threads.

I suck the water with a wet vac and a home made tube contraption, then I use a gun cleaning kit to clean the threads.

#3

TECH Senior Member

iTrader: (5)

On each side of the block there are drain plugs. The one on the driver side is a big allen key, I think its a #17mm. The one on the pass side is smaller. Take both out and let the coolant drain. I did this when installing my studs and had verry little water in the bolt holes and in the cylinders.

#4

TECH Junkie

iTrader: (28)

Join Date: Jan 2004

Location: Houston

Posts: 3,250

Likes: 0

Received 0 Likes

on

0 Posts

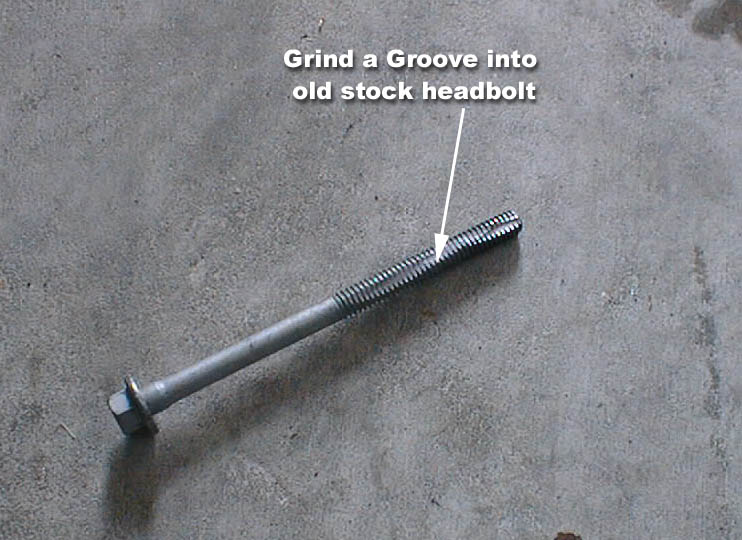

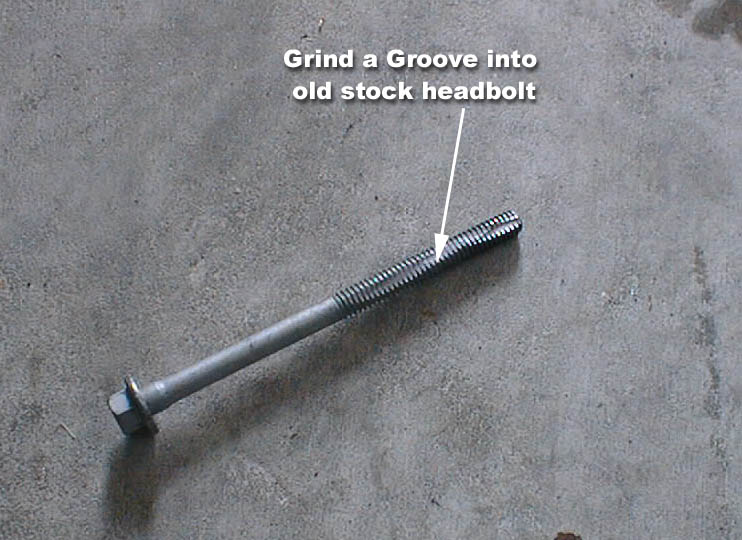

take the stock TTY bolts and grind a groove into them as seen here

http://www.ls1howto.com/index.php?article=2

This makes short work of cleaning the threads out.

to get the coolant out of the holes, I used a bunch of paper towels and a shop vac.

http://www.ls1howto.com/index.php?article=2

This makes short work of cleaning the threads out.

to get the coolant out of the holes, I used a bunch of paper towels and a shop vac.

Trending Topics

#8

TECH Fanatic

Join Date: Jan 2003

Location: Northern Va

Posts: 1,094

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by 618HAWK

Going to do a H/C swap. I understand that cleaning the head bolt holes is a no fun but a must do. Going to install ARP studs as well.

Here is the idea that came to me,while removing the head bolts. If a stud(stud only) was installed one at a time, in place of the bolt that was removed, would this be a safe way to avoid any contamination to the holes, prior to lifting the head.

Here is the idea that came to me,while removing the head bolts. If a stud(stud only) was installed one at a time, in place of the bolt that was removed, would this be a safe way to avoid any contamination to the holes, prior to lifting the head.

#9

TECH Fanatic

iTrader: (10)

Drain all the coolant, and take out the freeze plug in the pass side, and the coolant temp sensor in the driver's side. That should drain alot of the coolant from the heads. Then when removing the heads, loosen up all of the bolts just enough to lift the head from the block, without removing them. Then lift the head while the bolts are still threaded and let the coolant drain out. These steps should keep most of the coolant out of the bolt holes.

I used a can of compressed air, a grooved stock bolt, and threaded paper towels down into the hole to clean them out after removing the head.

I used a can of compressed air, a grooved stock bolt, and threaded paper towels down into the hole to clean them out after removing the head.

#11

TECH Junkie

iTrader: (28)

Join Date: Jan 2004

Location: Houston

Posts: 3,250

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Black Z/28

I am also about to install my heads using ARP studs. I think your basic idea is still good- replace each bolt (one at a time, as you mentioned) with a stud and then lightly tighten a nut down on each stud. When all the bolts have been replaced with studs/nuts, remove the nuts from the studs and pull the heads. After cleaning up the colant, pull each stud and clean each hole. Wouldn't this equal easier cleanup? I've never done heads before so I am probably missing something.

by R&Ring the bolts and replacing them with studs, you run the risk of warping the heads. There is a torque sequence to follow when you remove and install heads

#12

TECH Addict

iTrader: (49)

Another vote for the removal of the freeze plugs. A little more work up front but a lot less work cleaning up the mess. You still need to clean the holes but it's a lot easier and less mess to clean this way. Here's an old link with pics and wrench sizes for the freeze plugs.

https://ls1tech.com/forums/generation-iii-internal-engine/335413-afr-s-fast-90-nw-90tb-poly-mounts-fast-rails-finally-done.html

https://ls1tech.com/forums/generation-iii-internal-engine/335413-afr-s-fast-90-nw-90tb-poly-mounts-fast-rails-finally-done.html

#13

TECH Fanatic

Join Date: Jan 2003

Location: Northern Va

Posts: 1,094

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by TAQuickness

by R&Ring the bolts and replacing them with studs, you run the risk of warping the heads. There is a torque sequence to follow when you remove and install heads

(just trying to keep the heads from lifting before all the studs were in place). Besides, the original heads haven't even been removed at this point. Sorry I wasn't clear. Besides, I like NHRATA01's idea.

(just trying to keep the heads from lifting before all the studs were in place). Besides, the original heads haven't even been removed at this point. Sorry I wasn't clear. Besides, I like NHRATA01's idea.

#15

Teching In

Join Date: Oct 2005

Location: Annapolis, MD

Posts: 16

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by TAQuickness

by R&Ring the bolts and replacing them with studs, you run the risk of warping the heads. There is a torque sequence to follow when you remove and install heads

#16

TECH Junkie

iTrader: (28)

Join Date: Jan 2004

Location: Houston

Posts: 3,250

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by AnnapolisSilverado

TAQuickness, are you saying that the studs cannot be torqued in sequence?

I'm saying if you don't follow the sequence, you stand a chance of warping your heads. would have been more clear to say removing one bolt at a time and replacing with studs with out following the proper sequence will cause warpage