Some spring questions...

#1

TECH Junkie

Thread Starter

iTrader: (21)

Join Date: Aug 2004

Location: Virginia Beach, VA

Posts: 3,164

Likes: 0

Received 0 Likes

on

0 Posts

I have a set of AFR 8017 springs, and Patrick G says they're good to .650 lift when shimmed to within .050" of coil bind. Im trying to make sure I can use them with a MS4...

Does shimming them have any ill effects on the springs? Is there any how-to's on shimming springs?

And can I use the stock retainers with the springs?

Does shimming them have any ill effects on the springs? Is there any how-to's on shimming springs?

And can I use the stock retainers with the springs?

#4

TECH Senior Member

iTrader: (21)

Join Date: Nov 2001

Location: Cecil County Raceway!!!

Posts: 8,484

Likes: 0

Received 0 Likes

on

0 Posts

the shimming goes under the lower spring seat, just reduces the installed height of the spring by the amount of shim. If you are trying to achieve .050 from coil bind, you need to measure your current installed height (with a valve spring micrometer), subtract off the coil bind height (AFR can tell you this number or you can have a machine shop measure) and then you subtract off the lift of the cam. this number is the amount from coil bind you have.

#6

TECH Junkie

Thread Starter

iTrader: (21)

Join Date: Aug 2004

Location: Virginia Beach, VA

Posts: 3,164

Likes: 0

Received 0 Likes

on

0 Posts

Well, I picked up a set of 8017s a few months back for $100..I wasnt planning on running a MS4, but I can get it and new prushrods for $300, so i figured what the hell.... and since I already have these springs, I wanted to try and use them.

So, from what vettenuts said, if I use the 8017s and shim them, i need to buy new seals as well?

And as far as spring height goes...is it something that is usually the same from car to car? im just wondering If i have to install the springs, then measure, then order the shim and then put the shim in...or can I just find out what the installed height is from AFR?

So, from what vettenuts said, if I use the 8017s and shim them, i need to buy new seals as well?

And as far as spring height goes...is it something that is usually the same from car to car? im just wondering If i have to install the springs, then measure, then order the shim and then put the shim in...or can I just find out what the installed height is from AFR?

#7

Moderator

iTrader: (20)

Well, I picked up a set of 8017s a few months back for $100..I wasnt planning on running a MS4, but I can get it and new prushrods for $300, so i figured what the hell.... and since I already have these springs, I wanted to try and use them.

So, from what vettenuts said, if I use the 8017s and shim them, i need to buy new seals as well?

And as far as spring height goes...is it something that is usually the same from car to car? im just wondering If i have to install the springs, then measure, then order the shim and then put the shim in...or can I just find out what the installed height is from AFR?

So, from what vettenuts said, if I use the 8017s and shim them, i need to buy new seals as well?

And as far as spring height goes...is it something that is usually the same from car to car? im just wondering If i have to install the springs, then measure, then order the shim and then put the shim in...or can I just find out what the installed height is from AFR?

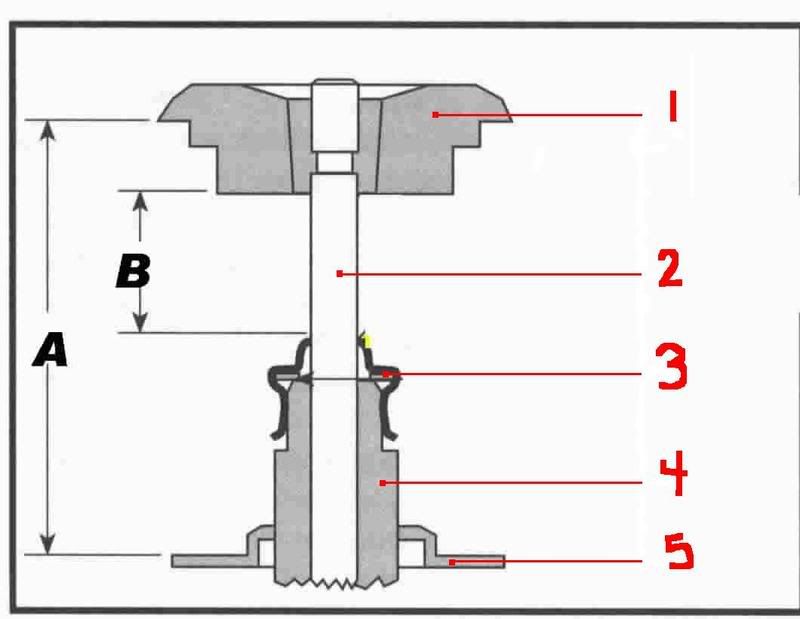

OK so what you're looking at is the valvetrain that you will be dealing with.

1=The retainer

2=The valve stem

3=The valve seal

4=The guide

5=The spring seat/locator

A=Installed height

B=Retainer-seal clearance

Basically what you do is measure the installed height (A) with a micrometer. You do that by placing the mic over the locator (5) and then put the retainer and locks (1) on top. The mic expands vertically until the valve is tight against the seat and the retainer won't go up anymore. Usually it's gonna be around 1.75"-1.85". That number, minus your cam's net lift (lobe lift X rocker ratio) is going to be your open height. That number needs to be at least .050" larger than coilbind. You can measure coilbind or it will give a less accurate number on the box or somewhere in the manufacturer's catalog or website.

If your open height is, lets say .080" from coilbind, you can put a .030" thick shim under the spring seat/locator (5) to decrease the installed height and open height. You have to remove the seal (3) to put a shim under the locator, and usually a seal isn't reusable. But, you will get more spring pressure and getting closer to coilbind helps dampen harmonics.

So, meausure YOUR installed height and coilbind height, then order shim accordingly. Good luck.

Trending Topics

#8

FormerVendor

iTrader: (2)

Join Date: Dec 2001

Location: Baton Rouge, LA, USA

Posts: 1,954

Likes: 0

Received 3 Likes

on

3 Posts

I've worked very closely with Patrick on his builds and what he is recommending is true. I do NOT recommend you trying this without testing each spring first to find that individual springs bind height.

Thanks,

Shane

Thanks,

Shane

#10

TECH Junkie

Thread Starter

iTrader: (21)

Join Date: Aug 2004

Location: Virginia Beach, VA

Posts: 3,164

Likes: 0

Received 0 Likes

on

0 Posts

well, I PM'd Tony and this is what I got:

So, I think I'm going to play it safe and not use the 8017s with a MS4. I might get new springs and use the MS4, or just get a new cam.

KCS, thanks for the awesome info and great pic though!

Originally Posted by Tony Mamo @ AFR

If you run an XER lobe which IMO will work better anyway you could set your 8017 springs at 1.750 seat height for more pressure and and enough seat and open pressure to effectively control a cam in the low .600 range.

That would be my advice if you want to keep and run our 8017's which are very durable springs btw.

Tony

That would be my advice if you want to keep and run our 8017's which are very durable springs btw.

Tony

Originally Posted by 99FormulaM6

Ok, fair enough.. Maybe the MS4 won't be going in after all..

Thanks for the info..

Few other questions..

Can I just put in the springs in place of the stock ones and run them, or do I need new retainers and seats/seals?

What is the safe lift for the 8017s compared to the 8019s?

Chris

Thanks for the info..

Few other questions..

Can I just put in the springs in place of the stock ones and run them, or do I need new retainers and seats/seals?

What is the safe lift for the 8017s compared to the 8019s?

Chris

Originally Posted by Tony Mamo @ AFR

Sell them and buy the RIGHT spring....thats my advice.

You would have better results with the 8019 spring. If yuo try the 8017's in that application I would be curious how they worked but I dont mess around with valve springs to save some money....there are better places to do that.

Tony

You would have better results with the 8019 spring. If yuo try the 8017's in that application I would be curious how they worked but I dont mess around with valve springs to save some money....there are better places to do that.

Tony

Originally Posted by 99FormulaM6

I currently have a set of AFR 8017 valve springs sitting at home, and I am purchasing a MS4 cam. I have been told that I can shim the 8017s within .050 of coil bind and still run them with the cam, which has a lift of .649. Can you tell me what shims I need to purchase (And anything else I would need to be able to use the springs.)? The heads are stock LS1 heads with stock valves and stock length pushrods. And anything else I would need to be able to use the springs. I know 8019s would be a better choice, but I have the 8017s and dont want to waste them.

Thanks,

Chris

Thanks,

Chris

KCS, thanks for the awesome info and great pic though!

#12

TECH Junkie

Thread Starter

iTrader: (21)

Join Date: Aug 2004

Location: Virginia Beach, VA

Posts: 3,164

Likes: 0

Received 0 Likes

on

0 Posts

bringing this back for a quick question...

can the stock retainers be reused with the springs? I have the springs and pushrods, and wanna know if i have to order the retainers too..

can the stock retainers be reused with the springs? I have the springs and pushrods, and wanna know if i have to order the retainers too..

#14

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

so with a comp 918 spring you would have to order new retainers? what about locks? comp has a kit for 250 that has 918s steel retainers and steel locks, seems like a good deal.