This is why you weld the pickup tube...PICS

#1

10 Second Club

Thread Starter

iTrader: (8)

Join Date: Feb 2006

Location: Round Rock, TX

Posts: 981

Likes: 0

Received 0 Likes

on

0 Posts

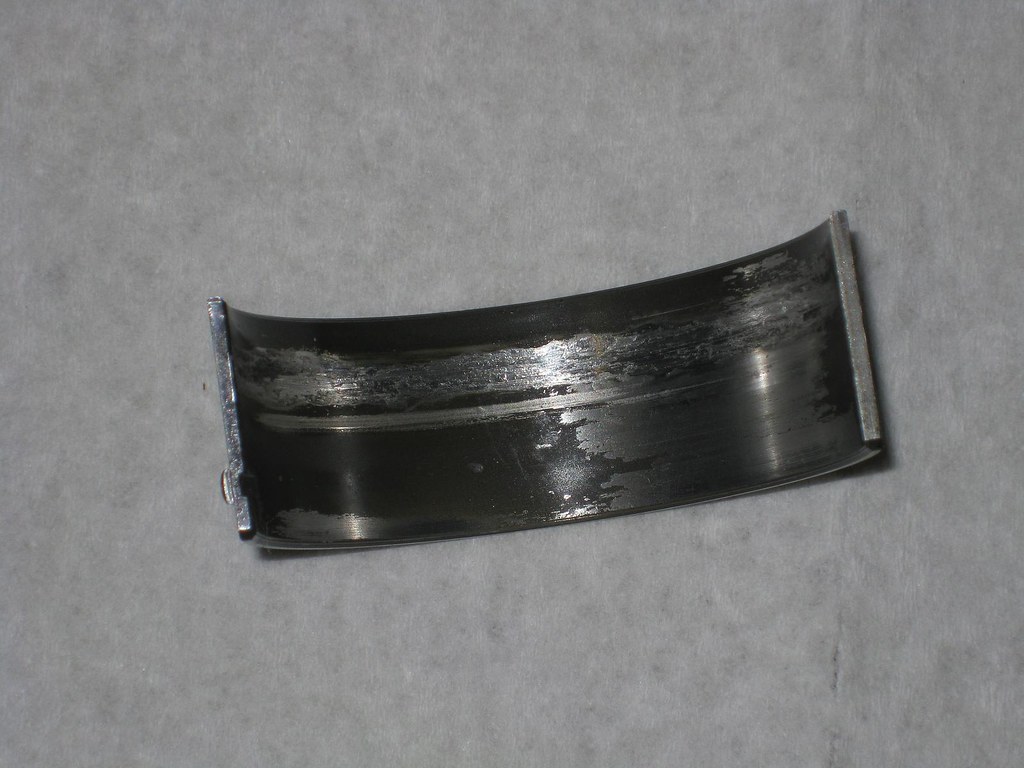

Here's two examples of why the pickup tube should be PROPERLY welded to the oil pump. See below...

1. You may find this in the bottom of your oil pan

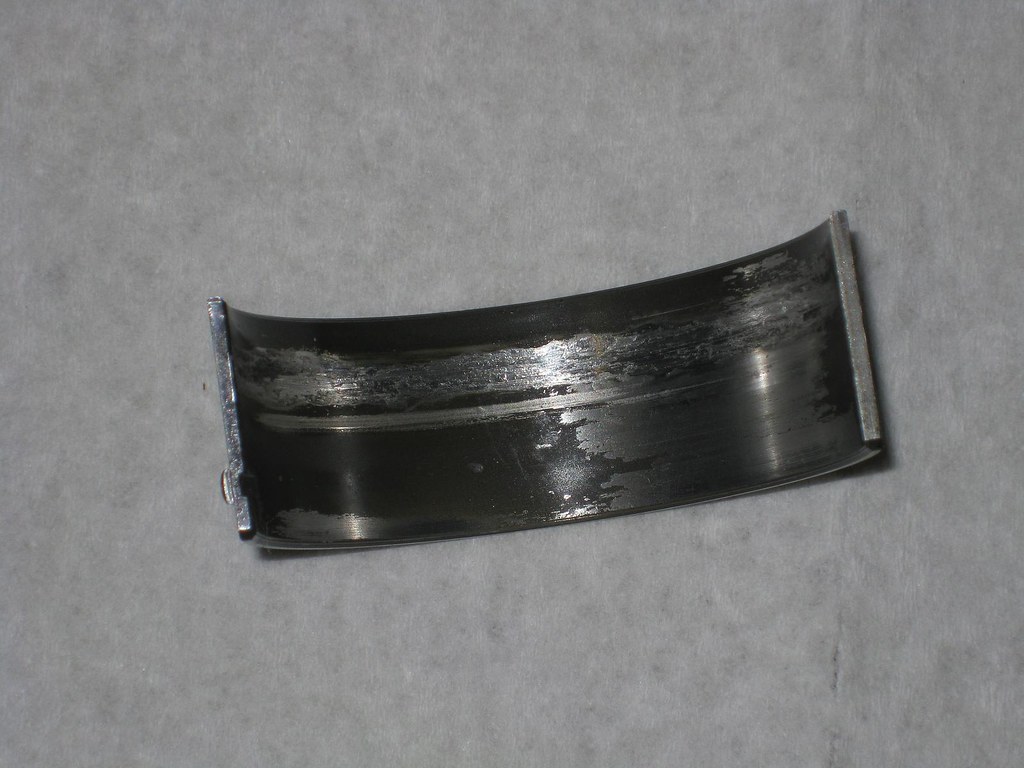

2. You may also find this when you pull a rod cap after finding #1

I'll probably be ok for a few more months then the motor is going to have to come out to put in some fresh bearings. The rod journals on the crank look ok for the ones we pulled and hopefully we won't find anything else.

1. You may find this in the bottom of your oil pan

2. You may also find this when you pull a rod cap after finding #1

I'll probably be ok for a few more months then the motor is going to have to come out to put in some fresh bearings. The rod journals on the crank look ok for the ones we pulled and hopefully we won't find anything else.

#5

10 Second Club

Thread Starter

iTrader: (8)

Join Date: Feb 2006

Location: Round Rock, TX

Posts: 981

Likes: 0

Received 0 Likes

on

0 Posts

I don't think you quite understand what has happened here. The tube was welded improperly and as a result it fell out resulting in the bearing damage. The issue is not a lack of welding...its a lack of proper welding.

Last edited by TX20D; 05-05-2008 at 10:45 AM.

#7

10 Second Club

Thread Starter

iTrader: (8)

Join Date: Feb 2006

Location: Round Rock, TX

Posts: 981

Likes: 0

Received 0 Likes

on

0 Posts

I agree...however, if one chooses to weld it then it should be done correctly. A TIG welder comes to mind here, but unfortunately a much more primitive method was used.

Trending Topics

#11

10 Second Club

iTrader: (8)

DAMN Kyle!!

You should have known Mr Know it all would have some thing to say, Ignore him the rest of us do

BTW I like to weld a Tab to the pick-up and attatch it under one of the cover bolts

Go ahead and change all the bearings now man before you do any more damage

Good luck man!

That one looks like it feel off with the drive shaft

You should have known Mr Know it all would have some thing to say, Ignore him the rest of us do

BTW I like to weld a Tab to the pick-up and attatch it under one of the cover bolts

Go ahead and change all the bearings now man before you do any more damage

Good luck man!

That one looks like it feel off with the drive shaft

#13

TECH Senior Member

iTrader: (3)

Join Date: Oct 2006

Location: Decatur, TN (N-W of Athens)

Posts: 7,564

Likes: 0

Received 3 Likes

on

3 Posts

Yea, we always just tack weld it on opposite sides, or at most 3 tacks. A full weld is not required at all. What happens if you plan to get a deeper oil pan? You'll have to replace the whole friggen pump then, instead of just grinding the welds off and putting in the deeper pickup.

#18

11 Second Club

iTrader: (1)

DAMN Kyle!!

You should have known Mr Know it all would have some thing to say, Ignore him the rest of us do

BTW I like to weld a Tab to the pick-up and attatch it under one of the cover bolts

Go ahead and change all the bearings now man before you do any more damage

Good luck man!

That one looks like it feel off with the drive shaft

You should have known Mr Know it all would have some thing to say, Ignore him the rest of us do

BTW I like to weld a Tab to the pick-up and attatch it under one of the cover bolts

Go ahead and change all the bearings now man before you do any more damage

Good luck man!

That one looks like it feel off with the drive shaft

The welding a tab and using a cover bolt is a much better solutuion than welding.

Sorry about the damage Kyle. I hope its not too bad.

Sorry about the damage Kyle. I hope its not too bad.