All about Flexplates, Converters, Transmissions and Spacers

#1

Moderator

Thread Starter

When installing a different (non-stock) transmission there is often confusion over what flexplate to use and whether a spacer is needed. When swapping an LS engine into a custom Hotrod, there is even more confusion:

A key concept is understanding what is meant by "short crank" versus "long crank". The SBC, BBC and all GM engines before the LS engine had a crank which ended about .740" past the back of the block. This position of the crank with respect to the back of the block is now called "long crank". The LS engine was designed with a shorter crank, it is about .400" shorter than an SBC/BBC crank with respect to the back of the block and is therefore called a "short crank". (The LS crank only extends about .340 past the back of the block.)

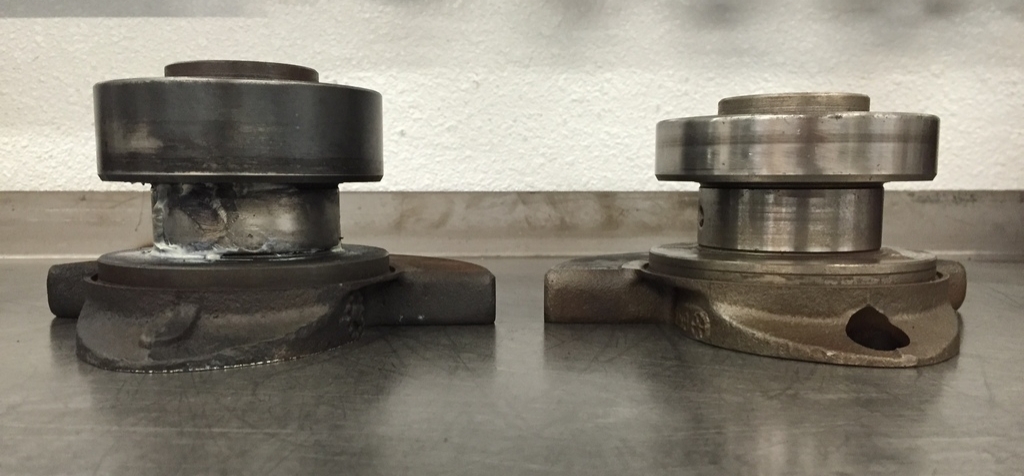

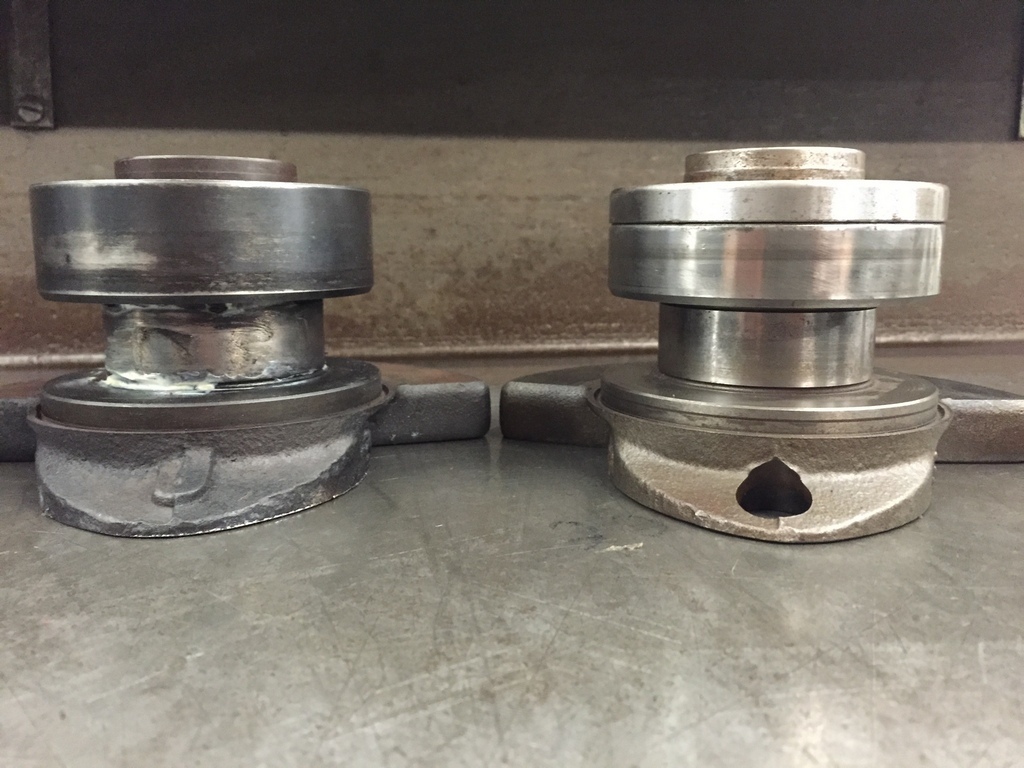

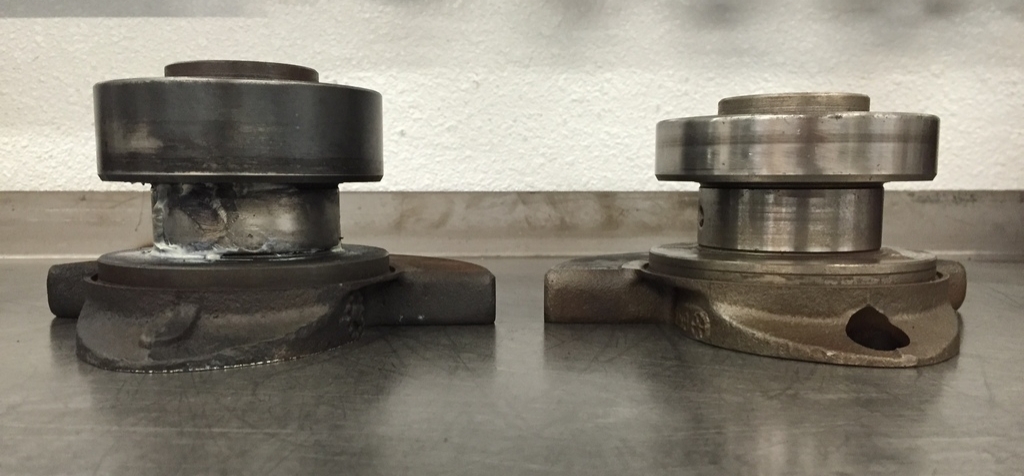

Here is a picture of the short versus the long crank. (Both cranks were cut at about the position of the rear-most connecting rod.) Notice that the cranks have a lip of about .300" depth for mounting the flexplate.

To add a bit of confusion, a few LS engines in '99 and '00 for truck applications were built with a "long crank"; I will detail that later.

Lets start with a stock Gen-4 FBody with an LS1 engine and 4L60E transmission. It has a short crank and a dished flexplate. While the LS crank is short, GM wanted the starter and converter in a "normal" GM position and therefore created a dished flexplate with a 0.575" offset. The LS-style 4L60E transmission has a 300mm input shaft (and a bolt hole in the 12 O'Clock position) and uses an LS-style converter. The 3 converter bolts are on a unique 11.066" diameter pattern, which is different from previous SBC and BBC patterns. The LS converter also has a longer (than SBC/BBC) pilot extending about .600" past the converter pads.

To install a different transmission into your LS1 F-Body, you need to know the bolt pattern and pilot depth of different converters. Here they are:

The pilot for all non-LS converters extends only .250" past the mounting pads (versus about .600 for LS-converters).

Therefore, if you want to install a 4L80E in your LS1 car, you have two problems - the bolt pattern is wrong and the converter's pilot is too short. The solution is to install the GM spacer and a flat flexplate that has the 11.5" bolt pattern. The .405" thick spacer is installed between the crank and the flat flexplate, effectively making the crank act like a "long crank" with the hole for the pilot extended far enough to properly engage a 4L80E converter. The starter will also properly engage.

Here is a picture of the GM spacer part #12563532; you also need 6 longer bolts #19257940.

And when it it bolted to a short crank, the combination is the same length as a long crank.

In other words, to use a flat flexplate you need either a long crank or a short crank with the GM spacer.

Someone on a tight budget might be inclined to try to use the stock dished flexplate, drill new holes for the 11.5" or 10.75 bolt pattern and place the spacer after the flexplate (crank, flexplate, spacer). While this will bolt up properly, care must be taken to ensure that the spacer is properly centered by the lip on the crankshaft. (Details: The lip is .300", the stock flexplate is .150" leaving .150"; now subtract the .040" chamfer on the crank and .040 chamfer on the spacer and only .070" is available to center the spacer. However, sometimes the lip is less and/or the flexplate is thicker.) If the spacer if only positioned by the bolts and not centered on the lip of the crank, this may cause vibration and potential future breakage or problems.

Instead of using a spacer, a pilot extender sleeve can be used with a dished flexplate. It is not ideal; since the extender is relatively loose, there are reports of it causing noise. This is what the sleeve looks like:

As mentioned, some '99 and '00 LS1 truck engines came with long cranks, a flat flexplate and a 4L80E transmission without a spacer. It appears that most (all?) LQ4 6.0l Vortec truck engine have the long crank; there are reports that some 4.8l Vortec engines also have the long crank. Obviously these long crank engines will bolt up easily to a non-LS transmission, but they cannot be used with an LS-style 4L60E unless a custom converter with a shorter pilot is purchased.

For those of you calculating the offset numbers, the OEM flat flexplate is .175" thick, plus the .405" spacer gives a total offset of .580". This compares with the OEM dished flexplate which is .150" thick and has a dish of .425" for a total offset of .575.

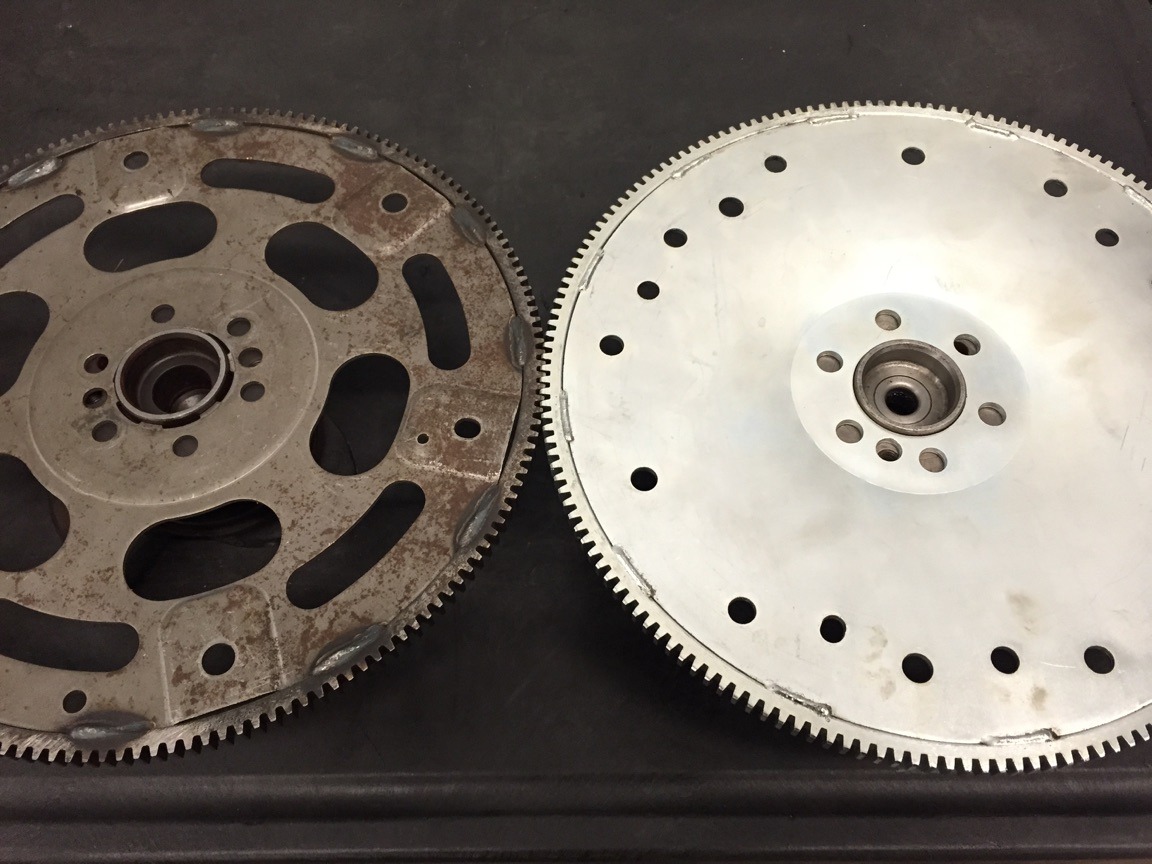

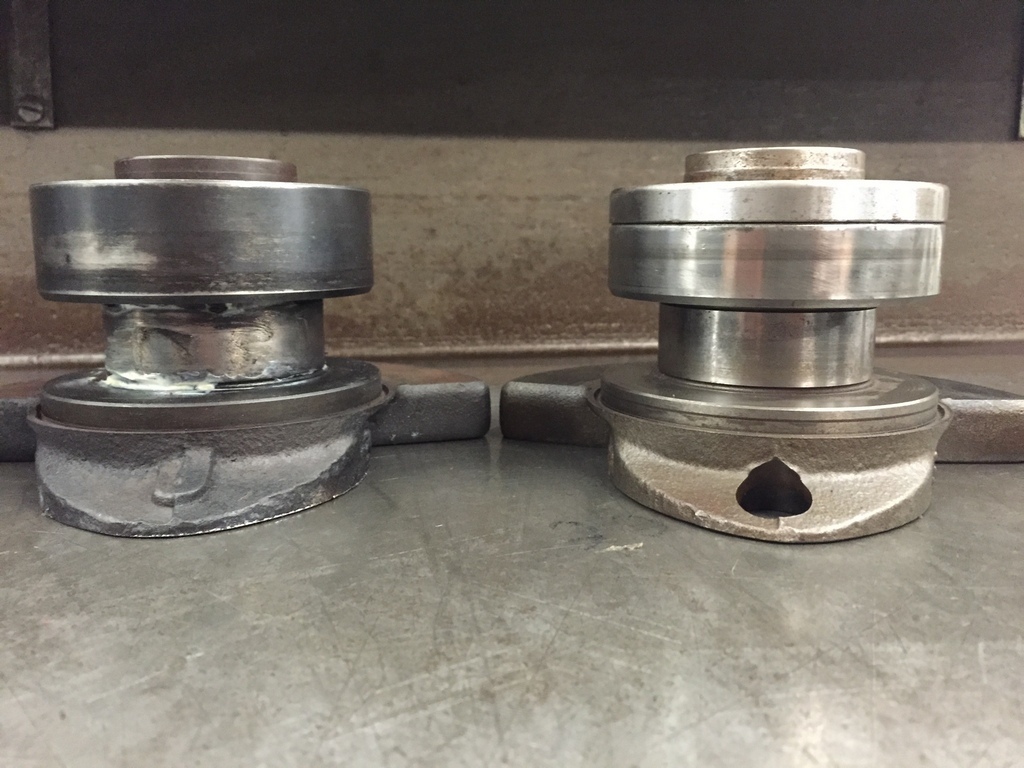

In the following picture a stock flat flexplate is on the left and a multi pattern dished flexplate is on the right:

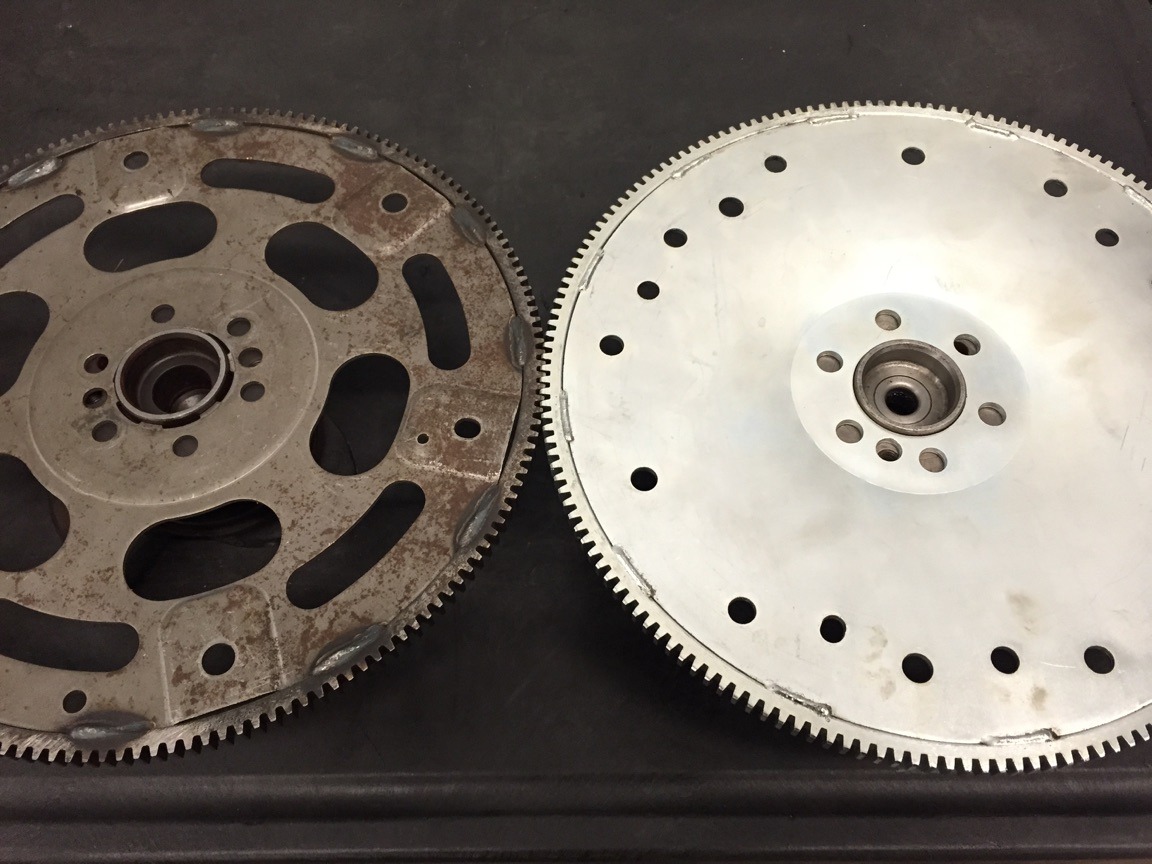

The following picture shows the flat flexplate sitting on a long crank (left), and the dished flexplate sitting on a short crank (right). Notice that the total offset of each combo is the same:

A popular LS flexplate upgrade is the TCI #399753 which has a dual pattern to support both 10.75" and 11.066" diameter converters. While it appears flat, its thick design and and thick mounting pads for both the crank and the converter mimic the stock dished flexplate with its .575" offset. Due to its thick design it should not be used with the GM spacer because there is no crank lip left on which to properly center the spacer.

Similarly, the TCI flexplate #399754 is identical to the 753 except it is drilled with the 11.5" 6-hole pattern to support 4L80E converters. It is very thick and has the same .575" offset. To mount a 4L80E converter Chris recommends not using the GM spacer with it (no lip left to center it) and instead using a pilot extender sleeve.

Last, remember that a custom converter company like CircleD can build e.g. a 4L80E or TH400 converter with a longer pilot so that a spacer or pilot extender sleeve is not needed. Generally there is little or no additional charge for this.

- long versus short cranks

- dished versus flat flexplates

- whether the desired transmission needs a spacer or a pilot extender sleeve.

A key concept is understanding what is meant by "short crank" versus "long crank". The SBC, BBC and all GM engines before the LS engine had a crank which ended about .740" past the back of the block. This position of the crank with respect to the back of the block is now called "long crank". The LS engine was designed with a shorter crank, it is about .400" shorter than an SBC/BBC crank with respect to the back of the block and is therefore called a "short crank". (The LS crank only extends about .340 past the back of the block.)

Here is a picture of the short versus the long crank. (Both cranks were cut at about the position of the rear-most connecting rod.) Notice that the cranks have a lip of about .300" depth for mounting the flexplate.

To add a bit of confusion, a few LS engines in '99 and '00 for truck applications were built with a "long crank"; I will detail that later.

Lets start with a stock Gen-4 FBody with an LS1 engine and 4L60E transmission. It has a short crank and a dished flexplate. While the LS crank is short, GM wanted the starter and converter in a "normal" GM position and therefore created a dished flexplate with a 0.575" offset. The LS-style 4L60E transmission has a 300mm input shaft (and a bolt hole in the 12 O'Clock position) and uses an LS-style converter. The 3 converter bolts are on a unique 11.066" diameter pattern, which is different from previous SBC and BBC patterns. The LS converter also has a longer (than SBC/BBC) pilot extending about .600" past the converter pads.

To install a different transmission into your LS1 F-Body, you need to know the bolt pattern and pilot depth of different converters. Here they are:

- TH400 and 4L80E have a 11.5" diameter bolt pattern, sometimes called the "big" pattern.

- TH350, 700R4 and LT-style 4L60E have a 10.75" diameter bolt pattern.

- LS-style 4L60E have a 11.066" diameter bolt pattern.

The pilot for all non-LS converters extends only .250" past the mounting pads (versus about .600 for LS-converters).

Therefore, if you want to install a 4L80E in your LS1 car, you have two problems - the bolt pattern is wrong and the converter's pilot is too short. The solution is to install the GM spacer and a flat flexplate that has the 11.5" bolt pattern. The .405" thick spacer is installed between the crank and the flat flexplate, effectively making the crank act like a "long crank" with the hole for the pilot extended far enough to properly engage a 4L80E converter. The starter will also properly engage.

Here is a picture of the GM spacer part #12563532; you also need 6 longer bolts #19257940.

And when it it bolted to a short crank, the combination is the same length as a long crank.

In other words, to use a flat flexplate you need either a long crank or a short crank with the GM spacer.

Someone on a tight budget might be inclined to try to use the stock dished flexplate, drill new holes for the 11.5" or 10.75 bolt pattern and place the spacer after the flexplate (crank, flexplate, spacer). While this will bolt up properly, care must be taken to ensure that the spacer is properly centered by the lip on the crankshaft. (Details: The lip is .300", the stock flexplate is .150" leaving .150"; now subtract the .040" chamfer on the crank and .040 chamfer on the spacer and only .070" is available to center the spacer. However, sometimes the lip is less and/or the flexplate is thicker.) If the spacer if only positioned by the bolts and not centered on the lip of the crank, this may cause vibration and potential future breakage or problems.

Instead of using a spacer, a pilot extender sleeve can be used with a dished flexplate. It is not ideal; since the extender is relatively loose, there are reports of it causing noise. This is what the sleeve looks like:

As mentioned, some '99 and '00 LS1 truck engines came with long cranks, a flat flexplate and a 4L80E transmission without a spacer. It appears that most (all?) LQ4 6.0l Vortec truck engine have the long crank; there are reports that some 4.8l Vortec engines also have the long crank. Obviously these long crank engines will bolt up easily to a non-LS transmission, but they cannot be used with an LS-style 4L60E unless a custom converter with a shorter pilot is purchased.

For those of you calculating the offset numbers, the OEM flat flexplate is .175" thick, plus the .405" spacer gives a total offset of .580". This compares with the OEM dished flexplate which is .150" thick and has a dish of .425" for a total offset of .575.

In the following picture a stock flat flexplate is on the left and a multi pattern dished flexplate is on the right:

The following picture shows the flat flexplate sitting on a long crank (left), and the dished flexplate sitting on a short crank (right). Notice that the total offset of each combo is the same:

A popular LS flexplate upgrade is the TCI #399753 which has a dual pattern to support both 10.75" and 11.066" diameter converters. While it appears flat, its thick design and and thick mounting pads for both the crank and the converter mimic the stock dished flexplate with its .575" offset. Due to its thick design it should not be used with the GM spacer because there is no crank lip left on which to properly center the spacer.

Similarly, the TCI flexplate #399754 is identical to the 753 except it is drilled with the 11.5" 6-hole pattern to support 4L80E converters. It is very thick and has the same .575" offset. To mount a 4L80E converter Chris recommends not using the GM spacer with it (no lip left to center it) and instead using a pilot extender sleeve.

Last, remember that a custom converter company like CircleD can build e.g. a 4L80E or TH400 converter with a longer pilot so that a spacer or pilot extender sleeve is not needed. Generally there is little or no additional charge for this.

Last edited by mrvedit; 04-02-2015 at 10:45 PM. Reason: More pictures

The following 7 users liked this post by mrvedit:

98maro13 (10-18-2019), cturboaddict (08-24-2021), Homer_Simpson (08-05-2023), Jimbo1367 (02-12-2023), MYALIMONY (08-05-2022), and 2 others liked this post.

The following users liked this post:

Jimbo1367 (02-12-2023)

#3

Moderator

Thread Starter

The flexplate pictures above are of Circle D's "LS Multi pattern" dished flexplate which is both a nice upgrade from the stock flexplate and will bolt any short crank LSx to many GM converters. (You may need the pilot extender sleeve for some combinations.)

In more detail, it has:

6 Bolt holes for 4L80E and TH400 converters (11.5" pattern)

6 Bolt holes for 4L60E LS-style and 6L80E converters (11.066" pattern)

3 Bolt holes for 4L60E LT-style, 700R4, TH350 converters (10.75 pattern)

Hopefully my posts in this thread are reducing confusion and not increasing it.

In more detail, it has:

6 Bolt holes for 4L80E and TH400 converters (11.5" pattern)

6 Bolt holes for 4L60E LS-style and 6L80E converters (11.066" pattern)

3 Bolt holes for 4L60E LT-style, 700R4, TH350 converters (10.75 pattern)

Hopefully my posts in this thread are reducing confusion and not increasing it.

The following users liked this post:

Missjessie39 (07-12-2022)

The following 3 users liked this post by 01ssreda4:

#7

On The Tree

iTrader: (1)

I'm getting on this a little late. I just picked up an LQ9 which has the flat flex plate and will be mated to my 700R4. According to what I just read, I simply need to get TCI flexplate #399754 and that's it? No spacer or longer bolts required?

Last edited by Ozz1967; 08-21-2016 at 07:54 PM. Reason: Removed the excessively long "quote".

Trending Topics

#8

If you have the flat flex plate, you most likely have an LQ4, as the LQ9 came with 4l6x style dished flex plates. Assuming your motor is 2001+, you can remove the flat flex plate and the spacer behind it and run the 399753. It will come with it's own crank bolts as well as the necessary pilot extender to properly engage the crankshaft.

-Brian

-Brian

#9

On The Tree

iTrader: (1)

just found this thread i'm doing th4oo swap to my ls3 11.5 bolt pattern converter 3-4000 rpm stall

i have purchased the tci 399754 flexplate and couldn't figure it out with the sleeve spacer etc. (lost or threw out my instructions haha)

(2010 camaro ss 6.2 L LS3)

ok i found my issue.....well one of em haha so my engine was a manual trans prior to my swap and it had the pilot bearing installed preventing me from figuring out the spacer bushing piece with the 399754 TCI flywheel simple mistake haha and for the th350 trans i used the first time i simply bought a 6.0L flywheel and gm adaptor piece/bolts from the junkyard and ovaled out 3 torque converter holes so it would bolt up and she worked fine. the 6.0 L engine must have a 4l80 trans behind it for it to be the right flywheel for this. i was told but after reading this thread there may be more to it than that !!!

so i now have the new flywheel bolted up (399754) the flywheel simply bolts up as normal the torque converter centering ring/bushing/sleeve slides into the end of the crank freely before or after bolting up flywheel (did not have to hammer it into seat) and the torque converter snout fits snugly into that.

the trans and stall torque converter to flywheel/ block are going to mate up perfectly (measured) but when i tested the converter alone to see how far the snout penetrated the bushing it was not fully seated into it thus leaving approx 1/8" or more space where the bushing could walk outwards onto the TC. snout and that creates a situation where it wouldn't be penetrated into the crank enough anymore to keep the TC. perfectly centered.. and would most definetly vibrate/ be noisy or cause failure not good.

now even if the snout was longer on my converter there would still be that space of 1/8 " or so for the sleeve extender to walk out onto snout causing issues. or maybe not if it bottoms out on the centering sleeve inside lip..?? unless of course it was long enough to penetrate the crank itself but i already have the converter and paid cash so....

(need longer centering sleeve???? is there one???)

i think if i had a ring spacer to put on the converter snout prior to installing it to close this 1/8" or more gap it would work great or weld it to the TC. or weld it to the centering Bushing/sleeve (would be better less movable parts) just when i thought i had her figured out hmmmmm

if no spacer rings existed i thought of purchasing another sleeve bushing and simply cutting off the amount i need to make up and close that gap...

part numbers for spacer rings?? or i guess snout extender weld on rings??

what ya think? any extra info appreciated thx.

FIGURED IT OUT

got the centering bushing knearled to make it snuggly fit as to have no movement during operation and the 1/8 inch ish gap (between converter and bushing) is necessary as the converter gets hot and expands and contracts during use so im good here!!! only thing now is to test the starter gear engagement and make sure it is sufficient

i have purchased the tci 399754 flexplate and couldn't figure it out with the sleeve spacer etc. (lost or threw out my instructions haha)

(2010 camaro ss 6.2 L LS3)

ok i found my issue.....well one of em haha so my engine was a manual trans prior to my swap and it had the pilot bearing installed preventing me from figuring out the spacer bushing piece with the 399754 TCI flywheel simple mistake haha and for the th350 trans i used the first time i simply bought a 6.0L flywheel and gm adaptor piece/bolts from the junkyard and ovaled out 3 torque converter holes so it would bolt up and she worked fine. the 6.0 L engine must have a 4l80 trans behind it for it to be the right flywheel for this. i was told but after reading this thread there may be more to it than that !!!

so i now have the new flywheel bolted up (399754) the flywheel simply bolts up as normal the torque converter centering ring/bushing/sleeve slides into the end of the crank freely before or after bolting up flywheel (did not have to hammer it into seat) and the torque converter snout fits snugly into that.

the trans and stall torque converter to flywheel/ block are going to mate up perfectly (measured) but when i tested the converter alone to see how far the snout penetrated the bushing it was not fully seated into it thus leaving approx 1/8" or more space where the bushing could walk outwards onto the TC. snout and that creates a situation where it wouldn't be penetrated into the crank enough anymore to keep the TC. perfectly centered.. and would most definetly vibrate/ be noisy or cause failure not good.

now even if the snout was longer on my converter there would still be that space of 1/8 " or so for the sleeve extender to walk out onto snout causing issues. or maybe not if it bottoms out on the centering sleeve inside lip..?? unless of course it was long enough to penetrate the crank itself but i already have the converter and paid cash so....

(need longer centering sleeve???? is there one???)

i think if i had a ring spacer to put on the converter snout prior to installing it to close this 1/8" or more gap it would work great or weld it to the TC. or weld it to the centering Bushing/sleeve (would be better less movable parts) just when i thought i had her figured out hmmmmm

if no spacer rings existed i thought of purchasing another sleeve bushing and simply cutting off the amount i need to make up and close that gap...

part numbers for spacer rings?? or i guess snout extender weld on rings??

what ya think? any extra info appreciated thx.

FIGURED IT OUT

got the centering bushing knearled to make it snuggly fit as to have no movement during operation and the 1/8 inch ish gap (between converter and bushing) is necessary as the converter gets hot and expands and contracts during use so im good here!!! only thing now is to test the starter gear engagement and make sure it is sufficient

Last edited by G-BODY-JAMES; 12-18-2016 at 05:00 PM.

#11

I know TCI 399753 would work for you. I believe they also have a newer option that would be the 399853, but don't hold me to that one. I don't have any personal experience with it yet.

-Brian

-Brian

#14

No spacer necessary. It comes with a pilot extender that you will NOT use. This flex plate uses thick washers to replicate the "dished" shape, you you will need the appropriate longer converter bolts. Probably 20mm under head length for your yank converter, but always check for proper thread engagement. It actually comes with new crank bolts too, so you're covered there.

-Brian

-Brian

#15

On The Tree

iTrader: (1)

on my th400 I will be using the centering bushing provided being that my converter wasn't fabricated with a long snout to mate directly to the crank pilot hole

note!!!! The bushing TCI provided would slide in and out of pilot hole by hand, you do not want this as it will walk back and forth causing vibrations, noise other problems I had the end of the bushing that inserts into the crank pilot hole Knearled so that it will press into crank per say and used sleeve retainer thus not allowing any movement of the bushing

the knearl process gave me about 3-5 thousandths

tapped into crank using piece of wood BAM!!!

my 2 cents

#17

On The Tree

iTrader: (1)

1994 converter won't fit a 2000 4L60e. In 98 they changed bolt patterns when the LS1 came out . 97 and older converter would fit a 700R4 as well. And yes, it would need a spacer either way but 97 and older also needs flex plate with different bolt holes or elongating a factory bolt hole.

#18

#19

Ok, so what about going the other way? I am building my 6.0 now but I have a 4l60e and stand alone driver to go behind my 99 carbed sbc in the meantime. I have been told to use this adapter kit from GM and some say its not needed. It would make sense to space the trans back instead correct?

gm #19154766

gm #19154766

#20

On The Tree

iTrader: (1)

Ok, so what about going the other way? I am building my 6.0 now but I have a 4l60e and stand alone driver to go behind my 99 carbed sbc in the meantime. I have been told to use this adapter kit from GM and some say its not needed. It would make sense to space the trans back instead correct?

gm #19154766

gm #19154766

SORRY, but unless I am misunderstanding the statement, that is the OPPOSITE of what is true.

See my next post.

Last edited by mrvedit; 01-07-2017 at 11:06 AM.