PHB Confusion

#1

12 Second Club

Thread Starter

Join Date: Sep 2010

Location: Annapolis, MD

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Maybe you guys can help me figure this out or set me straight about this. PHB's come with several linkage options:poly,rubber,rods ends, delsphere, rotojoint etc. To my knowledge a PHB with poly/rubber bushings only allows the PHB to rotate on a single axis(up and down). This creates a binding effect when taking hard corners. So rod ends/roto joints allows the PHB to rotate on multiple axes(up-down, forward-background, twisting) to eliminate this bind. So why do companies manufacture PHB's (and other suspension parts) with a single axis joint (bushing) at one end, and a multiple axis joint at the other end? It seems to me that the lone multiple axis joint is useless because the system is still limited by the range of motion of the bushing. Someone help me out here...

#2

TECH Senior Member

Maybe you guys can help me figure this out or set me straight about this. PHB's come with several linkage options:poly,rubber,rods ends, delsphere, rotojoint etc. To my knowledge a PHB with poly/rubber bushings only allows the PHB to rotate on a single axis(up and down). This creates a binding effect when taking hard corners. So rod ends/roto joints allows the PHB to rotate on multiple axes(up-down, forward-background, twisting) to eliminate this bind. So why do companies manufacture PHB's (and other suspension parts) with a single axis joint (bushing) at one end, and a multiple axis joint at the other end? It seems to me that the lone multiple axis joint is useless because the system is still limited by the range of motion of the bushing. Someone help me out here...

Companies offer different choices because the rod ended joints are known to become noisy and harsh over time. The rotojoiint is supposed to be stiffer than the poly, but not noisy or harsh like the rod ended. And the poly is supposed to be the softest (other than stock) least noisy and harsh.

#4

What do you use the car for? If just driving on the road and occasional 1/4 passes, get a set of these

These have Poly bushings for the chasis mount, are stiffer than rubber however are very quiet, however the rotojoint end will allow the axle to move freely. I would recommend the rotojoint over a rod end as they're not as noisy on the road. I have poly/rod on my car and i wish I had gone with roto/roto to reduce noise a little.

Personally, I suggest roto/roto for all applications, and if you're a DD only..then just deal with the noise...haha

These have Poly bushings for the chasis mount, are stiffer than rubber however are very quiet, however the rotojoint end will allow the axle to move freely. I would recommend the rotojoint over a rod end as they're not as noisy on the road. I have poly/rod on my car and i wish I had gone with roto/roto to reduce noise a little.

Personally, I suggest roto/roto for all applications, and if you're a DD only..then just deal with the noise...haha

#5

TECH Senior Member

iTrader: (35)

Someone please correct me if Im wrong but I don't think the poly/poly PHB will cause binding because the alxe shouldn't be moving like you say (the LCA's and torque arm should be keeping it from either twisting or moving forward/backwards) while the PHB is used to keep it moving side to side.

Companies offer different choices because the rod ended joints are known to become noisy and harsh over time. The rotojoiint is supposed to be stiffer than the poly, but not noisy or harsh like the rod ended. And the poly is supposed to be the softest (other than stock) least noisy and harsh.

Companies offer different choices because the rod ended joints are known to become noisy and harsh over time. The rotojoiint is supposed to be stiffer than the poly, but not noisy or harsh like the rod ended. And the poly is supposed to be the softest (other than stock) least noisy and harsh.

#6

12 Second Club

Thread Starter

Join Date: Sep 2010

Location: Annapolis, MD

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

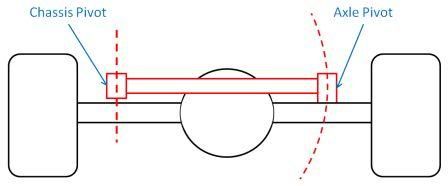

OK I understand that. This range of motion is regardless of whether the pivot point have bushing or rods ends. But this is what I'm confused about:

Looking down at the setup, assume the chassis pivot has a plain old bushing, that the axle pivot has a rod end or delsphere, and that the axle is free to move up and down in the picture. The chassis pivot can rotate only around the axis shown. But the axle pivot could theoretically rotate around the axis shown at its end. The axle pivot cannot follow that path unless the chassis pivot can rotate in place (which it also cannot do because its fixed).

The only instance I can this of where a setup like this is helpful is if

1. The axle itself was pivoting at the axle pivot point and the PHB was not rotating or

2. The axle is rotating about its own axis.

I'm assuming this is what LCA's are for so those would never happen.

So this is where I need help. My conclusion is that a PHB is limited by its weakest link. A rod end is useless if the other end is a bushing because the PHB can only move so far as the bushing's tolerances.

I feel like I'm making a big deal out of something that isn't so complicated. Feel free to let me know if I am.

#7

TECH Fanatic

iTrader: (5)

So this is where I need help. My conclusion is that a PHB is limited by its weakest link. A rod end is useless if the other end is a bushing because the PHB can only move so far as the bushing's tolerances.

I feel like I'm making a big deal out of something that isn't so complicated. Feel free to let me know if I am.

I feel like I'm making a big deal out of something that isn't so complicated. Feel free to let me know if I am.

I wouldn't worry so much about axis rotation, as you're not going to see a lot of that in a panhard rod (LCAs are a different story). Semi-orbital movement without bind is always a good thing, but it has NVH trade-offs that some people don't like.

I have a rather black-and-white view on it (as much as my thoughts mean around here) - if you want the best handling, go rod/rod. Yeah, you'll have a little more NVH, but not a whole lot until the rods are shouting to be replaced, and you don't need to worry about binding up. If you want less bind than stock with very minimal NVH increase, go poly/poly. You'll still get bind at some point, but they'll (typically) do better than stock and don't have the end-life NVH transmissibility rod-ends do. Poly/rod combos, to me, simply seem to give you the downsides of both - end-life noise with rod-ends, and limited articulation without bind with poly (which negates the lack of bind on the rod-end side).

Trending Topics

#11

TECH Senior Member

iTrader: (14)

Someone please correct me if Im wrong but I don't think the poly/poly PHB will cause binding because the alxe shouldn't be moving like you say (the LCA's and torque arm should be keeping it from either twisting or moving forward/backwards) while the PHB is used to keep it moving side to side.

Companies offer different choices because the rod ended joints are known to become noisy and harsh over time. The rotojoiint is supposed to be stiffer than the poly, but not noisy or harsh like the rod ended. And the poly is supposed to be the softest (other than stock) least noisy and harsh.

Companies offer different choices because the rod ended joints are known to become noisy and harsh over time. The rotojoiint is supposed to be stiffer than the poly, but not noisy or harsh like the rod ended. And the poly is supposed to be the softest (other than stock) least noisy and harsh.

Also if both sides of the suspension move up and down equally and the LCAs are precisely aligned and perfectly level, with the amount of travel being the same during compression and droop. Perfect world.

Real world? It's never perfect.

As the body rolls during a turn, suspension compression on one side and droop on the other sees the wheel base change from side to side.

This will slightly twist the PHB and cause torsional bind. Add the frictional bind and it adds up.

Most of the noise generated with rod ends is not necessarily the bearing loose in the housing, rather the housing racking back and forth and hitting the car mount.

Don't get me wrong ... general road noise will increase. But the banging many complain about is the housing.

#12

12 Second Club

Thread Starter

Join Date: Sep 2010

Location: Annapolis, MD

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the info everyone. I was looking to buy a poly/roto PHB and then actually thought about it. I'll be purchasing a double rod end or roto for sure.

#13

It seems to me like, when the rear suspension goes up and down, whole rear axle will rotate with the front torque arm being the center of rotation. It will force the panhard rod to "twist" if the panhard rod had solid busing. With the length of the torque arm, it probably is not a "problem" with poly busing in the real world.

I actually have UMI poly-poly on-car adjustable panhard rod, and only time I felt it bind was during the installation. I only had the car for six months, and once I start to autocross the car, I may want to try different configuration.

I actually have UMI poly-poly on-car adjustable panhard rod, and only time I felt it bind was during the installation. I only had the car for six months, and once I start to autocross the car, I may want to try different configuration.

#14

TECH Fanatic

iTrader: (2)

You have to remember that having a poly bushing isn't necessarily going to mean it's held at one point and cannot/will not move or rotate, just that it will resist it more than having a spherical type of bushing. Poly bushings are not ROCK SOLID, if the suspension moves a certain way, they should give to a certain point to allow it to have at least minimal articulation.

The bushing connected to the rear of the PHB is more important in allowing the rear to rotate and rock fore/aft than the one connected on the body side. Consider going over a bumpy road, the axle may be rotating clockwise/counterclockwise depending on which tire is moving up/down, and the bushing connected to the rear has to allow for this more than the bushing connected to the body. In the case of taking a turn, when the body side has to allow for some rotation, the actual number of degrees the body side bushing has to rotate is a very small number, maybe a few degrees? In the case of having your LCA's swing up and down, causing a small fore/aft movement, the bushing connected to the rear end matters more in this case also, allowing it to swivel fore/aft without necessarily disturbing the body side end. In cases where the body side end would have to allow for some fore/aft moment, the actual amount of movement on that end would be quite small. If there is any binding or hindrance to suspension articulation, I can't imagine it being very noticeable. Basically, I see the need for the rear end bushing to articulate is much greater than the need for the body side to articulate. A PHB is quite long, and any rotation on the rear side doesn't really create a huge angle that requires the body side to move a great deal. Also, being the PHB is quite long, any force put on the rear side of the bar would result in a moment on the body side that would result in at least some movement.

This being said, I wish I would have gotten a roto/roto PHB, but having looked at drawings on how they move during certain scenarios, I don't think having a poly bushing on the body side makes nearly as big of a difference as having a poly bushing on the rear side. In the case of LCA's, I think it would be more necessary to have the body side rotate also, as the actual arm of the LCA's is much shorter than the PHB, requiring a greater angle of articulation.

If my way of thinking about this is wrong, please correct me!!!!

The bushing connected to the rear of the PHB is more important in allowing the rear to rotate and rock fore/aft than the one connected on the body side. Consider going over a bumpy road, the axle may be rotating clockwise/counterclockwise depending on which tire is moving up/down, and the bushing connected to the rear has to allow for this more than the bushing connected to the body. In the case of taking a turn, when the body side has to allow for some rotation, the actual number of degrees the body side bushing has to rotate is a very small number, maybe a few degrees? In the case of having your LCA's swing up and down, causing a small fore/aft movement, the bushing connected to the rear end matters more in this case also, allowing it to swivel fore/aft without necessarily disturbing the body side end. In cases where the body side end would have to allow for some fore/aft moment, the actual amount of movement on that end would be quite small. If there is any binding or hindrance to suspension articulation, I can't imagine it being very noticeable. Basically, I see the need for the rear end bushing to articulate is much greater than the need for the body side to articulate. A PHB is quite long, and any rotation on the rear side doesn't really create a huge angle that requires the body side to move a great deal. Also, being the PHB is quite long, any force put on the rear side of the bar would result in a moment on the body side that would result in at least some movement.

This being said, I wish I would have gotten a roto/roto PHB, but having looked at drawings on how they move during certain scenarios, I don't think having a poly bushing on the body side makes nearly as big of a difference as having a poly bushing on the rear side. In the case of LCA's, I think it would be more necessary to have the body side rotate also, as the actual arm of the LCA's is much shorter than the PHB, requiring a greater angle of articulation.

If my way of thinking about this is wrong, please correct me!!!!

#15

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

I think OP is really over thinking this. The suspension design is not the best to begin with. Worrying about trivial little details is quite silly IMO. Because, the main flaw is still there.

#17

UNDER PRESSURE MOD

iTrader: (19)

I had a poly/poly panhard bar and it gave me headaches because the joints were most definitely binding, to the point that it was causing the rear to be jittery and bounce around corners or bumps. Upon investigating, the poly had 'frozen' inside the housing, causing it to bind. Unbolting one end, you could pull the panhard bar and it would snap back like it was a spring.

#18

LS1TECH Sponsor

iTrader: (41)

Poly is never the ideal bushing material in anything that has to move. It's used because it's inexpensive and pretty stiff. What you never hear is that it's sticky, and when used in things that have to move, causes the movement of said part to be compromised in some way. There are places it's better to use vs. others..... A PHB is one of the better places to use it, but they aren't ideal there either.

In theory the axle is only moving up and down and a lubed bushing should rotate pretty freely. But it's not theory... and there are things happening. As the body rolls vs. the axle, or the axle moves vs. the body however you want to view it the control arms swing in arcs which turn the axle relative to the body. That in turn puts a little twist on the PHB bushings and causes some stickiness in the movement of the body vs. the axle. Also urethane isn't indestructable, it can and will cold-flow and wear out given enough time.

See The Alchemist's post just above about how his bar was effecting the ride. And if your PHB for some reason runs a little forward or backward from the body mount to the axle mount (say you have an aftermarket axle, or you use adjustable LCA's and they have shifted the axle a bit) when viewed from directly underneath, that's another source of bind.

If you use a PHB with one rotating end, that helps a lot as you've cut any chance of bind more than in half as the rotating end allows rotational movement the bushings don't really give you.. you might be relying on one end to do the job, but one is way better than none. And of course a Roto-joint or rod-end have less lateral deflection in them than a urethane bushing does too.

In theory the axle is only moving up and down and a lubed bushing should rotate pretty freely. But it's not theory... and there are things happening. As the body rolls vs. the axle, or the axle moves vs. the body however you want to view it the control arms swing in arcs which turn the axle relative to the body. That in turn puts a little twist on the PHB bushings and causes some stickiness in the movement of the body vs. the axle. Also urethane isn't indestructable, it can and will cold-flow and wear out given enough time.

See The Alchemist's post just above about how his bar was effecting the ride. And if your PHB for some reason runs a little forward or backward from the body mount to the axle mount (say you have an aftermarket axle, or you use adjustable LCA's and they have shifted the axle a bit) when viewed from directly underneath, that's another source of bind.

If you use a PHB with one rotating end, that helps a lot as you've cut any chance of bind more than in half as the rotating end allows rotational movement the bushings don't really give you.. you might be relying on one end to do the job, but one is way better than none. And of course a Roto-joint or rod-end have less lateral deflection in them than a urethane bushing does too.

__________________

www.stranoparts.com --814-849-3450

18 SCCA National Championships in house, many more for our customers prove we know our stuff.Talk is cheap, results matter.

Check out our KONI prices, our Master Cylinder Brace, and new Xtracker Hub/wheel bearing upgrade kits!

www.stranoparts.com --814-849-3450

18 SCCA National Championships in house, many more for our customers prove we know our stuff.Talk is cheap, results matter.

Check out our KONI prices, our Master Cylinder Brace, and new Xtracker Hub/wheel bearing upgrade kits!

#19

TECH Fanatic

iTrader: (5)

If you use a PHB with one rotating end, that helps a lot as you've cut any chance of bind more than in half as the rotating end allows rotational movement the bushings don't really give you.. you might be relying on one end to do the job, but one is way better than none. And of course a Roto-joint or rod-end have less lateral deflection in them than a urethane bushing does too.

By design, you can't leave the bushing loose side-to-side, or you'll have play, but when you tighten the mounts/tabs up to apply pressure against the bushing to prevent lateral play, you limit how easily the suspension part can pivot about the bushing itself. I'm sure you could play with torque values with a torque wrench and feeler gauges, but without a lot of time spent figuring out what's too tight and what's too loose, poly doesn't seem like that much better of an alternative than rubber in certain places.

#20

LS1TECH Sponsor

iTrader: (41)

But that still doesn't solve the issue of bushing friction between the mounting tab surface and the bushing side face, though. I had an issue similar to what Alchemist had, although mine were LCAs - after unbolting the axle side, I literally couldn't move the LCA up and down at all (rod-end axle side, poly body side) because the poly bushing had frozen to the body mount and required a LOT of force to allow them to pivot. That was with recently greased bushings, also.

Best you can do it not overtighten them, use a good lubricant that's not water soluble on the bushing face and deal with the rest if you aren't going to use something that has full and free range of motion at both ends.

Best you can do it not overtighten them, use a good lubricant that's not water soluble on the bushing face and deal with the rest if you aren't going to use something that has full and free range of motion at both ends.

__________________

www.stranoparts.com --814-849-3450

18 SCCA National Championships in house, many more for our customers prove we know our stuff.Talk is cheap, results matter.

Check out our KONI prices, our Master Cylinder Brace, and new Xtracker Hub/wheel bearing upgrade kits!

www.stranoparts.com --814-849-3450

18 SCCA National Championships in house, many more for our customers prove we know our stuff.Talk is cheap, results matter.

Check out our KONI prices, our Master Cylinder Brace, and new Xtracker Hub/wheel bearing upgrade kits!