Post your best welds!

#21

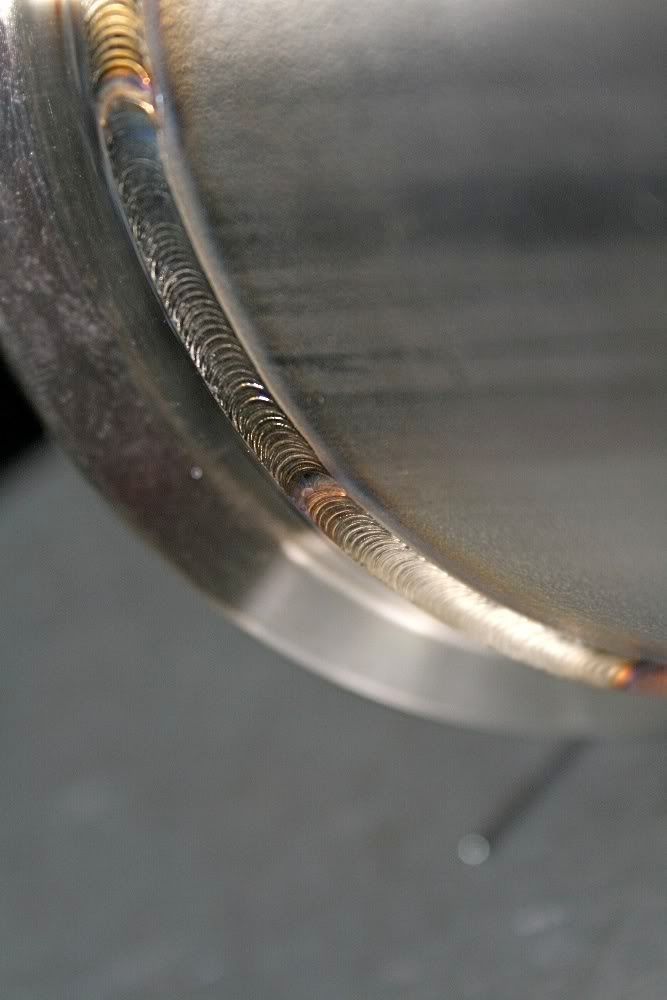

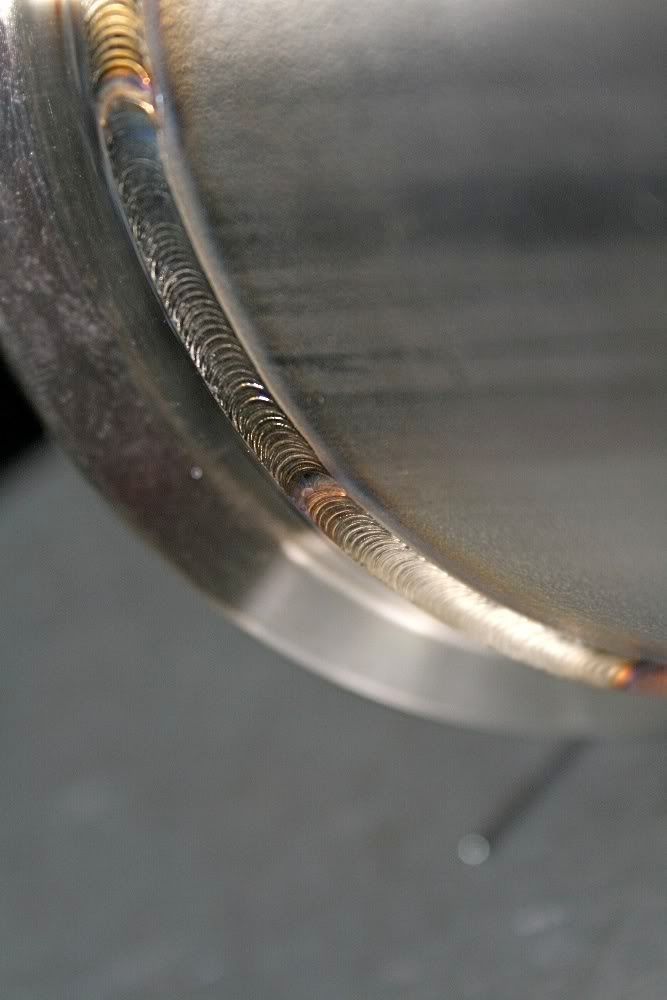

Those were my first thoughts, very consistant weld but be careful with undercuts OP, I'm not bashing just trying to give some constructive critism that may save you from a headache in the future. I'll try and post some pics of my welds, I used to weld for a living and loved every minute of it. Welding is something every car guy should know or keep it a secret that they know because all the sudden when somebody needs something welded "you have a new best friend" lol

#22

Those were my first thoughts, very consistant weld but be careful with undercuts OP, I'm not bashing just trying to give some constructive critism that may save you from a headache in the future. I'll try and post some pics of my welds, I used to weld for a living and loved every minute of it. Welding is something every car guy should know or keep it a secret that they know because all the sudden when somebody needs something welded "you have a new best friend" lol

Yep, as i wrote before i could use a bit more filler, BUT i digged back in the drawings for the particular part, as i was confused why i have'nt dipped more filler in and found out the there wasnt allowed almost any weld. Im from denmark, so i dont know what its called in english but we call it A-measure.. Hope you understand what i mean

#23

Yeah, you have to purge teh stainless, though so many don't.

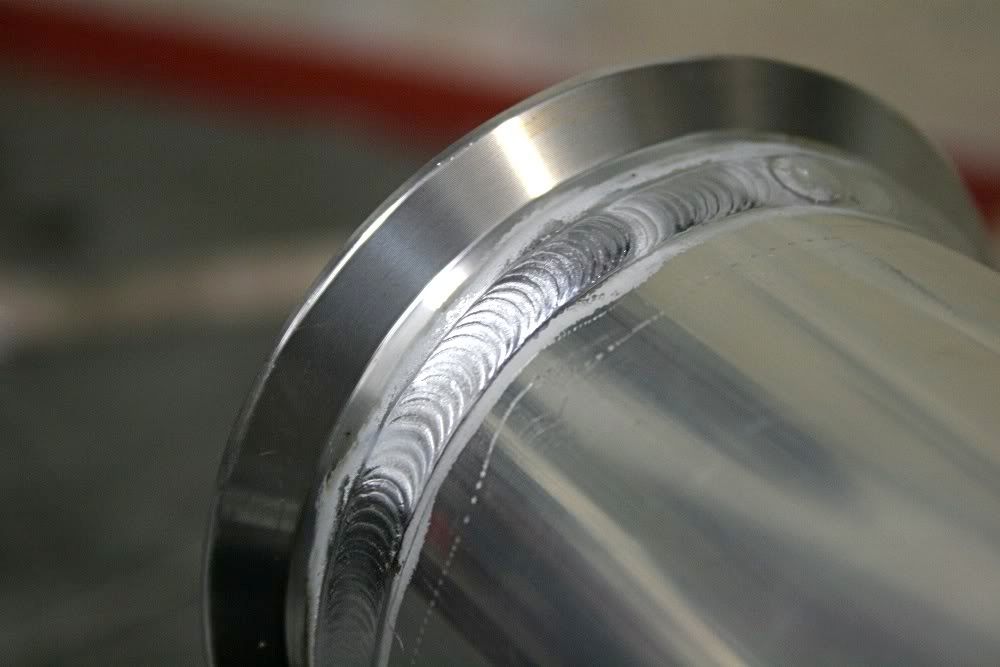

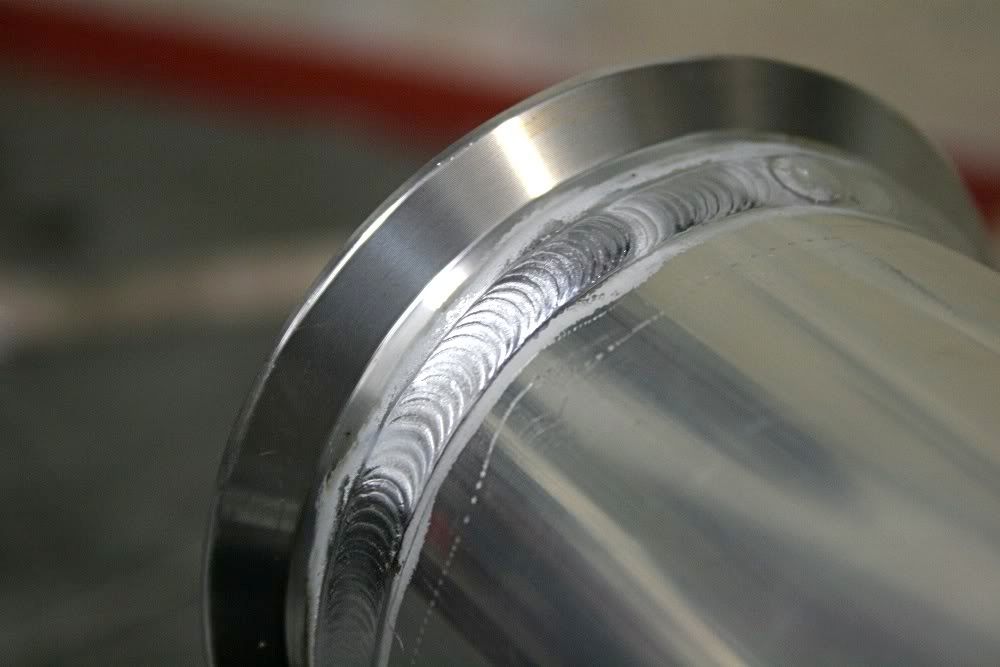

Ilike the aluminum to be right through too...

This one was doen with a larger cup, colours are better, but it's not really needed.

This one turned out good even with the smaller cup, because I went hotter and faster. 80 amps no pulse on this, I usually do 60 or so on the v-band fillets

I go hotter and faster on aluminum too than most, but it is harder to get the look consistent

This is before I switched to autogenous pulse...this one is filler no pulse, moving fast

4130 to mild steel plate weld with ER80sD-2

Gotta agree about the signature though. When I was in shops, I ran a few, and after a while I could tell just by looking who had welded it out my crew. Even 2 very good welds, both similar in style, can be different in just the most subtle ways.

6G is a good place to get pipe skills, but if you want great TIG hands, start on gas welding. That is how we used to teach the 1st years. Slows everything down, and you can really see the puddle and fusion.

Ilike the aluminum to be right through too...

This one was doen with a larger cup, colours are better, but it's not really needed.

This one turned out good even with the smaller cup, because I went hotter and faster. 80 amps no pulse on this, I usually do 60 or so on the v-band fillets

I go hotter and faster on aluminum too than most, but it is harder to get the look consistent

This is before I switched to autogenous pulse...this one is filler no pulse, moving fast

4130 to mild steel plate weld with ER80sD-2

Gotta agree about the signature though. When I was in shops, I ran a few, and after a while I could tell just by looking who had welded it out my crew. Even 2 very good welds, both similar in style, can be different in just the most subtle ways.

6G is a good place to get pipe skills, but if you want great TIG hands, start on gas welding. That is how we used to teach the 1st years. Slows everything down, and you can really see the puddle and fusion.

#24

i'm just learning here

what kind of tungsten do you guys like to run? I have 2% thorinated and 2% lantinated..they seem to weld pretty similar, but i'm a noob so what do I know. I keep getting nodules when I weld on ac...don't know why. I also seem to be having a hard time with aluminum fillet welds.

out of curiosity what do you like to use for stainless 304 16ga tube? I'm using 45 amps with a 1/16 thorinated tungsten and a .045 308l filler rod.

what kind of tungsten do you guys like to run? I have 2% thorinated and 2% lantinated..they seem to weld pretty similar, but i'm a noob so what do I know. I keep getting nodules when I weld on ac...don't know why. I also seem to be having a hard time with aluminum fillet welds.

out of curiosity what do you like to use for stainless 304 16ga tube? I'm using 45 amps with a 1/16 thorinated tungsten and a .045 308l filler rod.

#29

#33

On The Tree

iTrader: (2)

Join Date: Mar 2011

Location: Tower City, PA

Posts: 120

Likes: 0

Received 0 Likes

on

0 Posts

Jesus!! I hope you guys are doing this for a living! No reason at all you can't be making mad cash with skills like that! I am a welder myself. However, it's MIG welding at high production. I can hold my own with a MIG, and have been playing with a TIG at work when I get time. Mostly just small stainless stuff fusion style. But...DAMN!! Some of these pictures look as though they were robotically welded. I tip my hat to you gentlemen. Beautiful work!

#36

TECH Addict

iTrader: (8)

Post your best welds and write witch settings and machine there are used. It would might help beginners. I see waaaaay to often VERY bad welding at vital points.

beside that, who doesnt love seeing some good craftmanship?

anyways, here's some of my work. everything is welded with my lincoln invertec v160t pulse

aisi 316 stainless steel about 150 amps, no pulse

Mild steel about 90 amps, no pulse

As you can see, there's a hole in the end due lack of slope down (i was in a hurry, and as you can see i havent grinded the surface of witch you always should do to get a cleaner weld)

aisi 304 stainless steel, about 80 amps, no pulse

aisi 316 stainless steel, about 65 amps, no pulse (fusion weld)

random shot of me i process

beside that, who doesnt love seeing some good craftmanship?

anyways, here's some of my work. everything is welded with my lincoln invertec v160t pulse

aisi 316 stainless steel about 150 amps, no pulse

Mild steel about 90 amps, no pulse

As you can see, there's a hole in the end due lack of slope down (i was in a hurry, and as you can see i havent grinded the surface of witch you always should do to get a cleaner weld)

aisi 304 stainless steel, about 80 amps, no pulse

aisi 316 stainless steel, about 65 amps, no pulse (fusion weld)

random shot of me i process

#38

Pwrtrip75 is right about this. These welds are awesome, but the one thing that they need is more throat. The throat being concave cerates a stress riser. It is important for your welds to look good, however it is more important for your weld to be strong. I am not saying that any of these welds have or will fail, however from an engineering standpoint they are more susceptible to fatigue and yield. Keep up the good work guys!

#39

I'm another one that can hang with the best with a MIG but can barely TIG. I own a synchrowave 180SD, which compared to some of the welders out there now is sort of big, primitive and simple. I've debated selling it and picking up a newer small inverter (maybe even an import, I have a 50A import plasma that I honestly love), just to get the extra features + the portability (both in size and power source) with the hope that it would get me to use it more and get enough practice to lay down better welds.

Any recommendations? I wish you guys posted not only power but what welder you were using/what torch/cup... I know that it's mostly about technique, but the fact is that once you got that down enough to lay welds like those you usually have some firm opinions on equipment.

I'm curious, if you guys were going to recommend a torch, cups... for the kind of work you're showing here what would they be?

Any recommendations? I wish you guys posted not only power but what welder you were using/what torch/cup... I know that it's mostly about technique, but the fact is that once you got that down enough to lay welds like those you usually have some firm opinions on equipment.

I'm curious, if you guys were going to recommend a torch, cups... for the kind of work you're showing here what would they be?

same strength as regular dab technique but more suited for round things as it maintains consistent arc length and bead width as I move around the tube. It's the industry standard for tubes and pipe

same strength as regular dab technique but more suited for round things as it maintains consistent arc length and bead width as I move around the tube. It's the industry standard for tubes and pipe