Post your best welds!

#1

Post your best welds and write witch settings and machine there are used. It would might help beginners. I see waaaaay to often VERY bad welding at vital points.

beside that, who doesnt love seeing some good craftmanship?

anyways, here's some of my work. everything is welded with my lincoln invertec v160t pulse

aisi 316 stainless steel about 150 amps, no pulse

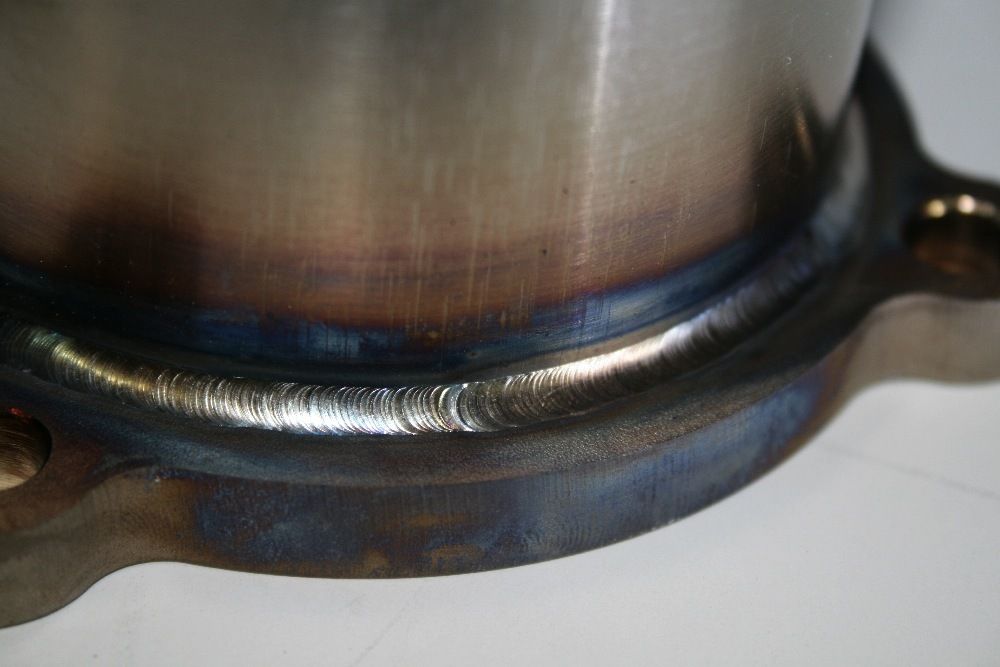

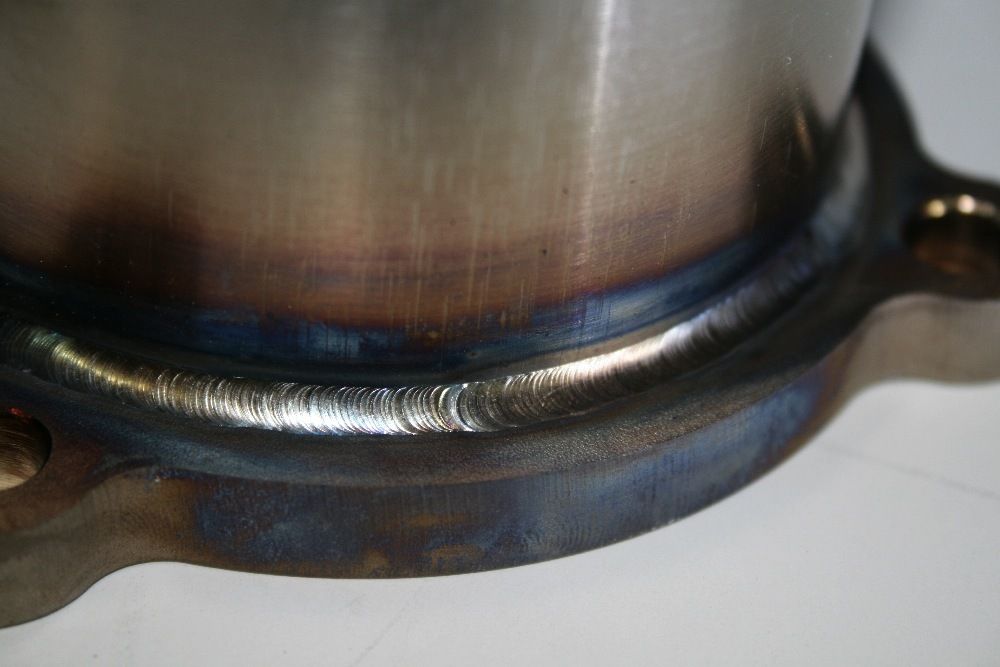

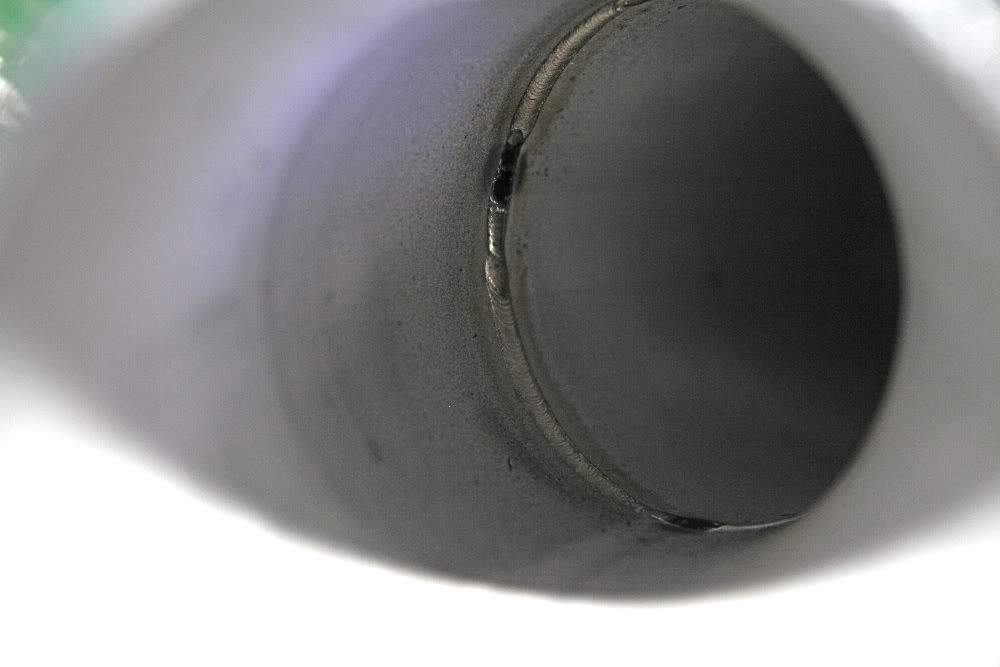

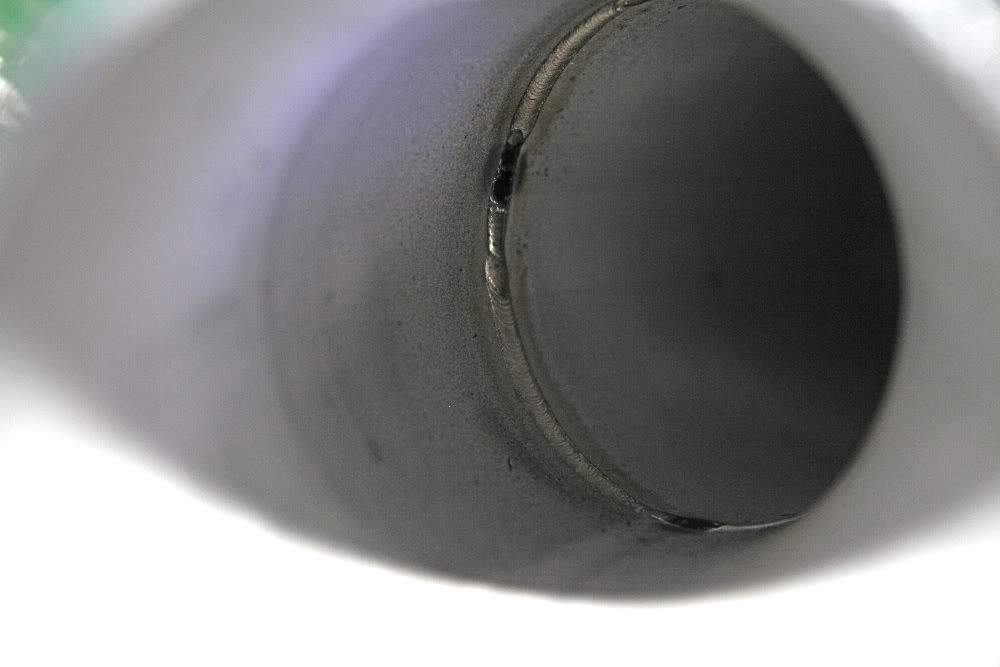

Mild steel about 90 amps, no pulse

As you can see, there's a hole in the end due lack of slope down (i was in a hurry, and as you can see i havent grinded the surface of witch you always should do to get a cleaner weld)

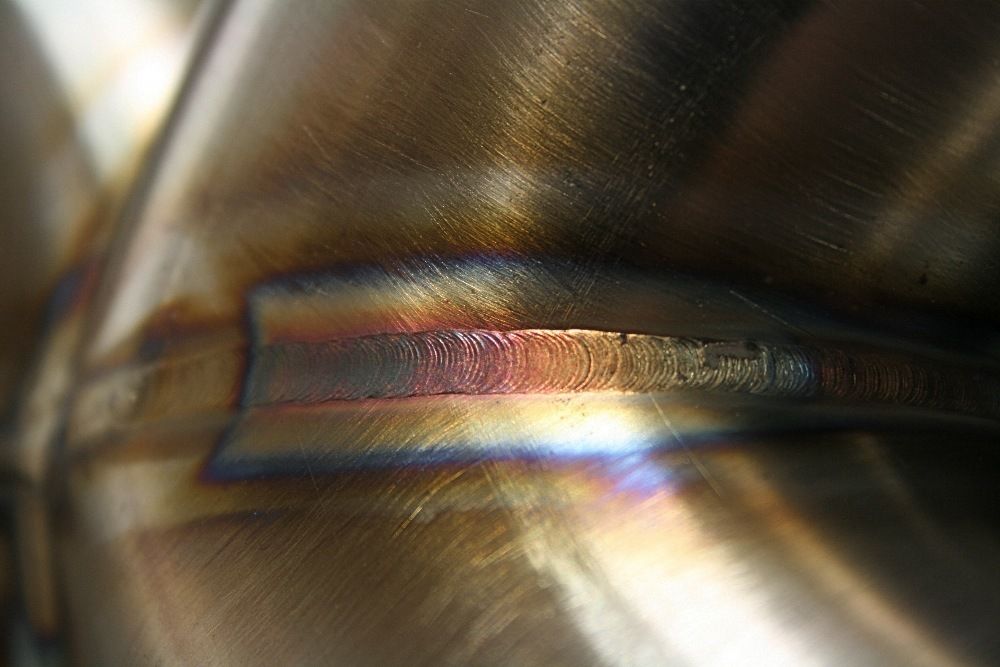

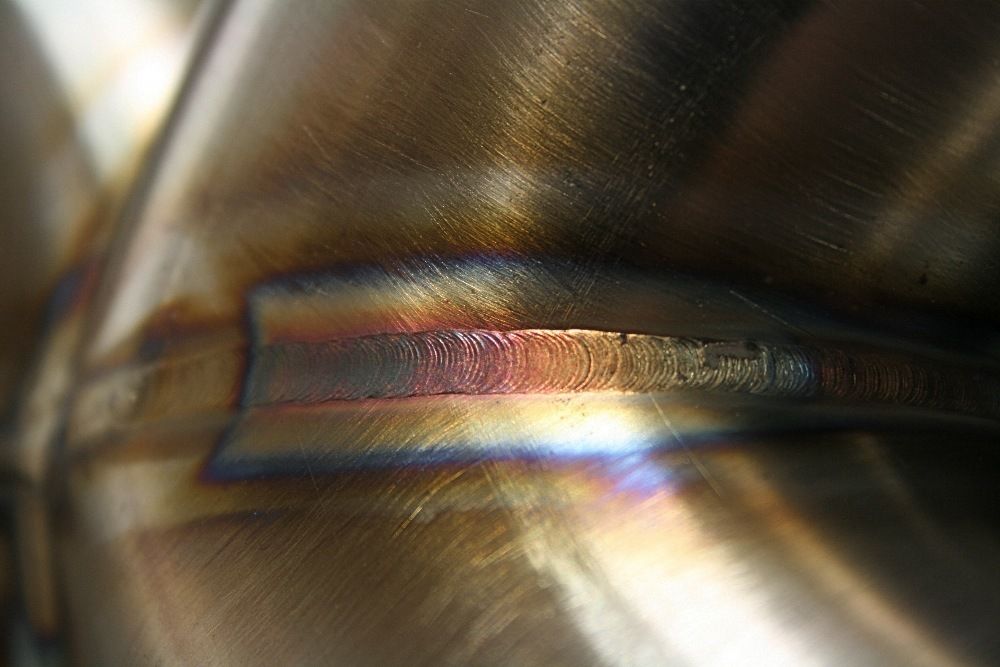

aisi 304 stainless steel, about 80 amps, no pulse

aisi 316 stainless steel, about 65 amps, no pulse (fusion weld)

random shot of me i process

beside that, who doesnt love seeing some good craftmanship?

anyways, here's some of my work. everything is welded with my lincoln invertec v160t pulse

aisi 316 stainless steel about 150 amps, no pulse

Mild steel about 90 amps, no pulse

As you can see, there's a hole in the end due lack of slope down (i was in a hurry, and as you can see i havent grinded the surface of witch you always should do to get a cleaner weld)

aisi 304 stainless steel, about 80 amps, no pulse

aisi 316 stainless steel, about 65 amps, no pulse (fusion weld)

random shot of me i process

#7

Temp and speed look good, but you should use a little more rod in your welds. CWB/ASA/TSSA/NASA Cert here... I'm the guy that TIG welded some of the Engine Oil Plates for Bell Helicopter during the Gulf War. Your team and ours used many of these choppers during the fight over there. I love seeing good work, and you look to be pretty young! I'd say you are headed down a fruitful road with your trade, good luck with it!

Trending Topics

#8

Temp and speed look good, but you should use a little more rod in your welds. CWB/ASA/TSSA/NASA Cert here... I'm the guy that TIG welded some of the Engine Oil Plates for Bell Helicopter during the Gulf War. Your team and ours used many of these choppers during the fight over there. I love seeing good work, and you look to be pretty young! I'd say you are headed down a fruitful road with your trade, good luck with it!

#9

I'll toss up a few...

4130 weld, 100 amps, no pulse

304ss welded with pulse

Titanium welded with 50 amps, no pulse, on used corvette exhaust

Titanium welded with 85 amps, no pulse

321ss welded with 35 amps, no pulse

321 to 304 about 75 amps, no pulse

Aluminum welded at 140amps

4130 weld, 100 amps, no pulse

304ss welded with pulse

Titanium welded with 50 amps, no pulse, on used corvette exhaust

Titanium welded with 85 amps, no pulse

321ss welded with 35 amps, no pulse

321 to 304 about 75 amps, no pulse

Aluminum welded at 140amps

#11

I'd say about 5 years of TIG part-time, and now 2 years full time, but I started on TIG as just a kid, and did lots of other welding for 15 years now.

Still getting better, and still love learning what others do and have done.

Here are a few more...

Stainless pulse and non-pulse fillet

Inside a cross-over

Aluminum at about 140 again

321 Stainless no pulse fillet

Inside some 321 headers

Stainless random

Still getting better, and still love learning what others do and have done.

Here are a few more...

Stainless pulse and non-pulse fillet

Inside a cross-over

Aluminum at about 140 again

321 Stainless no pulse fillet

Inside some 321 headers

Stainless random

Last edited by Unobtainium; 03-26-2013 at 06:28 PM.

#13

#15

Anyone getting into welding, my advise, get your 6G ticket first. Once you can nail a 6G weld, TIG will be the most fun you ever had. Yes, 6G is stick, but takes one hell of a steady hand and a boat load of knowledge to do it right! In Canada it is a TSSA Cert, I am not sure what the ticket is in AWS??

#16

Very nice. I do have to comment that the flat stock in the very first pic....the weld looks a little undercut. Know what I mean or am I just crazy. Amateur tig welder here.

You should note.....those pics of the inside of a stainless weld have to be back purged to look like that. Although that is the only way to weld stainless. Ask me how I know...lol

I tried practicing on stainless several years ago and was like "what the f is this sugar looking stuff"

Anyway, I was watching a vid from a guy that welds for Cagnazzi. He made the comment that everyones weld is like a signature. When looking closely at it...each persons bead looks a little different. Just cause it doesn't look like a very defined stack of dimes doesn't mean its done wrong. You definitely have a signature.

You should note.....those pics of the inside of a stainless weld have to be back purged to look like that. Although that is the only way to weld stainless. Ask me how I know...lol

I tried practicing on stainless several years ago and was like "what the f is this sugar looking stuff"

Anyway, I was watching a vid from a guy that welds for Cagnazzi. He made the comment that everyones weld is like a signature. When looking closely at it...each persons bead looks a little different. Just cause it doesn't look like a very defined stack of dimes doesn't mean its done wrong. You definitely have a signature.

#19

That inside weld is exactly what you are looking for. The inside should perfectly match the outside weld! That is a nice one....

The first time I saw that process I was blown away. You can do amazing things with a TIG

The first time I saw that process I was blown away. You can do amazing things with a TIG

#20

Those were my first thoughts, very consistant weld but be careful with undercuts OP, I'm not bashing just trying to give some constructive critism that may save you from a headache in the future. I'll try and post some pics of my welds, I used to weld for a living and loved every minute of it. Welding is something every car guy should know or keep it a secret that they know because all the sudden when somebody needs something welded "you have a new best friend" lol