Engine Breakdown: 402-Stroker LS2

He got the engine for a steal, but will it be worth it? Andrew Attalla and I break down a 402-ci Stroker LS2.

In the world of drifting, power is something drivers don’t always feel like they have enough of. Even in the ProAm series of Formula Drift, drivers still want anything over 500-horsepower. Step up to Pro2 and you’ll need at least 650-horsepower. For the drivers who draw the big crowds, you’re looking at over 800-horsepower, and it’s not unusual to hear figures in the four-digit range. Knowing that, racer Andrew Attala found a LS2 with a 402-ci stroker kit already installed to see if this could do the trick.

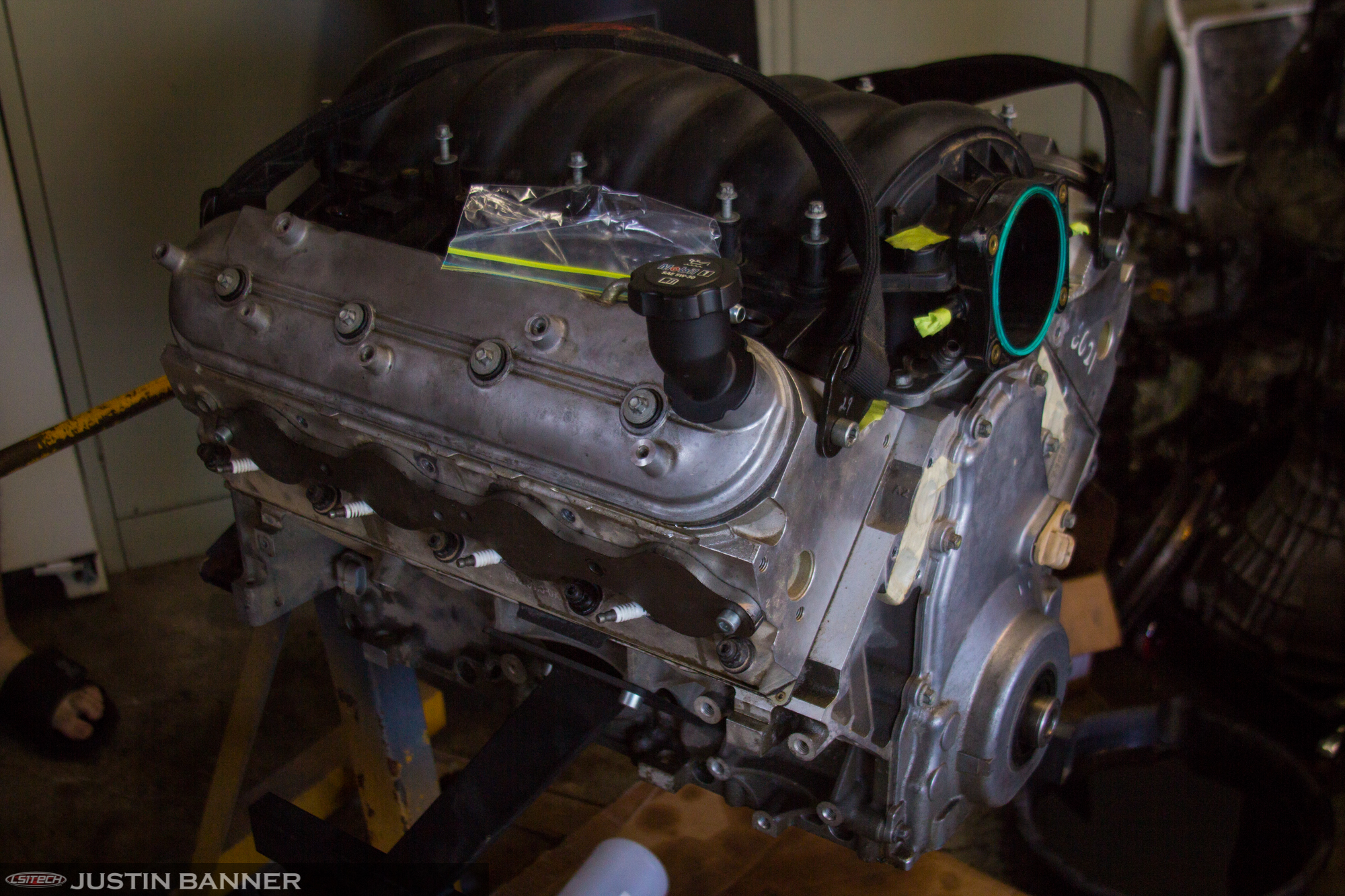

The LS2 comes as a 6-liter displacement with a 4-inch bore and 3.622-inch stroke, and it is good enough for about 400-horsepower in stock form. While it’s fairly simple to get 100-horsepower more out of the engine with simple mods, sometimes a stroker can beneficial if you can get a quality kit for a low price. In our case, we decided to get one used. To get an extra 37.9-ci out of the engine, a crankshaft with a longer stroke of 4-inches is needed. This makes the LS2 into a square engine when it comes to bore and stroke.

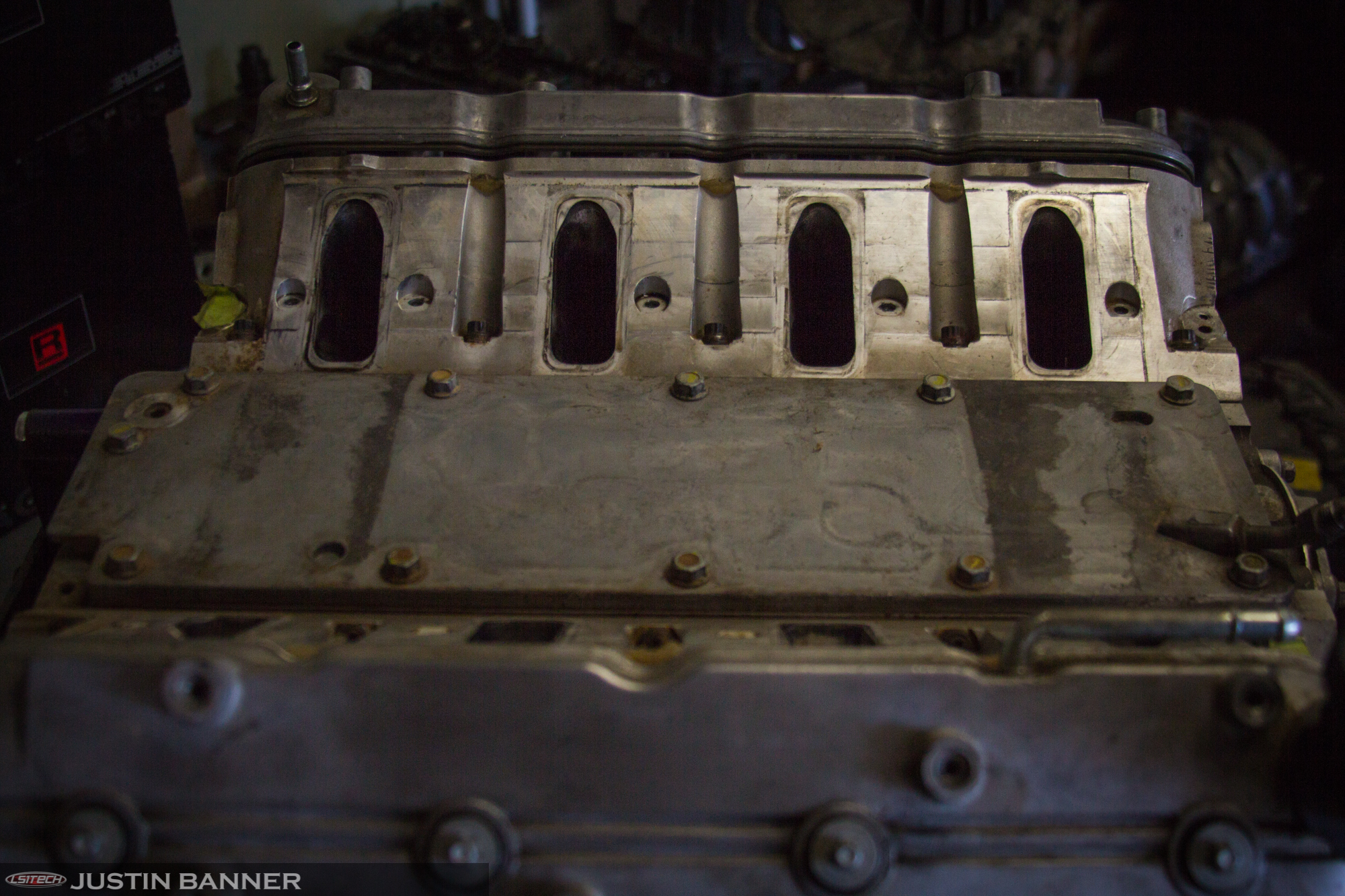

This engine was intended to be used as a spare for a sand rail car, according to the guy Andrew bought it from. It had been sitting around for a couple of years and the seller wanted to be rid of it. From the outside, this engine wasn’t a slouch build and featured a few things to help prevent sand from getting between the intake and head bolts. The cathedral port heads had also seen some work done, and showed evidence of some porting. Underneath the stock center bolt valve covers were a set of roller rockers and dual valve springs.

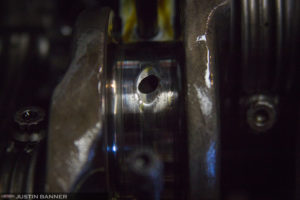

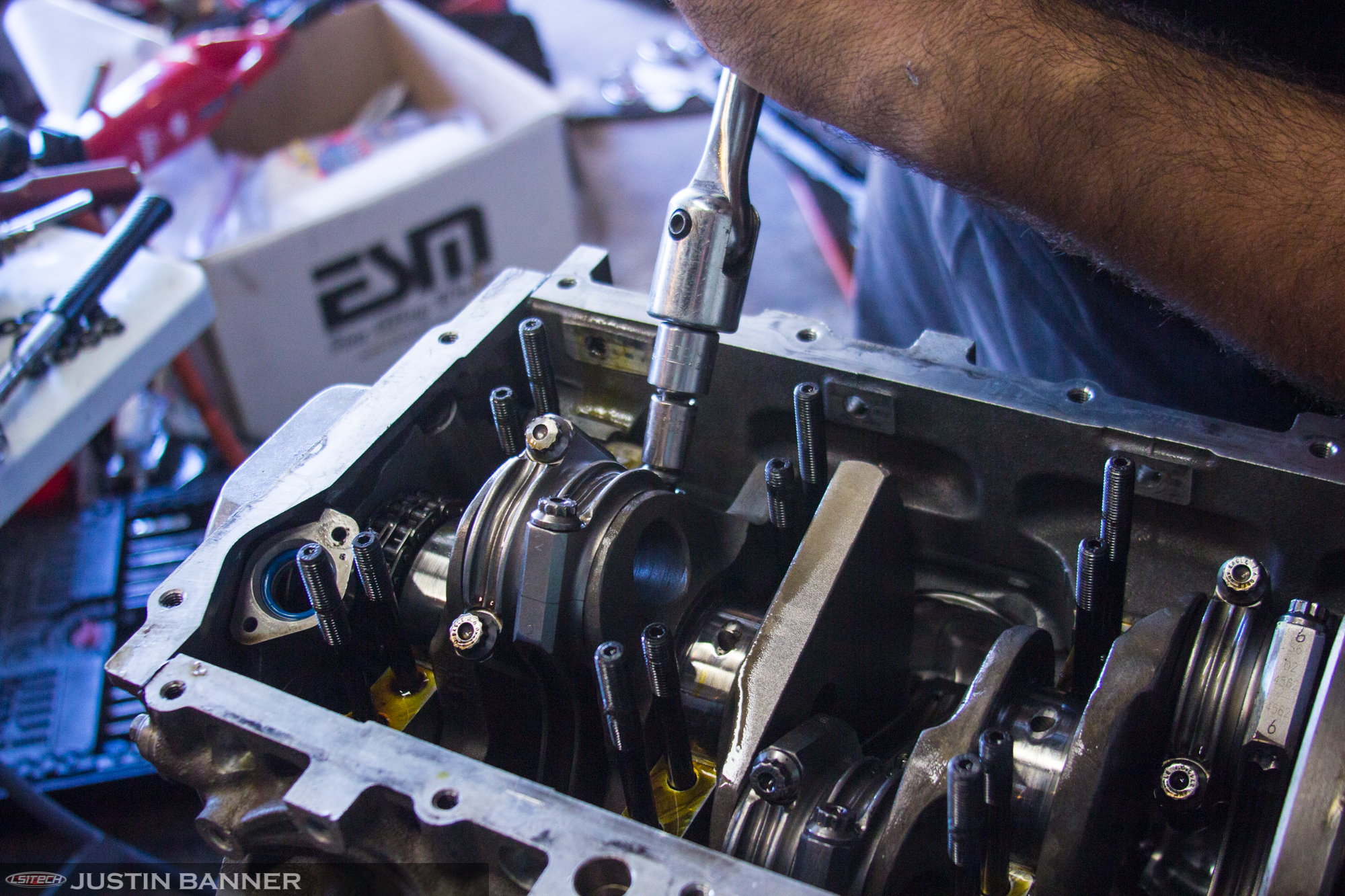

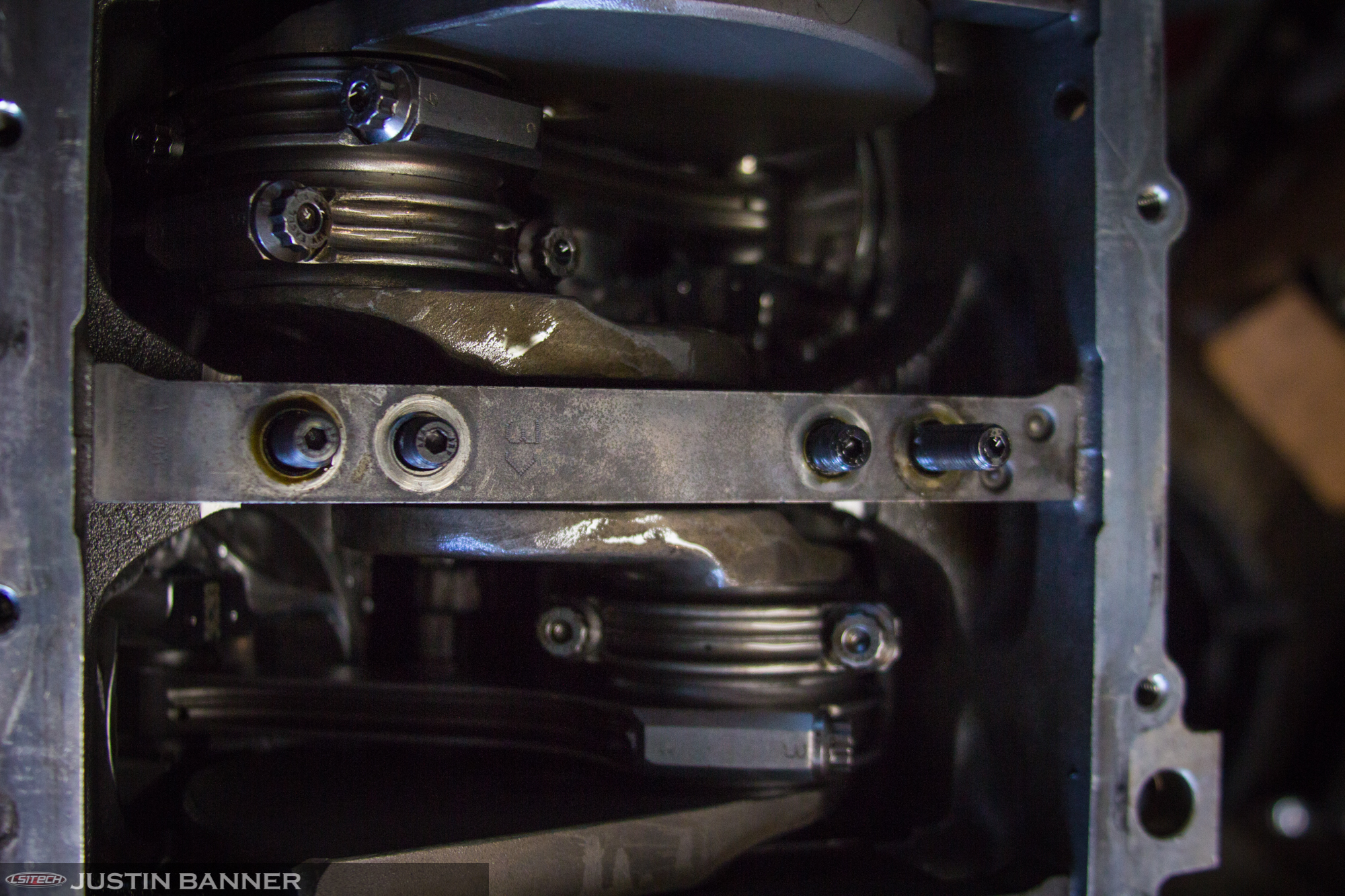

When we took off the pan, we discovered a set of ARP main cap studs and nuts on the stock main caps. There was also a dual timing chain setup under the front timing cover. Once the windage tray was removed, we moved on to remove the main cap bolts. This also revealed the 58x timing on the crankshaft. So far, things were looking good, until we looked at a couple of main bearings in the light.

The rust on the bearings wasn’t good, but that happens if an engine sits for two years without rotating the crank. This also meant that our valve springs that were compressed most likely no good either. The crank revealed some odd scoring on a couple of the journals that weren’t on the bearings. This may indicate that a brand new crank was not installed. It wasn’t bad scoring, though, and we hoped it might be able to be returned to a polished state with some emory cloth. But we opted to take it to local shop that deals with crankshaft repair to be sure.

Pulling the rod caps off showed no wear nor any rust, so we were be lucky there. It was still odd that everything other than the crank showed very slight wear. This was the reason we thought that this crank was used at some point but reinstalled into this engine.

Next, we will be going to take it to a local shop to see what can be done with the scoring. We will plan our next steps after hearing back from them. Stay tuned.

We’d love to hear your thoughts and feedback on this project!

Gallery: