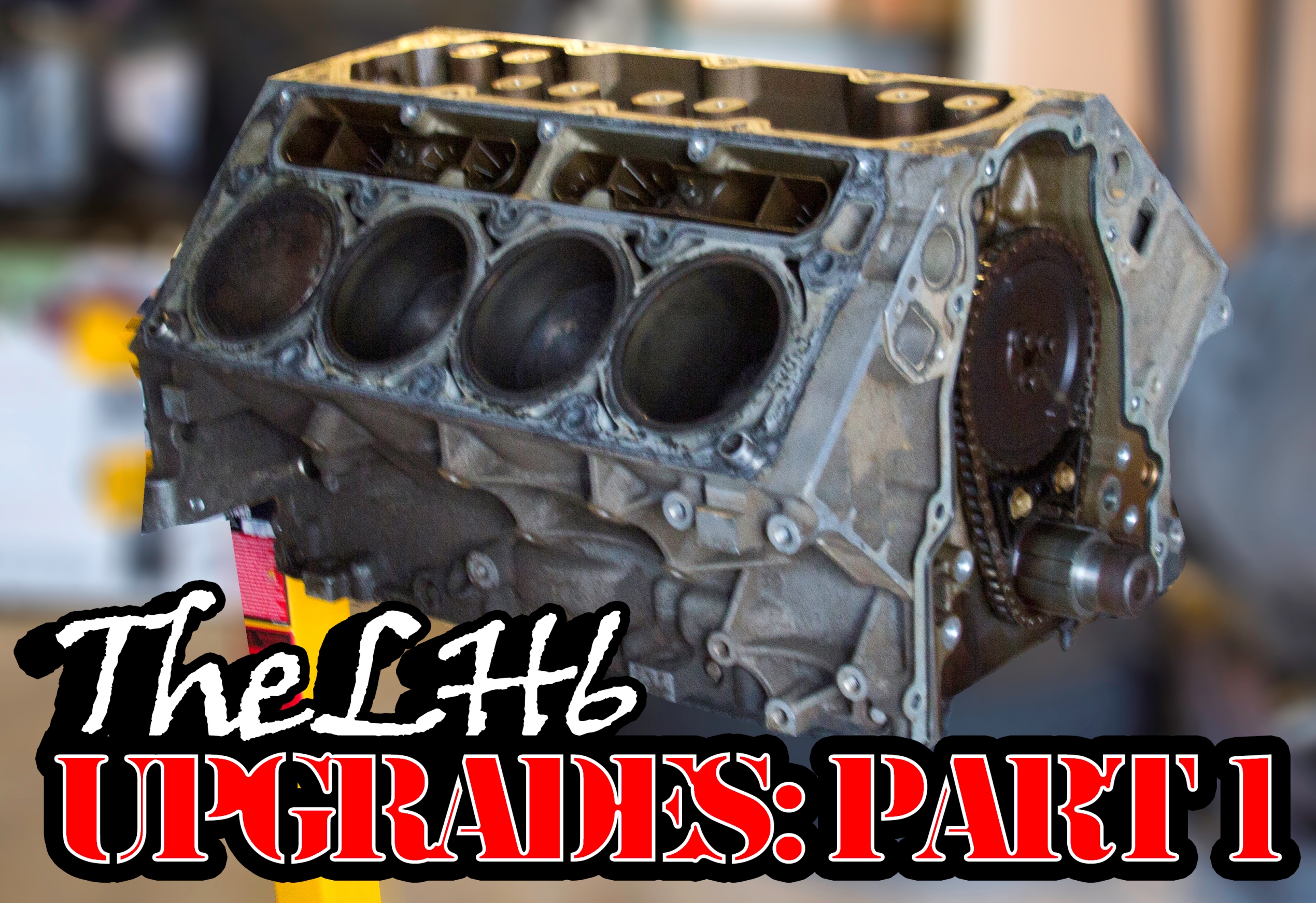

Project Ron Burgundy – The LH6: Upgrades Part 1

We finally get some work done on the LH6 slated for our track rat project!

Yes, we know, LS1Tech’s Project Ron Burgundy has been slow but the progress has been steady. In this installment we’re tearing down and building up the LH6 of Project Ron Burgundy. The bottom end is staying stock as it’s more than enough for the naturally-aspirated power it’s going to see initially. However, there is one thing that not many of you think about doing with your own AFM-removed LH-engines.

The number one thing we do is tap and plug the oil towers that feed the AFM lifters. Since we’re converting the engine away from that slightly less reliable system to a more traditional camshaft and lifter system, we also want to make sure oil wouldn’t leak out of these towers past the o-rings of the LS2 valley pan we’re going to use. Is it overkill? Yes. In fact, if you don’t feel comfortable tapping into your aluminum block, don’t and just leave them alone. However, if you are or are willing to pay someone who is, it’s not a bad process to do as it just adds more peace of mind.

The next part of the conversion is the TSP 212/218-114 camshaft that’s hotter than stock but doesn’t require shorter pushrods or upgraded rocker arms. Though, it does come with new valve springs and pushrods as we’ll detail in the next video. After that, we install a set of GM lifter buckets for the LS2, which you have to do for the conversion as the old buckets won’t allow the Johnson Lifters 2110R reduced travel lifters from Cam Motion to pass through where the AFM lifters were. Why? The openings are different to account for the special lifters of the system.

Check out the next video where we detail install of the new valve springs, install the heads, oil pan, and more!

Project Ron Burgundy is sponsored by these fine vendors. We thank each and every one of them for their support:

|

|

|

|

|

|

|

|

|

|