'70 Nova LY6/TH400 6.0VVT

#1

Summary

I started this thread in 2010 to document my engine swap. I spent a lot more time than most fiddling with things and making it my own, finally getting the car running in 2016. Since then I have continued to modify the car and use this thread to document it. I ended up rebuilding the engine and modifying the wiring harness myself. Some of the more unique aspects include low mount accessory drive with notched sub frame, aftermarket VVT cam, and ignition coils mounted on the firewall. I added this summary and table of contents in 2017 and will update it if appropriate.

Here is a photo of the car as of July 2018

Here is a photo from October 2018 of the engine bay

Here is a video from August 2018

Specifications

Please note the car has change a lot in the 10+ years since I started the LS swap. The specs below are "current" as of April 2020.

Engine: gen IV LY6, +0.030, Wiseco flat top, 2010 vintage TSP VVT2 cam 227/235 .614/.621 113LSA+6 (107ICL), Compstar rods, other stuff

Transmission (current): Magnum-F 6spd manual, Monster Stage II clutch, Silver Sport STX Shifter, Silver Sport Crossmember, custom fabricated tunnel

Transmission (until 2020): TH400, TCI flexplate, BTE converter, Lokar dipstick

Rear axle: Narrowed 1" per side 12bolt, limited slip clutch-type posi, 3.73:1 ratio, Ford tapered bearings, Strange axles

Engine Mounts: Dougs SK100 adapters

Oil Pan: Autokraft fabricated pan aka Canton Road Race w/ active baffling

Cooling: Volvo 2speed fan in fabricated shroud, Griffin aluminum radiator

Headers/exhaust: Dougs D3337 headers, 3" fabricated from mandrel bends, H pipe, large case Dynomax Super Turbo, tailpipes w/ rear quarter panel exit

FEAD: truck balancer, low mount truck AC compressor, low mount truck alternator in '98-02 camaro bracket, L99 Camaro water pump, L99 Camaro power steering pump, notched subframe both sides

Intake: 2010 Camaro / LS3 Corvette

Wiring: Reworked harness (heavily around the ignition coils), custom fuse center based on Littelfuse module, Corvette C6 DBW pedal, custom MSD plug wires, E38 ecm on firewall, battery in trunk with push-pull disconnect and impact safety switch

Fuel (Current): Ricks Restomod tank with Gen 5 Camaro SS fuel module and Vaporworx mechanical regulator

Fuel (Prior to mid 2021): Tanks Inc. PA-4 recessed into a stock tank (before they started making a Nova-specific tank!) with Walbro 255 and lC4 FPR.

Suspension (Front): stock frame w/ Guldstrand mod, Global west uppers, 600lb/in AFCO springs w/ adjusters, Hotchkis-Bilstein shocks, 1-1/8" Helwig tubular sway bar

Suspension (Rear): Hotchkis 1.5" drop leafs, Helwig 7/8" tubular adjustable sway bar, Hotchkis-Bilstein shocks

Brakes: C6 "standard" 325mm dual piston front on Kore3 billet hubs, '02 F-Body single piston 305mm rear, 1" master cylinder, dual 9in booster, Hawk HPS pads

Steering: Sweet Mfg 12.7:1 "sportsman" box with heavy 235in t-bar

Wheels and Tires (Current): 245/40R18 and 275/35R18 Falken RT660 on 18x8 & 18x9 Rev 107 rally wheels 0 offset (Note rear axle was narrowed 1" ea side)

Wheels and Tires (Former): 235/40R18 and 255/40R18 Michelin Pilot Sport on Rev 107s above. 205/60R15 and 275/60R15 on Centerline Convo Pros

Interior: Procar houndstooth rally seats, custom lowered frames, Morris 3pt retracting seatbelts front and rear, TMI 1pc headliner, a pair of Speedhut CANbus gauges under the dash for oil & coolant

Driver: Father of 2 mechanical engineer who overthinks things and chooses to do things the "hard way" whenever possible.

Table of contents by post ranges:

1-40: strip down, clean, paint engine. Add LS3 manifold. Modify truck accessories to work with it, add L99 waterpump

41-80: try out trailblazer ac compressor, machine motor adapter plates, plan for frame notches, try out alternator positions

81-120: Autokraft oil pan, solid body bushings, machine custom lift motor mount adapters, start Guldstrand modification to frame

121-160: more Guldstrand mod, test fit motor with custom lift motor mount adapters

161-200: clearance problems with motor mount adapters, machine "standard" adapter plates, continued clearance problems

201-240: settled on Doug's SK100 motor mount adapters, fiddled with Trailblazer AC compressor,

started on frame notch, bought TSP VVT-2 camshaft

241-280: switched to a truck-style AC compressor, completed driver's side frame notch for low alternator

281-320: passenger side frame not for low AC compressor, made a flywheel stop, discovered rust in engine

321-360: engine tear down and planning, engine block mockup in frame with low accessories

361-400: added AFCO spring adjusters and coil springs, planned motor rebuild

401-440: damaged pistons with simple green, machine work on block

441-480: continued machine work discussion, block damaged at machine shop, painted subframe with prevail sprayer

481-520: swaybar spacer, bearing clearances, start engine assembly

521-560: engine build, install crank, install some rods, rings, pistons, degree VVT cam

561-600: install remaining pistons, measure valve clearance

601-640: rebuild heads, install Harland Sharp rocker trunnions, finish longblock assembly

641-680: measure/install pushrods, install engine and accessory drive, evaluate ignition coil mounting options

681-720: mount ignition coils, transmission dipstick, take apart wiring harness, start wiring

721-760: power steering line, electric fan, fuel lines, install Tanks Inc. in stock fuel tank without recess

761-800: attempt to add recess to stock tank (fail), mockup Bussman fuse/relay center, add v-bands to header

801-840: mounted ECM to firewall, new MAP sensor pigtail, wiring for DBW throttle body and MAF, crimping tools and details for MX64, GT150 and Metripak terminals

841-880: more details on crimping, detail on soldering wire extensions, wiring for fuel injectors, wiring for ignition coils

881-920: finish ignition coil wiring, fabricate exhaust from mandrel bends, repair stripped header bolt,

921-960 : try Proform valve covers (too tall), refinish/powdercoat GMPP valve covers, space alternator bracket, finish exhaust fabrication

961-1000: install AC condenser, transmission cooler, fabricate fan shroud, move car to new home

1001-1040: MAF pad / air intake, install fuel tank recess and Tanks Inc PA-4 fuel pump, Wix filter regalator, fuel line details, trunk mount battery box, battery disconnect, battery wiring

1041-1080: battery cable routing from trunk through car, wire crimping test, fuse and relay center, spark plug wires, finalize cold air intake

1081-1120: through-firewall wiring, fuel pump safety interia switch, jump start post, PCV valve, steam vent, transmission cooler lines, body reassembly, AC box fiberglass

1098, 1100, 1107, 1115 FIRST STARTUP & FIRST DRIVE VIDEOS

1121-1160: dyno tune, TH400 transmission issues,go pro mounting, driving impressions, cars & coffee

1161-1200: transmission valvebody rebuild

1201-1240: summary of transmission changes & fix, cruise night Santa Paula, radiator overflow, new mufflers and add tailpipes, alignment, first autocross

1241-1280: rear axle narrowing and "LS1" rear brakes

1281-1320: finish narrowing, diff assembly/backlash gear pattern check

1321-1360: rear brake lines, rear suspension reassembly, Helwig sway bar, ls1 parking brake cables

1361-1400: ls1 parking brake cables and brackets, new 18" wheels and tires, replumb master and prop valve, car driveable again

1401-1440: paint restoration/detailing, 3pt rear seatbelts

1441-1480: local cruise nights, driving impressions, issues with stock front brakes, start of C6 brake swap, first Procar Rally seat

1481-1520: swap rear shocks, master/booster interference, autocross prep, second Procar Rally seat, autocross photos and videos

1521-1560: paint restoration/detailing/compound/wax, convex side mirrors, cruise nights & car shows

1561-1600: fan fuse blow, custom AC hoses, POA valve test, v-band failure

1601-1640: POA adjustment, AC flush wiring charge, LED tail lights, powder coat intake tube, replace noisy Walbro fuel pump

1641-1680: Plumb heater, restore front grill area

1681-1720: All in one polish/wax, vinyl cleaning, waterless wash, cruise night, TMI 1pc headliner, Morris 3 pt front seatbelts, dyno tuning, autocross, front C6 Kore3 brakes

This photo was taken just after getting the car running again in 2016

I started this thread in 2010 to document my engine swap. I spent a lot more time than most fiddling with things and making it my own, finally getting the car running in 2016. Since then I have continued to modify the car and use this thread to document it. I ended up rebuilding the engine and modifying the wiring harness myself. Some of the more unique aspects include low mount accessory drive with notched sub frame, aftermarket VVT cam, and ignition coils mounted on the firewall. I added this summary and table of contents in 2017 and will update it if appropriate.

Here is a photo of the car as of July 2018

Here is a photo from October 2018 of the engine bay

Here is a video from August 2018

Specifications

Please note the car has change a lot in the 10+ years since I started the LS swap. The specs below are "current" as of April 2020.

Engine: gen IV LY6, +0.030, Wiseco flat top, 2010 vintage TSP VVT2 cam 227/235 .614/.621 113LSA+6 (107ICL), Compstar rods, other stuff

Transmission (current): Magnum-F 6spd manual, Monster Stage II clutch, Silver Sport STX Shifter, Silver Sport Crossmember, custom fabricated tunnel

Transmission (until 2020): TH400, TCI flexplate, BTE converter, Lokar dipstick

Rear axle: Narrowed 1" per side 12bolt, limited slip clutch-type posi, 3.73:1 ratio, Ford tapered bearings, Strange axles

Engine Mounts: Dougs SK100 adapters

Oil Pan: Autokraft fabricated pan aka Canton Road Race w/ active baffling

Cooling: Volvo 2speed fan in fabricated shroud, Griffin aluminum radiator

Headers/exhaust: Dougs D3337 headers, 3" fabricated from mandrel bends, H pipe, large case Dynomax Super Turbo, tailpipes w/ rear quarter panel exit

FEAD: truck balancer, low mount truck AC compressor, low mount truck alternator in '98-02 camaro bracket, L99 Camaro water pump, L99 Camaro power steering pump, notched subframe both sides

Intake: 2010 Camaro / LS3 Corvette

Wiring: Reworked harness (heavily around the ignition coils), custom fuse center based on Littelfuse module, Corvette C6 DBW pedal, custom MSD plug wires, E38 ecm on firewall, battery in trunk with push-pull disconnect and impact safety switch

Fuel (Current): Ricks Restomod tank with Gen 5 Camaro SS fuel module and Vaporworx mechanical regulator

Fuel (Prior to mid 2021): Tanks Inc. PA-4 recessed into a stock tank (before they started making a Nova-specific tank!) with Walbro 255 and lC4 FPR.

Suspension (Front): stock frame w/ Guldstrand mod, Global west uppers, 600lb/in AFCO springs w/ adjusters, Hotchkis-Bilstein shocks, 1-1/8" Helwig tubular sway bar

Suspension (Rear): Hotchkis 1.5" drop leafs, Helwig 7/8" tubular adjustable sway bar, Hotchkis-Bilstein shocks

Brakes: C6 "standard" 325mm dual piston front on Kore3 billet hubs, '02 F-Body single piston 305mm rear, 1" master cylinder, dual 9in booster, Hawk HPS pads

Steering: Sweet Mfg 12.7:1 "sportsman" box with heavy 235in t-bar

Wheels and Tires (Current): 245/40R18 and 275/35R18 Falken RT660 on 18x8 & 18x9 Rev 107 rally wheels 0 offset (Note rear axle was narrowed 1" ea side)

Wheels and Tires (Former): 235/40R18 and 255/40R18 Michelin Pilot Sport on Rev 107s above. 205/60R15 and 275/60R15 on Centerline Convo Pros

Interior: Procar houndstooth rally seats, custom lowered frames, Morris 3pt retracting seatbelts front and rear, TMI 1pc headliner, a pair of Speedhut CANbus gauges under the dash for oil & coolant

Driver: Father of 2 mechanical engineer who overthinks things and chooses to do things the "hard way" whenever possible.

Table of contents by post ranges:

1-40: strip down, clean, paint engine. Add LS3 manifold. Modify truck accessories to work with it, add L99 waterpump

41-80: try out trailblazer ac compressor, machine motor adapter plates, plan for frame notches, try out alternator positions

81-120: Autokraft oil pan, solid body bushings, machine custom lift motor mount adapters, start Guldstrand modification to frame

121-160: more Guldstrand mod, test fit motor with custom lift motor mount adapters

161-200: clearance problems with motor mount adapters, machine "standard" adapter plates, continued clearance problems

201-240: settled on Doug's SK100 motor mount adapters, fiddled with Trailblazer AC compressor,

started on frame notch, bought TSP VVT-2 camshaft

241-280: switched to a truck-style AC compressor, completed driver's side frame notch for low alternator

281-320: passenger side frame not for low AC compressor, made a flywheel stop, discovered rust in engine

321-360: engine tear down and planning, engine block mockup in frame with low accessories

361-400: added AFCO spring adjusters and coil springs, planned motor rebuild

401-440: damaged pistons with simple green, machine work on block

441-480: continued machine work discussion, block damaged at machine shop, painted subframe with prevail sprayer

481-520: swaybar spacer, bearing clearances, start engine assembly

521-560: engine build, install crank, install some rods, rings, pistons, degree VVT cam

561-600: install remaining pistons, measure valve clearance

601-640: rebuild heads, install Harland Sharp rocker trunnions, finish longblock assembly

641-680: measure/install pushrods, install engine and accessory drive, evaluate ignition coil mounting options

681-720: mount ignition coils, transmission dipstick, take apart wiring harness, start wiring

721-760: power steering line, electric fan, fuel lines, install Tanks Inc. in stock fuel tank without recess

761-800: attempt to add recess to stock tank (fail), mockup Bussman fuse/relay center, add v-bands to header

801-840: mounted ECM to firewall, new MAP sensor pigtail, wiring for DBW throttle body and MAF, crimping tools and details for MX64, GT150 and Metripak terminals

841-880: more details on crimping, detail on soldering wire extensions, wiring for fuel injectors, wiring for ignition coils

881-920: finish ignition coil wiring, fabricate exhaust from mandrel bends, repair stripped header bolt,

921-960 : try Proform valve covers (too tall), refinish/powdercoat GMPP valve covers, space alternator bracket, finish exhaust fabrication

961-1000: install AC condenser, transmission cooler, fabricate fan shroud, move car to new home

1001-1040: MAF pad / air intake, install fuel tank recess and Tanks Inc PA-4 fuel pump, Wix filter regalator, fuel line details, trunk mount battery box, battery disconnect, battery wiring

1041-1080: battery cable routing from trunk through car, wire crimping test, fuse and relay center, spark plug wires, finalize cold air intake

1081-1120: through-firewall wiring, fuel pump safety interia switch, jump start post, PCV valve, steam vent, transmission cooler lines, body reassembly, AC box fiberglass

1098, 1100, 1107, 1115 FIRST STARTUP & FIRST DRIVE VIDEOS

1121-1160: dyno tune, TH400 transmission issues,go pro mounting, driving impressions, cars & coffee

1161-1200: transmission valvebody rebuild

1201-1240: summary of transmission changes & fix, cruise night Santa Paula, radiator overflow, new mufflers and add tailpipes, alignment, first autocross

1241-1280: rear axle narrowing and "LS1" rear brakes

1281-1320: finish narrowing, diff assembly/backlash gear pattern check

1321-1360: rear brake lines, rear suspension reassembly, Helwig sway bar, ls1 parking brake cables

1361-1400: ls1 parking brake cables and brackets, new 18" wheels and tires, replumb master and prop valve, car driveable again

1401-1440: paint restoration/detailing, 3pt rear seatbelts

1441-1480: local cruise nights, driving impressions, issues with stock front brakes, start of C6 brake swap, first Procar Rally seat

1481-1520: swap rear shocks, master/booster interference, autocross prep, second Procar Rally seat, autocross photos and videos

1521-1560: paint restoration/detailing/compound/wax, convex side mirrors, cruise nights & car shows

1561-1600: fan fuse blow, custom AC hoses, POA valve test, v-band failure

1601-1640: POA adjustment, AC flush wiring charge, LED tail lights, powder coat intake tube, replace noisy Walbro fuel pump

1641-1680: Plumb heater, restore front grill area

1681-1720: All in one polish/wax, vinyl cleaning, waterless wash, cruise night, TMI 1pc headliner, Morris 3 pt front seatbelts, dyno tuning, autocross, front C6 Kore3 brakes

This photo was taken just after getting the car running again in 2016

Last edited by -TheBandit-; 08-05-2021 at 03:05 PM.

#2

-----THE ORIGINAL THREAD BEGINS HERE----

This thread will document my swap from a tired gen I small block 350 to a modern 6.0VVT LY6. This will be my first time doing this kind of a swap, so bear with me! My name is Clint. I'm a mechanical engineer and I've had my Nova since I was fifteen. It was my first car and even though I'm now in my late twenties, married, and have a newborn son, it still holds a special place in my life.

First a few pictures. Here is a recent shot of the car. The wheels are Centerline Convo Pros 15x8.5 5" BS

275/60R15s out back and 15x7 3-3/8" BS 225/60R15 up front.

Finishing off an old pair of tires:

Autocrossing:

Here is the old small block in all its glory. When I was in high school I did a frame off on the car. It had Edelbrock Performer RPM heads, a Comp cam (232/236 @ 050 .488/.490), and a Demon 650DP. After over a decade of hotrodding, compression was getting low, oil was blowing from every gasketed interface, and the final straw was a bent pushrod and flat lobe on the cam.

Originally I was a big drag racing fan and always pictured this car tubbed and tubed with a big block. But as I grew older, I started to appreciate other aspects of driving like stopping and turning. I became increasingly frustrated with carburation. As the engine got more and more tired, started burning oil past the rings, and eventually met it's demise, I decided rather than rebuilding the smallblock, I wanted to go a new direction entirely. After much research, I decided on a modern, fuel injected LS engine.

More specifically, I decided on an LY6. The LY6 is an iron block 6.0L that comes in the new body style Chevy/GMC pickups and vans. It has the desireable L92/LS3 cylinder heads, an iron block, and some black magic voodoo few people want to mess with: variable valve timing. Being an engineer, I can't help but appreciate the academic merits of VVT and I plan to use it, along with an aftermarket cam (yet to be selected).

I found my LY6 from Eiss Brothers Salvage in New York. It has 60k miles and I paid $1650 for the longblock. On top of that I spent another $300 on accessories (ECM, alternator, PS pump, wire harness, starter, and drive by wire pedal assembly) and $200 in freight for a total of $2150 for an accessorized engine shipped across the country. It was like Christmas when the new engine arrived last month.

Time to put the old hoist back together:

I quickly cobbled together a lifting bar using some old scrap square tubing and 1/4" plate. I was worried about damaging the intake with chain, but looking back I probably could have come up with a simple chain system that would have worked just as well.

I used four M10x1.5 100mm long studs to attach the engine stand mount. I found the studs at my local Ace hardware. Unlike bolts, they don't need to be a specific size as long as they're long enough. They are probably only grade 5 or worse, but as long as they're snug, they should be fine.

I am using a Harbor Freight 2000lb capacity stand, part number 60715 (link). This is a pretty decent and stable stand. I wouldn't trust any of their lesser capacity stands. I don't buy a lot of chinese tools, but I don't think you can get a US-made engine stand for under $500 so this will have to do. 20% off coupon plus a sale and I paid $85 out the door.

With the engine on the stand, I started by stripping the wire harness. It's completely intact and I plan to use it, so I carefully labelled the connectors I could identify with my wife's label maker.

Without the harness, it starts looking like a good ol' American V8 again

Before I did anything else, I wanted to check the condition of the engine. I did a leakdown check first and got some varying results, with leakage past some valves sometimes and sometimes not. After talking with the salvage yard about the results, they recommended I put a little tranny fluid in all the cylinders and on the valves, turn the engine over a few times, then retest. I went a little further and decided to do a compression check, which would turn the engine over plenty and give additional diagnostic info. Here's my setup for cranking the engine with the starter on the stand. I would never do this if I didn't think the stand were very stable!

With that little bit of lube, the results improved and leakage was down to nil on all cylinders with good compression above 180psi on all cylinders.

This thread will document my swap from a tired gen I small block 350 to a modern 6.0VVT LY6. This will be my first time doing this kind of a swap, so bear with me! My name is Clint. I'm a mechanical engineer and I've had my Nova since I was fifteen. It was my first car and even though I'm now in my late twenties, married, and have a newborn son, it still holds a special place in my life.

First a few pictures. Here is a recent shot of the car. The wheels are Centerline Convo Pros 15x8.5 5" BS

275/60R15s out back and 15x7 3-3/8" BS 225/60R15 up front.

Finishing off an old pair of tires:

Autocrossing:

Here is the old small block in all its glory. When I was in high school I did a frame off on the car. It had Edelbrock Performer RPM heads, a Comp cam (232/236 @ 050 .488/.490), and a Demon 650DP. After over a decade of hotrodding, compression was getting low, oil was blowing from every gasketed interface, and the final straw was a bent pushrod and flat lobe on the cam.

Originally I was a big drag racing fan and always pictured this car tubbed and tubed with a big block. But as I grew older, I started to appreciate other aspects of driving like stopping and turning. I became increasingly frustrated with carburation. As the engine got more and more tired, started burning oil past the rings, and eventually met it's demise, I decided rather than rebuilding the smallblock, I wanted to go a new direction entirely. After much research, I decided on a modern, fuel injected LS engine.

More specifically, I decided on an LY6. The LY6 is an iron block 6.0L that comes in the new body style Chevy/GMC pickups and vans. It has the desireable L92/LS3 cylinder heads, an iron block, and some black magic voodoo few people want to mess with: variable valve timing. Being an engineer, I can't help but appreciate the academic merits of VVT and I plan to use it, along with an aftermarket cam (yet to be selected).

I found my LY6 from Eiss Brothers Salvage in New York. It has 60k miles and I paid $1650 for the longblock. On top of that I spent another $300 on accessories (ECM, alternator, PS pump, wire harness, starter, and drive by wire pedal assembly) and $200 in freight for a total of $2150 for an accessorized engine shipped across the country. It was like Christmas when the new engine arrived last month.

Time to put the old hoist back together:

I quickly cobbled together a lifting bar using some old scrap square tubing and 1/4" plate. I was worried about damaging the intake with chain, but looking back I probably could have come up with a simple chain system that would have worked just as well.

I used four M10x1.5 100mm long studs to attach the engine stand mount. I found the studs at my local Ace hardware. Unlike bolts, they don't need to be a specific size as long as they're long enough. They are probably only grade 5 or worse, but as long as they're snug, they should be fine.

I am using a Harbor Freight 2000lb capacity stand, part number 60715 (link). This is a pretty decent and stable stand. I wouldn't trust any of their lesser capacity stands. I don't buy a lot of chinese tools, but I don't think you can get a US-made engine stand for under $500 so this will have to do. 20% off coupon plus a sale and I paid $85 out the door.

With the engine on the stand, I started by stripping the wire harness. It's completely intact and I plan to use it, so I carefully labelled the connectors I could identify with my wife's label maker.

Without the harness, it starts looking like a good ol' American V8 again

Before I did anything else, I wanted to check the condition of the engine. I did a leakdown check first and got some varying results, with leakage past some valves sometimes and sometimes not. After talking with the salvage yard about the results, they recommended I put a little tranny fluid in all the cylinders and on the valves, turn the engine over a few times, then retest. I went a little further and decided to do a compression check, which would turn the engine over plenty and give additional diagnostic info. Here's my setup for cranking the engine with the starter on the stand. I would never do this if I didn't think the stand were very stable!

With that little bit of lube, the results improved and leakage was down to nil on all cylinders with good compression above 180psi on all cylinders.

Last edited by -TheBandit-; 04-05-2018 at 12:02 PM.

#3

I'm not a big fan of the tall truck intake, so I dug around and found a take-off LS3 intake from a 2010 Camaro for $215 shipped. I started this thread to collect more info on what's involved in swapping from a truck intake to a car intake on this engine.

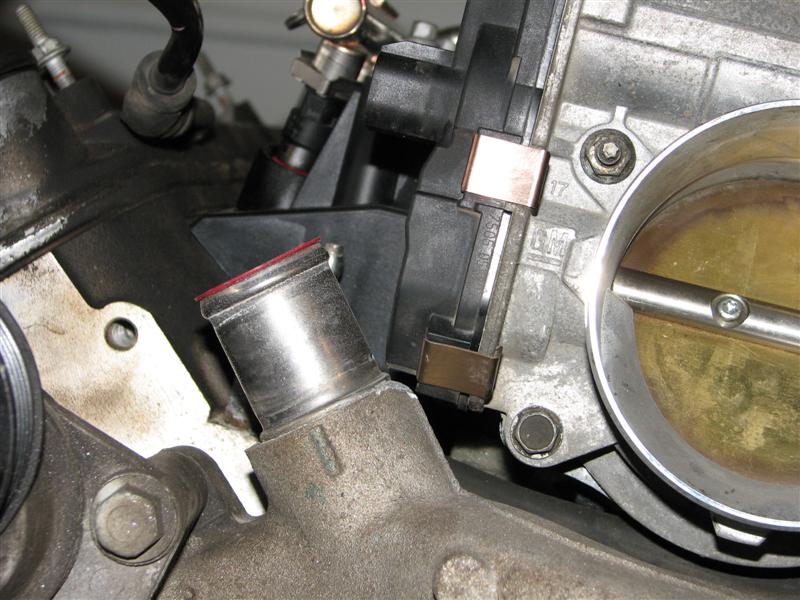

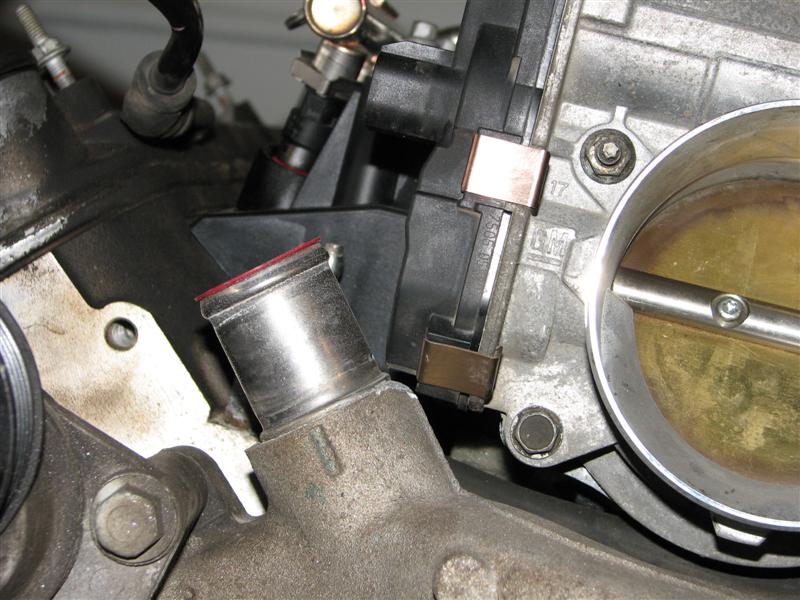

Because the car intake places the throttle body much lower, there are a few places where things interfere with the truck accessories. First is the waterpump outlet, which can interfere with the motor drive assembly on the electric throttle body as shown here. This is before snuggin the intake down.

I used a Dremel and a small cutoff wheel to remove the offending aluminum. I like cutoff wheels for trimming aluminum like this because they don't clog up dangerously the way grinding wheels do. Here it is trimmed:

The next order of business will be relocating the idler pulley which is now in the same area as the throttle body. I started by taking the pulley of it's bolt as shown:

Then I used washers for mockup to temporarily locate the idler on one of the mounting bolts for the accessory bracket. I have a new machined spacer and bolt on order that will permanently attach this for under $8. I will post the part numbers after I verify fitment.

After trimming off the accessory bracket, I think I will have the following two options for belt routing. The second option is my preference since it more closely resembles the original belt routing, it provides more wrap around the pulleys, and the tensioner is acting in the direction of the belt.

Because the car intake places the throttle body much lower, there are a few places where things interfere with the truck accessories. First is the waterpump outlet, which can interfere with the motor drive assembly on the electric throttle body as shown here. This is before snuggin the intake down.

I used a Dremel and a small cutoff wheel to remove the offending aluminum. I like cutoff wheels for trimming aluminum like this because they don't clog up dangerously the way grinding wheels do. Here it is trimmed:

The next order of business will be relocating the idler pulley which is now in the same area as the throttle body. I started by taking the pulley of it's bolt as shown:

Then I used washers for mockup to temporarily locate the idler on one of the mounting bolts for the accessory bracket. I have a new machined spacer and bolt on order that will permanently attach this for under $8. I will post the part numbers after I verify fitment.

After trimming off the accessory bracket, I think I will have the following two options for belt routing. The second option is my preference since it more closely resembles the original belt routing, it provides more wrap around the pulleys, and the tensioner is acting in the direction of the belt.

#4

Meanwhile, after selling off a bunch of parts from the old smallblock, I finally got around to pulling it. I supported the tranny with a ratchet strap prior to pulling the engine.

Goodbye old friend!

Things under the hood just aren't as pretty as they were over a decade ago when I did a frameoff. I'll have my work cutout for me cleaning this up.

That's all for now. This is going to be a slow build, but I'll be sure to post updates as I have them.

Goodbye old friend!

Things under the hood just aren't as pretty as they were over a decade ago when I did a frameoff. I'll have my work cutout for me cleaning this up.

That's all for now. This is going to be a slow build, but I'll be sure to post updates as I have them.

#5

Very good write up CLint. Have you decided on what color you will paint the engine yet?

#7

TECH Resident

iTrader: (24)

Join Date: Jun 2005

Location: Houston, TX

Posts: 860

Likes: 0

Received 0 Likes

on

0 Posts

I'm doing an ly6/tko swap into my 71' Nova and am about as far along as you are in the swap process. Hard to beat the LY6's, best bang for the buck out there IMO. Best of luck w/ it, & lookin forward to more updates!

Trending Topics

#9

Teching In

Join Date: Sep 2010

Location: Gilmer, Texas

Posts: 15

Likes: 0

Received 0 Likes

on

0 Posts

Great write up man! I've located an LY6 for my '70 Nova and am almost ready to drop the cash on it. I did the full frame off on mine with a new front end under it and all new brakes, dropped spindles, etc. I'll be following your build, keep us posted!

#10

12 Second Club

iTrader: (12)

You sure about keeping that TH400? I've got a line on an LY6/4L80e, but since I'm going T56 in the Goat I won't need the trans (and that harness/pcm is setup for it)...

tex, you may want to reconsider those drop spindles. even though CPP's gen ii spindles allow more backspace (4 3/8") than the first gen (~3.5" i think?), you may still run into fitment issues going with larger/wider wheels and tires (more info here). my fronts rub going over bumps and high-speed turns because of this, and i'm running 215/60-15s with 3 1/8" BS. as a guy who is going to be rebuilding my front end for the 5th time in as many years, i'd strongly suggest you look into drop springs instead of spindles.

tex, you may want to reconsider those drop spindles. even though CPP's gen ii spindles allow more backspace (4 3/8") than the first gen (~3.5" i think?), you may still run into fitment issues going with larger/wider wheels and tires (more info here). my fronts rub going over bumps and high-speed turns because of this, and i'm running 215/60-15s with 3 1/8" BS. as a guy who is going to be rebuilding my front end for the 5th time in as many years, i'd strongly suggest you look into drop springs instead of spindles.

Last edited by hookemdevils22; 09-14-2010 at 10:00 AM.

#11

9 Second Club

iTrader: (12)

Nice to see such a well written Nova build thread. It's refreshing to read proper English and spelling on a car forum - pretty impressive for an Engineer. I never have started a build thread for my '69 Nova conversion... maybe it's time to start one. Good luck with the progress and balancing with your family and job. It can certainly be difficult to keep the momentum going. Make sure you take some build pictures with your son - they will be great memories of two joys in life.

Couple things for you to consider:

* Engine mounts - I am placing my 6.0 block in the "neutral" position. That locates my TH-400 a couple inches closer to the front of the car. I found an existing bolt hole in the frame that works just right for the crossmember, so I just have to drill a second bolt hole on each side in the frame to mount the transmission cross member (using a stock transmission mount).

* Oil Pan - Several options ranging from modified stock, RetroLSX, Autokraft, Moroso... I chose the Moroso for increased oil capacity (my build will be turbocharged).

* Fuel Delivery - Stock fuel tank, trunk mounted cell, or custom built tank. I agonized a long time over this question. I wanted a tank in the stock location (keep that trunk space) but I didn't want an "ugly" sump hanging down in the back. I finally chose to pony up for a custom stainless steel tank from Rick's Tanks. Expensive but very nice.

* Harness - Another goal of mine is to try and make the LS engine a little more easy on the eyes. I reworked the stock harness in order to hide the wiring as much as possible. Print out the wiring diagram from your donor vehicle, and take out whatever you don't need in the harness. Re-route the wiring to keep things tidy.

I have lots of pictures, but I won't ***** your thread with my junk. But by all means let us know if you have any questions.

Keep us updated and try to keep the project fun.

Couple things for you to consider:

* Engine mounts - I am placing my 6.0 block in the "neutral" position. That locates my TH-400 a couple inches closer to the front of the car. I found an existing bolt hole in the frame that works just right for the crossmember, so I just have to drill a second bolt hole on each side in the frame to mount the transmission cross member (using a stock transmission mount).

* Oil Pan - Several options ranging from modified stock, RetroLSX, Autokraft, Moroso... I chose the Moroso for increased oil capacity (my build will be turbocharged).

* Fuel Delivery - Stock fuel tank, trunk mounted cell, or custom built tank. I agonized a long time over this question. I wanted a tank in the stock location (keep that trunk space) but I didn't want an "ugly" sump hanging down in the back. I finally chose to pony up for a custom stainless steel tank from Rick's Tanks. Expensive but very nice.

* Harness - Another goal of mine is to try and make the LS engine a little more easy on the eyes. I reworked the stock harness in order to hide the wiring as much as possible. Print out the wiring diagram from your donor vehicle, and take out whatever you don't need in the harness. Re-route the wiring to keep things tidy.

I have lots of pictures, but I won't ***** your thread with my junk. But by all means let us know if you have any questions.

Keep us updated and try to keep the project fun.

Last edited by Chevy406; 09-14-2010 at 11:05 AM.

#12

#13

Thanks all for the comments and encouragement.

Jimbo - I plan to paint the block black. I may also paint the timing and valve covers black, but I'm undecided. I like the look of a raw aluminum colored engine, but I want something easy to maintain that wont show grease, dirt or oil too badly.

hotrodscrap - I bought a TCI flexplate that should have the right pattern and came with the appropriate spacer to support the nose of the TH400 converter. It is TCI P/N 399754 and cost $225 through summitracing.com. It came with fasteners for attaching to the crank, but not for attaching to the converter. I used it for running the compression check and it engaged properly with the starter. I plan to mockup the stall converter on it next time the engine is on a hoist.

hookedemdevils - I decided to run the TH400 for a few reasons: it's somewhat built already (shift kit etc), I have a BTE 2,800 rpm stall on it, I have a cable shifter that works well with it and is already integrated into my console, and it will drive my original speedometer without any changes. Making some tweeks to the crossmember shouldn't be a problem if the tranny moves forward and I should have plenty of slip in the yoke to accomodate some movement. The main purpose really for keeping the TH400 is to limit the scope of the project.

Chevy406 - I appreciate the kind words! My son will most certainly find his way into photos here and there, especially as he gets bigger. Right now he is only two weeks old, so we are literally just starting our family. It is a big change for sure and it's one of the reasons I have no real timeline for this. I am going to plug away at it as long as it is fun for me and eventually it will get done.

Plans are ever changing, but my thoughts on the subjects you mentioned are as follows:

Engine Mounts: I will probably use the "neutral" mounts that put the tranny forward about an inch. My firewall clearance is not very good and I want to give myself some room for the A/C box, which I plan to modify to add space for the valvecover, coilpacks, and headers.

Oil Pan: I plan to autocross my car, so I will likely go with the Champ/Autokraft pan. I would prefer a cast pan in terms of sealing, but none of the cast pans I've seen offer good oil control for that sort of driving. I am strongly considering an Accusump as well.

Fuel Delivery: Whatever way I go, I want an in-tank pump and appropriate baffling so I can run an autocross course without starving for fuel. I may fabricate a tank myself, but it depends on what sort of time I have. I don't think a $1k stainless tank is in the budget.

Harness: I do plan to modify the harness for a clean fit. I haven't decided on a location for the ECU, but this is stuff I can figure out after the engine is in. Right now my focuss is on getting the engine and bay prepped.

Jimbo - I plan to paint the block black. I may also paint the timing and valve covers black, but I'm undecided. I like the look of a raw aluminum colored engine, but I want something easy to maintain that wont show grease, dirt or oil too badly.

hotrodscrap - I bought a TCI flexplate that should have the right pattern and came with the appropriate spacer to support the nose of the TH400 converter. It is TCI P/N 399754 and cost $225 through summitracing.com. It came with fasteners for attaching to the crank, but not for attaching to the converter. I used it for running the compression check and it engaged properly with the starter. I plan to mockup the stall converter on it next time the engine is on a hoist.

hookedemdevils - I decided to run the TH400 for a few reasons: it's somewhat built already (shift kit etc), I have a BTE 2,800 rpm stall on it, I have a cable shifter that works well with it and is already integrated into my console, and it will drive my original speedometer without any changes. Making some tweeks to the crossmember shouldn't be a problem if the tranny moves forward and I should have plenty of slip in the yoke to accomodate some movement. The main purpose really for keeping the TH400 is to limit the scope of the project.

Chevy406 - I appreciate the kind words! My son will most certainly find his way into photos here and there, especially as he gets bigger. Right now he is only two weeks old, so we are literally just starting our family. It is a big change for sure and it's one of the reasons I have no real timeline for this. I am going to plug away at it as long as it is fun for me and eventually it will get done.

Plans are ever changing, but my thoughts on the subjects you mentioned are as follows:

Engine Mounts: I will probably use the "neutral" mounts that put the tranny forward about an inch. My firewall clearance is not very good and I want to give myself some room for the A/C box, which I plan to modify to add space for the valvecover, coilpacks, and headers.

Oil Pan: I plan to autocross my car, so I will likely go with the Champ/Autokraft pan. I would prefer a cast pan in terms of sealing, but none of the cast pans I've seen offer good oil control for that sort of driving. I am strongly considering an Accusump as well.

Fuel Delivery: Whatever way I go, I want an in-tank pump and appropriate baffling so I can run an autocross course without starving for fuel. I may fabricate a tank myself, but it depends on what sort of time I have. I don't think a $1k stainless tank is in the budget.

Harness: I do plan to modify the harness for a clean fit. I haven't decided on a location for the ECU, but this is stuff I can figure out after the engine is in. Right now my focuss is on getting the engine and bay prepped.

Last edited by -TheBandit-; 09-28-2011 at 10:58 PM.

#16

TheBandit,

I think you got a great deal on the LS3 intake assembly !!!

I think you got a great deal on the LS3 intake assembly !!!

#17

hookemdevils - I saw the Tanks Inc setup and while I like the idea, I think additional baffling in the tank is in order. I am thinking about building a tank myself, but the fuel system is a ways out.

Jimbo - I did get a great deal on the LS3 intake. That's the advantage of calling people and talking with them for a while. The guy I got it from had one listed on eBay and after getting his number I talked him out of a second intake he had for a reasonable cost. He didn't have to pay auction fees and I got a good deal - win win.

As promised, here is how I relocated the idler pulley and made the truck accessories work with the LS3 intake for under $10. Granted I do still need to buy a belt, but I'm also thinking about scrapping this altogether and making my own brackets from scratch. I don't like how high the alternator sits with this setup.

First off the parts. From Misumi USA (www.misumiusa.com), the spacer is PN KNCLM10-30-20 and cost $5.70. It is nickel plated steel, 10mm ID, 30MM OD and 20MM length. The bolt is PN CB10-160 and cost $2.40. It is M10x160mm length. Total $8.10.

Here you can see that the spacer is the appropriate height to position the idler in line with where it originally was

I am spoiled with a mill in my garage, so I used it to cleanly trim down the bracket. You could also do this with a vertical bandsaw or even a hacksaw.

Here is the trimmed bracket around the throttle body

And here you can see a notch I added for the vacuum port on the drivers side of the intake

Here is the ilder pulley mounted with a ratchet strap used as a mockup belt

The Misumi spacer installs here:

And this is what the finished accessory drive looks like using a ratchet strap to mockup the belt path.

Sorry about the black & white pictures. Somehow the setting got changed while I was taking pictures.

I haven't decided yet if I want to keep this setup or scrap it altogether in favor of putting the alternator on the passenger side (lower) and making my own brackets for everything.

That's all for now!

Jimbo - I did get a great deal on the LS3 intake. That's the advantage of calling people and talking with them for a while. The guy I got it from had one listed on eBay and after getting his number I talked him out of a second intake he had for a reasonable cost. He didn't have to pay auction fees and I got a good deal - win win.

As promised, here is how I relocated the idler pulley and made the truck accessories work with the LS3 intake for under $10. Granted I do still need to buy a belt, but I'm also thinking about scrapping this altogether and making my own brackets from scratch. I don't like how high the alternator sits with this setup.

First off the parts. From Misumi USA (www.misumiusa.com), the spacer is PN KNCLM10-30-20 and cost $5.70. It is nickel plated steel, 10mm ID, 30MM OD and 20MM length. The bolt is PN CB10-160 and cost $2.40. It is M10x160mm length. Total $8.10.

Here you can see that the spacer is the appropriate height to position the idler in line with where it originally was

I am spoiled with a mill in my garage, so I used it to cleanly trim down the bracket. You could also do this with a vertical bandsaw or even a hacksaw.

Here is the trimmed bracket around the throttle body

And here you can see a notch I added for the vacuum port on the drivers side of the intake

Here is the ilder pulley mounted with a ratchet strap used as a mockup belt

The Misumi spacer installs here:

And this is what the finished accessory drive looks like using a ratchet strap to mockup the belt path.

Sorry about the black & white pictures. Somehow the setting got changed while I was taking pictures.

I haven't decided yet if I want to keep this setup or scrap it altogether in favor of putting the alternator on the passenger side (lower) and making my own brackets for everything.

That's all for now!

#18

TECH Apprentice

iTrader: (6)

If you want a low mount alternator get the 4th gen f-body alt bracket and power steering pump / bracket. Your truck alternator will bolt into the f-body bracket. You will need .75" spacers for both brackets to line up with the truck crank pulley. If you want to run the car water pump for the forward facing outlet then space it 1.5" from the block to clear the VVT cover. You will then need a Vette tensioner to mount to the pump.

#19

If you want a low mount alternator get the 4th gen f-body alt bracket and power steering pump / bracket. Your truck alternator will bolt into the f-body bracket. You will need .75" spacers for both brackets to line up with the truck crank pulley. If you want to run the car water pump for the forward facing outlet then space it 1.5" from the block to clear the VVT cover. You will then need a Vette tensioner to mount to the pump.

Another option is a 2010 CamaroLS3 FEAD kit that PACE sells. http://www.paceperformance.com/index...&ProdID=265470 Comes with the WP and balancer. I wish I would of waited til this came out and bought this, since it would of been cheaper (I wanted a car WP.) Plus it would look "factory" not having the WP spacers

#20

Jimbo thanks for the link! I've been eyeballing that setup for a while. I really like where the waterpump outlet is. The full system price is a bit much and it includes some things I might not need. I was thinking about heading to a local dealer or contacting Pace to price out some of the parts separately. I'm guessing I wouldn't need the tensioner, balancer, or idler and I'm curious if my truck powersteering pump would work. I'm pretty sure the truck alternator wouldn't fit down low like that and even 5th gen camaro alternator may not fit, but things can be done about that and it's certainly one of the options.

LOL

LOL