@@ Lobe Dynamics @@

#24

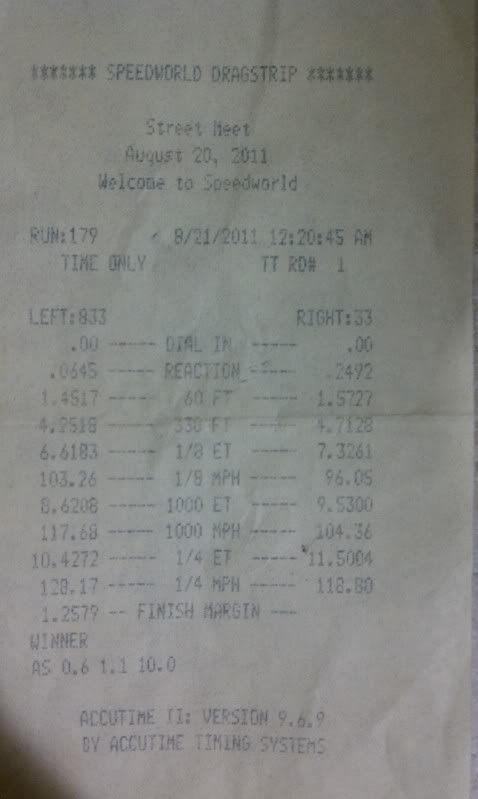

11 Second Club

iTrader: (2)

I remember reading somewhere on here that EPS lobes while ground by comp

were uniquely designed by Geoff and Pat G....can any one verify this ????

I looked real closely @ my baby EPS to see if I could understand what was

different about it and the opening flank looks aggressive and fast like a LSR

shape, but then the closing side sorta looks gentle so as to set the valve on

the seat and not drop it....perhaps a HUC shape. Geoff reitterated many times

about "smooth control...like a stalled auto; not an M6 snap"......then I remembered all the threads I read when cam searching about quiet valvetrains

and killer power w/beehives, etc....I know I'm just rambling but relative to this

thread kinda makes me go Hmmmmm.

were uniquely designed by Geoff and Pat G....can any one verify this ????

I looked real closely @ my baby EPS to see if I could understand what was

different about it and the opening flank looks aggressive and fast like a LSR

shape, but then the closing side sorta looks gentle so as to set the valve on

the seat and not drop it....perhaps a HUC shape. Geoff reitterated many times

about "smooth control...like a stalled auto; not an M6 snap"......then I remembered all the threads I read when cam searching about quiet valvetrains

and killer power w/beehives, etc....I know I'm just rambling but relative to this

thread kinda makes me go Hmmmmm.

#26

TECH Apprentice

iTrader: (10)

Join Date: May 2008

Location: Odessa, Texas

Posts: 331

Likes: 0

Received 0 Likes

on

0 Posts

I remember reading somewhere on here that EPS lobes while ground by comp

were uniquely designed by Geoff and Pat G....can any one verify this ????

I looked real closely @ my baby EPS to see if I could understand what was

different about it and the opening flank looks aggressive and fast like a LSR

shape, but then the closing side sorta looks gentle so as to set the valve on

the seat and not drop it....perhaps a HUC shape. Geoff reitterated many times

about "smooth control...like a stalled auto; not an M6 snap"......then I remembered all the threads I read when cam searching about quiet valvetrains

and killer power w/beehives, etc....I know I'm just rambling but relative to this

thread kinda makes me go Hmmmmm.

were uniquely designed by Geoff and Pat G....can any one verify this ????

I looked real closely @ my baby EPS to see if I could understand what was

different about it and the opening flank looks aggressive and fast like a LSR

shape, but then the closing side sorta looks gentle so as to set the valve on

the seat and not drop it....perhaps a HUC shape. Geoff reitterated many times

about "smooth control...like a stalled auto; not an M6 snap"......then I remembered all the threads I read when cam searching about quiet valvetrains

and killer power w/beehives, etc....I know I'm just rambling but relative to this

thread kinda makes me go Hmmmmm.

#27

FormerVendor

iTrader: (2)

Hello there, I've been searching for a thread or post on LS engine lobe tech. And it seems there nothing out thread, so I figured I start one.

For me, I'm some what tech savvy but could still stand to learn more about the secrets of lobe dynamics.

Just to be clear, I'm only interested in hydr. roller cams.

My question is; has any one put these different lobe designs (with same; INT Open, INT Close,EXH Open, EXT Close, and with all other specs being equal ) in a cam doctor to check ramp rates at specific areas (.006, .050, .200, ect..).

I'm really interested in the new HUC lobes but theres not much info floating around.

Thanks...and I'm looking for an education..

For me, I'm some what tech savvy but could still stand to learn more about the secrets of lobe dynamics.

Just to be clear, I'm only interested in hydr. roller cams.

My question is; has any one put these different lobe designs (with same; INT Open, INT Close,EXH Open, EXT Close, and with all other specs being equal ) in a cam doctor to check ramp rates at specific areas (.006, .050, .200, ect..).

I'm really interested in the new HUC lobes but theres not much info floating around.

Thanks...and I'm looking for an education..

Most guys asking questions like this are attempting to determine what they are trading for performance, but with only vague generalities to go by it is rare that they manage to choose an appropriate grind based on forum claims. There are so many ways a lobe can be aggressive or mild depending on the remainder of the valve train system that your best bet is typically to do as you mentioned & find someone to determine what is appropriate for your specific setup & intended use. Lobe "aggressiveness" not only varies from lobe family to family, but also between various areas of the individual lobe. That is compounded by the fact that often times not all lobes in the family exhibit equivalent velocity/accels/jerk/etc, have slightly different operating ranges, etc. Furthermore, "aggressive" and "mild" are also relative terms and require a point of reference to be meaningful.

Beyond that, one can employ some of the same tools & software to come up with profiles for a particular system that do offer a performance advantage. Our proprietary grinds were refined/created based on simulations & testing w/ existing known good cam grinds. I used 4sthead which many cam companies, race teams, etc. utilize. There isn't a great deal of info on their site, but http://www.profblairandassociates.com/index.html does have some tech articles you may enjoy.

In the end, there being thousands of lobes out there, it is rare that it is actually worth creating a new lobe design. Additionally, getting a theoretical system "perfect" is simply beyond the point of diminishing returns for cams sold to the public. With no control over their implementation I personally ended up with so much headroom (safety margin) that almost invariably there was a readily available suitable lobe for a given application. We are typically supplying camshafts with our heads, and with a superior head design it does make it easier to simply back things down a notch & rely on the head to get the results. The power is in the head/manifold & machinework... while your valve train will largely determine the reliability/longevity of a given setup IMO. In the end, almost all common lobes can be made to run reliably if the rest of the VT is appropriately selected, installed, and adjusted.

Erik's comments are a good example of what I am talking about - the LSK's work OK for many people, but a milder lobe sacrifices little if anything considering the longevity, rpm headroom, etc. it may gain. That is the kind of mentality you want your builder to exhibit when it comes to engines that have to live awhile.

I think most would be surprised at how similar most of the commonly run LS lobes are. I realize this is tough to really read, but it illustrates the point:

Still, there are distinct advantages and disadvantages to them. To further muddy the waters, consider that those graphed are all similarly styled. There are many different styles of lobe out there.

In the end I think you'll find that the only truly useful info for the consumer is the link to our cam page. However, these discussions are certainly engrossing.

-Phil

#29

FormerVendor

iTrader: (2)

#30

I hope this question is not to generalized;

If my valve train is relatively light....

1)Intake valve..high 70's...grams

2)Exhaust valve..high 50's...grams

3)PRC .675...Install Height: 1.800"

Closed Spring Pressure: 157lbs @ 1.800"

Open Spring Pressure: 471lbs @ 1.125"

Maximum Spring Lift: .675"

Coil Bind 1.060"

Spring Rate: 483lbs/in

4)Comp Ti retainer..high 50's...grams

5) stock locks..3...grams (x16)

6)stock rockers..low 80's...grams + weight of trunnion....with the rocker arm trunnion supported and the tip of the rocker on the scale. Scale zeroed prior to measurement it measured 8.3 grams.

Is this cam optimal considering what was said about the LSL/HUC lobes ??

CAM

(LSL) INT. 235@.050 (HUC) EXH. 247@.050

Lift INT.=.620 w/1.7 EXH.=.632 w/1.7

Or would I be better with a "faster" ramp considering the lightness of the valve train ?? Or maybe I should first ask if you consider this a light setup ??

Thanks.....

If my valve train is relatively light....

1)Intake valve..high 70's...grams

2)Exhaust valve..high 50's...grams

3)PRC .675...Install Height: 1.800"

Closed Spring Pressure: 157lbs @ 1.800"

Open Spring Pressure: 471lbs @ 1.125"

Maximum Spring Lift: .675"

Coil Bind 1.060"

Spring Rate: 483lbs/in

4)Comp Ti retainer..high 50's...grams

5) stock locks..3...grams (x16)

6)stock rockers..low 80's...grams + weight of trunnion....with the rocker arm trunnion supported and the tip of the rocker on the scale. Scale zeroed prior to measurement it measured 8.3 grams.

Is this cam optimal considering what was said about the LSL/HUC lobes ??

CAM

(LSL) INT. 235@.050 (HUC) EXH. 247@.050

Lift INT.=.620 w/1.7 EXH.=.632 w/1.7

Or would I be better with a "faster" ramp considering the lightness of the valve train ?? Or maybe I should first ask if you consider this a light setup ??

Thanks.....

Last edited by LSOHOLIC; 08-21-2011 at 03:06 AM.

#31

TECH Apprentice

iTrader: (8)

Join Date: Nov 2001

Location: Houston, TX

Posts: 387

Likes: 0

Received 0 Likes

on

0 Posts

I hope this question is not to generalized;

If my valve train is relatively light....

1)Intake valve..high 70's...grams

2)Exhaust valve..high 50's...grams

3)PRC .675...Install Height: 1.800"

Closed Spring Pressure: 157lbs @ 1.800"

Open Spring Pressure: 471lbs @ 1.125"

Maximum Spring Lift: .675"

Coil Bind 1.060"

Spring Rate: 483lbs/in

4)Comp Ti retainer..high 50's...grams

5) stock locks..3...grams (x16)

6)stock rockers..low 80's...grams + weight of trunnion....with the rocker arm trunnion supported and the tip of the rocker on the scale. Scale zeroed prior to measurement it measured 8.3 grams.

Is this cam optimal considering what was said about the LSL/HUC lobes ??

CAM

(LSL) INT. 235@.050 (HUC) EXH. 247@.050

Lift INT.=.620 w/1.7 EXH.=.632 w/1.7

Or would I be better with a "faster" ramp considering the lightness of the valve train ?? Or maybe I should first ask if you consider this a light setup ??

Thanks.....

If my valve train is relatively light....

1)Intake valve..high 70's...grams

2)Exhaust valve..high 50's...grams

3)PRC .675...Install Height: 1.800"

Closed Spring Pressure: 157lbs @ 1.800"

Open Spring Pressure: 471lbs @ 1.125"

Maximum Spring Lift: .675"

Coil Bind 1.060"

Spring Rate: 483lbs/in

4)Comp Ti retainer..high 50's...grams

5) stock locks..3...grams (x16)

6)stock rockers..low 80's...grams + weight of trunnion....with the rocker arm trunnion supported and the tip of the rocker on the scale. Scale zeroed prior to measurement it measured 8.3 grams.

Is this cam optimal considering what was said about the LSL/HUC lobes ??

CAM

(LSL) INT. 235@.050 (HUC) EXH. 247@.050

Lift INT.=.620 w/1.7 EXH.=.632 w/1.7

Or would I be better with a "faster" ramp considering the lightness of the valve train ?? Or maybe I should first ask if you consider this a light setup ??

Thanks.....

I would think you would be just fine on the LSL lobe.

#32

FormerVendor

iTrader: (2)

I hope this question is not to generalized;

If my valve train is relatively light....

1)Intake valve..high 70's...grams

2)Exhaust valve..high 50's...grams

3)PRC .675...Install Height: 1.800"

Closed Spring Pressure: 157lbs @ 1.800"

Open Spring Pressure: 471lbs @ 1.125"

Maximum Spring Lift: .675"

Coil Bind 1.060"

Spring Rate: 483lbs/in

4)Comp Ti retainer..high 50's...grams

5) stock locks..3...grams (x16)

6)stock rockers..low 80's...grams + weight of trunnion....with the rocker arm trunnion supported and the tip of the rocker on the scale. Scale zeroed prior to measurement it measured 8.3 grams.

Is this cam optimal considering what was said about the LSL/HUC lobes ??

CAM

(LSL) INT. 235@.050 (HUC) EXH. 247@.050

Lift INT.=.620 w/1.7 EXH.=.632 w/1.7

Or would I be better with a "faster" ramp considering the lightness of the valve train ?? Or maybe I should first ask if you consider this a light setup ??

Thanks.....

If my valve train is relatively light....

1)Intake valve..high 70's...grams

2)Exhaust valve..high 50's...grams

3)PRC .675...Install Height: 1.800"

Closed Spring Pressure: 157lbs @ 1.800"

Open Spring Pressure: 471lbs @ 1.125"

Maximum Spring Lift: .675"

Coil Bind 1.060"

Spring Rate: 483lbs/in

4)Comp Ti retainer..high 50's...grams

5) stock locks..3...grams (x16)

6)stock rockers..low 80's...grams + weight of trunnion....with the rocker arm trunnion supported and the tip of the rocker on the scale. Scale zeroed prior to measurement it measured 8.3 grams.

Is this cam optimal considering what was said about the LSL/HUC lobes ??

CAM

(LSL) INT. 235@.050 (HUC) EXH. 247@.050

Lift INT.=.620 w/1.7 EXH.=.632 w/1.7

Or would I be better with a "faster" ramp considering the lightness of the valve train ?? Or maybe I should first ask if you consider this a light setup ??

Thanks.....

#34

Your masses appear off to me. You can run any lobe with any spring for the most part, the question is what kind of RPM will it control the valve train to, will it be hard on specific parts etc. That is quite a bit of spring load - the LSL's are typically controllable to 6800-7200rpm with far less spring & the HUC's even more so. If you were staying with Comp, you could move to one of their higher lift series lobes, but if they're in the same duration range it won't likely make a large difference in output vs. the LSL.

LS6: intake = 73 grams, exhaust = 65 grams ....not sure if that is what you were refuring to...and about the RPM..I'm spinning it to 6800-6900ish.

Thanks...

#35

On The Tree

Join Date: May 2006

Location: 60 mi SE of Melbourne, Australia

Posts: 137

Likes: 0

Received 0 Likes

on

0 Posts

Some good discussion here.

FWIW, I ran a 223/227 Comp LSK cam in my H/C LS1, which made approximately 295rwkW (395hp) on an Australian dyno. When I changed lifters at around 40k miles of (mostly) highway use - steady 60-70mph - I found it had become a bit pitted on a couple of lobes. I was using Patriot Gold duals with Ti retainers and set up properly, etc and was revving it to 6800rpm.

I put a 223/227 Comp LSL cam in to replace it and made 3rwkW (4hp) less at peak and a little less torque, so not a great deal of difference - certainly not to a purely street-driven car. So, in my application, not a large trade-off, for a slightly milder lobe.

I think the LSL is a good compromise lobe, not as aggressive from .006 - .050 as the XE-R and not as aggressive from .050 - .200 as the LSK, but a fairly good compromise between the two.

In my current car, I'm using a 215/223 LSL camshaft and it is making some great numbers (better than the larger cams did!) and peaks at 6250rpm, with the rev-limiter set at 6600rpm - no need to wring it out at all.

cheers

FWIW, I ran a 223/227 Comp LSK cam in my H/C LS1, which made approximately 295rwkW (395hp) on an Australian dyno. When I changed lifters at around 40k miles of (mostly) highway use - steady 60-70mph - I found it had become a bit pitted on a couple of lobes. I was using Patriot Gold duals with Ti retainers and set up properly, etc and was revving it to 6800rpm.

I put a 223/227 Comp LSL cam in to replace it and made 3rwkW (4hp) less at peak and a little less torque, so not a great deal of difference - certainly not to a purely street-driven car. So, in my application, not a large trade-off, for a slightly milder lobe.

I think the LSL is a good compromise lobe, not as aggressive from .006 - .050 as the XE-R and not as aggressive from .050 - .200 as the LSK, but a fairly good compromise between the two.

In my current car, I'm using a 215/223 LSL camshaft and it is making some great numbers (better than the larger cams did!) and peaks at 6250rpm, with the rev-limiter set at 6600rpm - no need to wring it out at all.

cheers

#40

Found some interesting reads....that I thought you guys might like.....of course valve train based.

http://www.cds-valvetrain.com/Doku/Valve%20Train.pdf

http://www.tech.plym.ac.uk/sme/desnotes/valvet1.htm

And here is an interesting thread on the bullet about increasing base circles...and the effects.

http://www.yellowbullet.com/forum/sh...d.php?t=420668

Thanks...........

http://www.cds-valvetrain.com/Doku/Valve%20Train.pdf

http://www.tech.plym.ac.uk/sme/desnotes/valvet1.htm

And here is an interesting thread on the bullet about increasing base circles...and the effects.

http://www.yellowbullet.com/forum/sh...d.php?t=420668

Thanks...........

Last edited by LSOHOLIC; 10-30-2011 at 11:04 PM.